SEBIM®

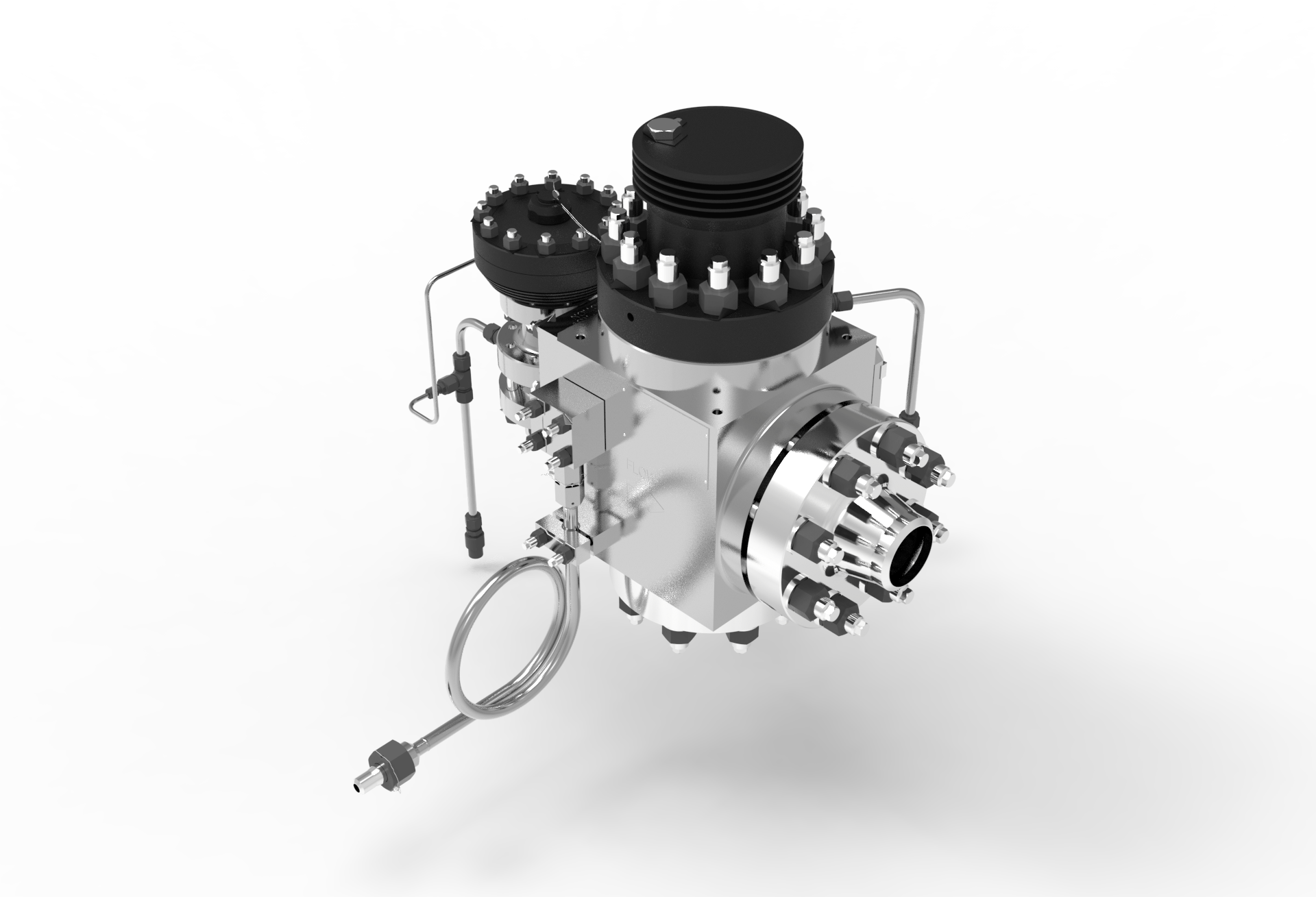

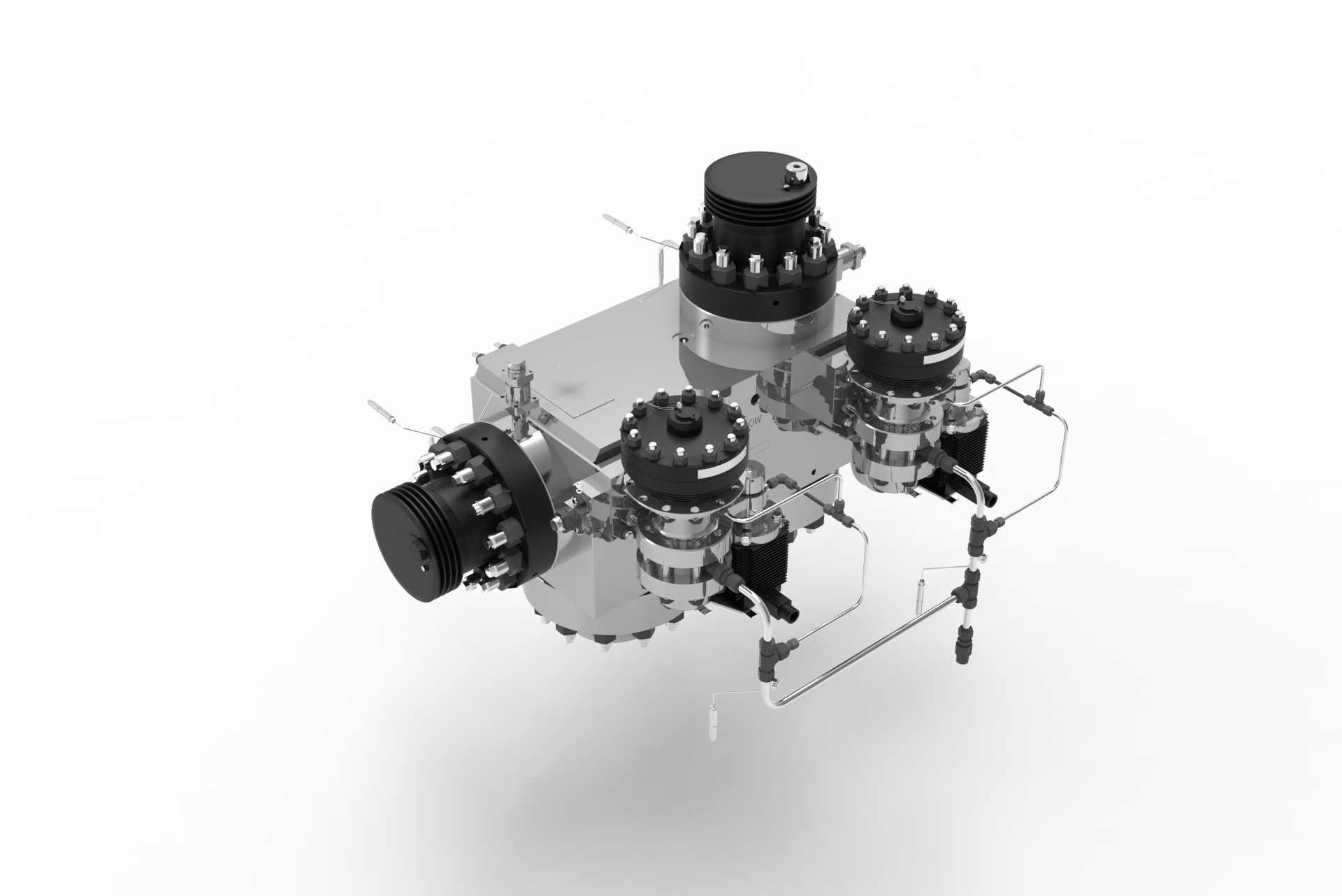

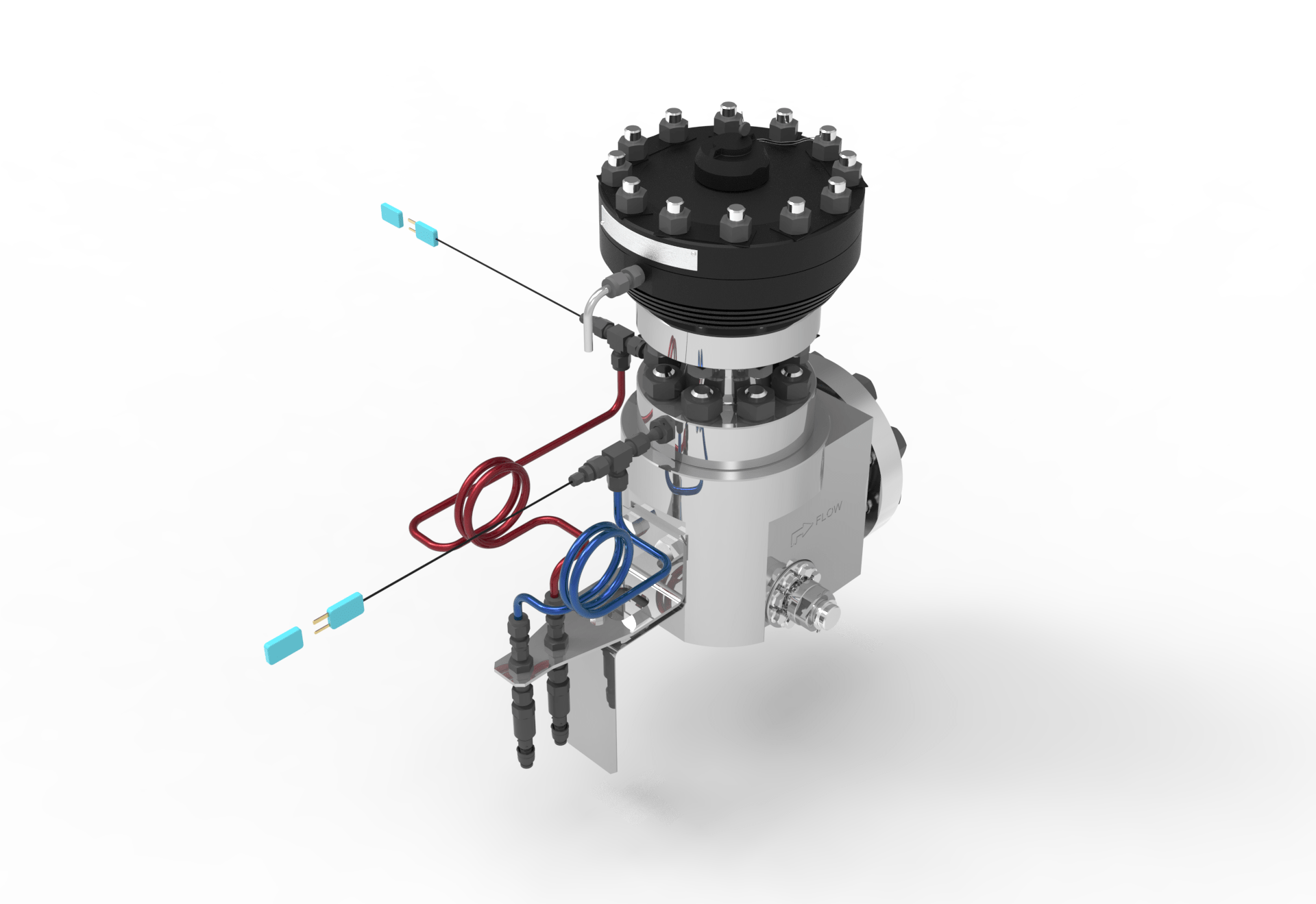

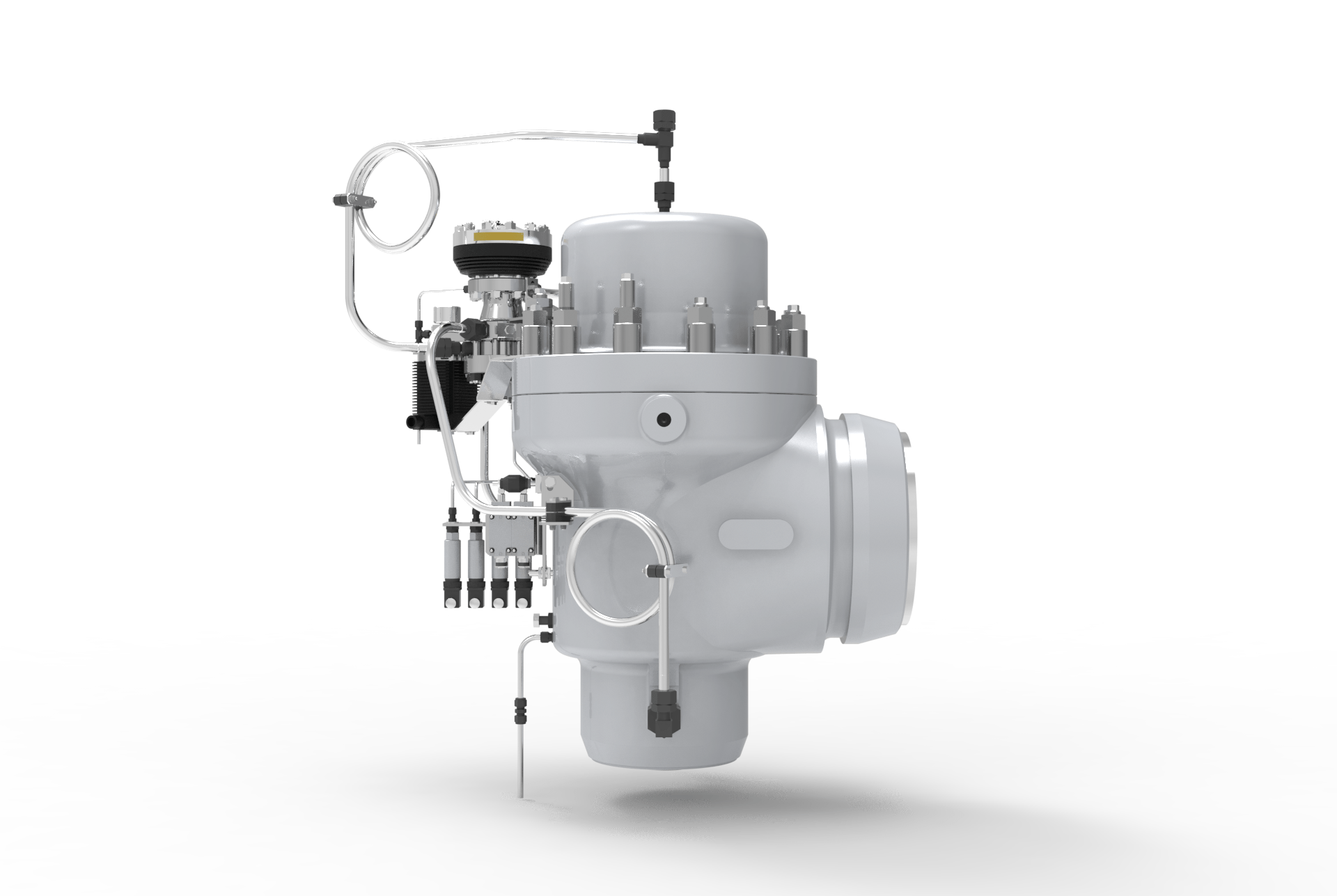

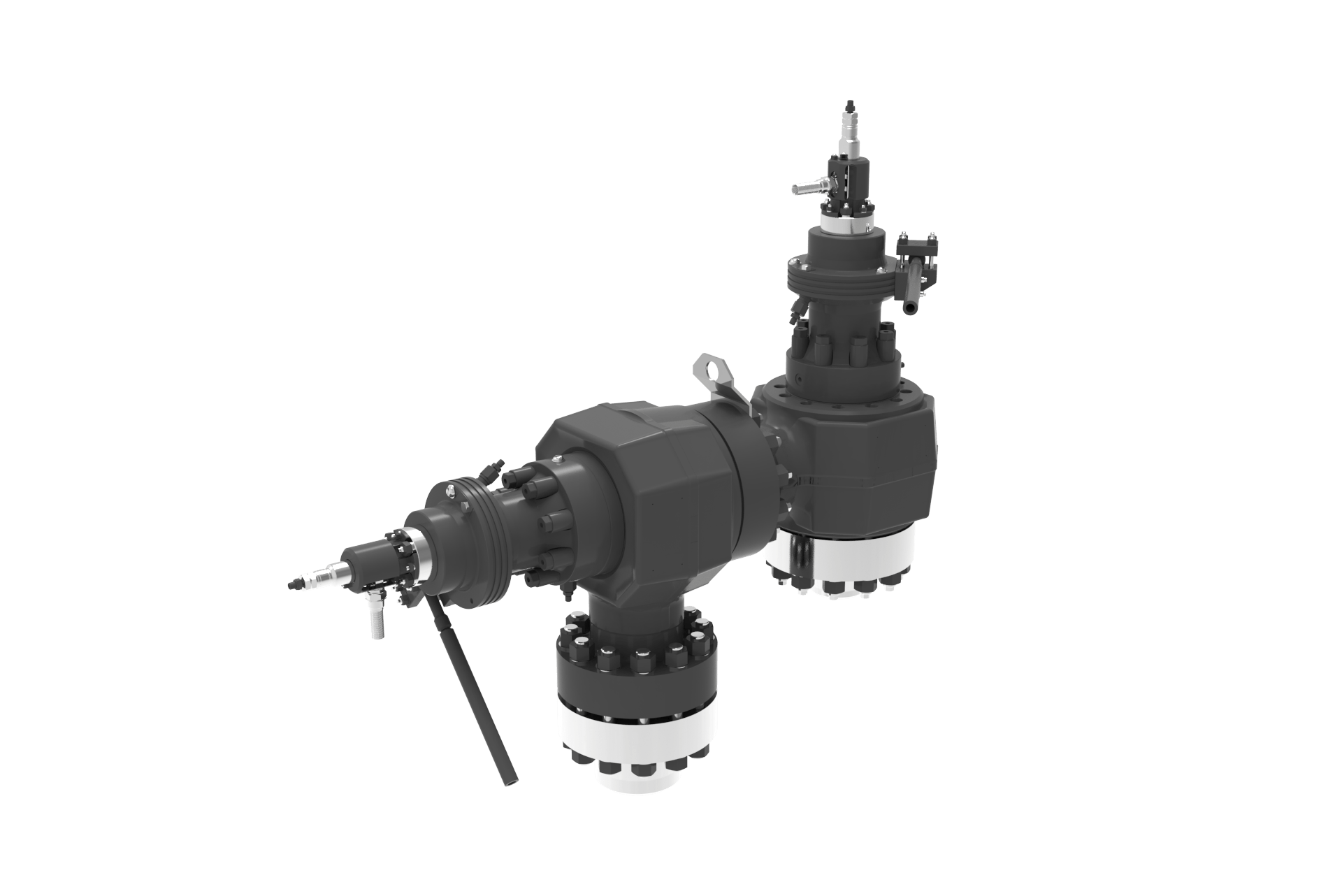

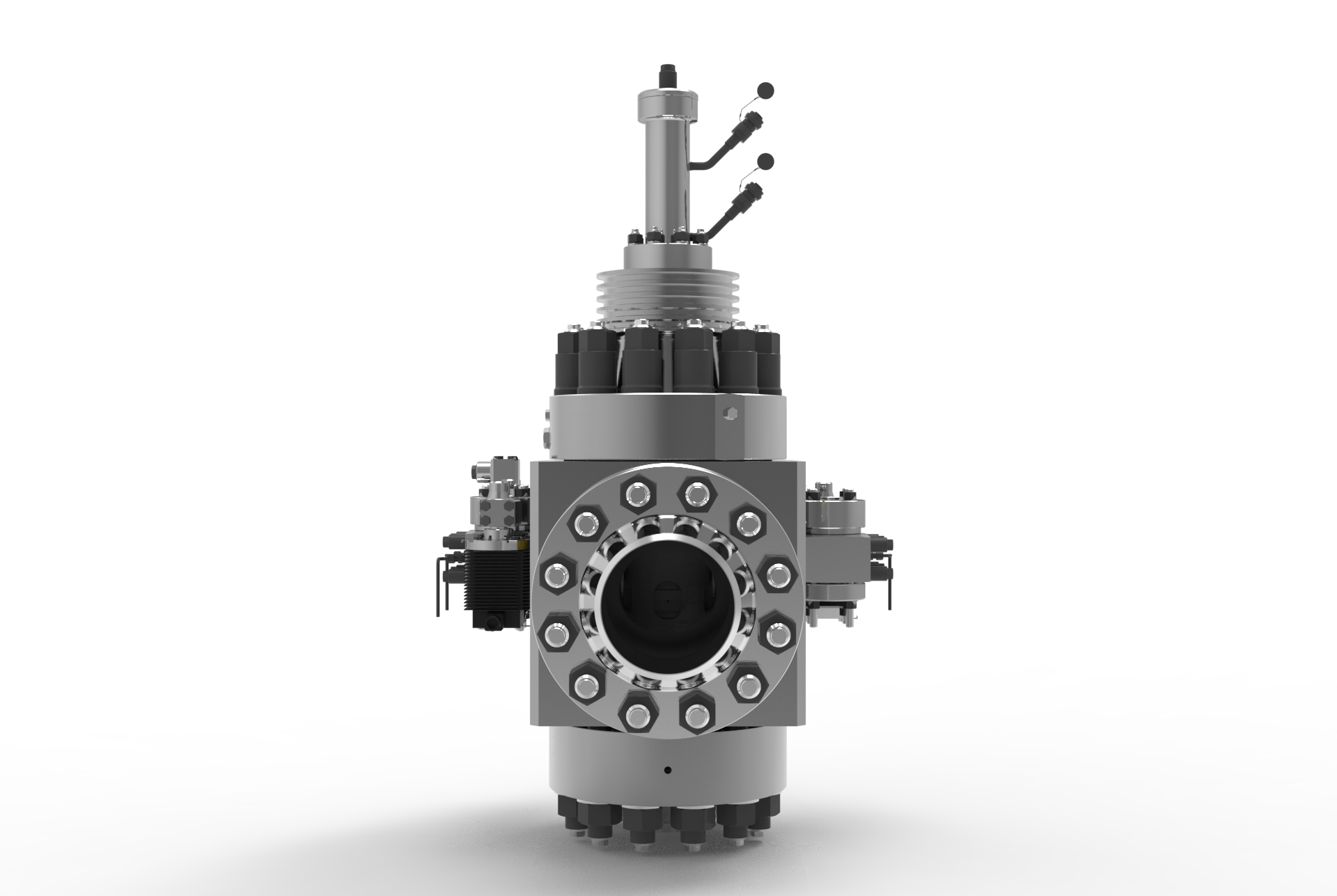

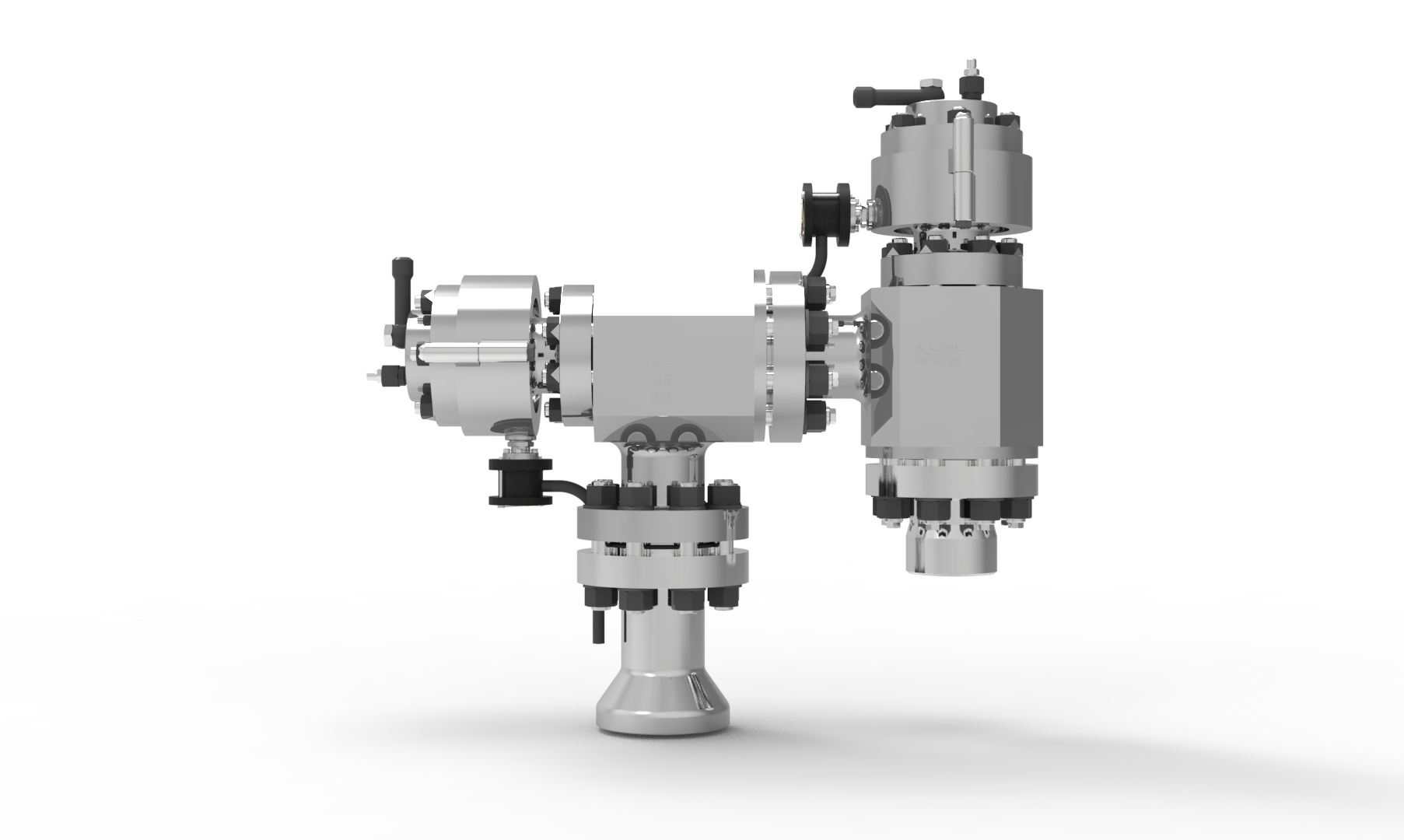

SEBIM® high performance pilot safety valves have a track record of over 32,000 reactor years of international experience in the nuclear field. SEBIM® valves are designed with unparalleled engineering knowledge and are renowned for its performance according to precise and rigorous design specifications.

ABOUT SEBIM®

SEBIM® high performance pilot safety valves have a track record of over 32,000 reactor years of international experience in the nuclear field. We deliver innovation and experience for critical valves in the safety related and non-safety areas of a nuclear power plant.

Our products are designed with unparalleled engineering expertise and are trusted to perform to design in the most trying conditions. When it comes to nuclear, SEBIM® is the choice when safety comes first.