SEBIM®

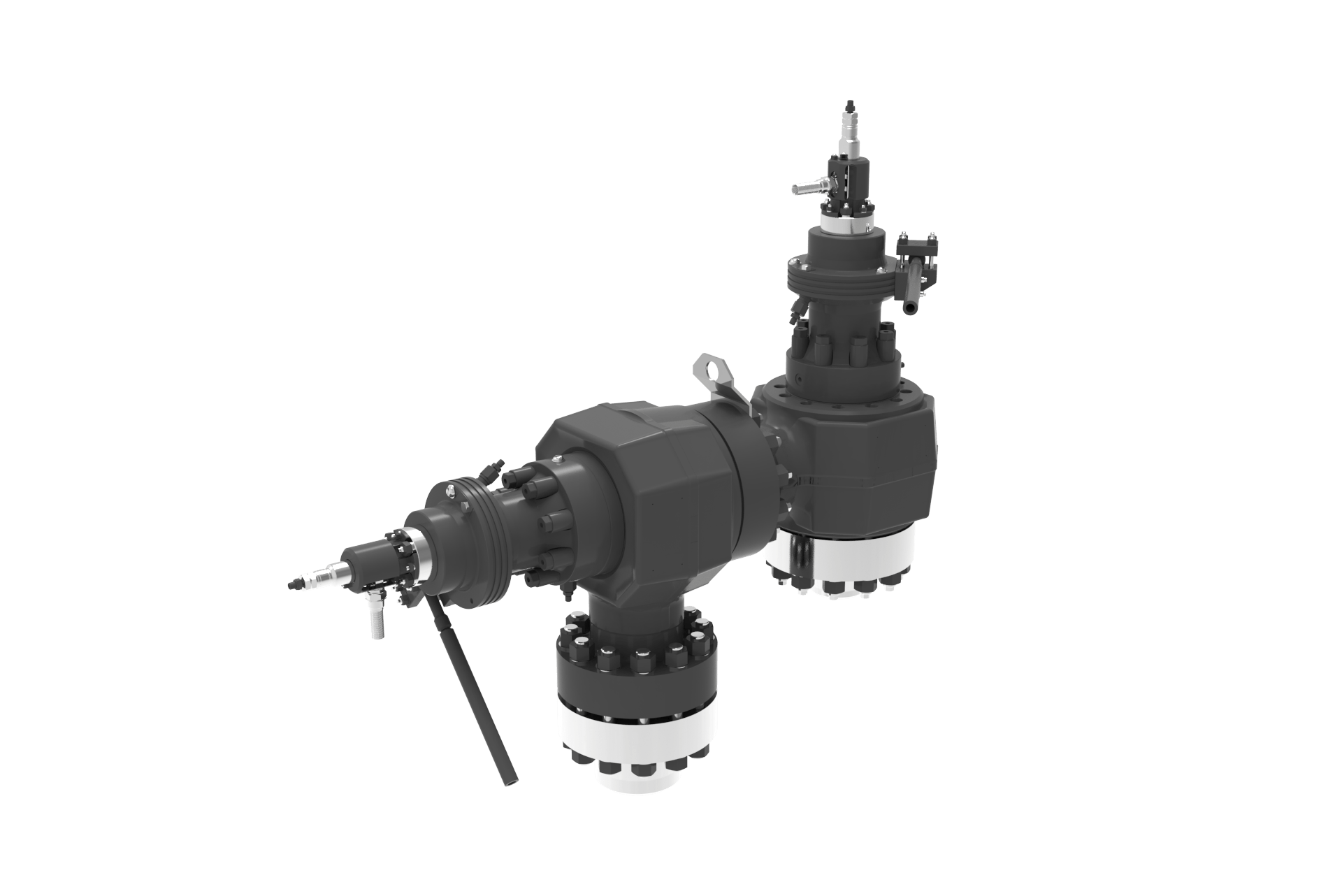

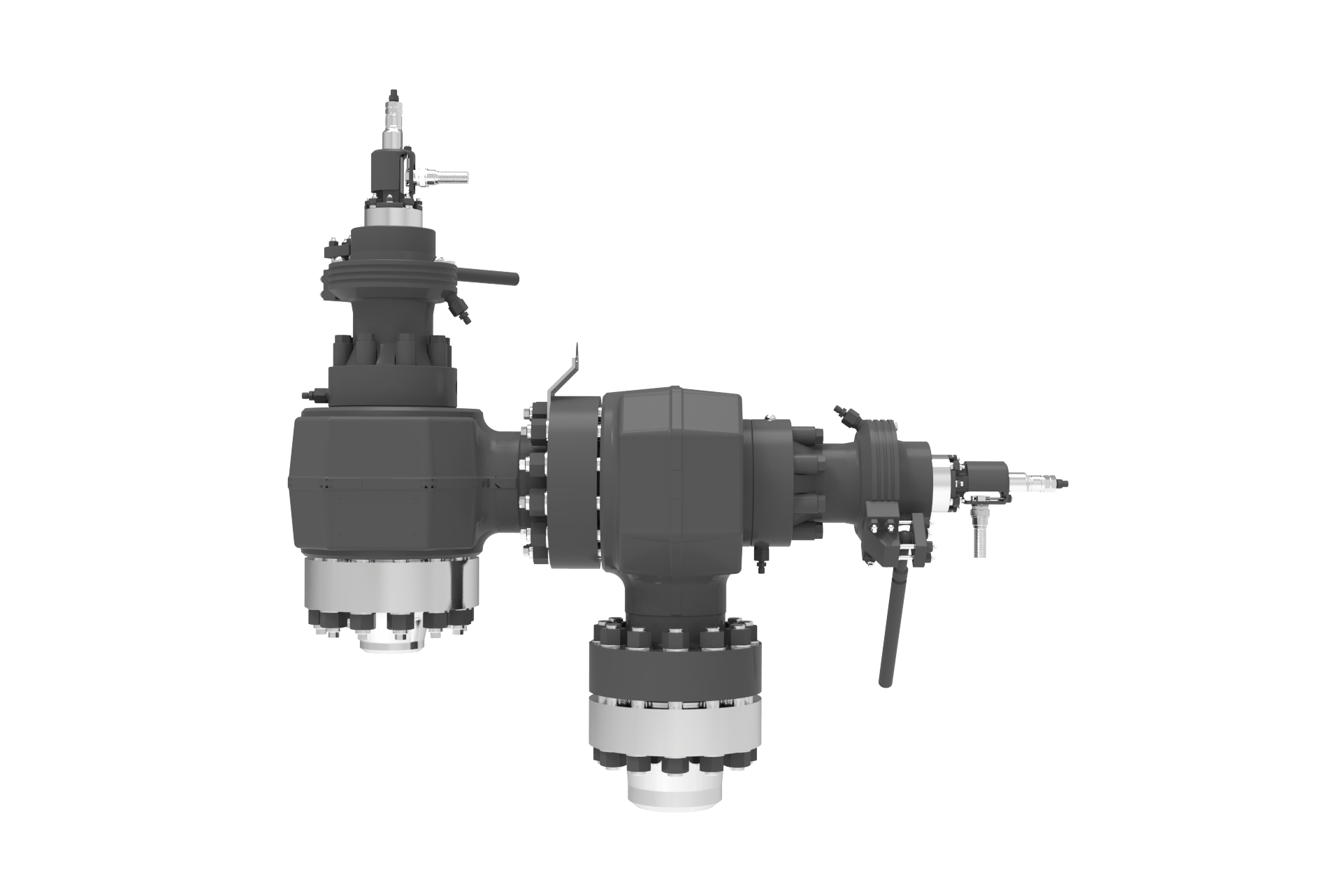

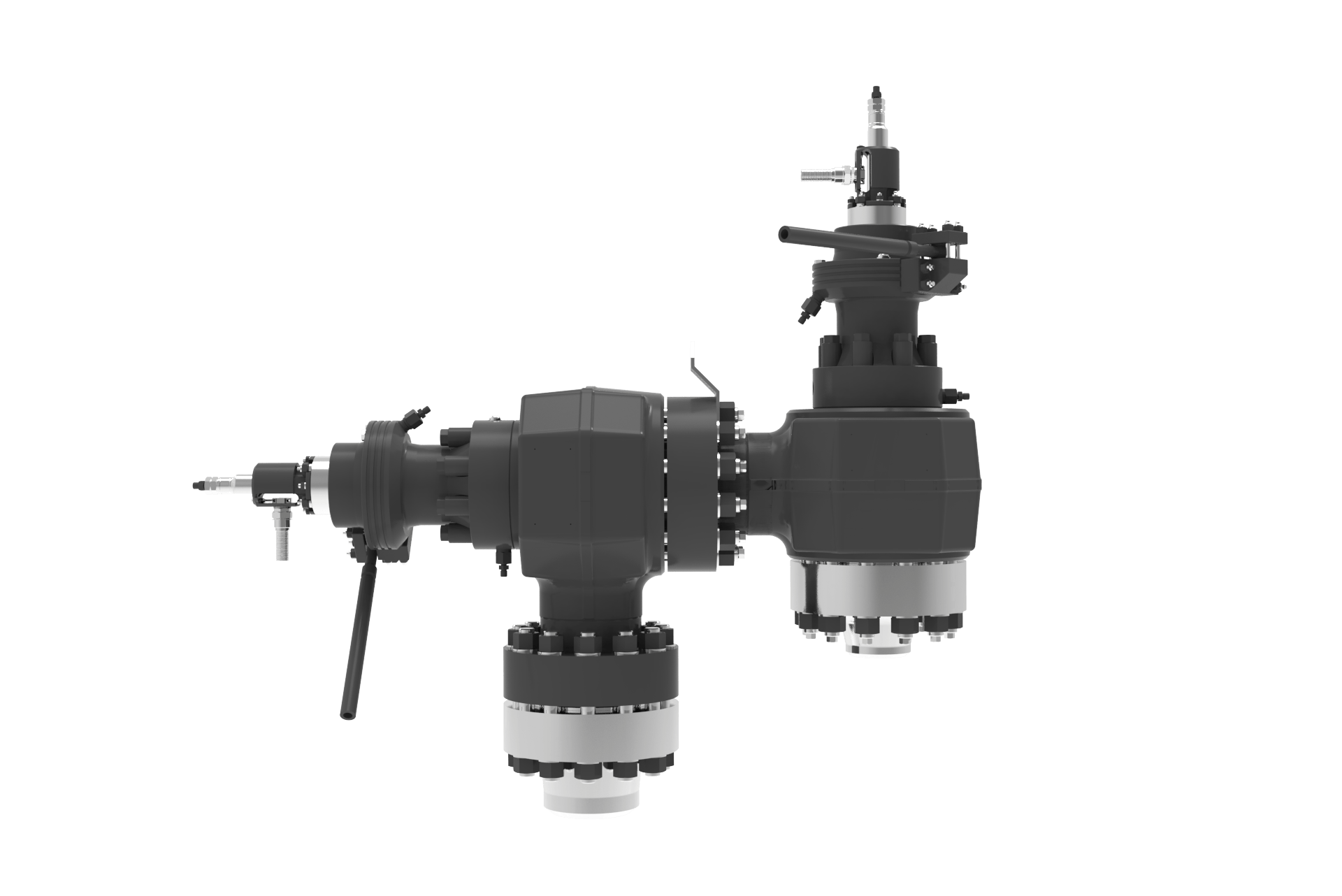

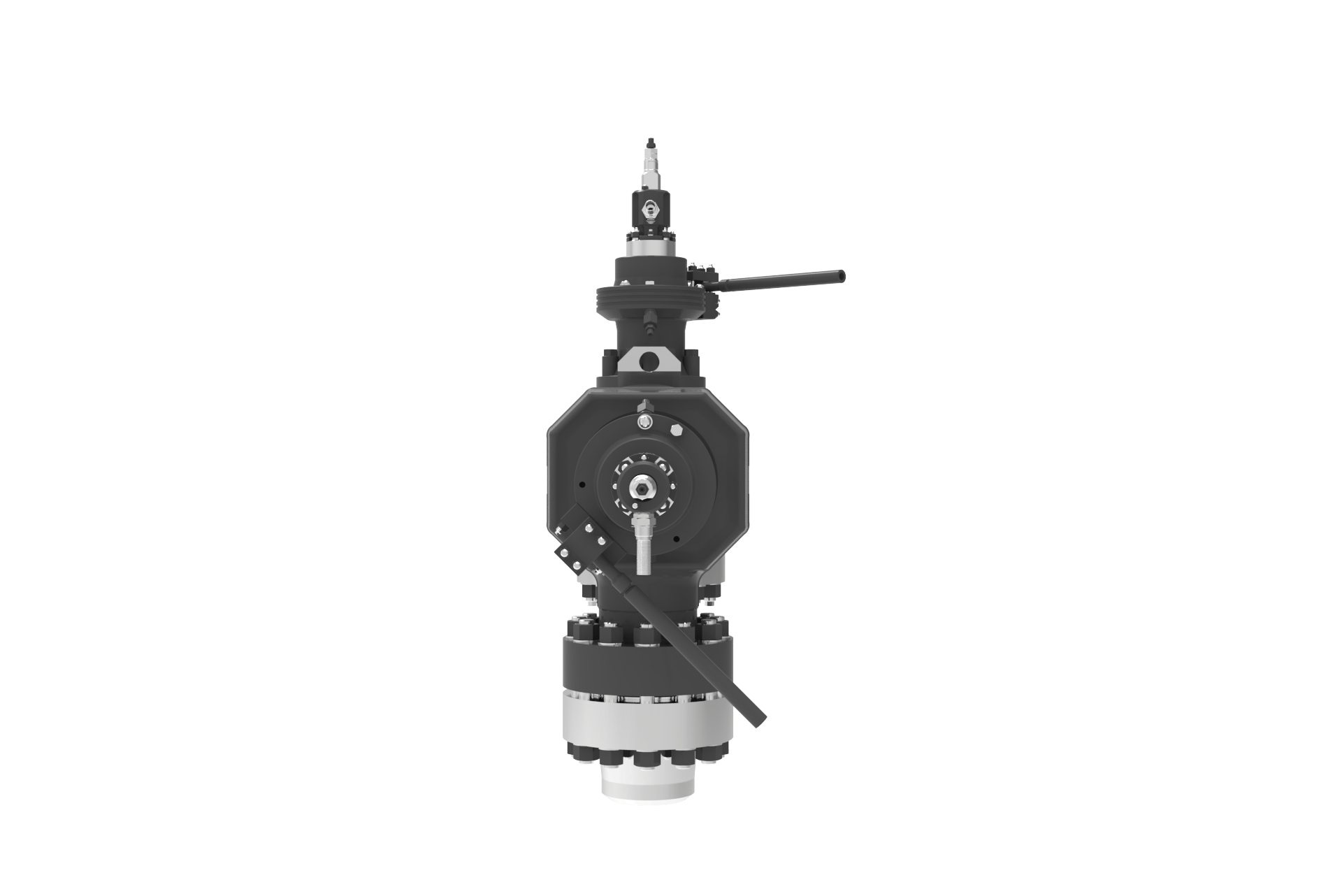

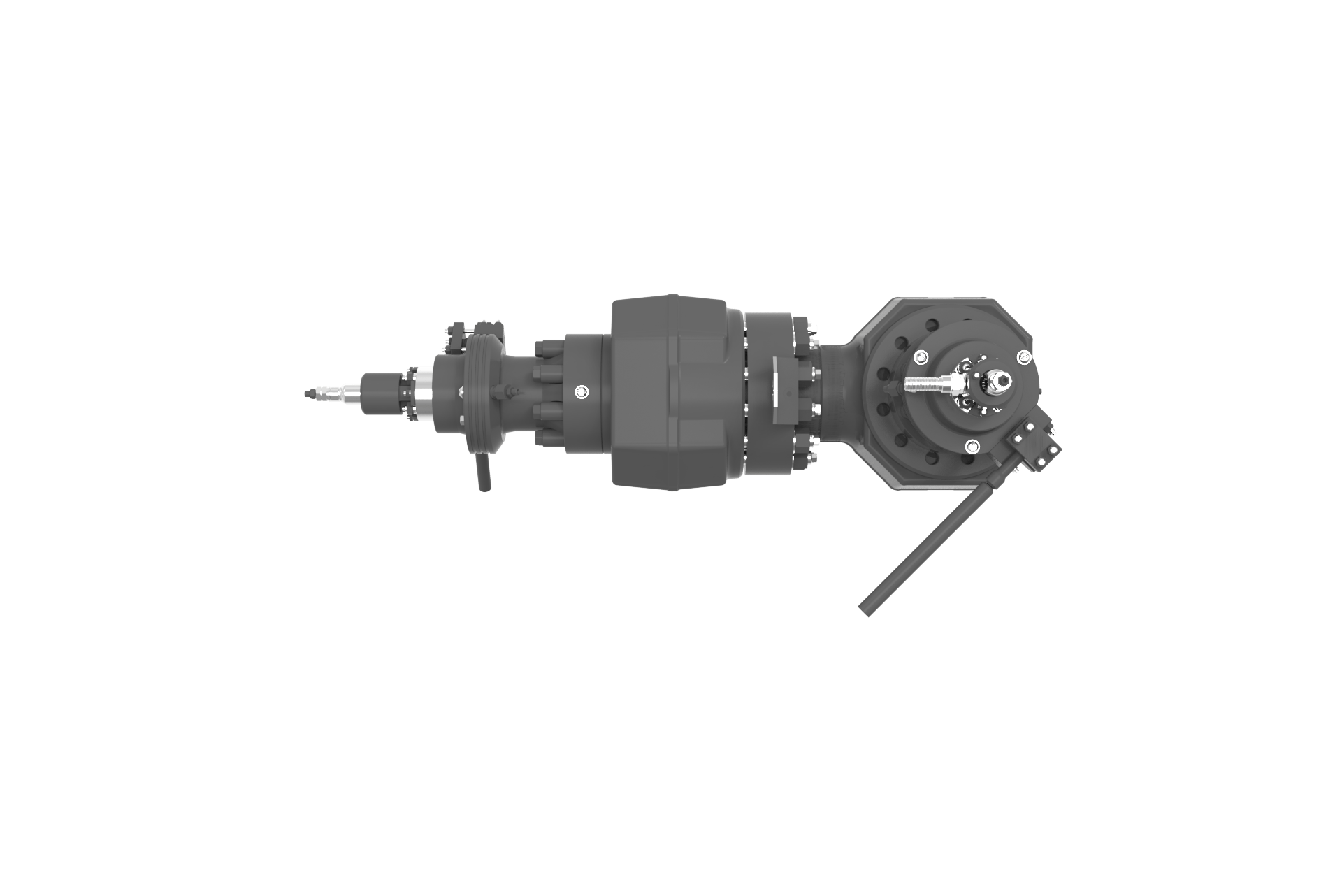

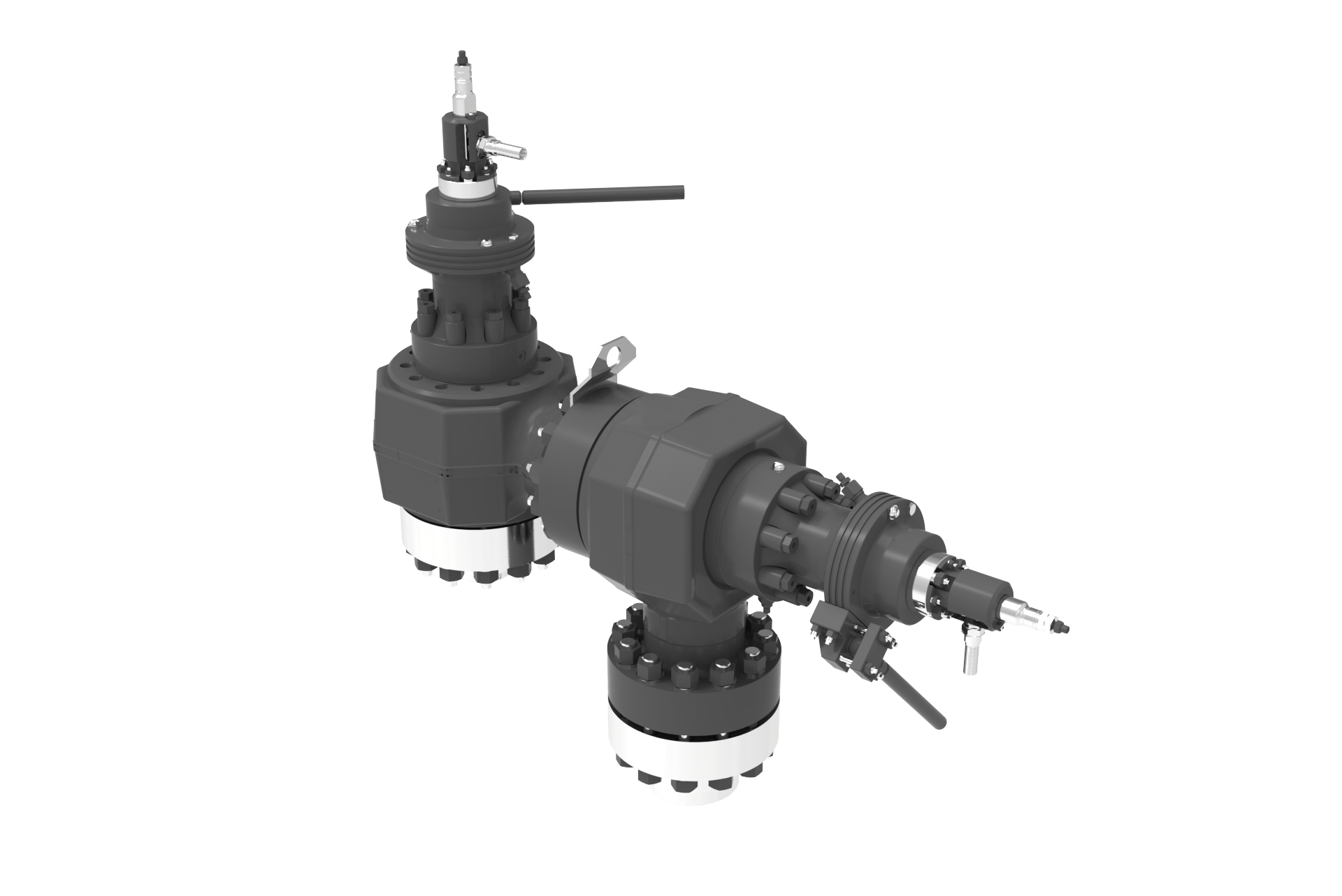

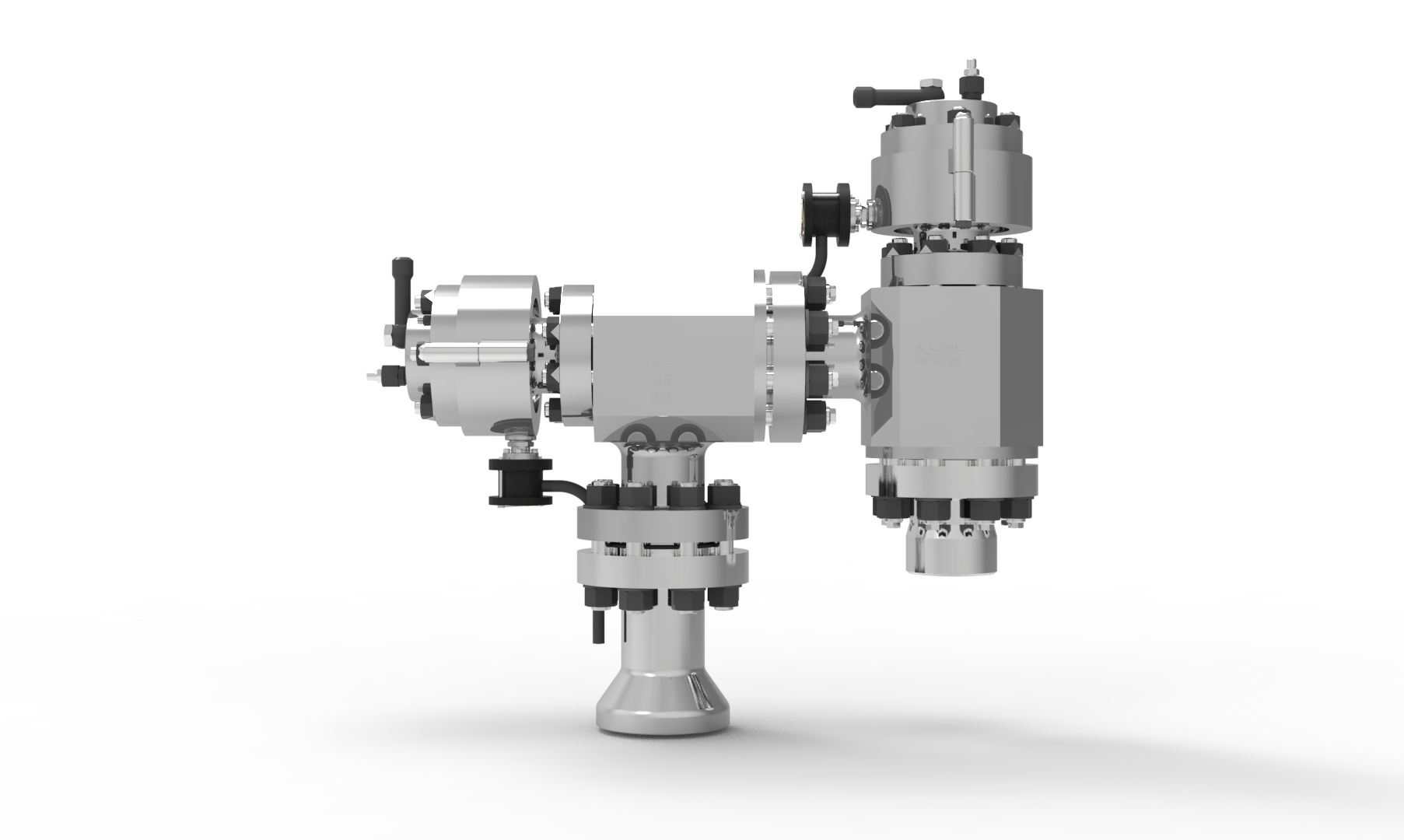

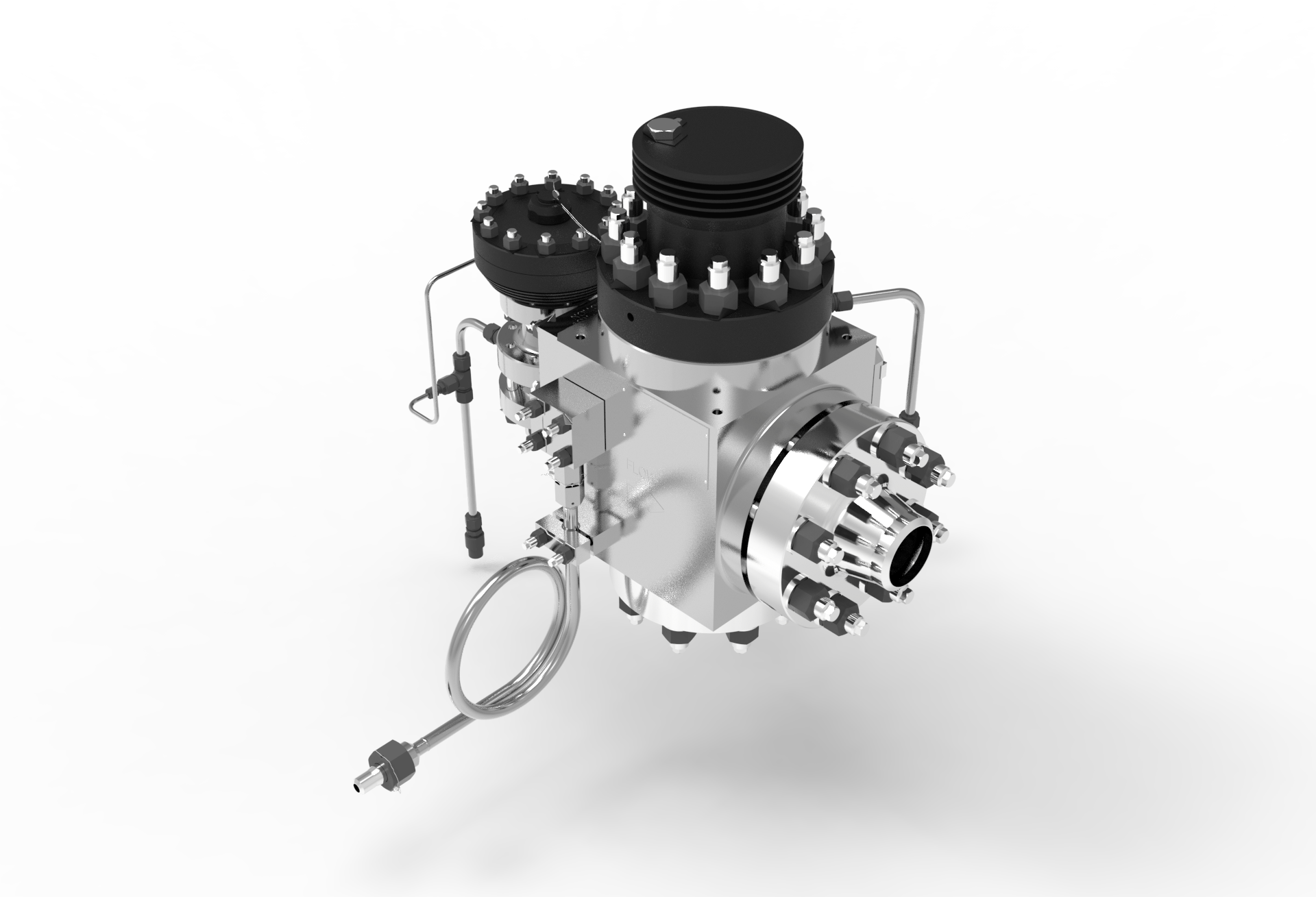

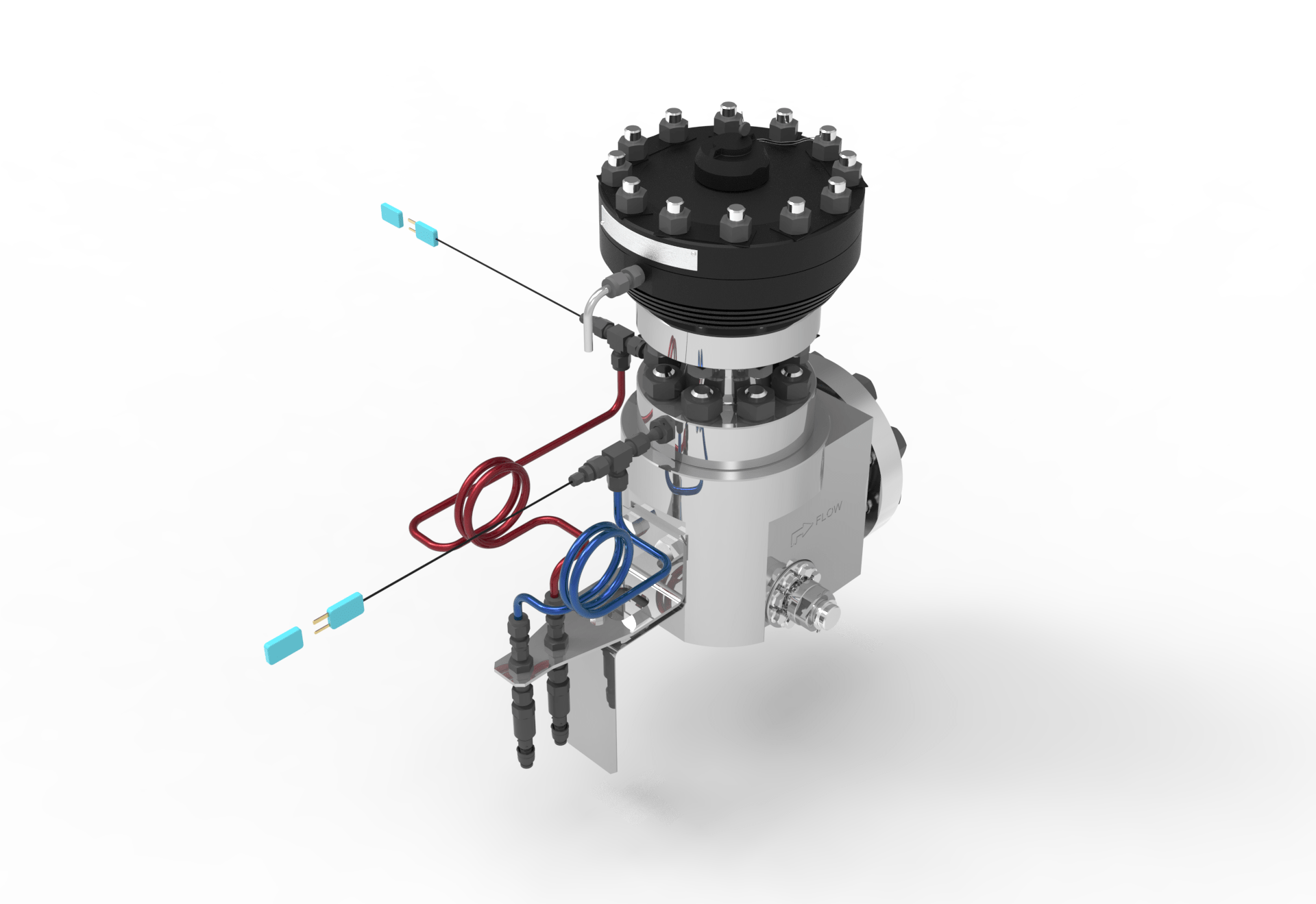

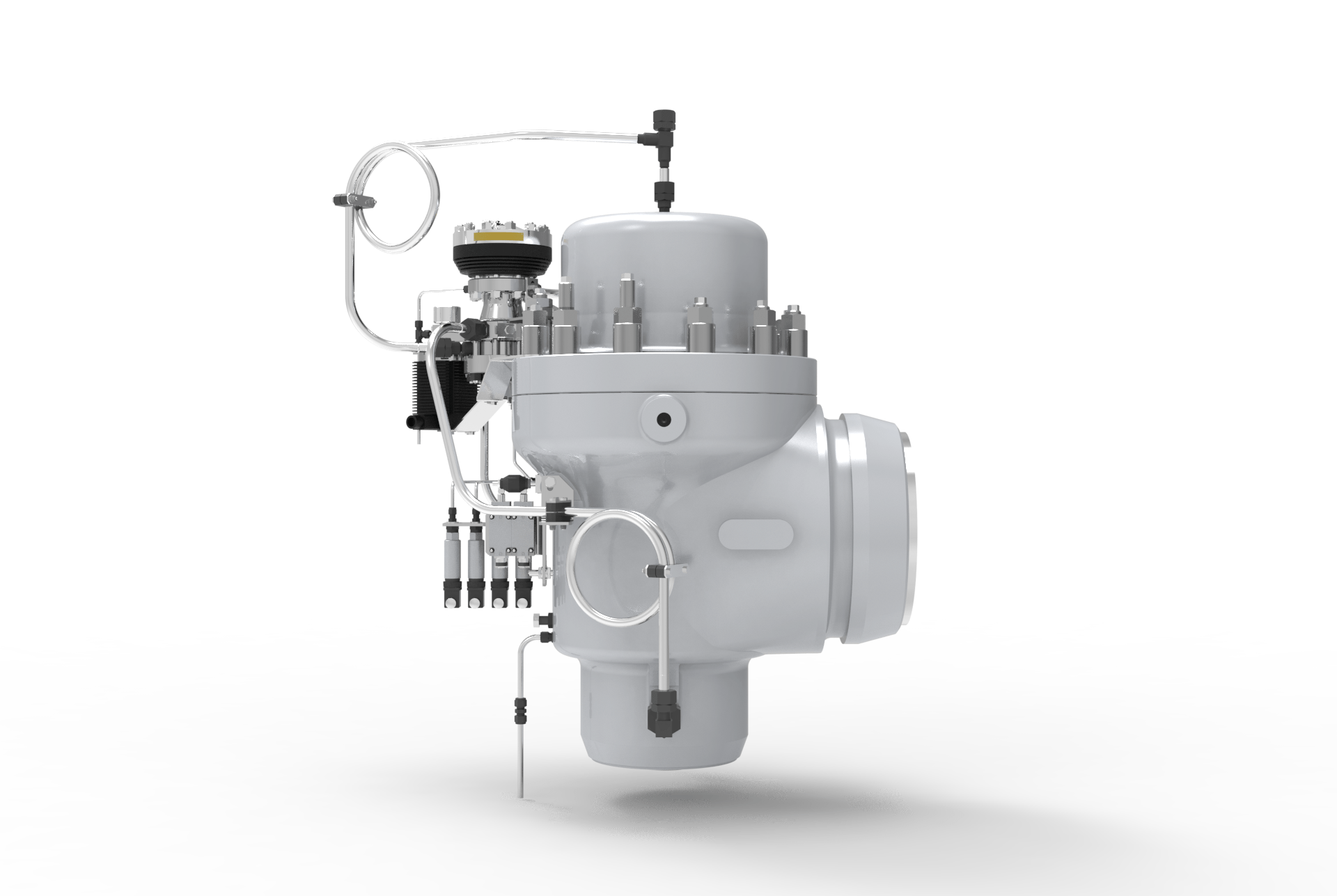

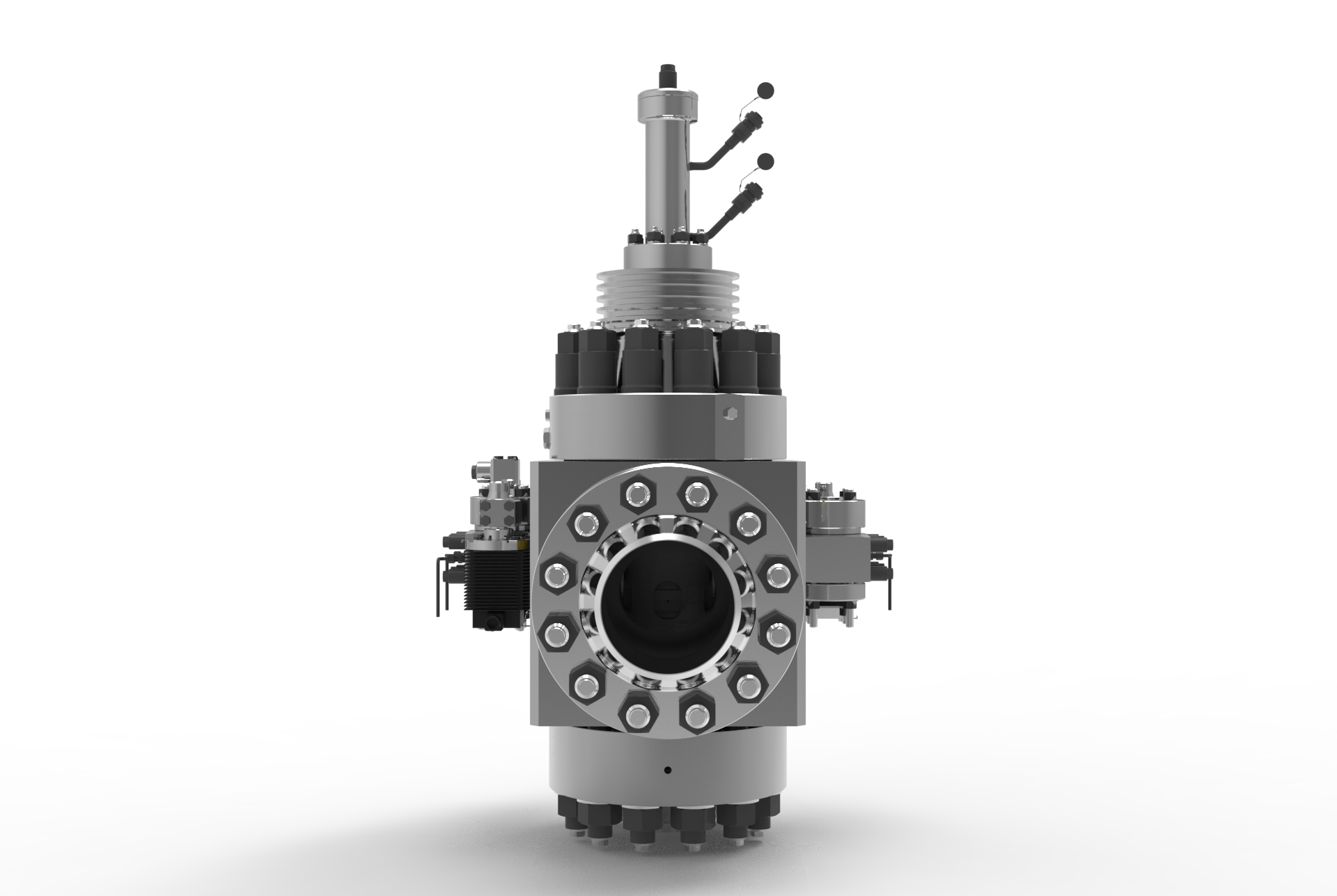

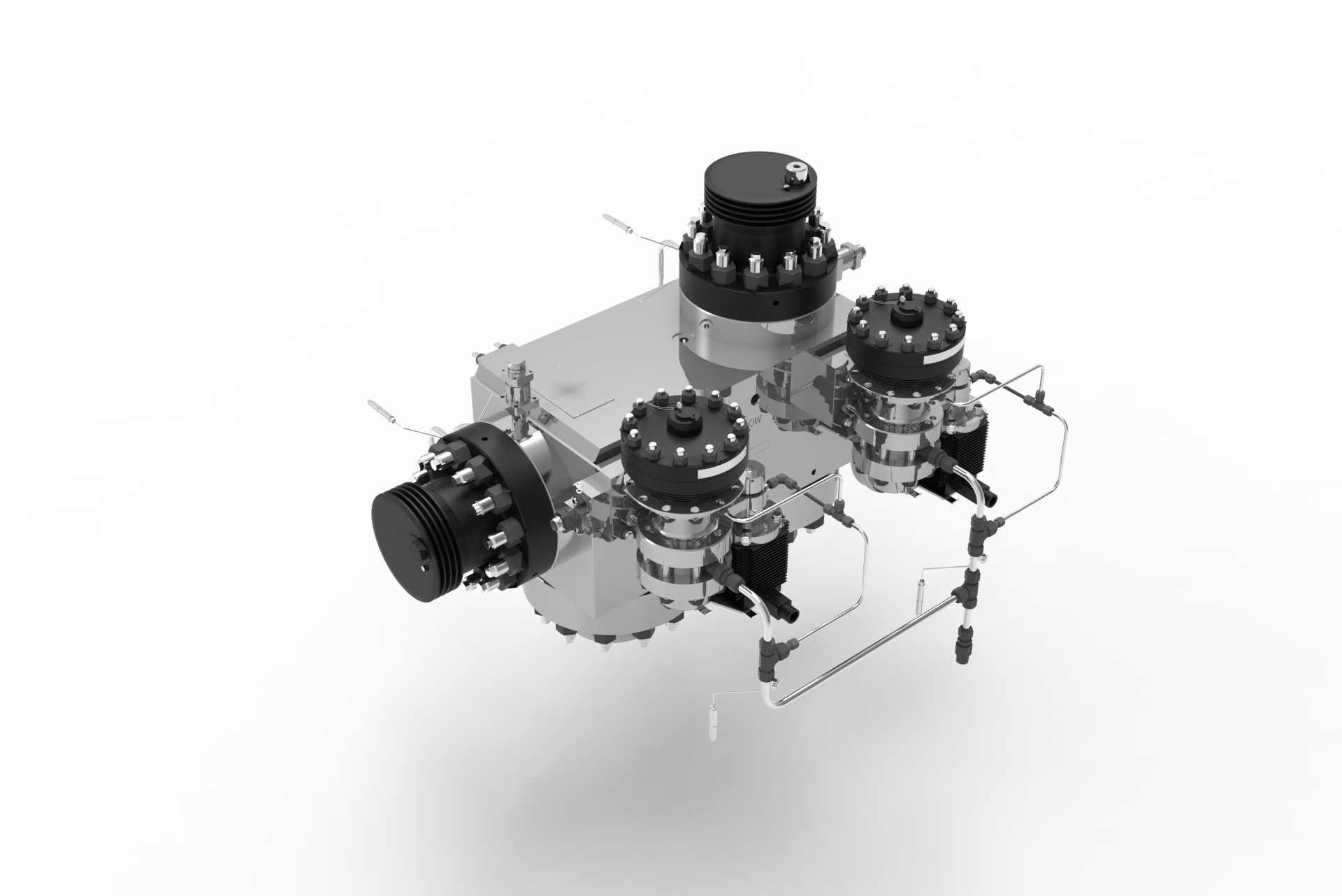

PRG 2000 POSV TANDEM SAFETY VALVE

The SEBIM® Pilot Operated Safety Valve (POSV type Tandem Safety Valves PRG 2000) is the upgrade of the tandem TSV 2000 known as “the cold solution” that has been in operation since the 1980s in French Pressurized Water Reactors.

The evolution PRG 2000 improves the discharge capacity of the safety valves under severe accident during “feed and bleed” operating mode and takes into account a “black out” scenario.

The safety valves ensure pressure safety and relief. Their autonomous piloting systems use dedicated and independent pressure impulse sources of fluid in the protected process (no external source of energy is needed for operation).

The No-Flow piloting system provides excellent leak tightness (the disc and the nozzle are leak tight up to the point of opening and immediately again after closing). Stable system: no mass spring effect.

KEY FEATURES

- Excellent operation irrespective of the type of fluid: steam, gas, liquid or two-phase

- Leak tightness up to the set-pressure maximize the operating pressure and output power

- Non-flowing pilot valve reduce ageing mechanism

- Accuracy of pilot set pressure opening value with repeatability better than 1%

- Soft opening/closing decrease the loads to the installation

- Perfect stability even when flow capacities are well below the maximum rate

- No erosion of sealing faces, no chattering

- Reduced maintenance

- Proven perfect repeatability and reliability

- Available remote control – power supply 48, 110, 220 V DC – IP 65 – 100% Operating factor

- K1 – 1 E qualified for applications within the containment area of nuclear plants

APPLICATIONS

- Primary circuit

DESIGN RATINGS

- RCC-M level 1, IEEE, NNSA

DESIGN STANDARDS

- ASME Class 150 to 2500 or customized

TEMPERATURE RANGE

- Up to 360°C (680°F)

CAPACITY

- 120 T/h – 17 MPa (Sat. Steam) adaptable

MATERIALS

- Stainless Steel

SIZE RANGE

- 4‘’ x 6’’ (DN100 – DN 150)

PRESSURE CLASS & POWER

- From 7 to 4300 PSI (0,5 to 30 Mpa)