SEBIM®

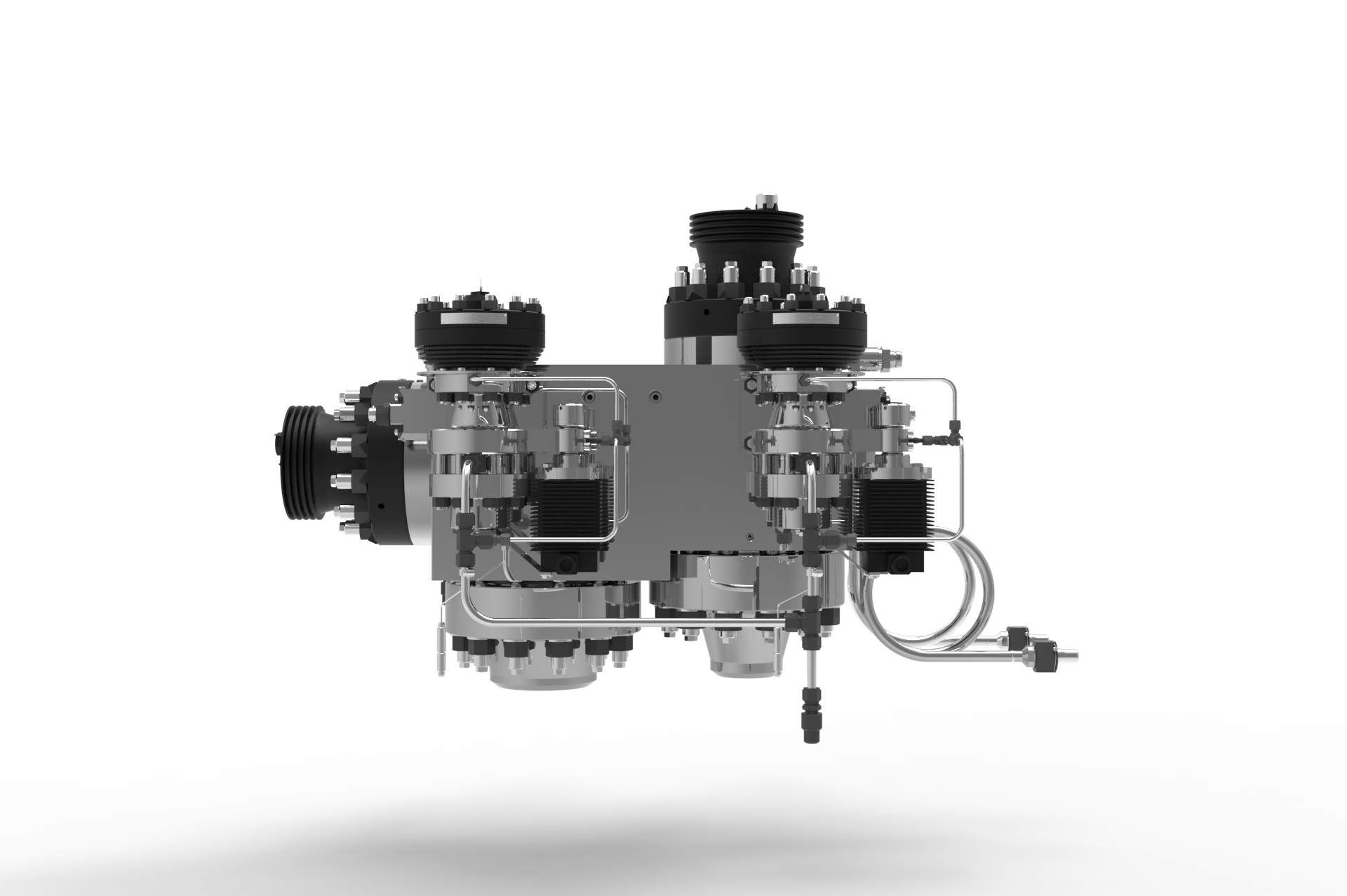

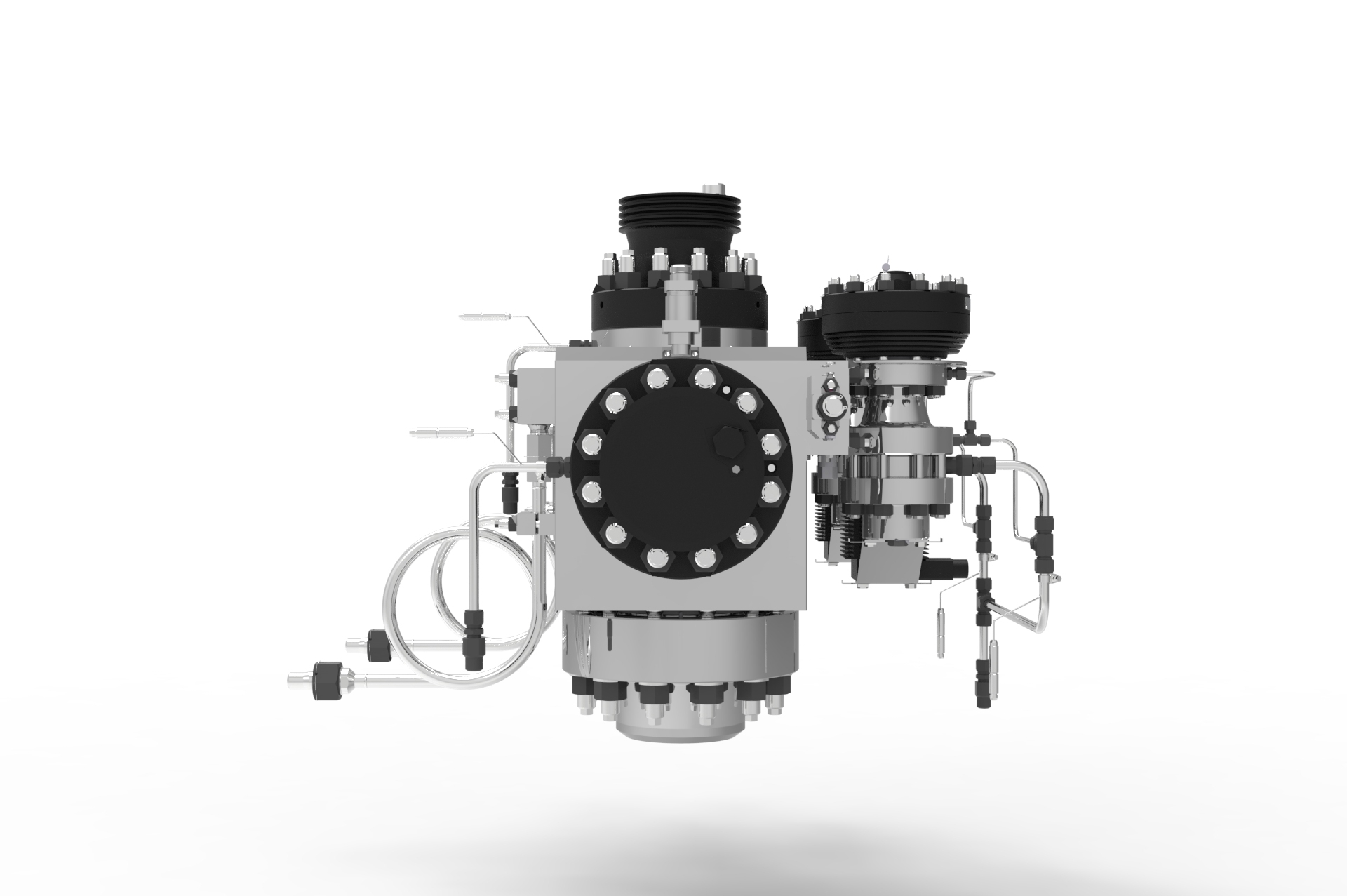

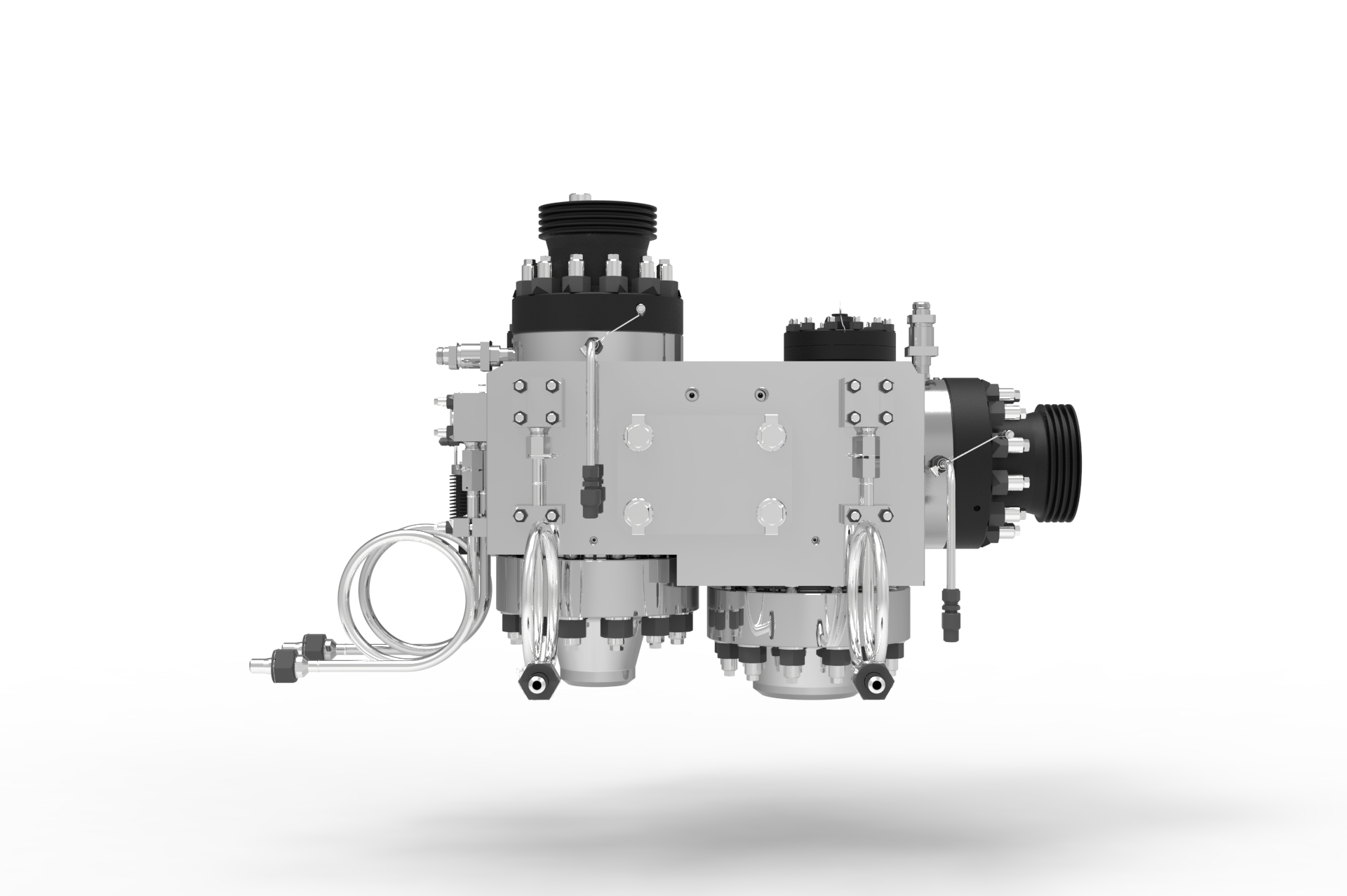

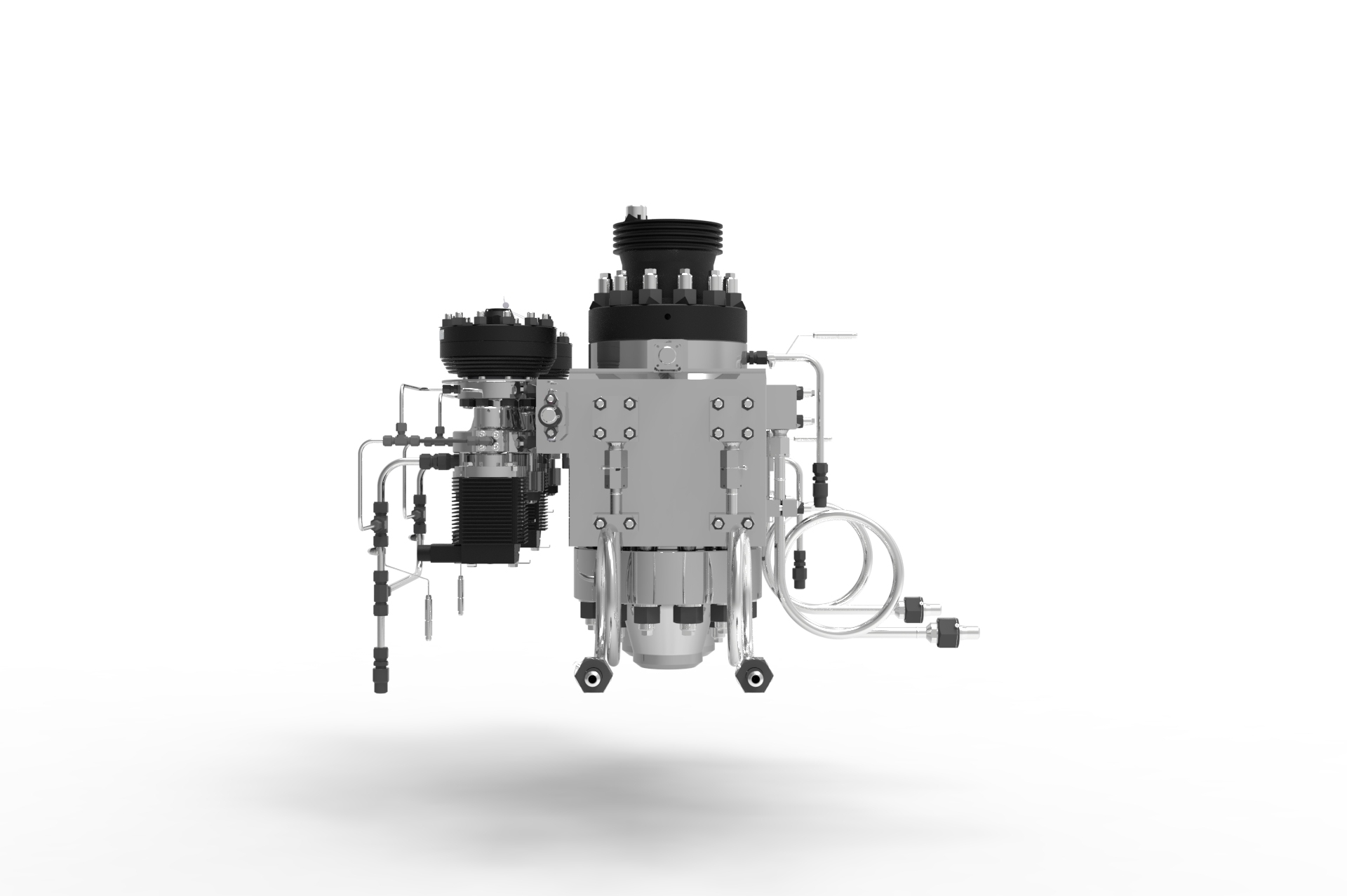

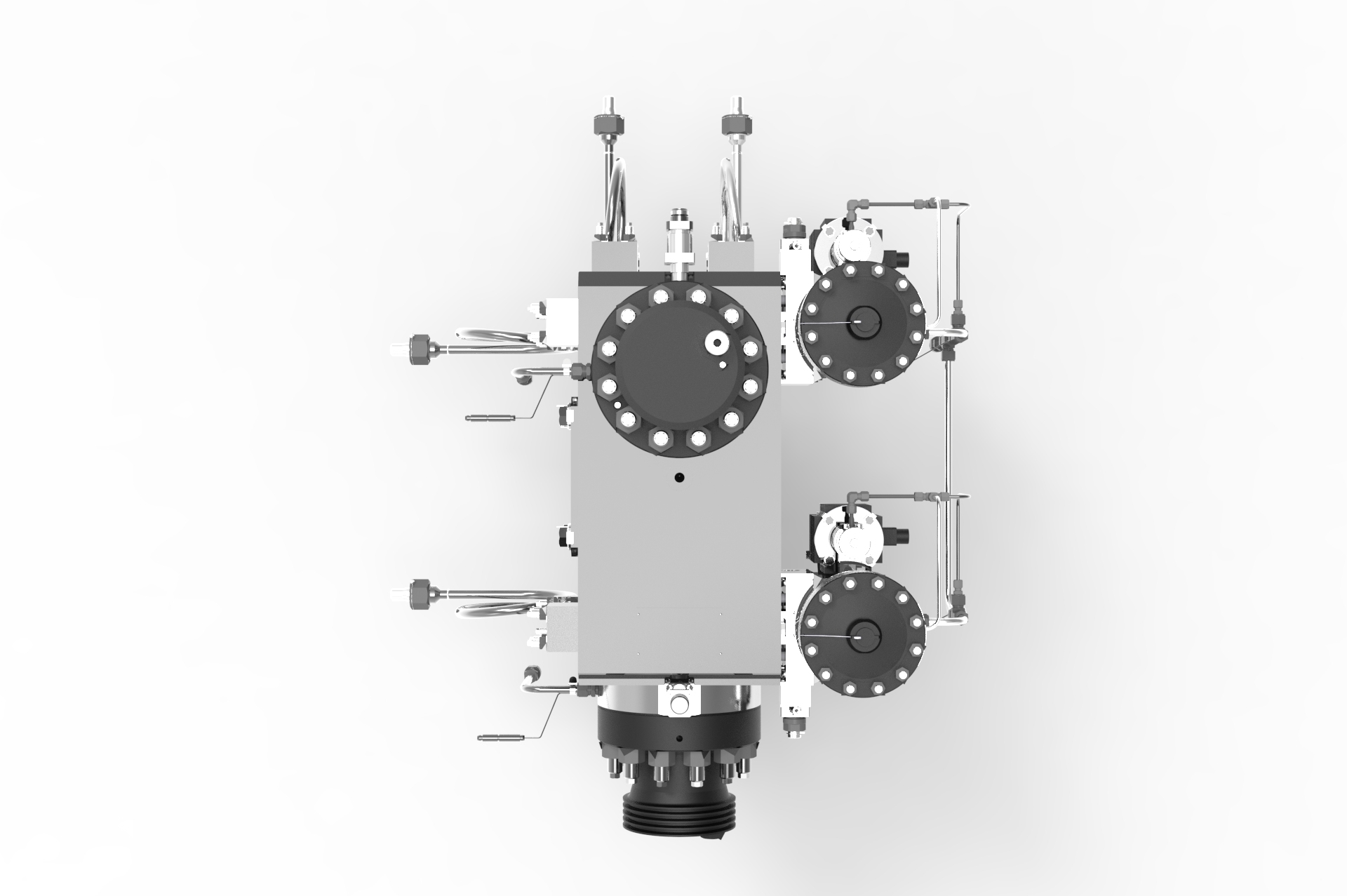

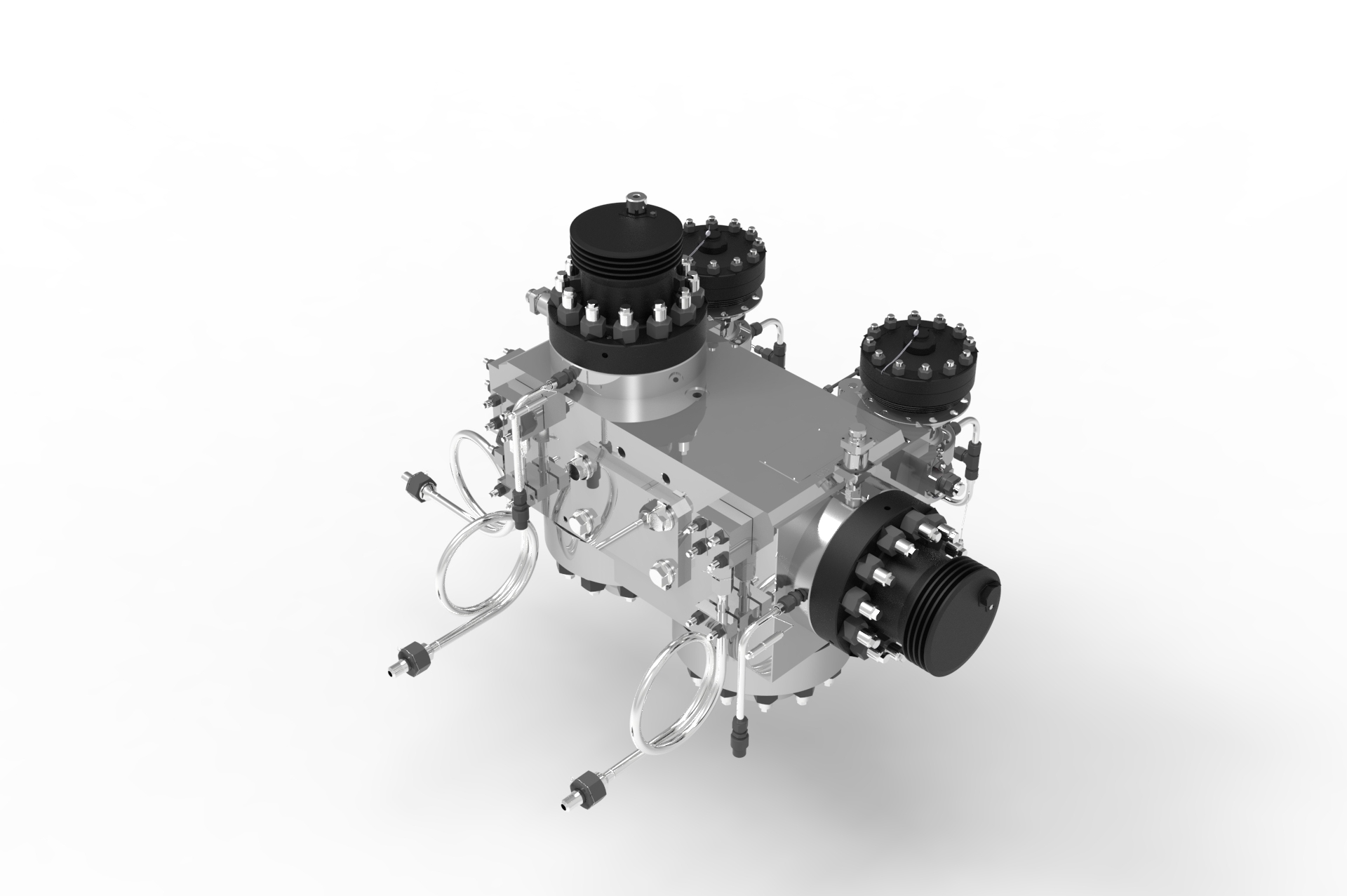

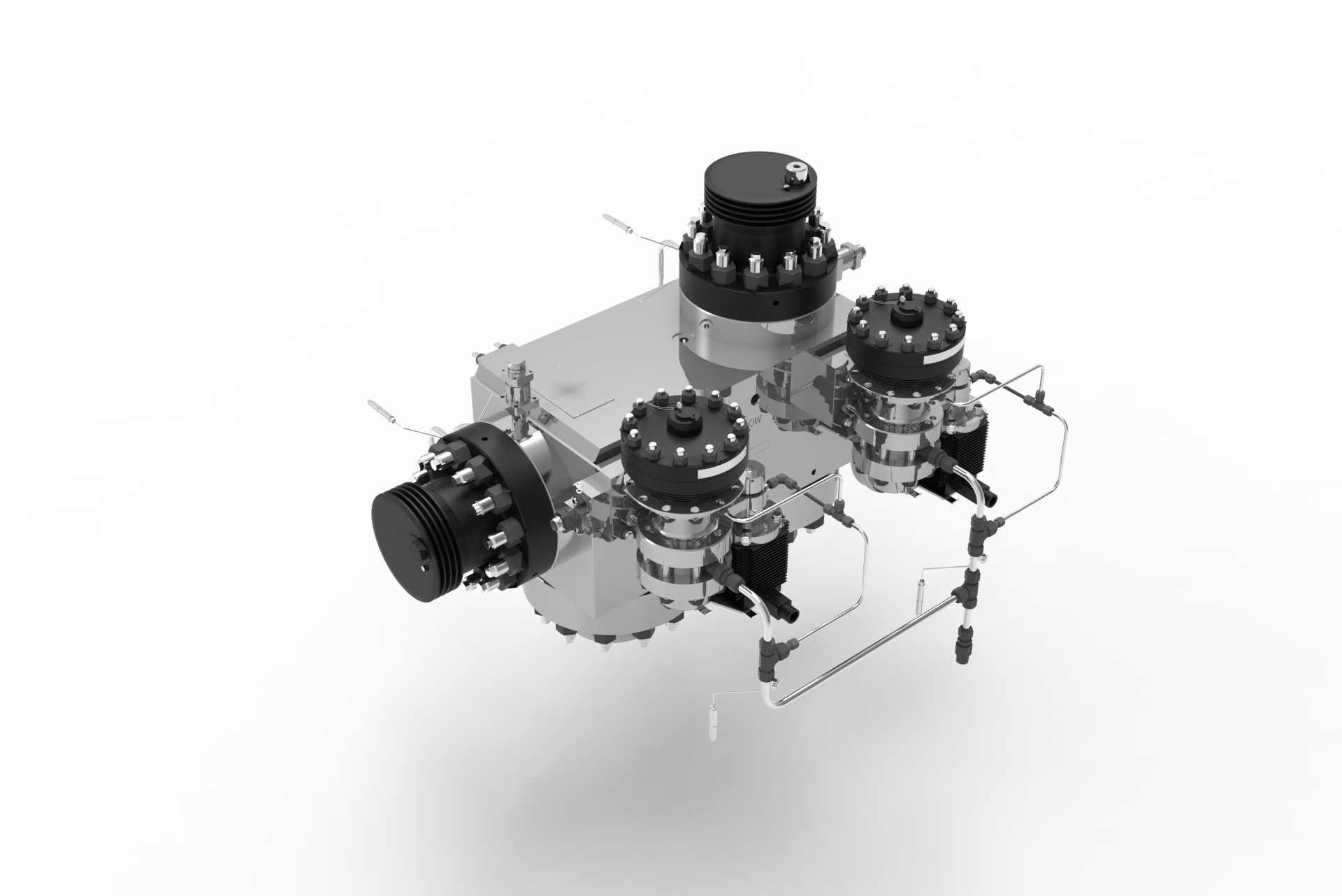

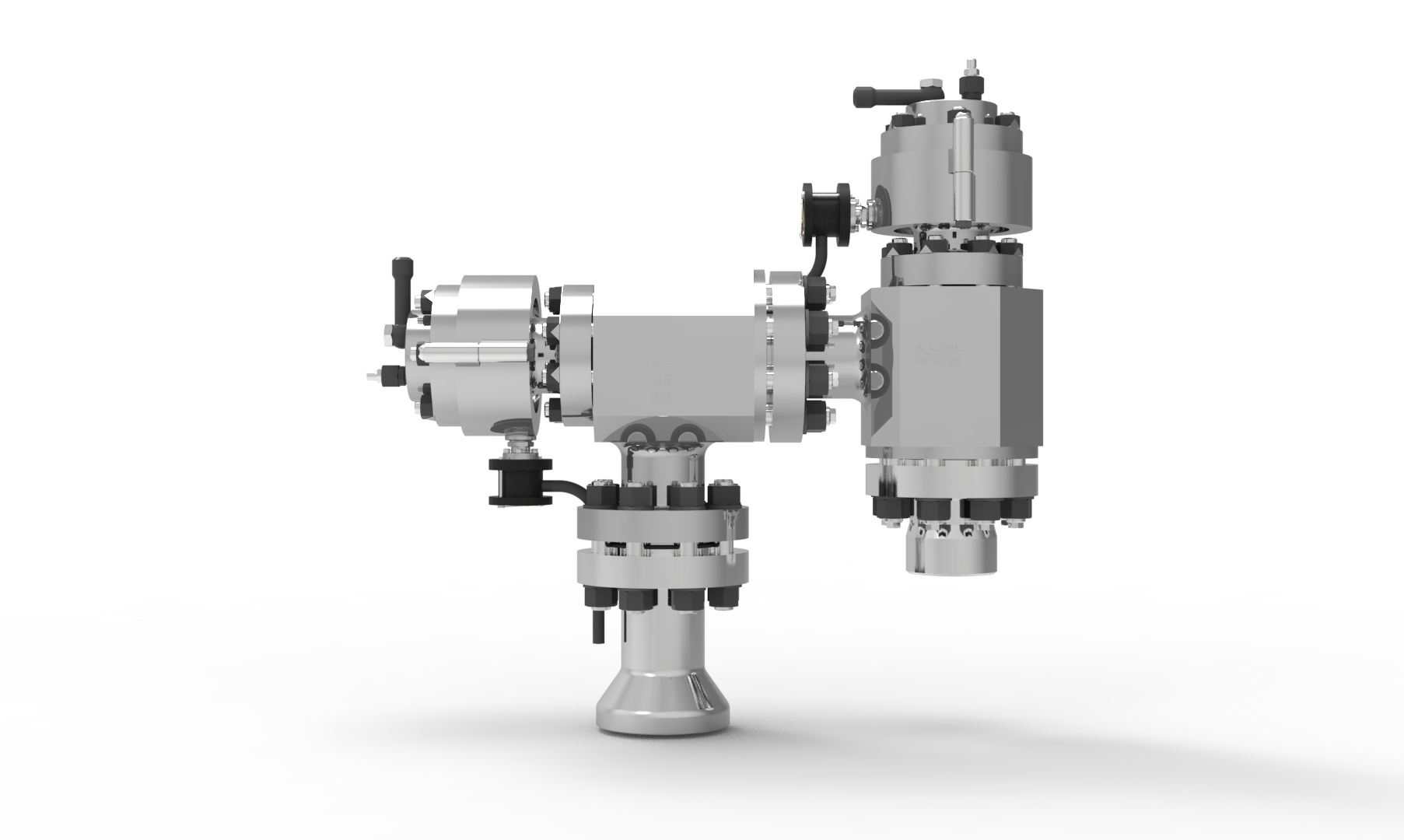

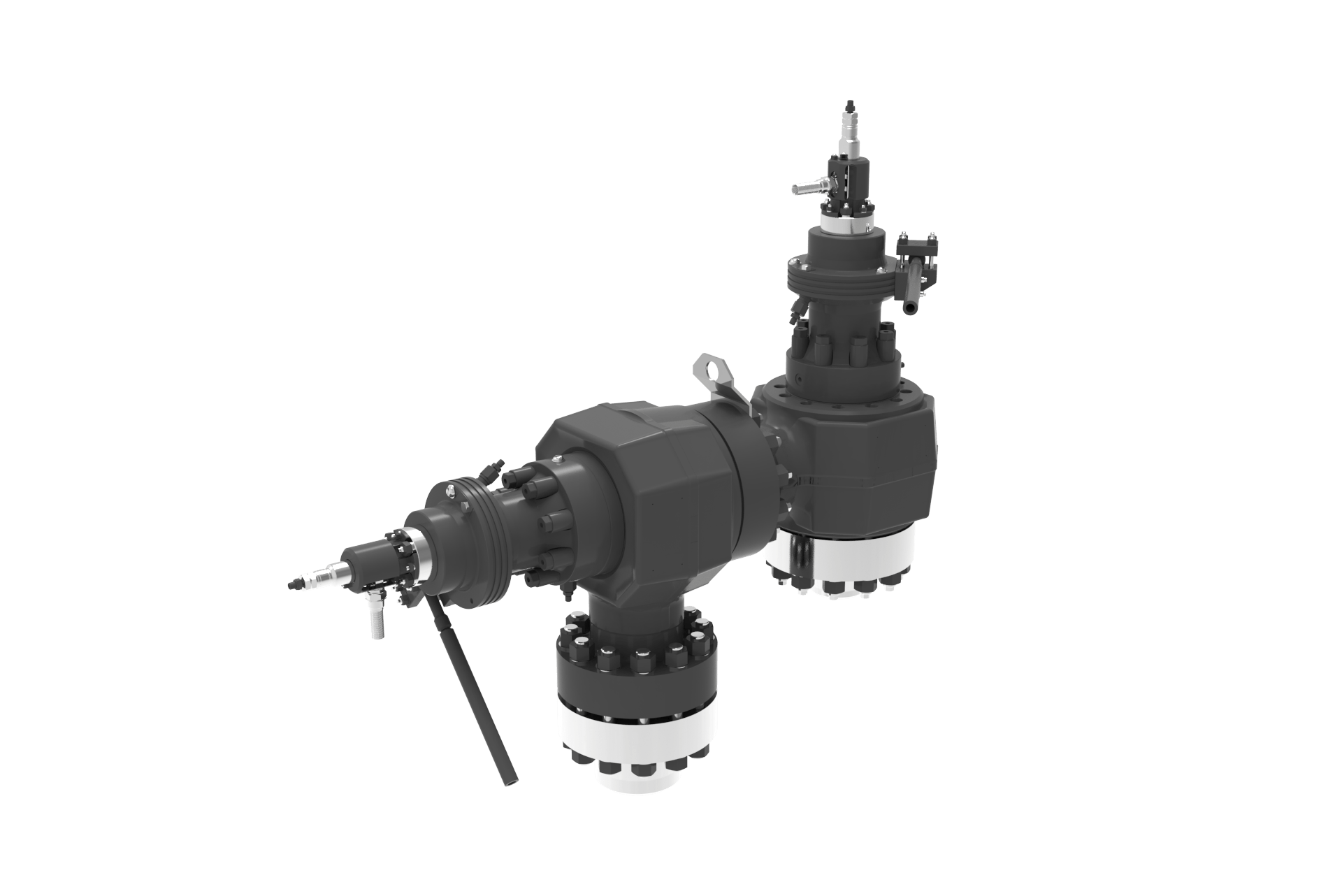

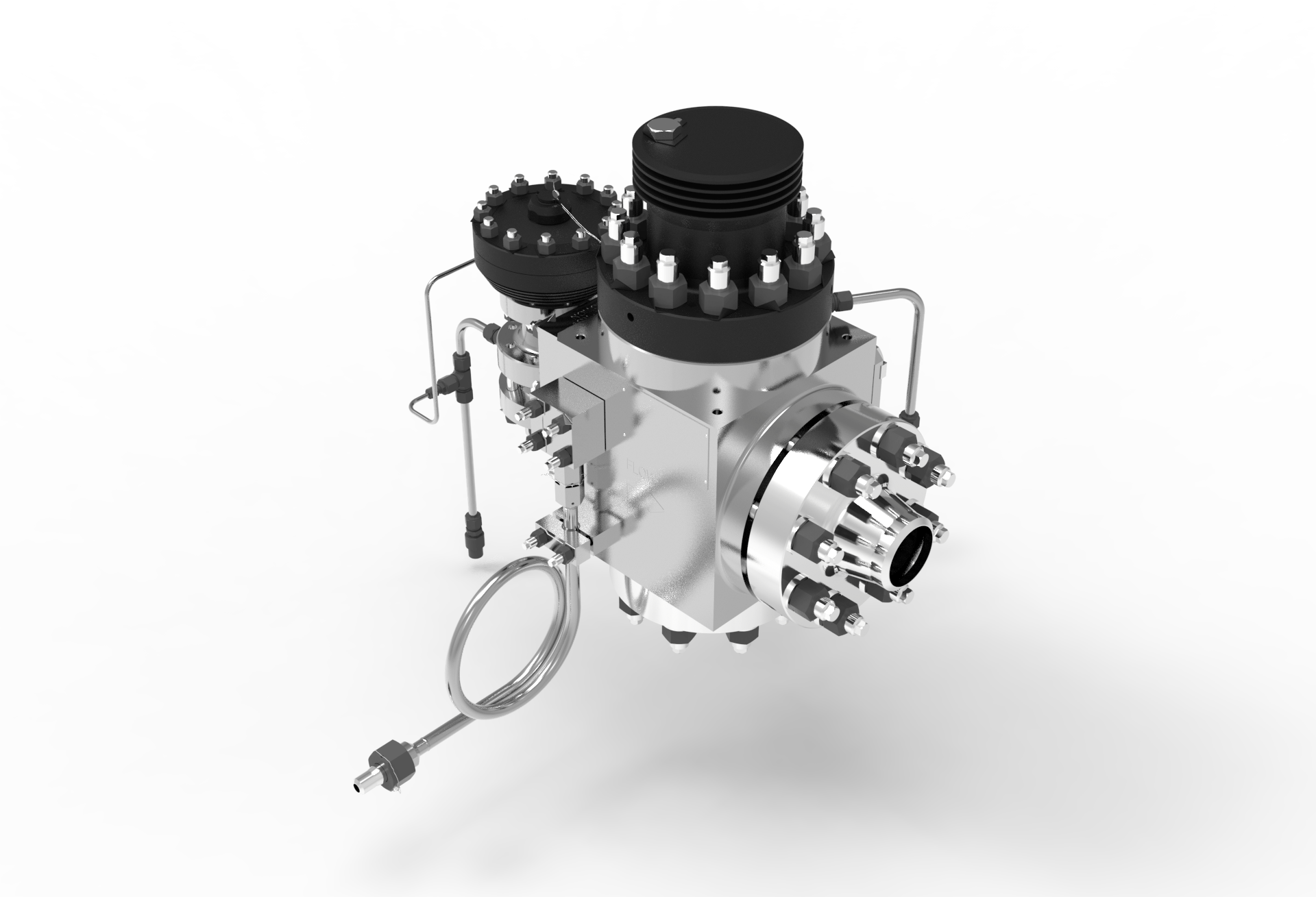

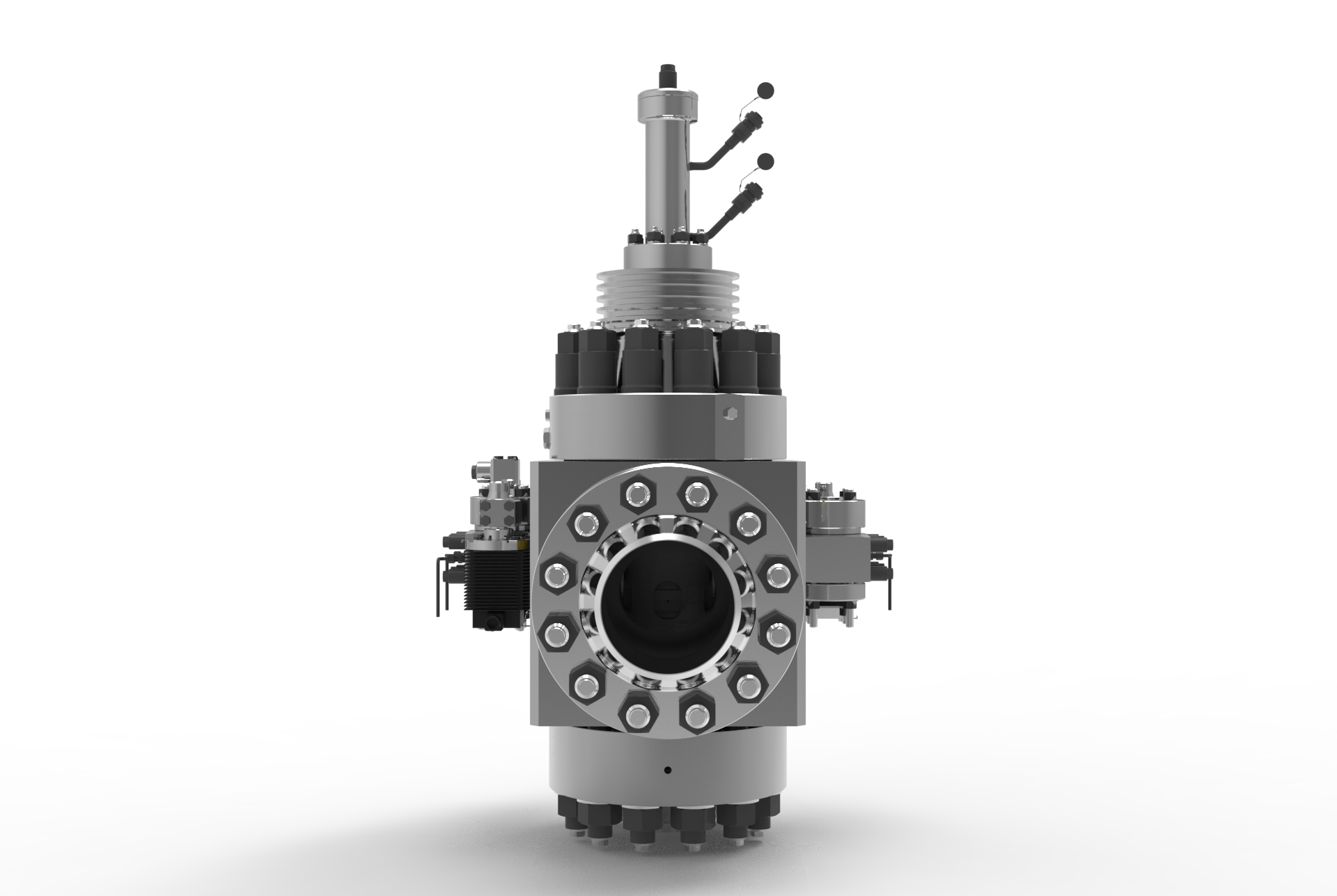

CTSV 3000 Tandem of primary coolant safety valves

The SEBIM® Tandem POSV type Compact Tandem Safety Valves (CTSV) feature a unique design for redundant safe closure in the over-pressure protection of cooling circuits.

The SEBIM® CTSV is the successor to the cold solution which has been in operation since the 1980’s in French pressurized water reactors. This hot solution design has operated globally since 1995 in VVER and CANDU reactors. The SEBIM® CTSV fits various types of nuclear reactors which require high and low overpressure protection on liquid, steam, gas, and steam & water mix applications.

MAIN CHARACTERISTICS

- Two independent POSRVs are housed in the same body. The first valve ensures pressure safety and relief. The second valve provides fail safe protection in the event of failure of the primary valve.

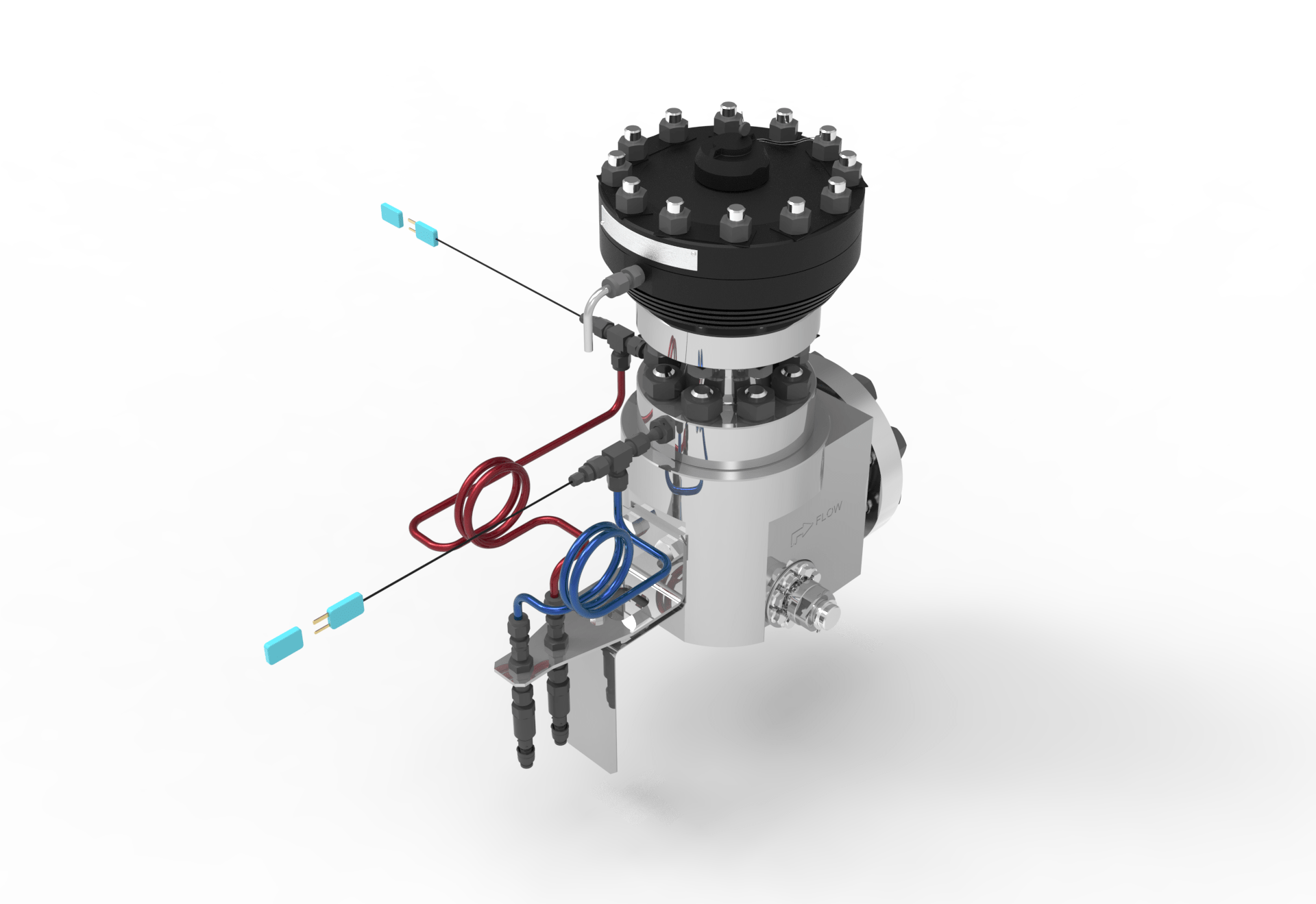

- Both autonomous piloting systems use dedicated and independent pressure impulse sources of fluid in the protected process

- No external source of energy is needed for operation

- No-Flow piloting system

- Compact design

- Excellent leak tightness. The disc and the nozzle are leak tight up to the point of opening and immediately again after closing.

- No erosion of sealing faces; no chattering.

- Proven perfect repeatability and reliability

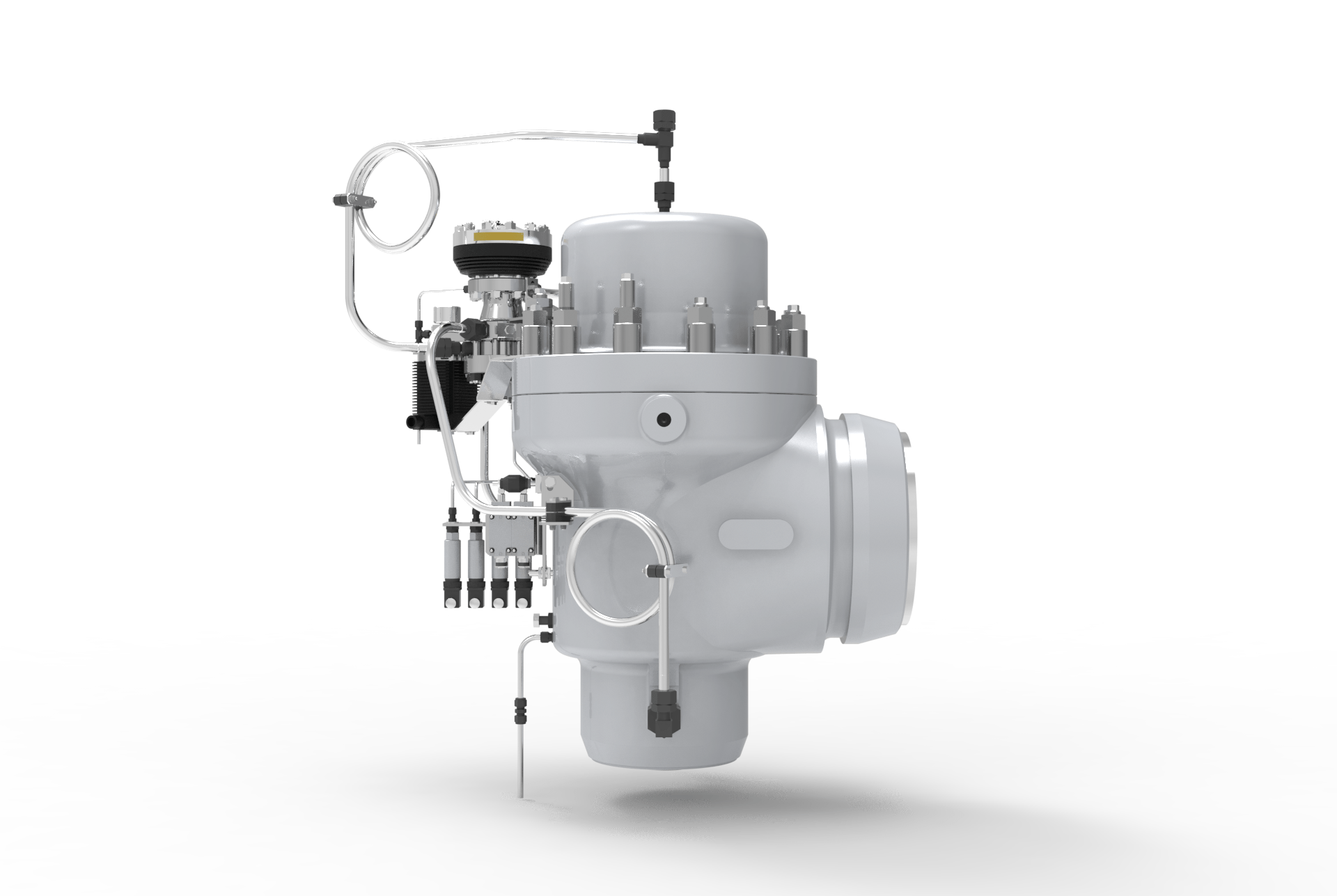

- System insensitive to back pressure

- Stable system: no mass spring effect.

APPLICATIONS

- Primary or secondary circuits

MATERIALS

- Stainless steel

KEY FEATURES & BENEFITS

- Excellent operation irrespective of the type of fluid; steam, gas, liquid, or two-phase.

- Leak tightness up to the set-pressure maximizes the operating pressure and power output

- Non-flowing pilot valve minimizes mechanisms rate of aging

- Proven reliability

- Excellent accuracy (better than 1%)

- Repeatability (lower than 1%)

- Soft opening & closing decreases the load on surrounding equipment

- Allows for low or high pressure in-situ test during operation for preventative maintenance

- Maintained stability even when flow capacity is below the maximum rate

- No erosion of sealing surfaces; no chattering.

- Reduced maintenance

- Low power consumption of the actuator

- Power supply 48 , 110, 220 V DC/AC IP 65 100% operating factorK1 1E qualified for applications within the containment area of nuclear plants.

- Protection against cold overpressure (nuclear vessel protection within the NDTT curve)

- Prevention of Loss of Coolant Accident

- Unique tandem design guarantees reliable closing

DESIGN STANDARDS

- All main standards including RCC-M level 1, ASME section III Sub.NB Class 1, OTT, IEEE, NNSA

DESIGN RATINGS

- ASME Class 150 to 2500 or customized

SIZE RANGE & DIMENSIONS

- 2 – 8 inches (DN50 – DN 200)

PRESSURE CLASS & POWER

- From 43 – 4350 psi (0,3 to 30 Mpa)

TEMPERATURE RANGE

- Up to 576°C (1069°F)