Hiller

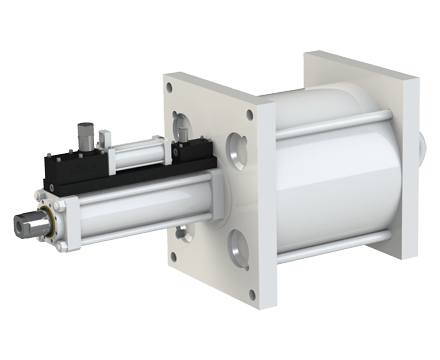

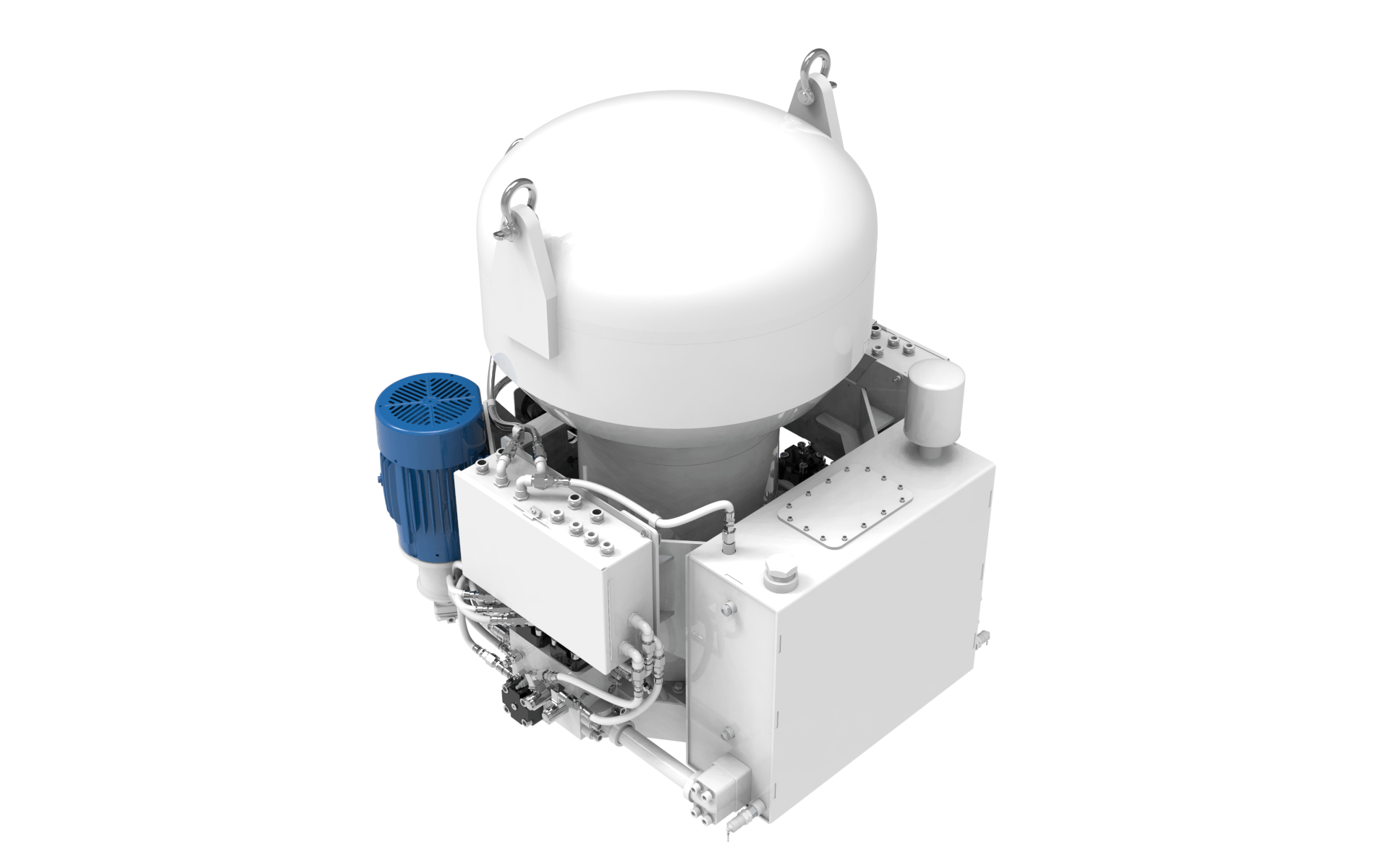

LP/LH Valve Actuators

SUPPLY PRESSURES

- Pneumatic – up to 652 psi (45 bar)

- Hydraulic – up to 5,000 psi (345 bar)

OUTPUT THRUST

- Final output thrust will vary depending on configuration but our qualified range envelopes up to 600,000 lbf (2,669 KN)

MANUAL OVERRIDE OPTIONS

- Jackscrew, Handwheel, and Hydraulic Override