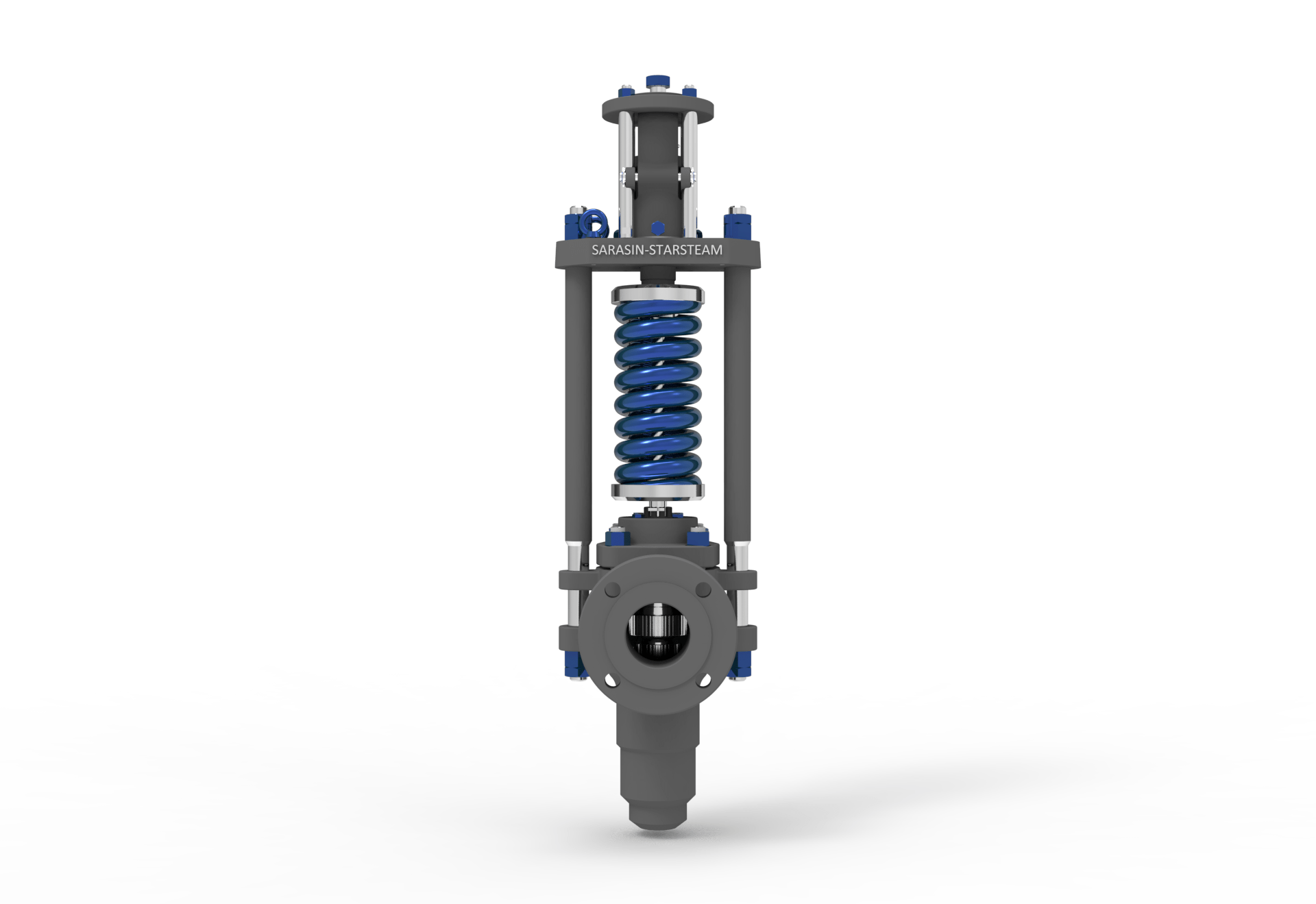

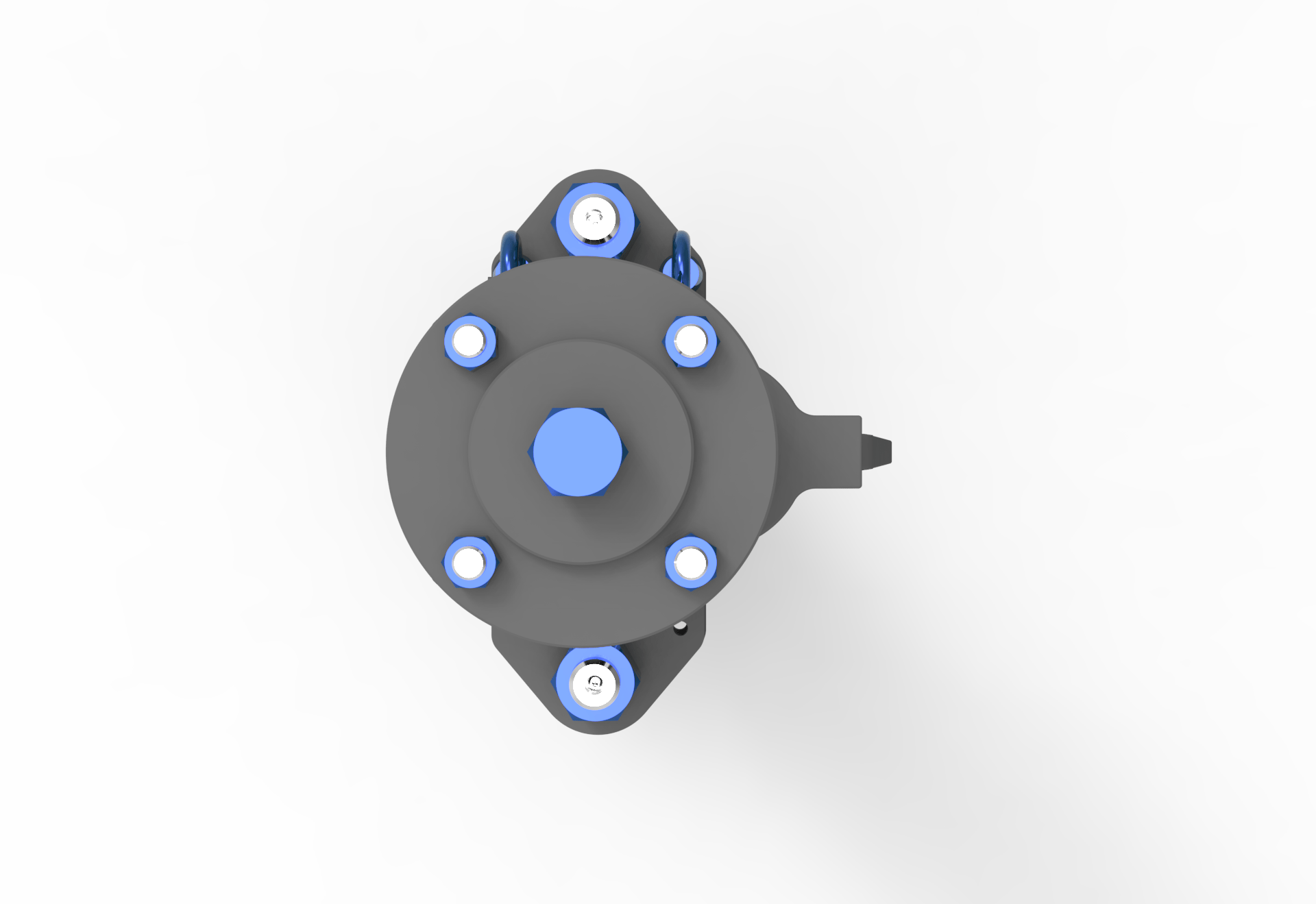

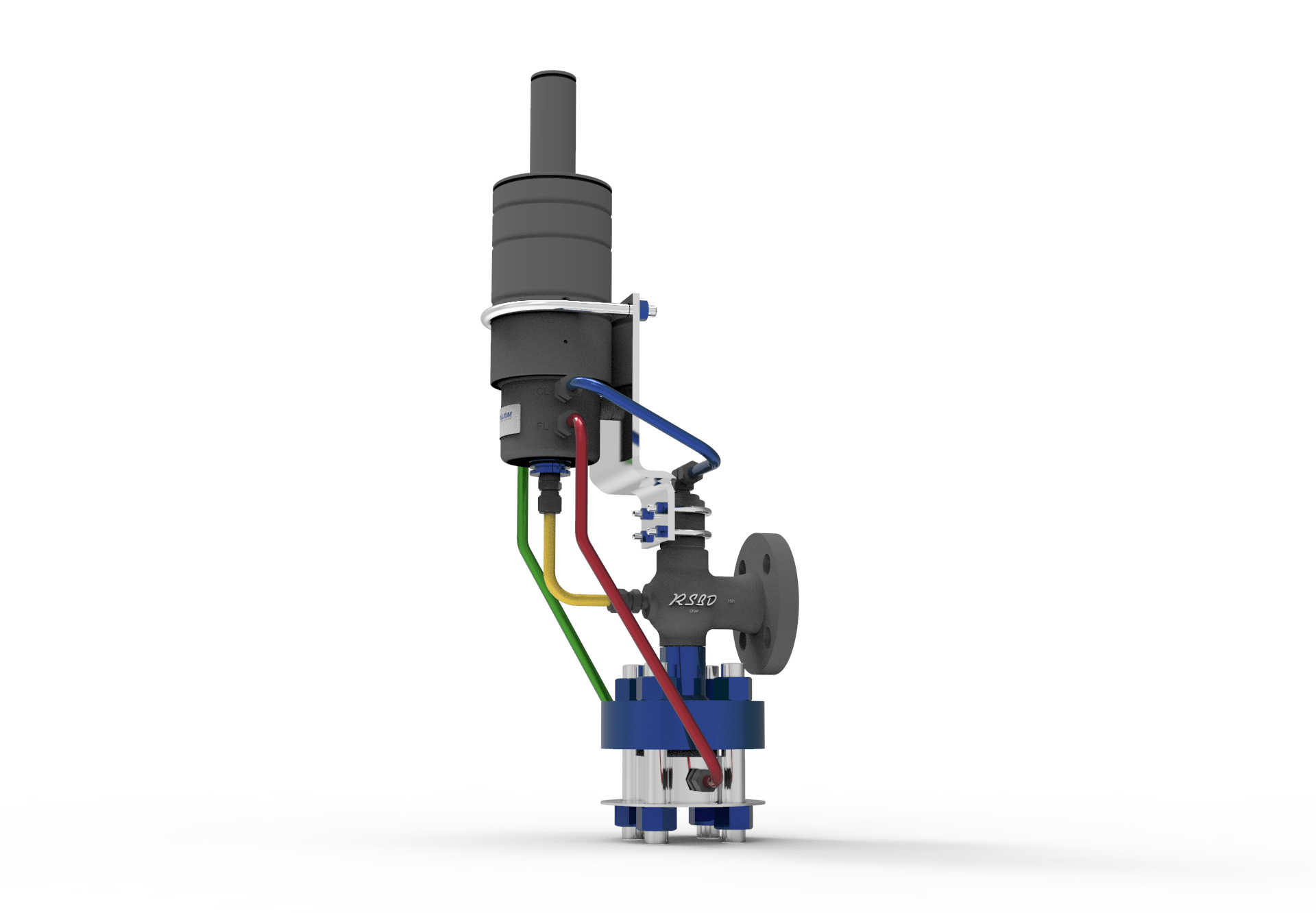

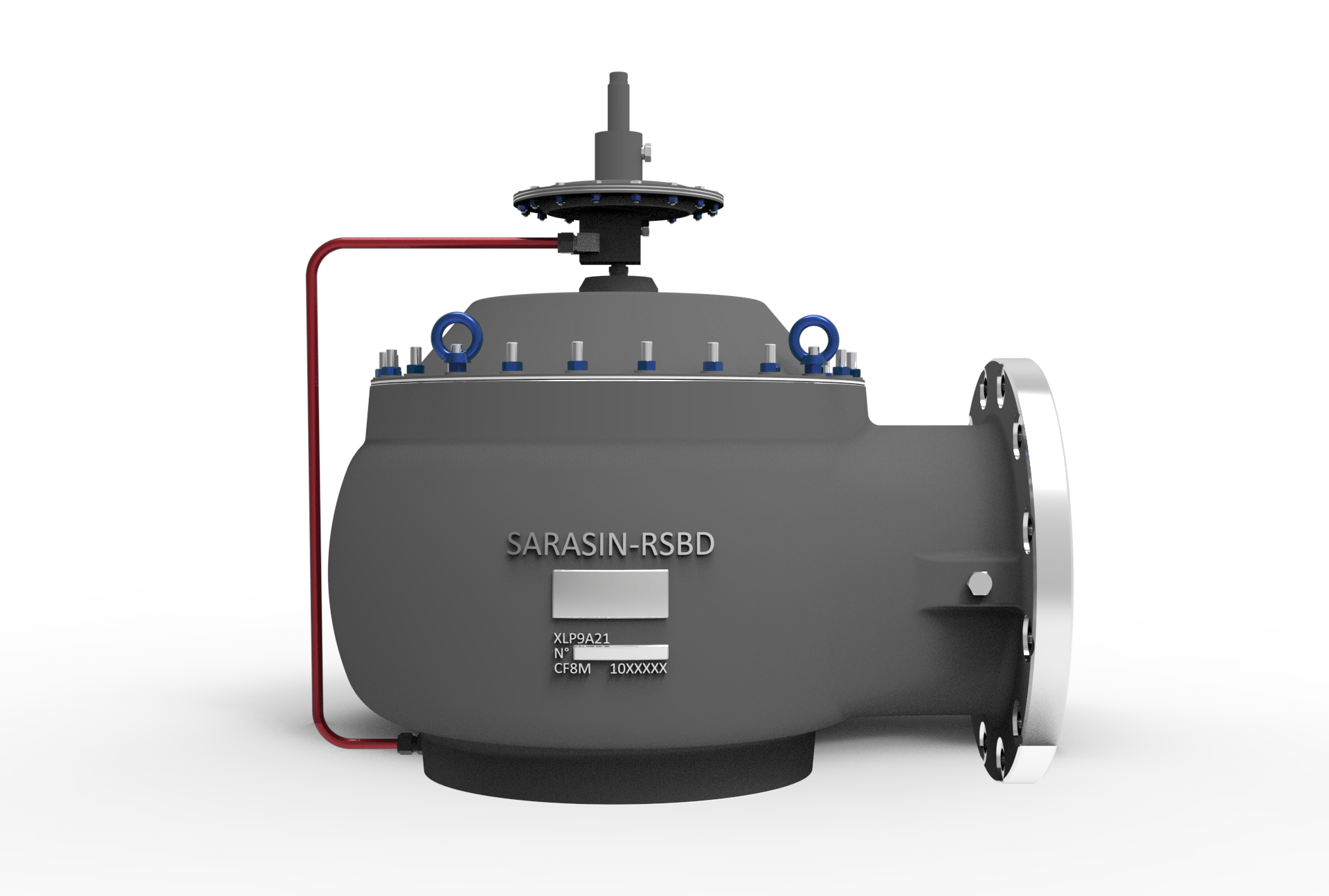

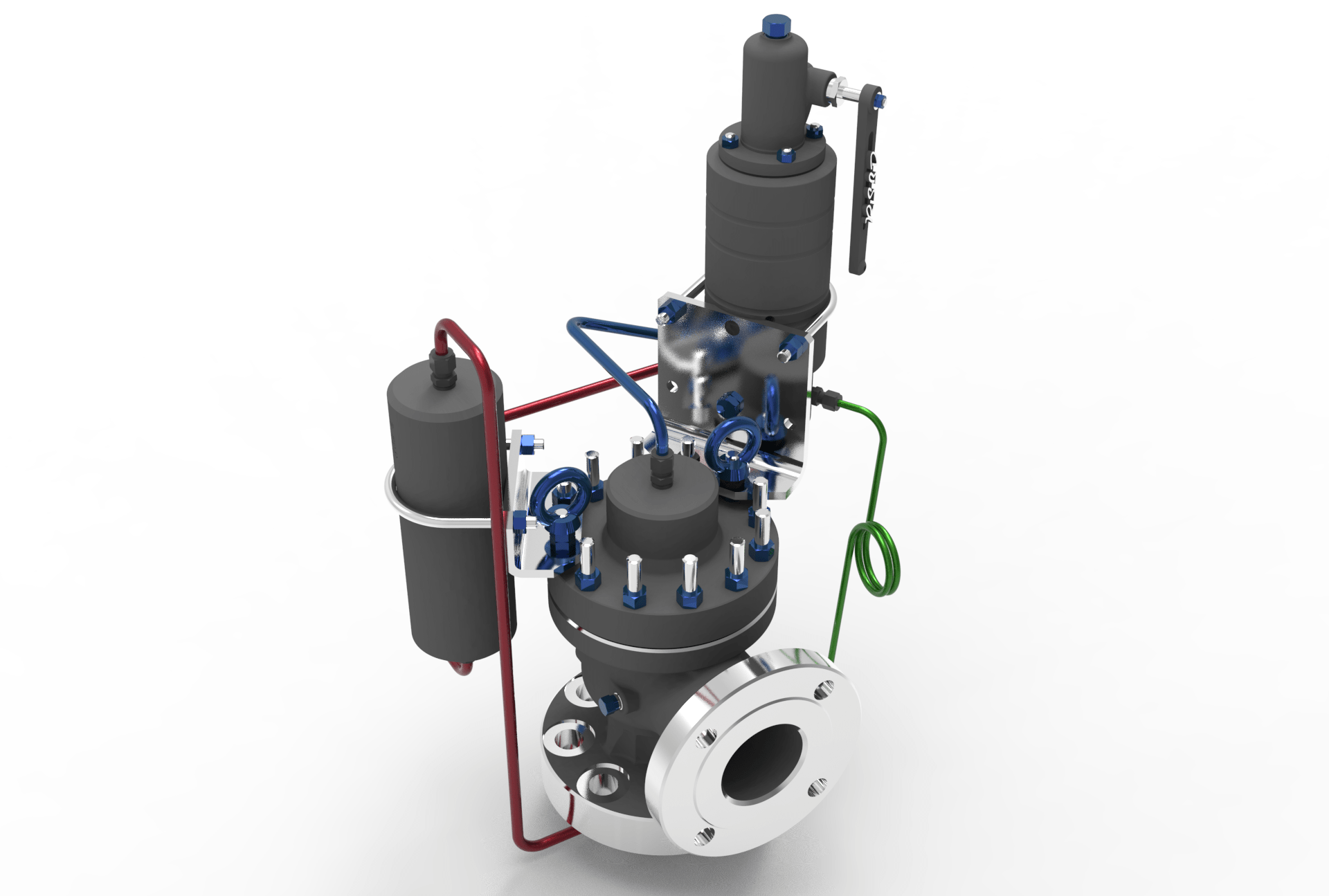

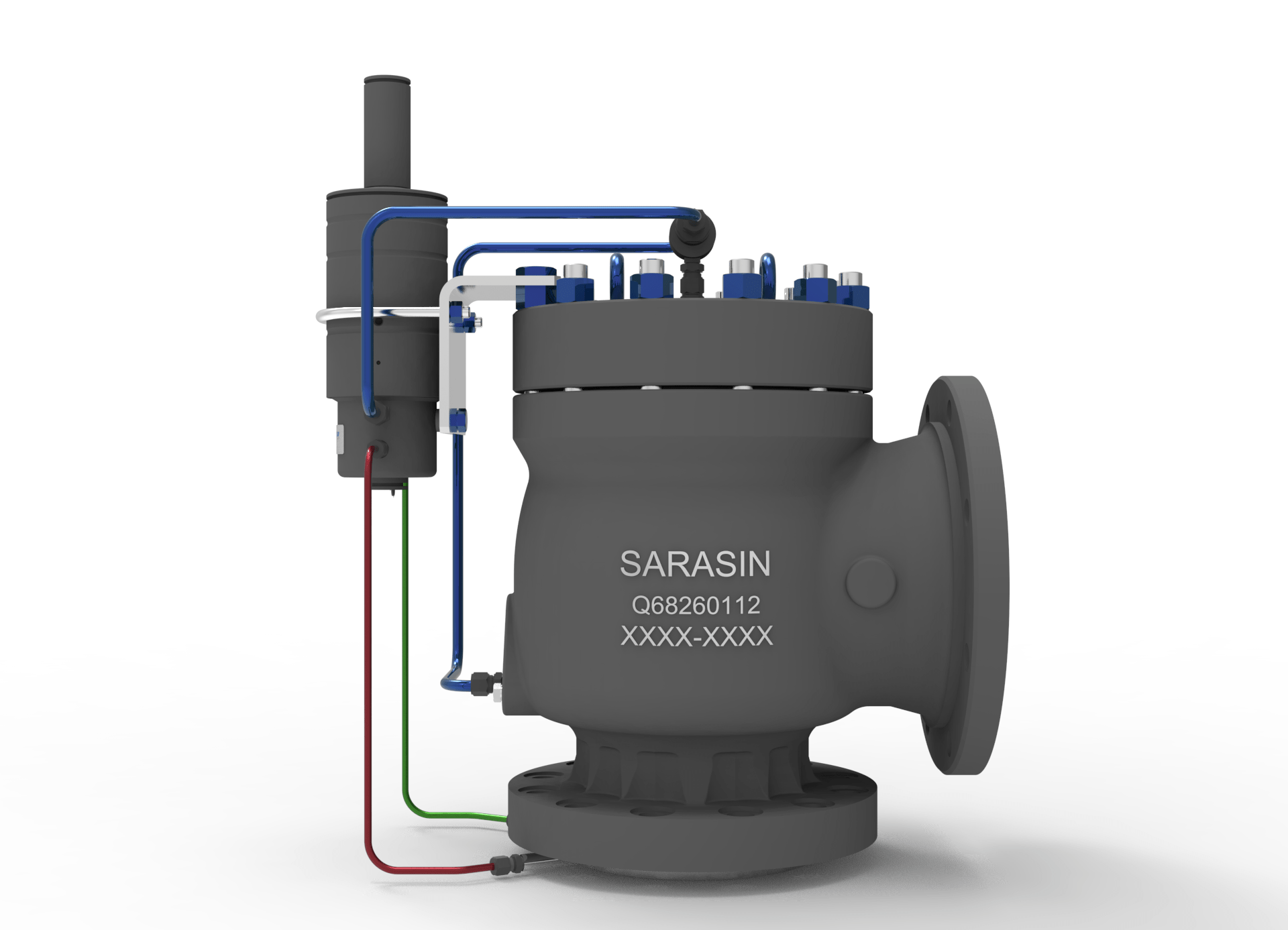

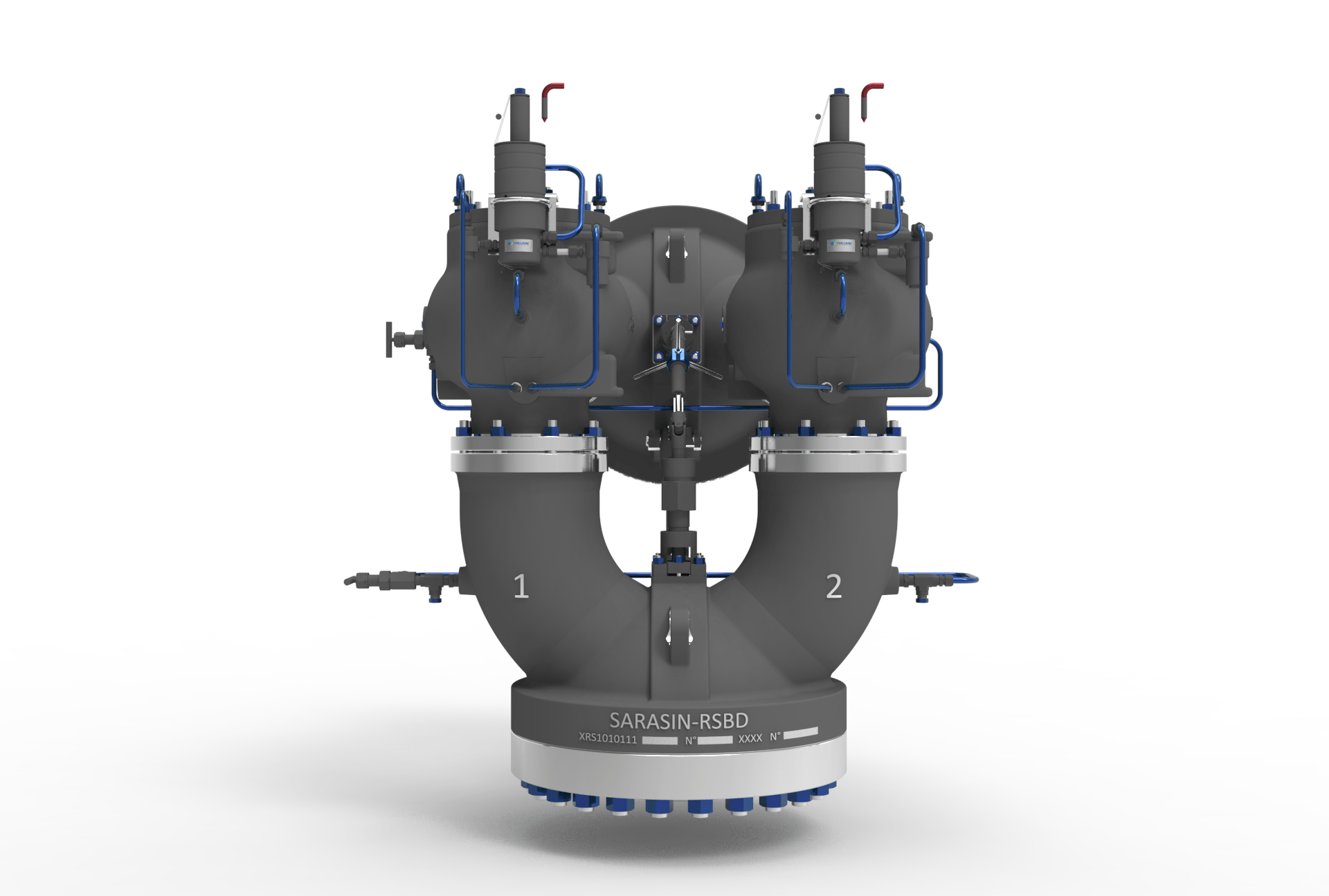

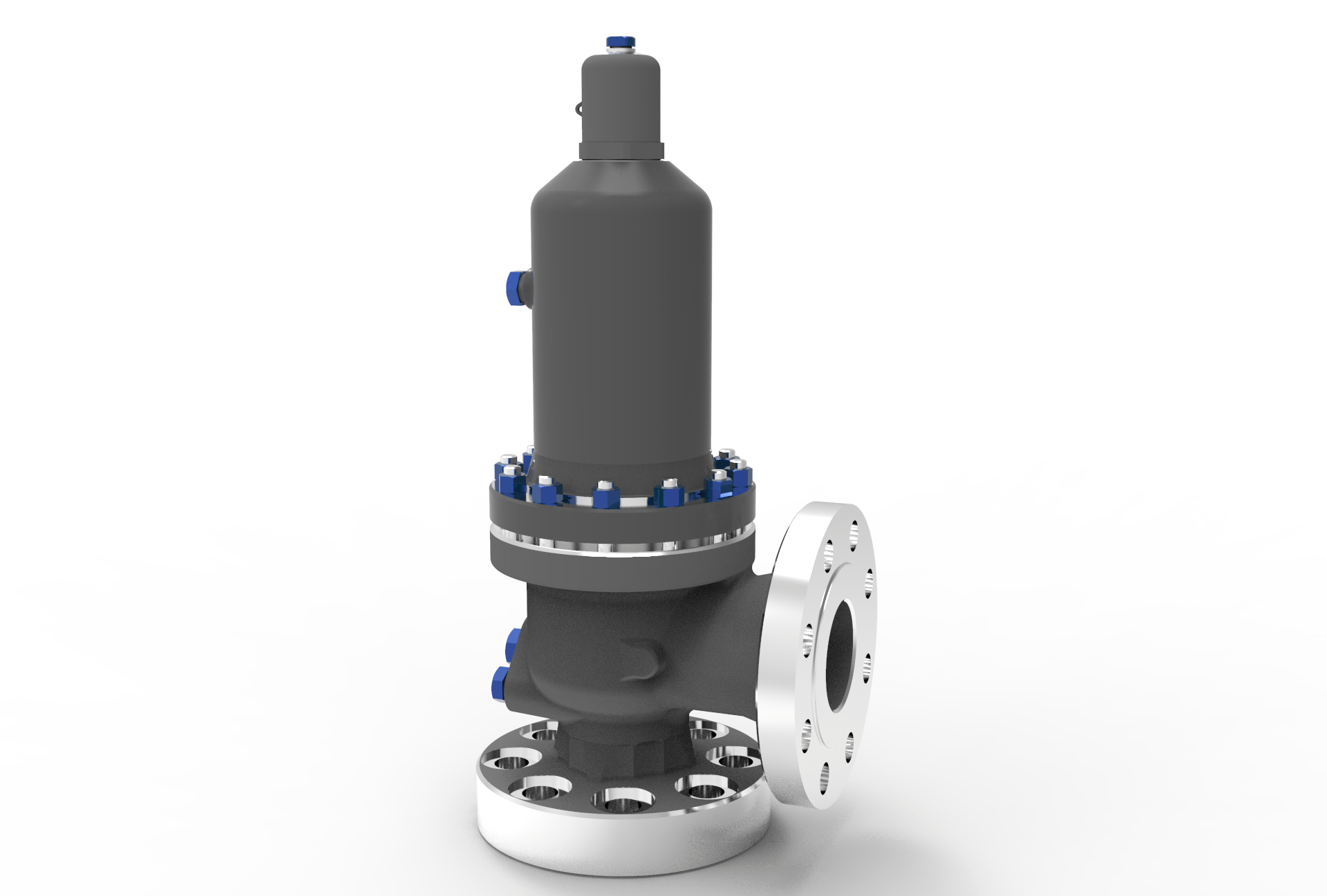

Sarasin-RSBD®

Starsteam

(V Series) Safety Valve

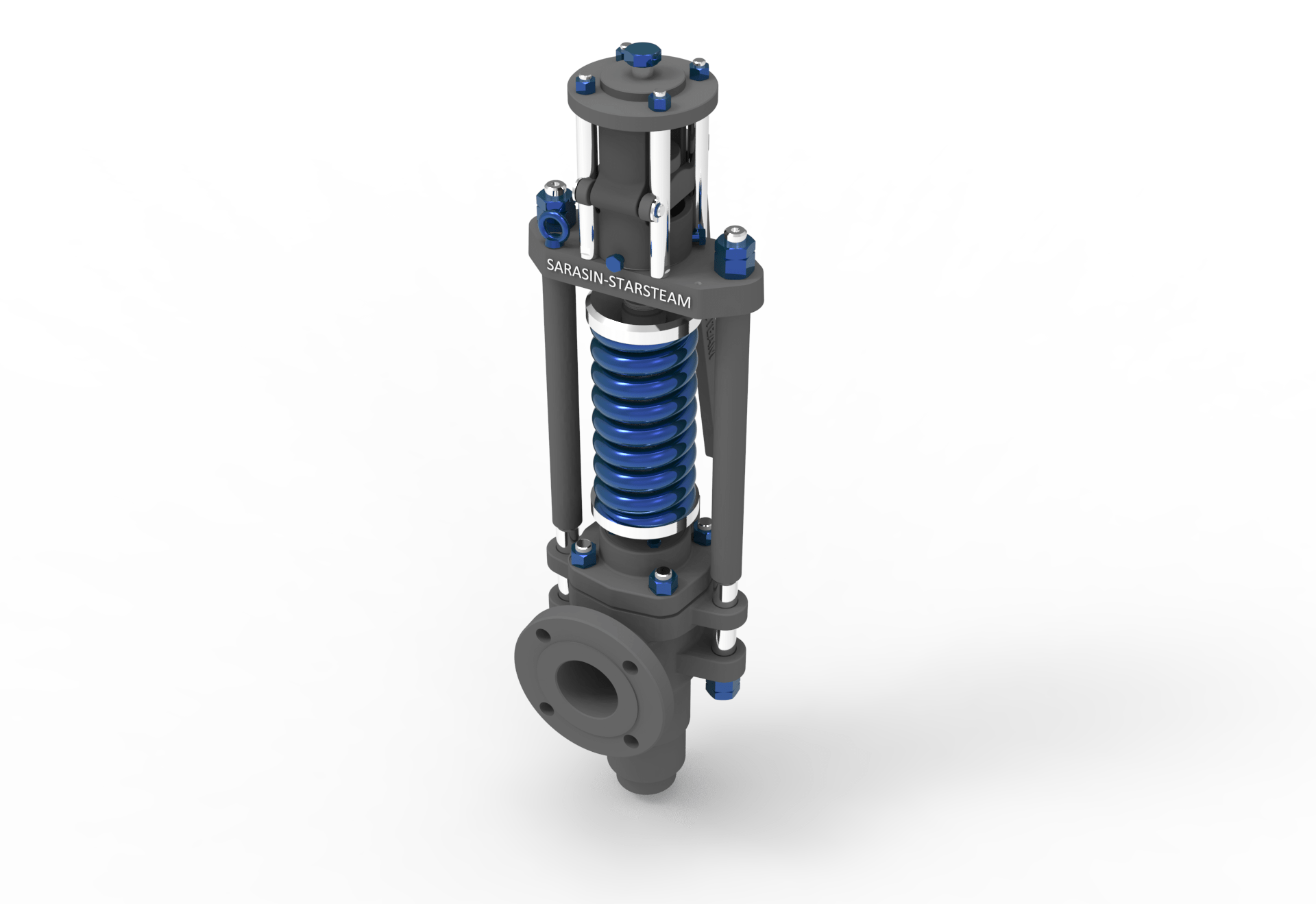

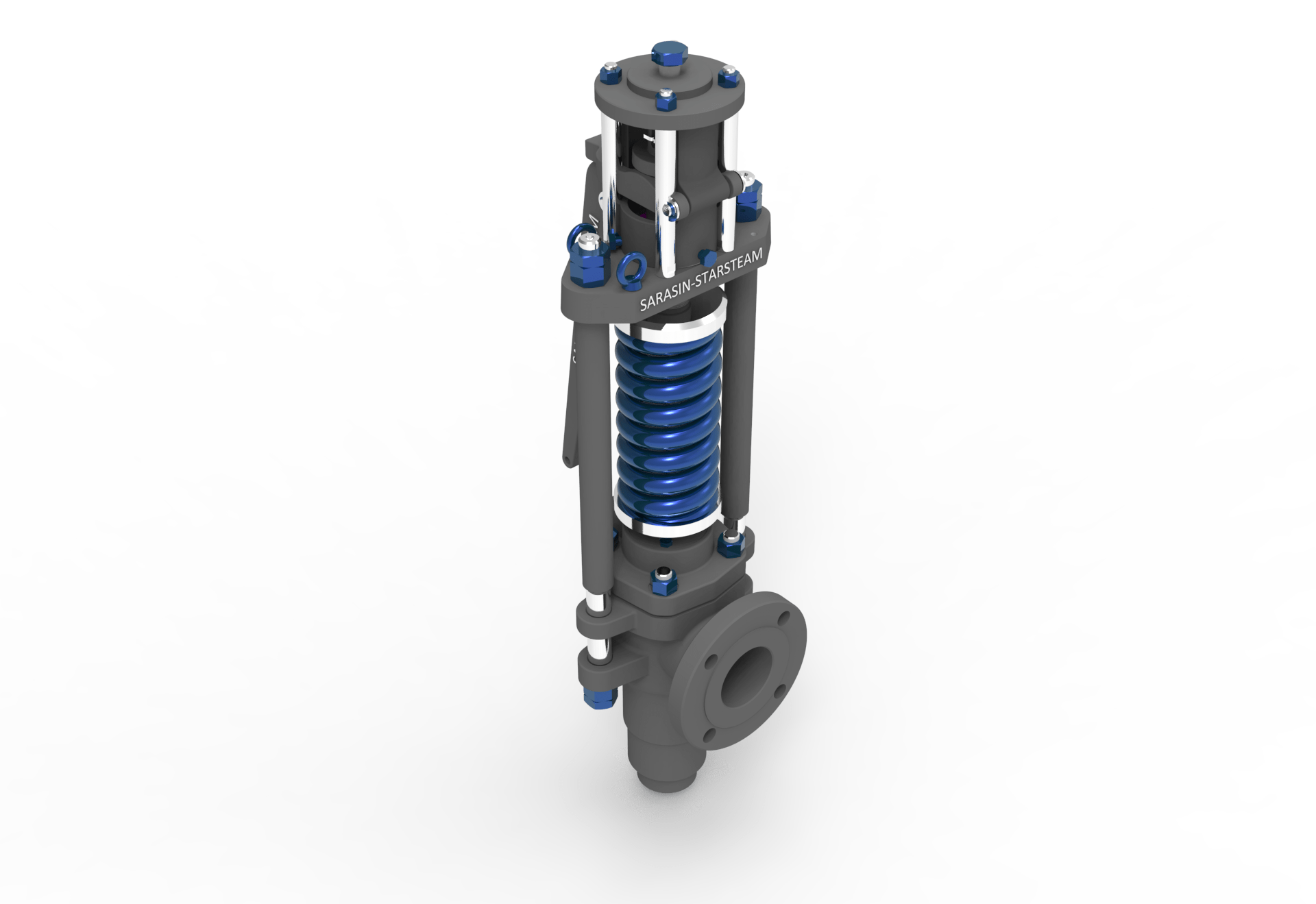

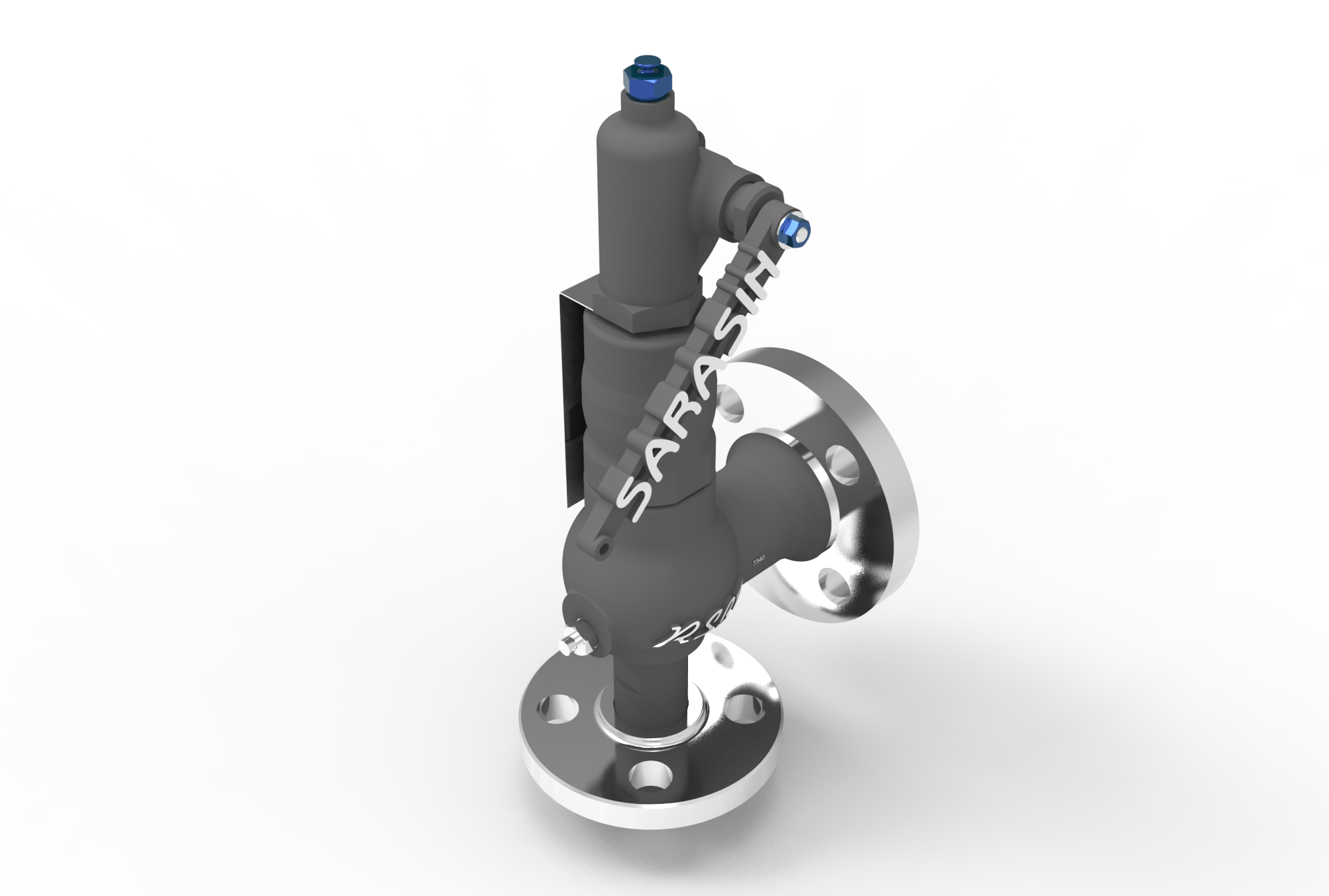

The Sarasin-RSBD® Starsteam Spring Loaded Safety Valve is designed to reliably meet the stringent requirements of ASME Boiler and Pressure Vessel Code Section I for Power applications.

The Starsteam Safety Valve is designed to meet the rigorous process conditions which are essential for steam boilers. This spring loaded safety valve is used in superheater and reheater applications and is specially engineered to provide fast response to overpressure and blowdown requirements.

The Sarasin-RSBD® Starsteam safety valves are designed to provide high integrity performance and repeatability particularly at high pressure and high temperatures in power plants as well as oil and gas boiler applications. This safety valve features a Stardisc design which guarantees perfect tightness at high temperatures as well as repeated and accurate positioning on the nozzle.

KEY BENEFITS & FEATURES

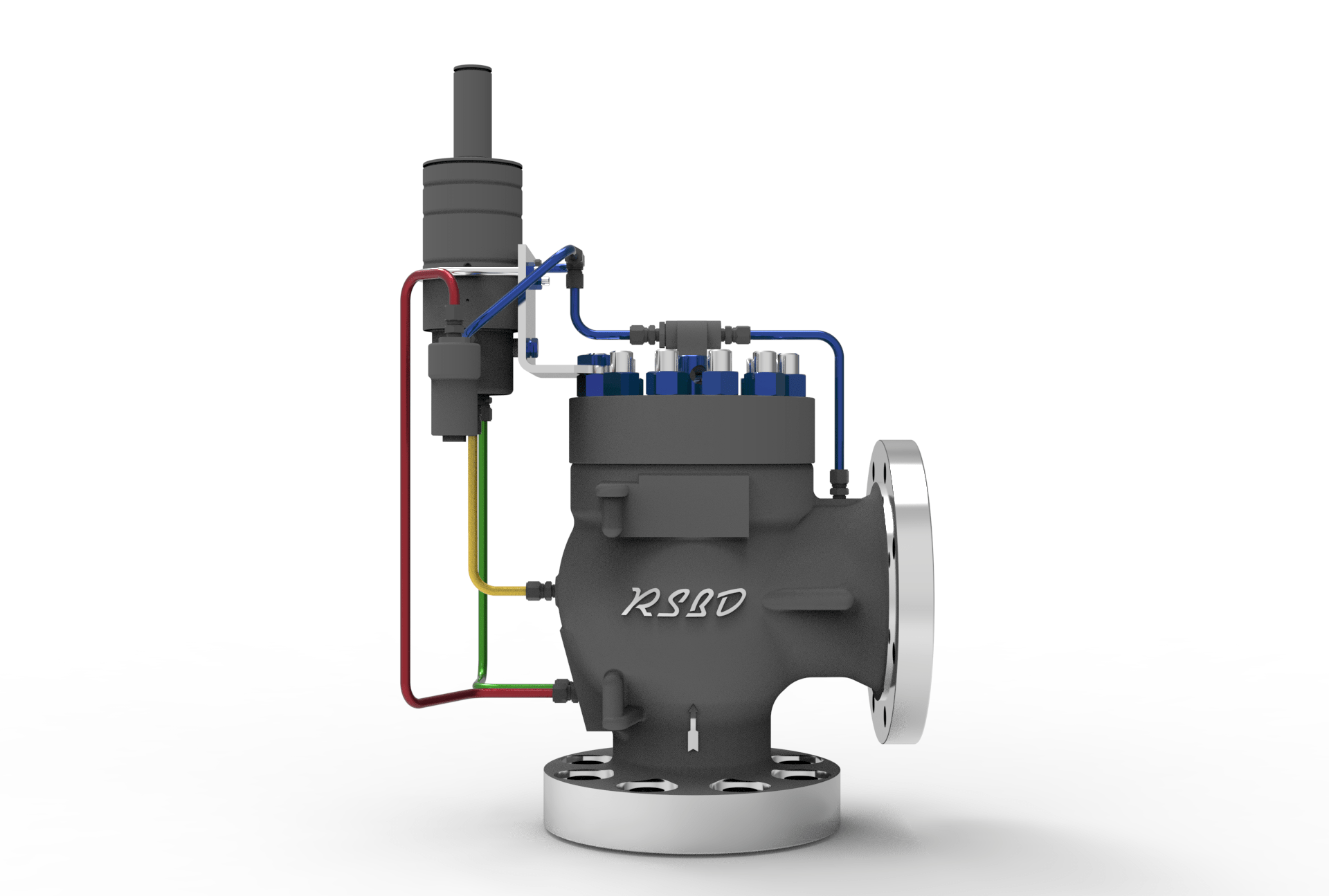

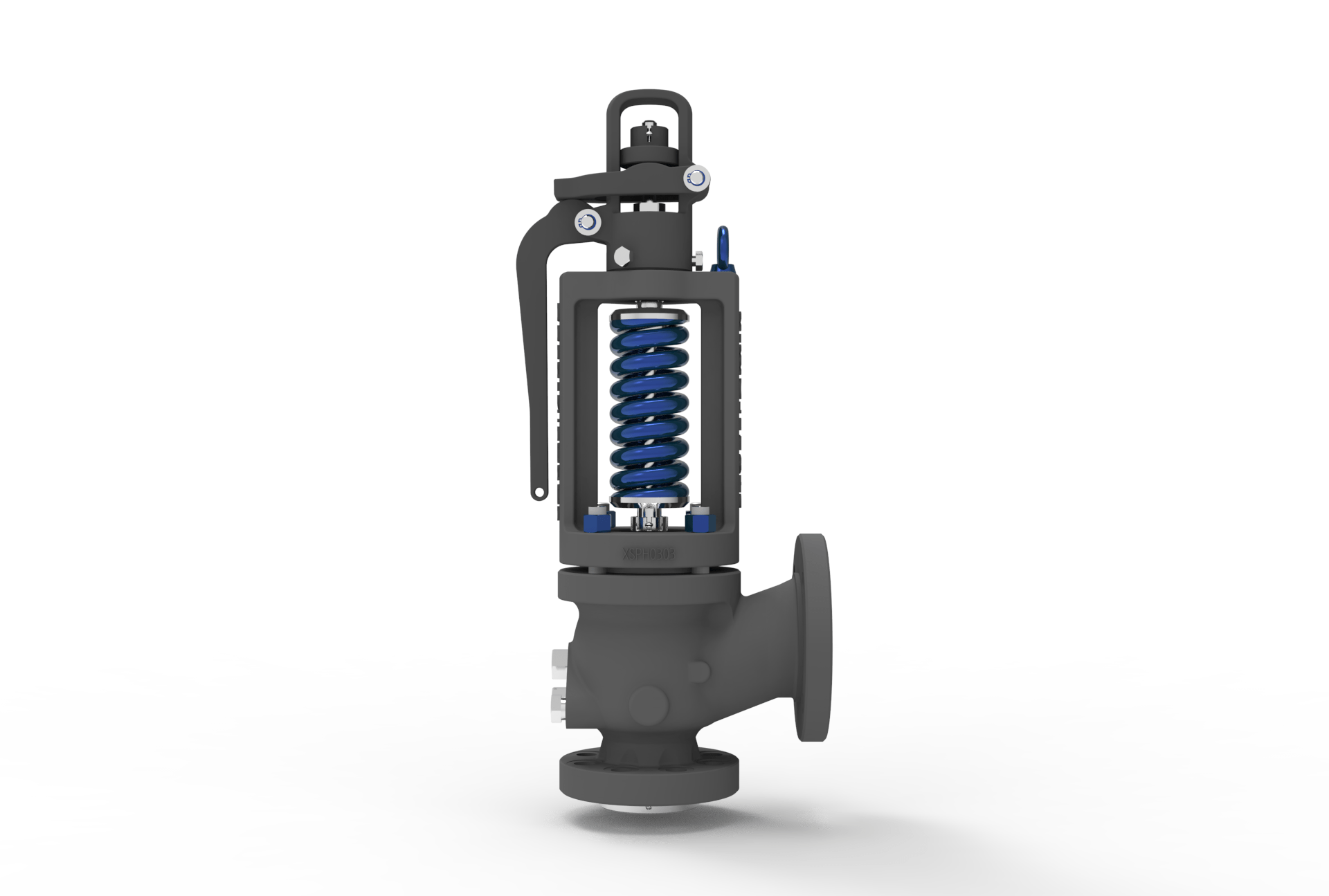

- A specially engineered internal design provides the fast response overpressure and blowdown requirements which are demanded by ASME BPVC Section I code of practice

- The valve is for use in boiler drum, superheater, and reheater applications

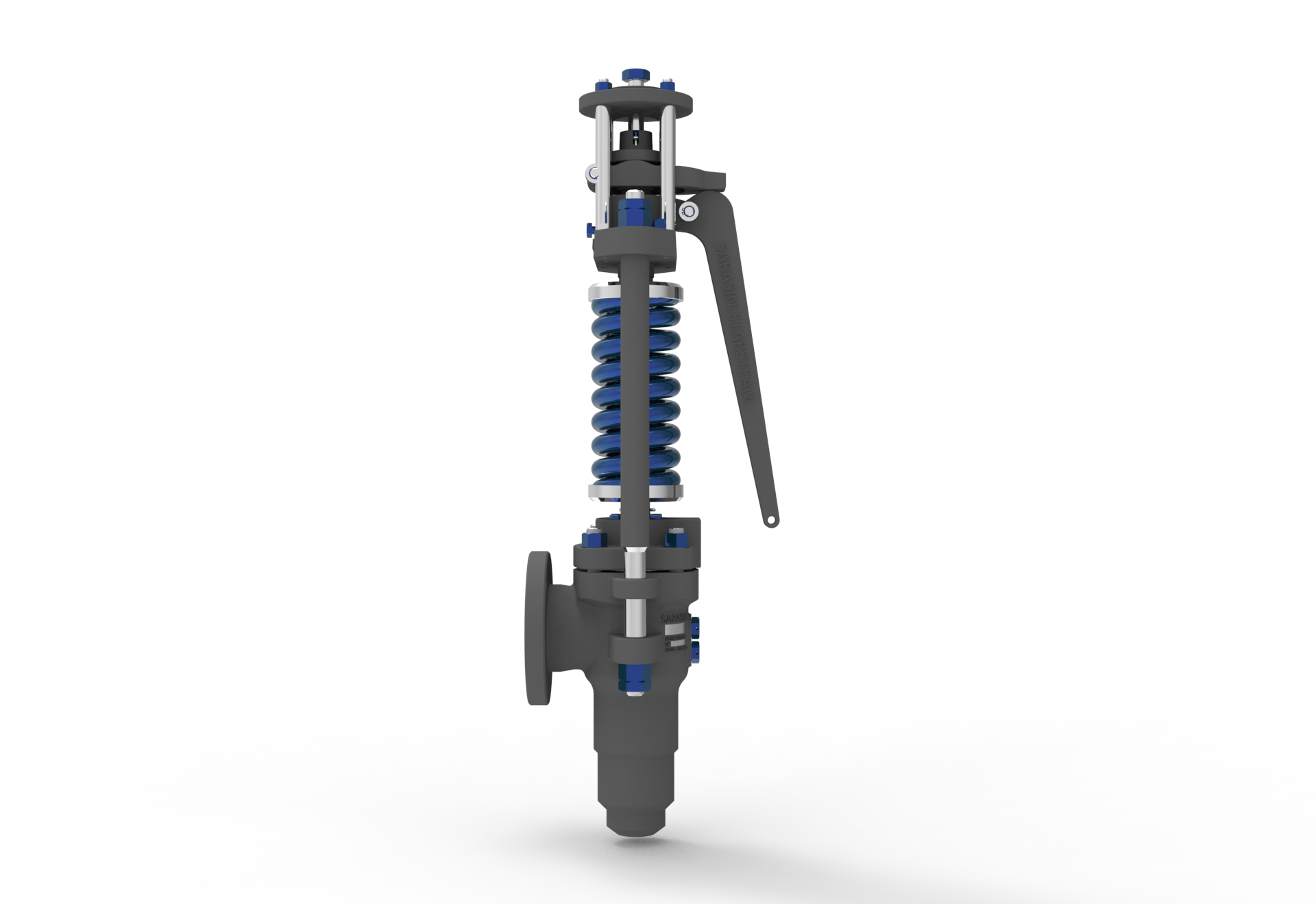

- Flanged or butt-weld inlet connections

- Flow capacity tested by the US National Board and carrying the ASME V code stamp (full lift and restricted lift)

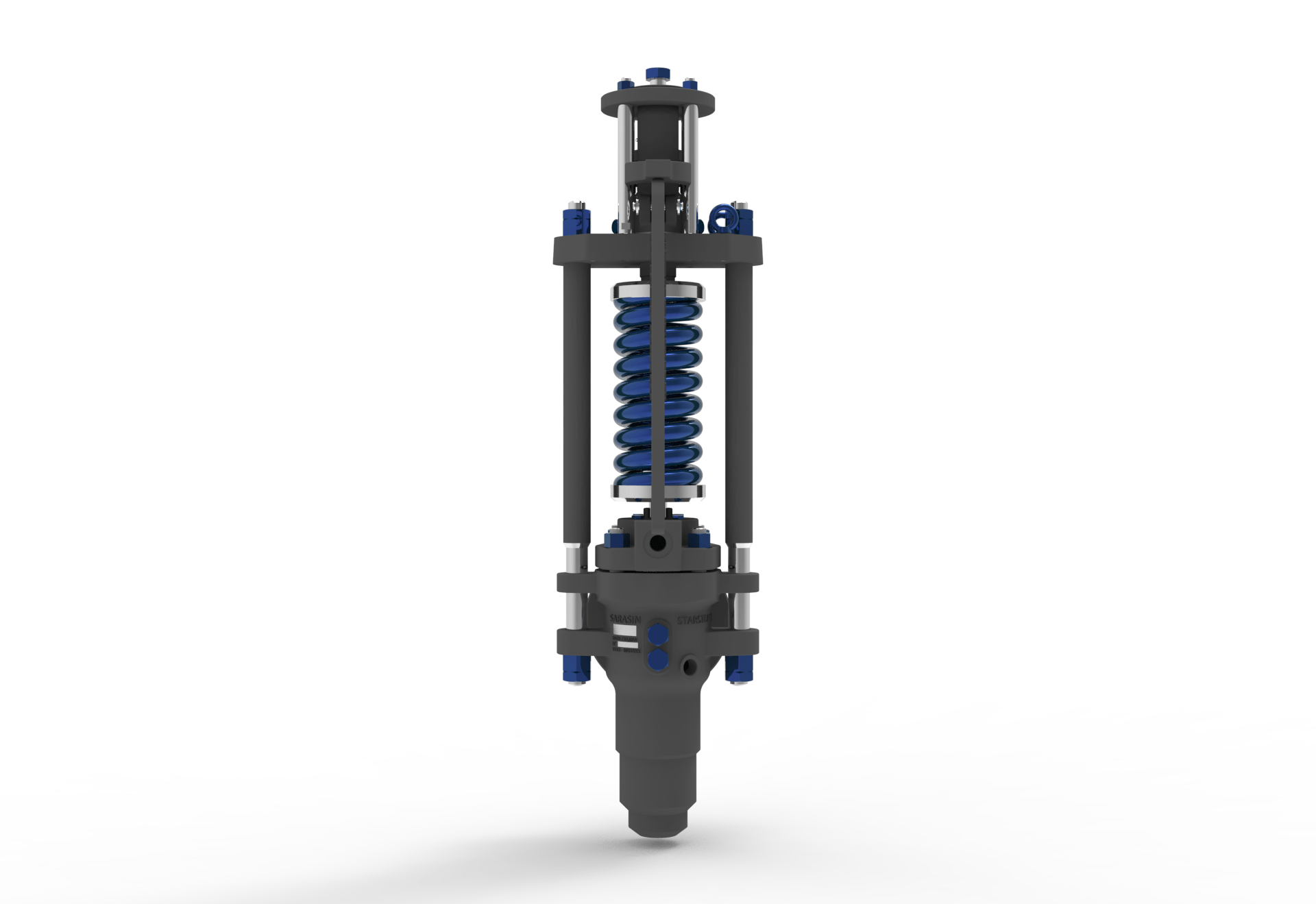

- Thermoglide design eliminates the risk of seizing or sticking of internal parts

- Thermoglide design improves the gliding characteristics of internal parts thus enabling the valve to achieve its full lift and re-seat point within the fastest possible time

- Stardisc disc lip design guarantees perfect tightness due to its flexibility at high temperature.

- Starsdisc low loading point guarantees repeated and accurate positioning on the nozzle

- Dual adjusting ring to adjust the accumulation chamber volume and guarantee short and fast action blowdown characteristics

- Seal welded semi-nozzle design

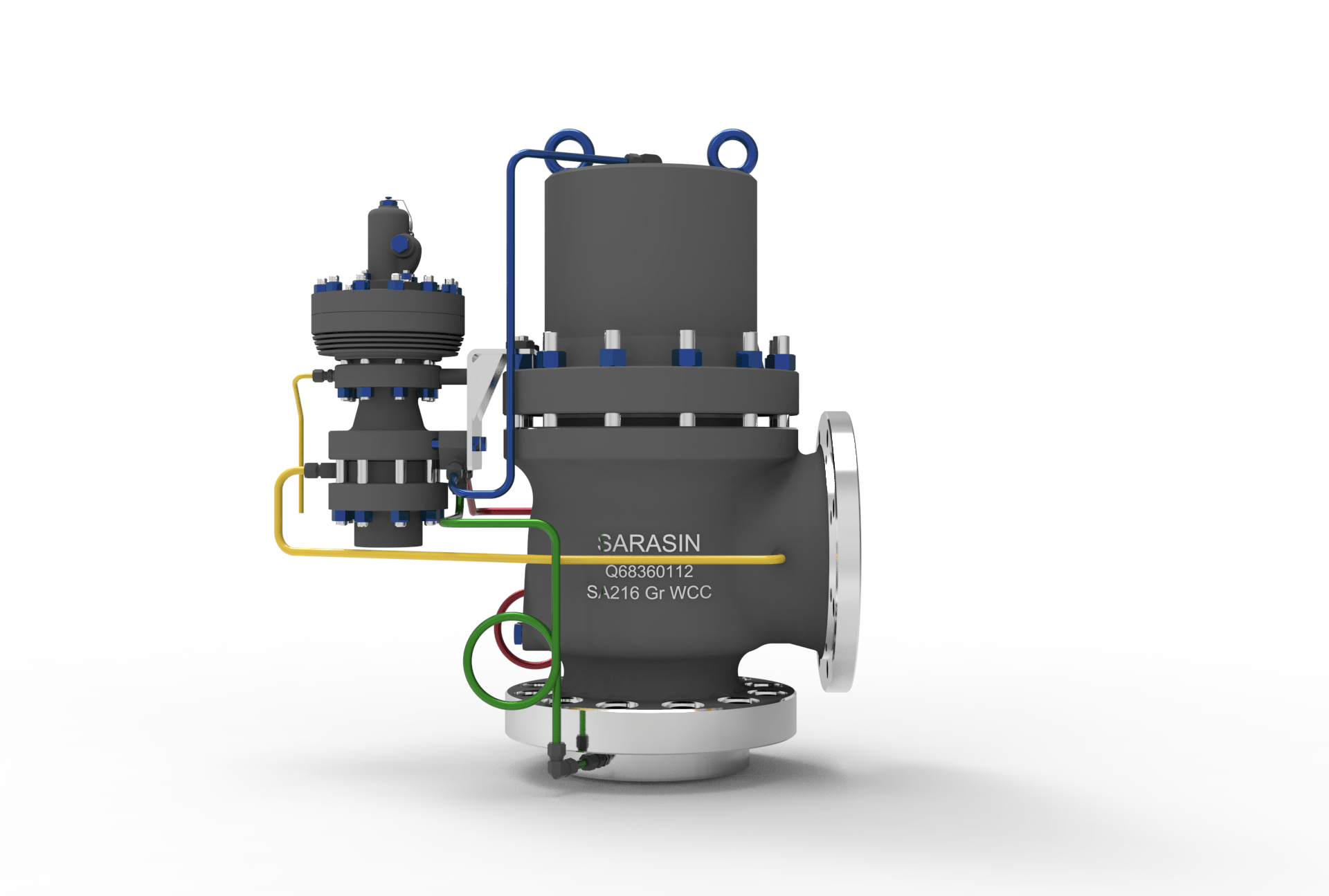

- Pre-drilled yoke mounting surface for in-situ electronic valve testing

APPLICATIONS

- Conventional power plants applications as detailed below

- Drum (subcritical)

- Superheater inlet (supercritical)

- Superheater outlet

- Reheater inlet and outlet

- Sootblower

- Oil & Gas applications

- Site boiler installations

- Nuclear power plants

DESIGN STANDARDS

- ASME BPVC I, ISO 4126, PED 2014/68/UE, ATEX 94/9/EC, EAC TR CU 10/12/32

- ASME Section III (St. Victoret Plant)

DESIGN RATINGS

- ASME Class 600 to 4500

- Flanged or Butt-weld

- Size range & dimensions

- 40 – 200mm (1.5 – 8 inches)

TEMPERATURE RANGE

- Saturated steam up to 649ºC (1200°F)

CAPACITY

- Individually calculated and selected for each process application

MATERIALS

- Carbon steel, various carbon & chrome moly steels austenitic stainless steels

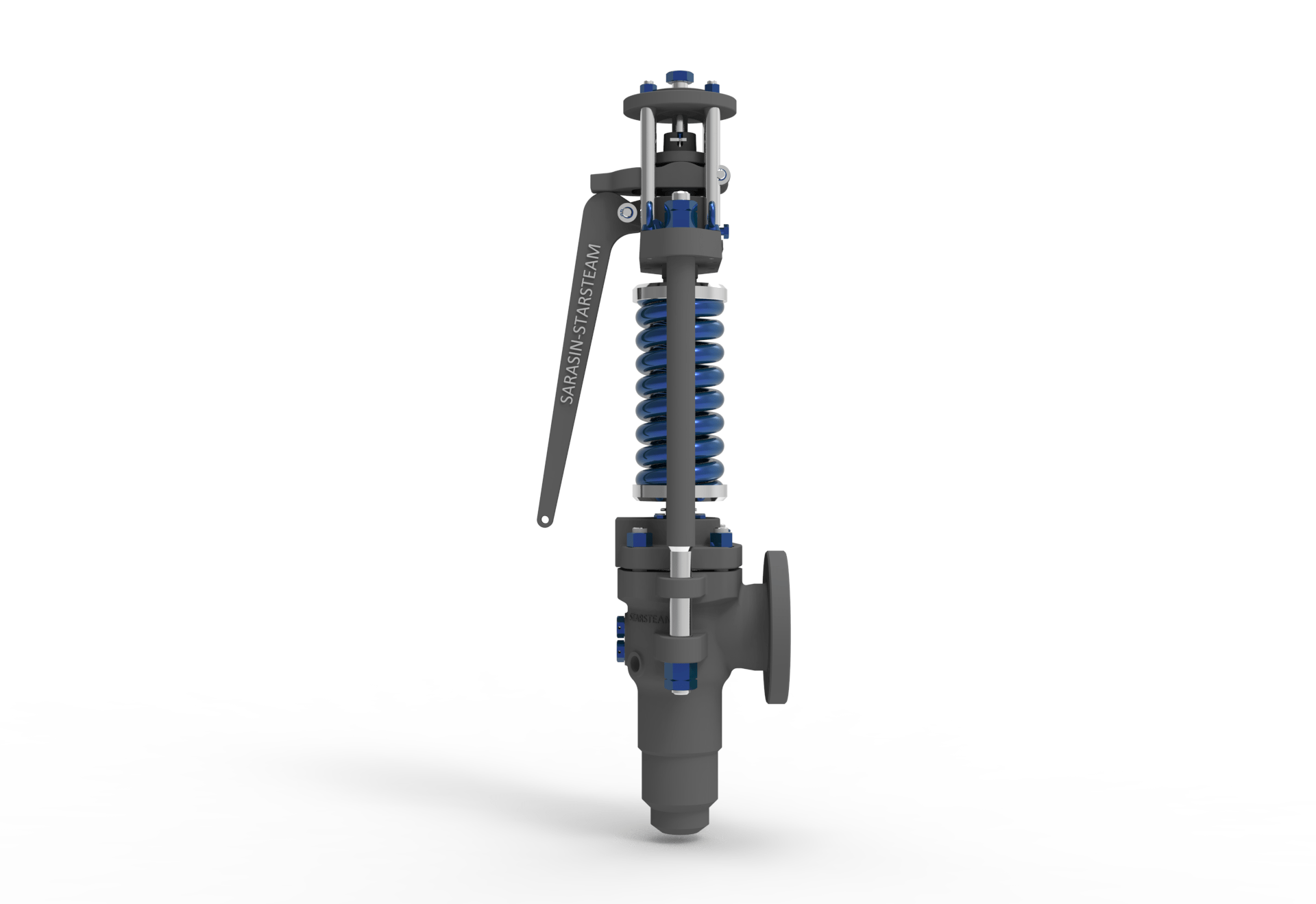

UPGRADES & ADAPTATIONS

- Assisted lift

- Restricted lift

- Supplementary loading