TRICENTRIC®

For nearly 50 years, the TRICENTRIC® brand has been recognized for excellent flow and control characteristics, sealing capabilities, and dependability across a wide range of specific applications. Today, as part of the Trillium Flow Technologies™ portfolio, TRICENTRIC® continues to deliver outstanding value.

HIGHLY ENGINEERED VALVES FOR A WIDE RANGE OF APPLICATIONS

Since the 1970s, the TRICENTRIC® brand has been recognized for excellent flow and control characteristics, sealing capabilities, and dependability in a wide range of specific applications. Today, as a Trillium Flow Technologies™ brand, TRICENTRIC® continues to deliver outstanding value.

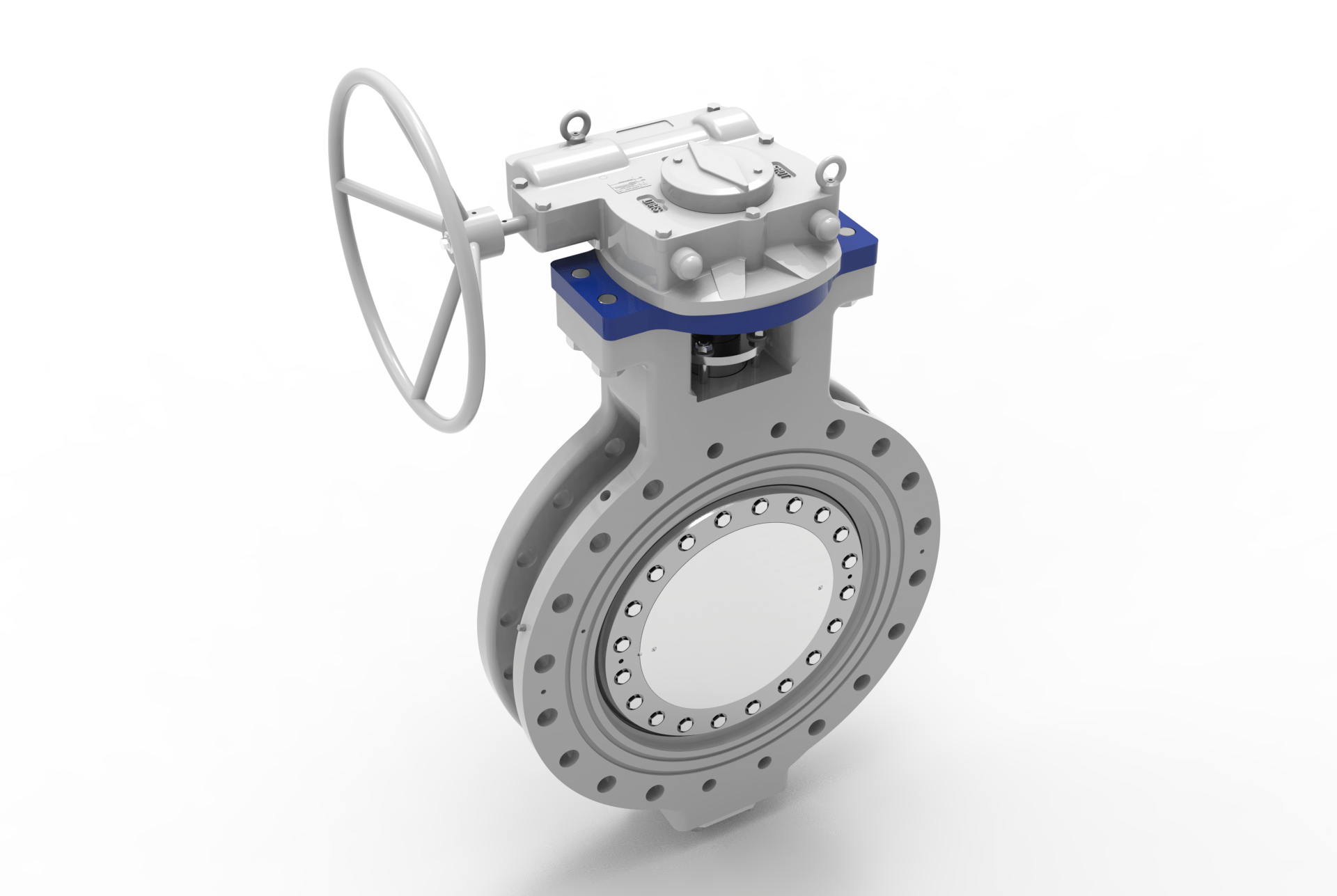

TRICENTRIC® triple offset butterfly valves are highly engineered, meet stringent industry requirements, and provide low cost of ownership to the end user through improved life cycle costs, emissions control, less downtime, and low maintenance costs.

A LONG LIFE AND A LASTING VALUE

Trillium Flow Technologies™ TRICENTRIC® valves are long lasting and durable under some of the most extreme conditions. We are dedicated to creating custom valve solutions that meet your specific industry needs for the life of your operation.

With TRICENTRIC®, you’ll have confidence in your flow control now and in the future.