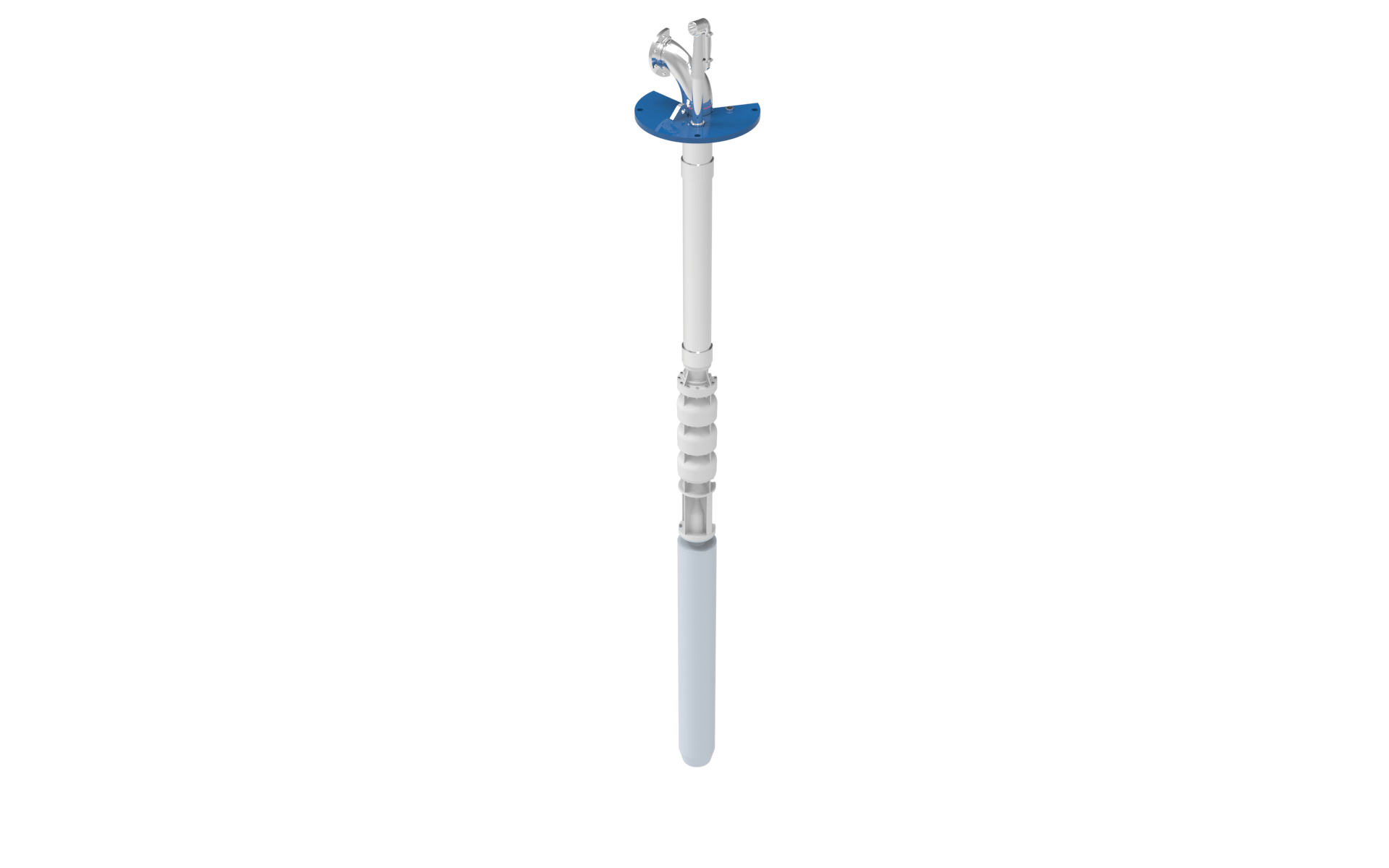

Floway®

The Trillium Flow Technologies™ Floway® brand is an international industry leader with more than 90 years of proven experience providing vertical turbine pumps to the water and wastewater, oil and gas, mining, energy, and industrial markets.

CELEBRATING 90 YEARS OF VERTICAL PUMPS

Since 1934 Trillium Flow Technologies™ Floway® brand is an international industry leader with more than 90 years of proven experience, providing vertical turbine pumps to the water and wastewater, oil and gas, mining, energy, and industrial markets.

Floway® pumps are known around the world for their superior quality, reliable hydraulic performance, and long service life.

With Trillium Flow Technologies™ Floway® pumps, you will receive exceptional service and support.

OUR FOCUS ON YOUR INDUSTRY LEADS TO REMARKABLE RESULTS

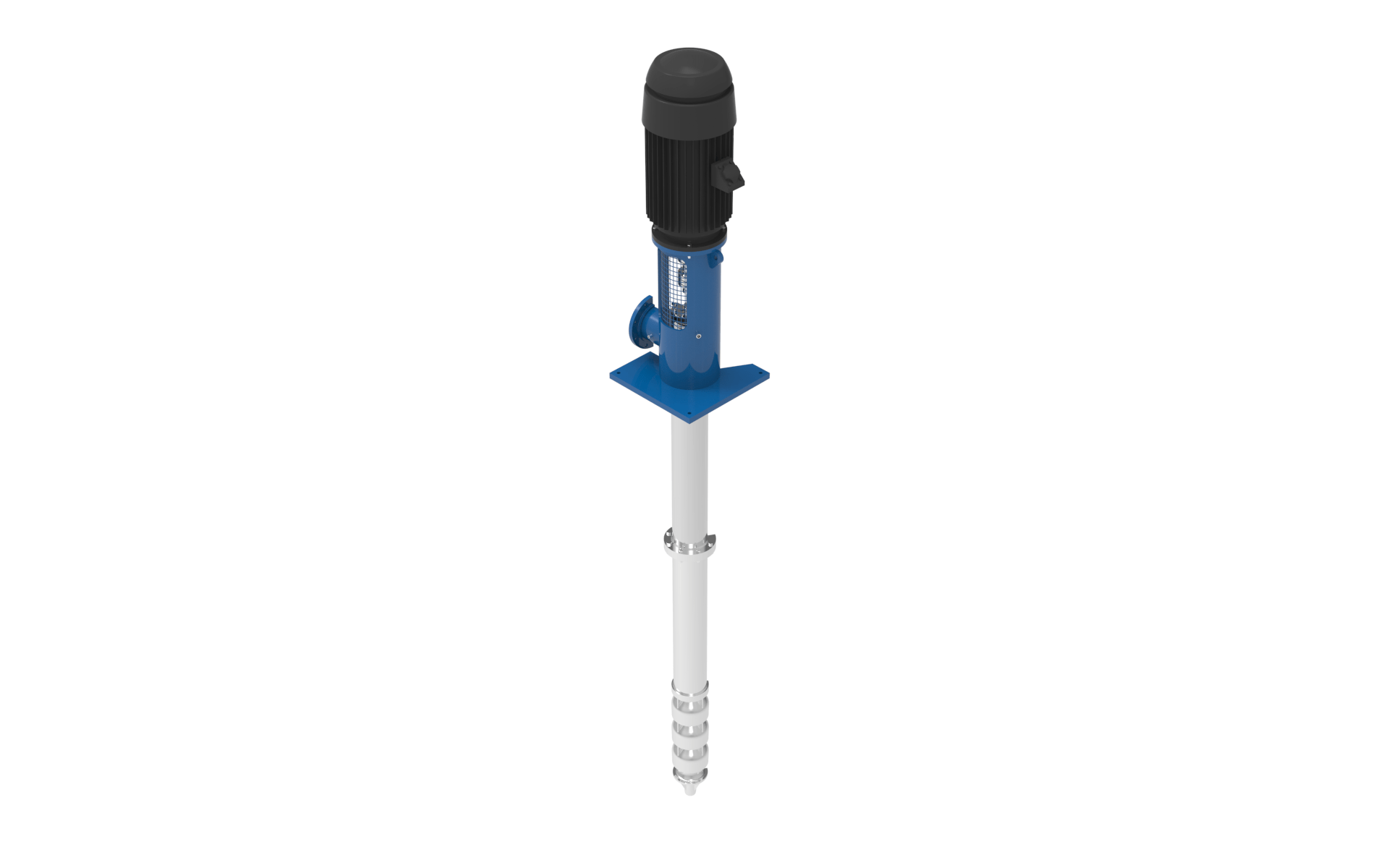

Trillium Flow Technologies™ Floway® range of vertical pump products are recognized worldwide for superior quality, top hydraulic performance, and long service life.

Through continuous improvements to materials, product design, engineering, and manufacturing techniques, we minimize downtime and disruption to your operation.

Working in close partnership with you allows us to develop end-to-end engineering solutions to the technical challenges you face, delivering a genuine competitive advantage.

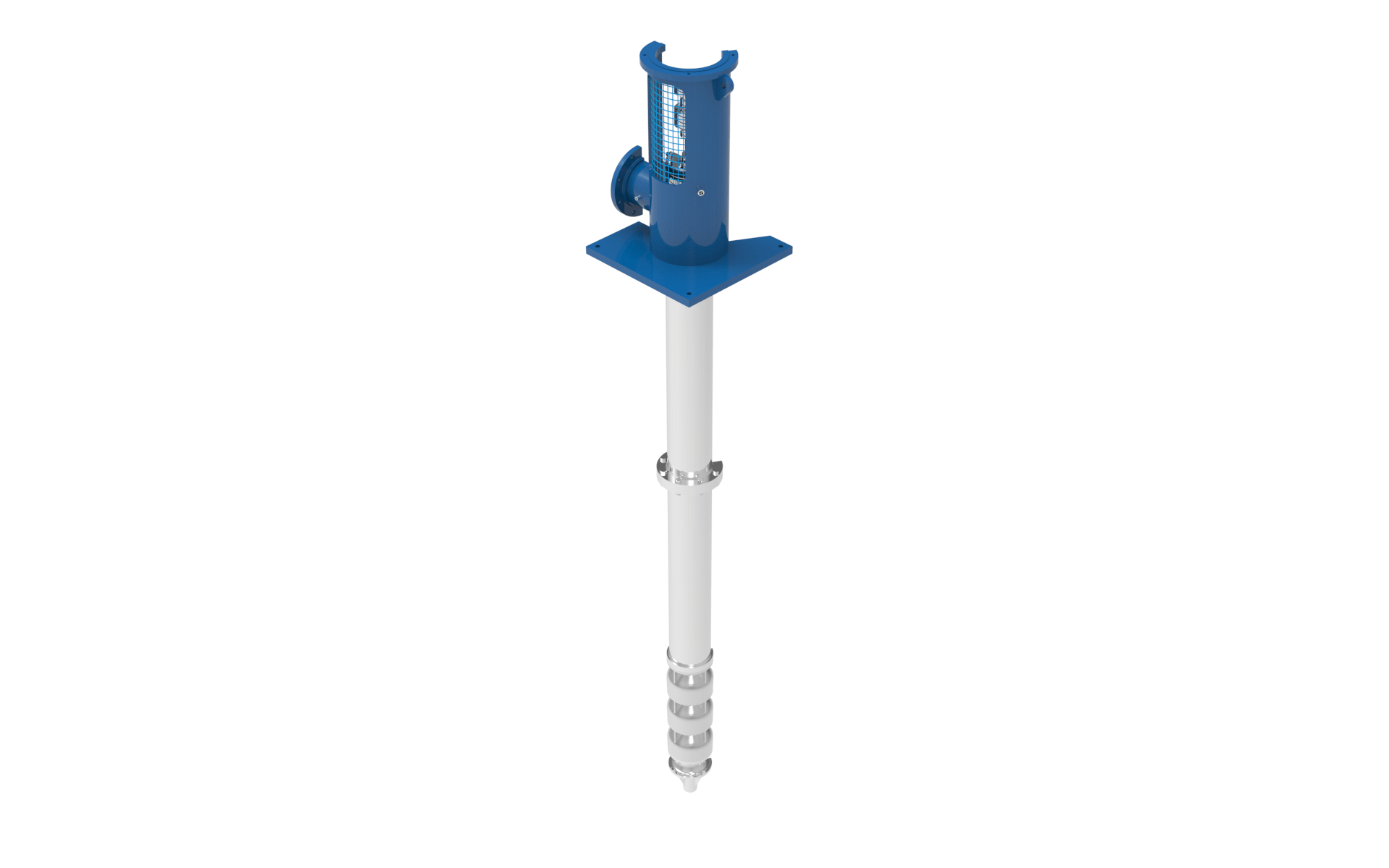

We provide each of our customers a unique level of service and support, so you are assured of guidance, responsive solutions, and long-term plans that optimize your efficiency and resources.

No matter your industry, the best way is Floway® for highly engineered vertical pumps and a unique level of service and support for the life of your operation. Let our dedicated Trillium Flow Technologies™ team ensure your success and give you confidence year after year, project after project.