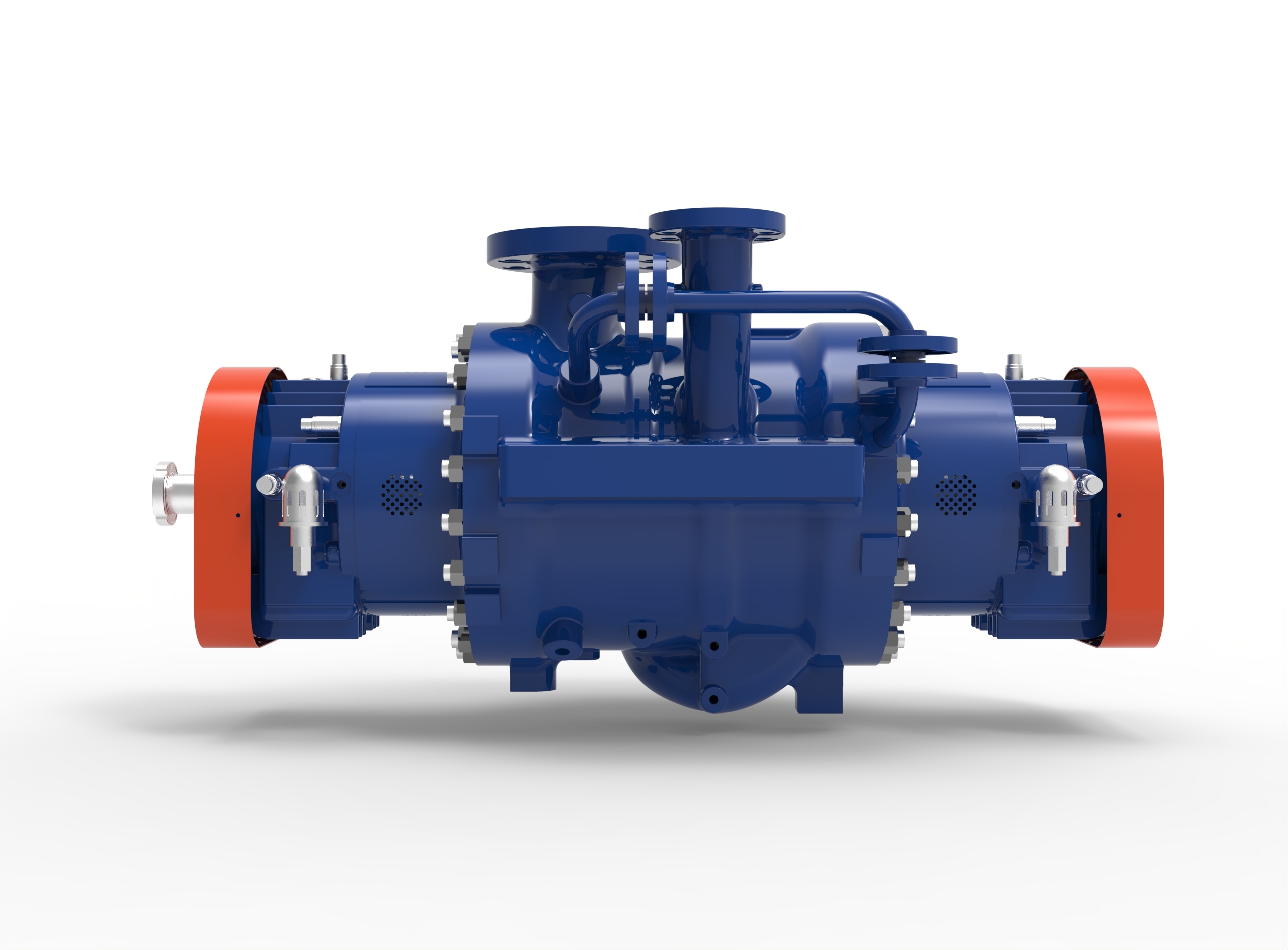

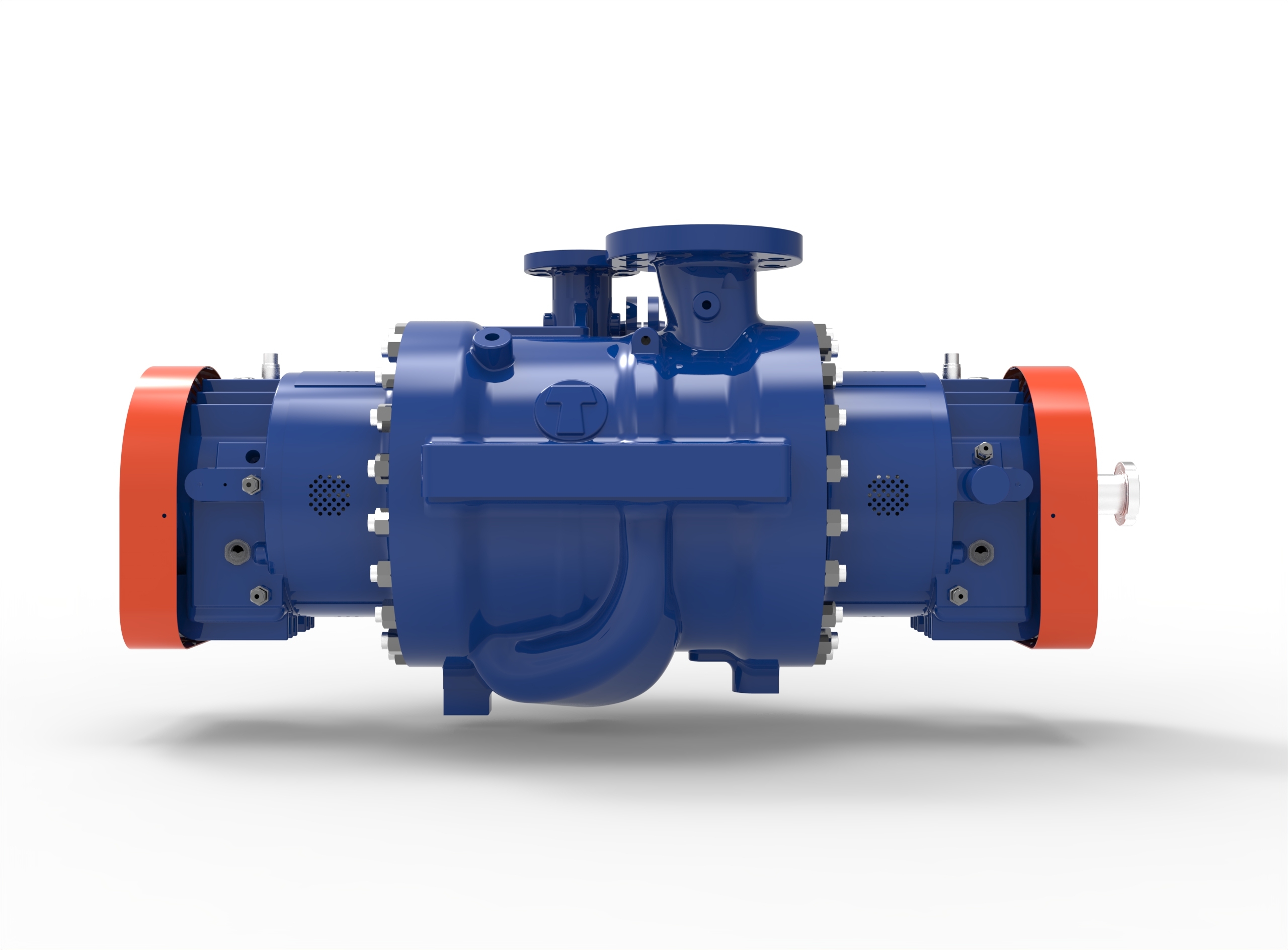

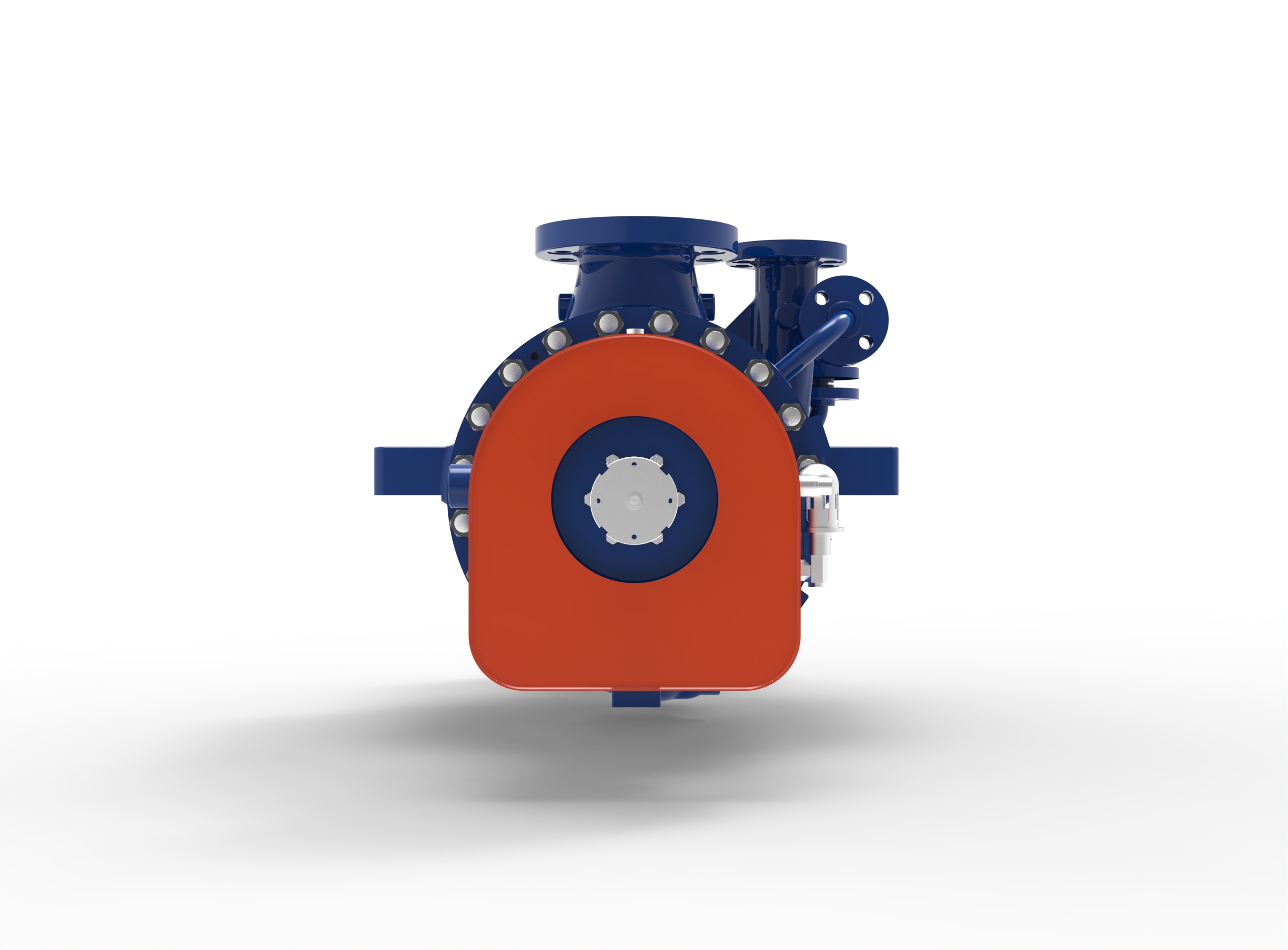

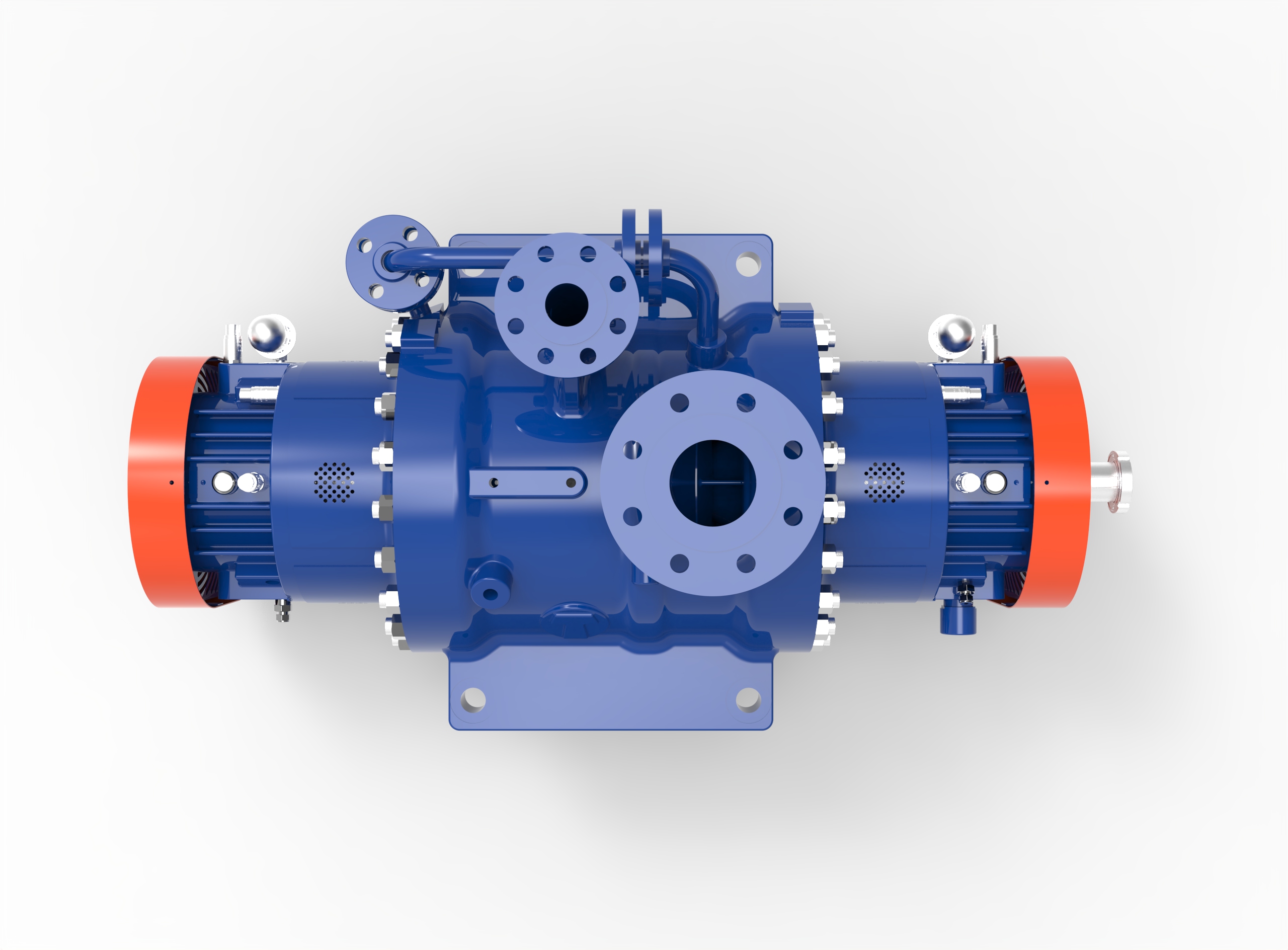

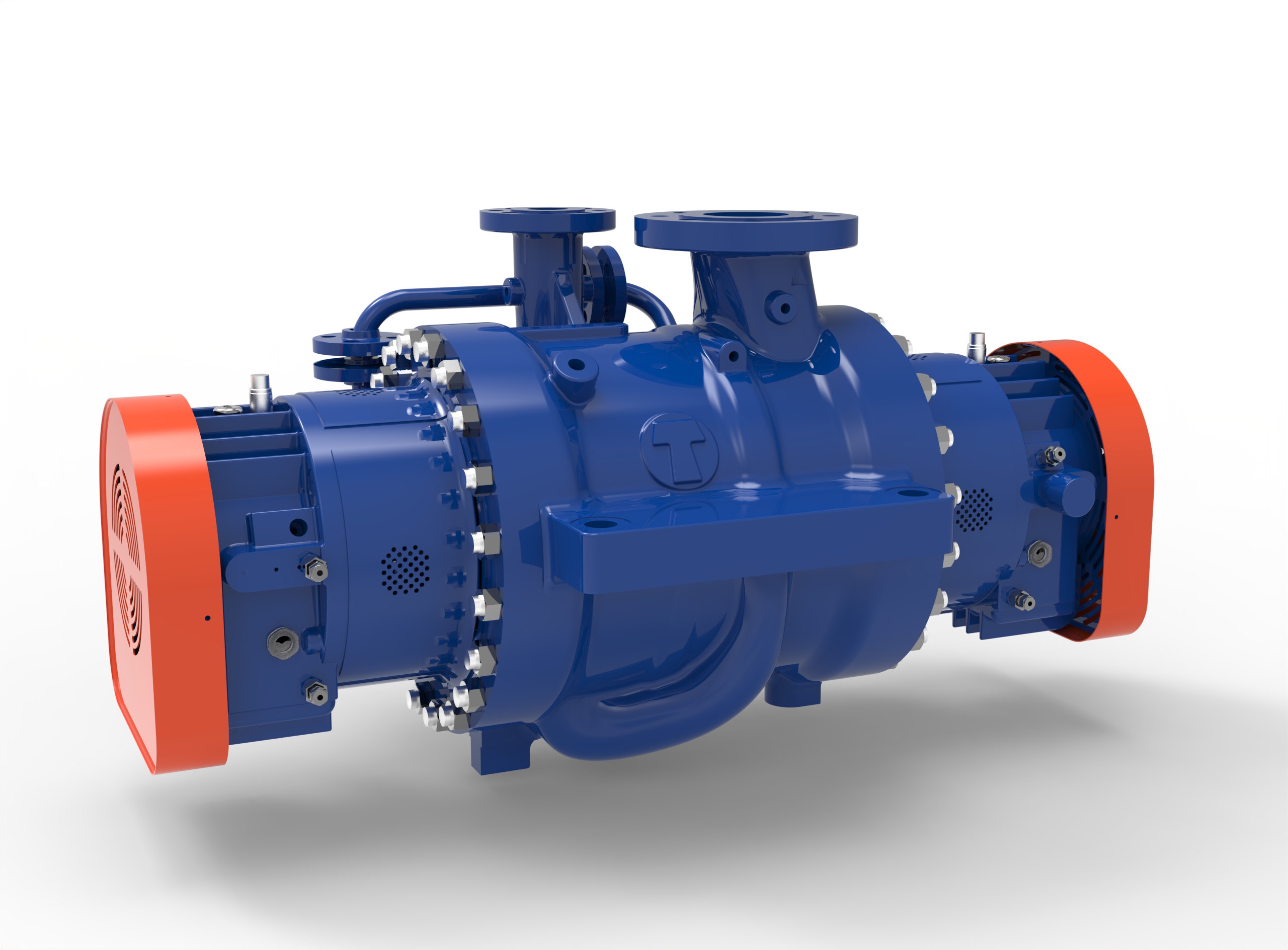

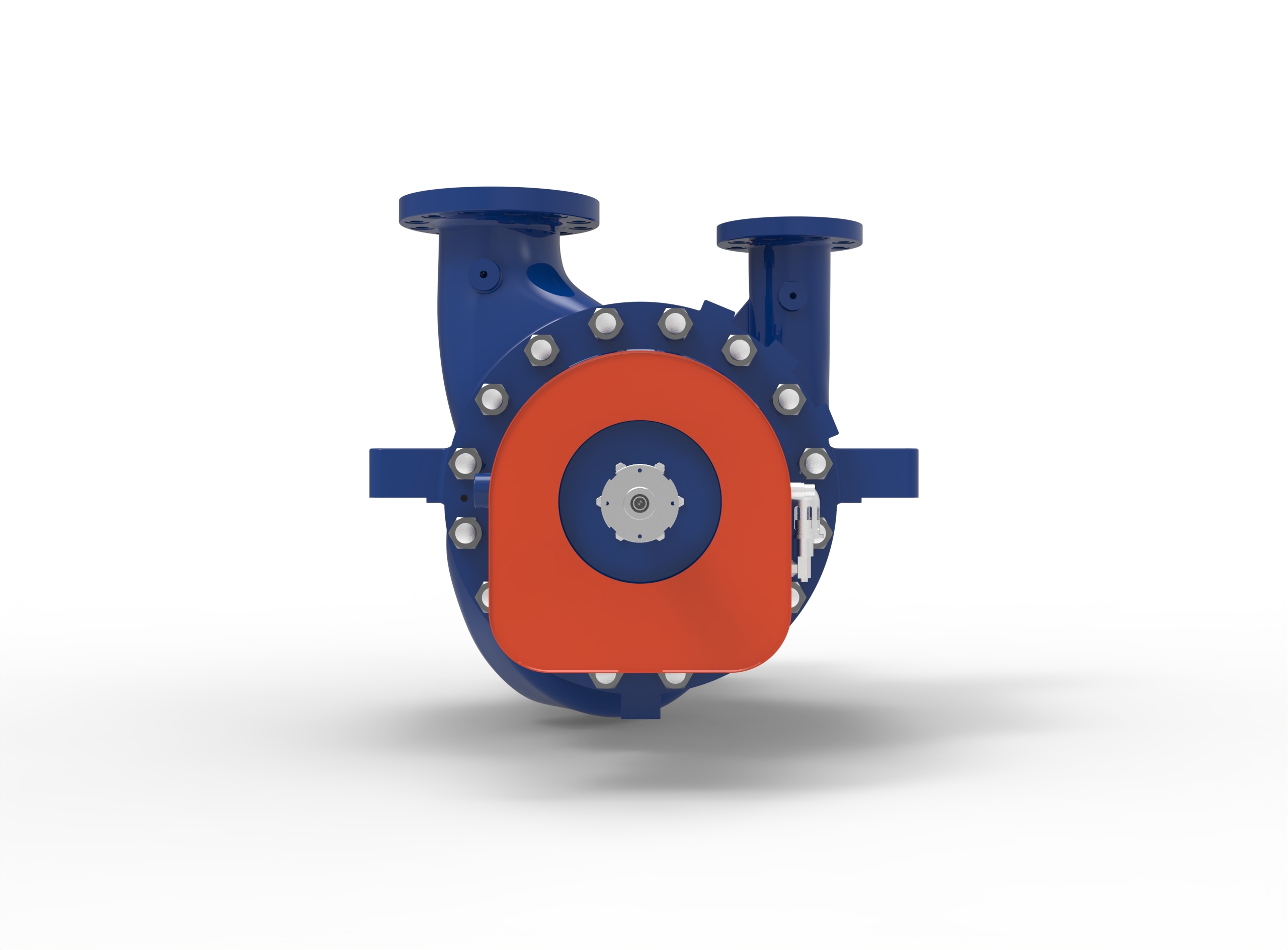

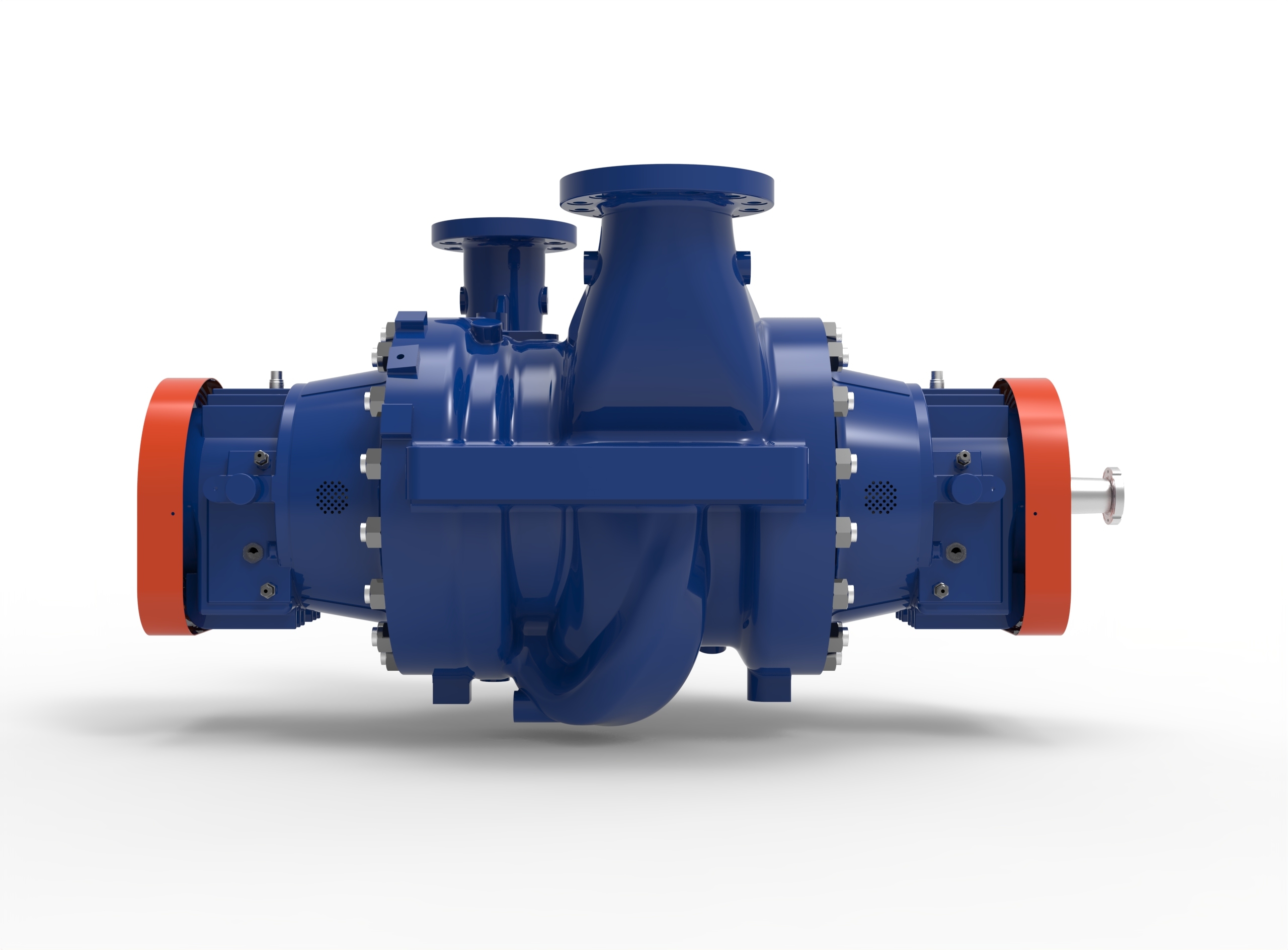

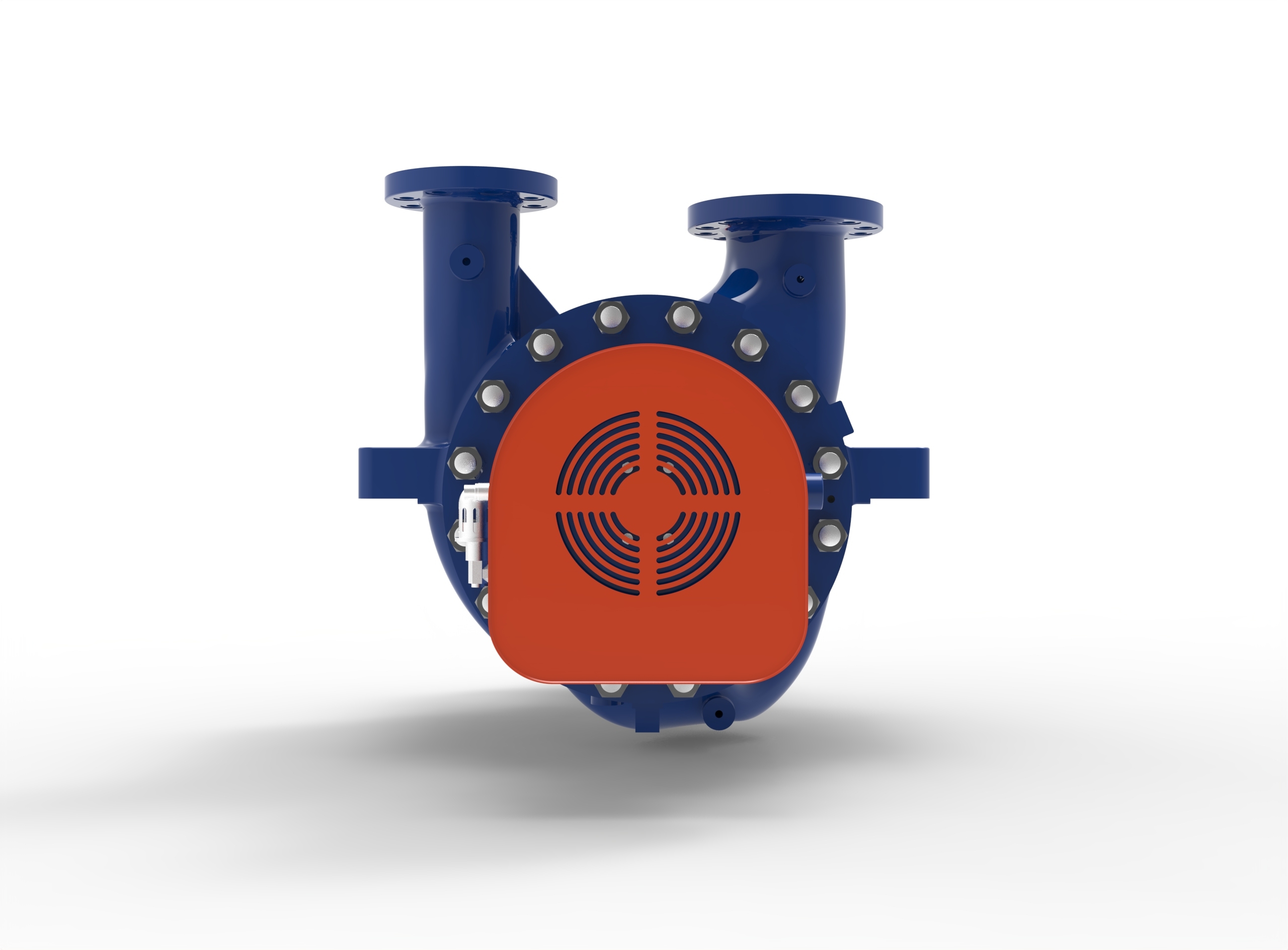

Termomeccanica Pompe

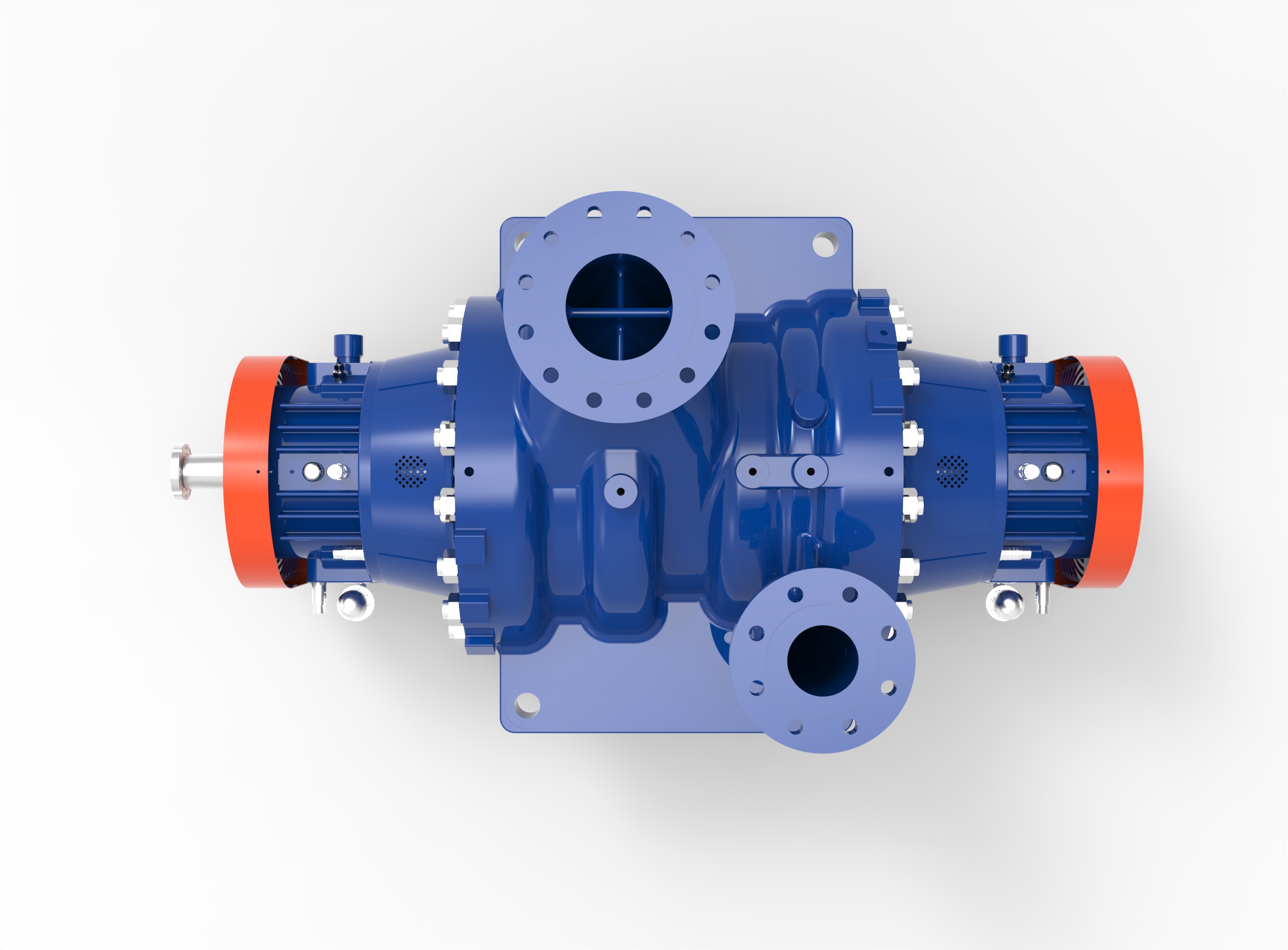

A2P & A2PD BB2 TYPE API 610 CENTRIFUGAL PUMP

Termomeccanica Pompe A2P & A2PD pumps are between bearings, radially split, two stage, and double volute heavy duty process pumps, centerline mounted for high temperature, high pressure services. Top-top nozzles are standard, but side-top or side-side nozzles are available upon request. On A2P models, the two single suction impellers with back-to-back arrangement compensate for axial hydraulic loads. A2PD models have a first stage double suction impeller for low NPSH applications.

OPERATING RANGE

- Capacity up to 2,000 m³/h (8,800 gpm)

- Head up to 750 m (2,460 ft.)

- Pressure up to 150 bar (2,180 psig)

- Temperature up to 450°C (840°F)

MAIN APPLICATIONS

- Oil well water injection

- Offshore installation

- Hydrocarbon pipelines

- Liquefied gas industry

- Refinery & petrochemical services

DESIGN STANDARD

- API 610 Latest Edition for O&G applications