Hopkinsons®

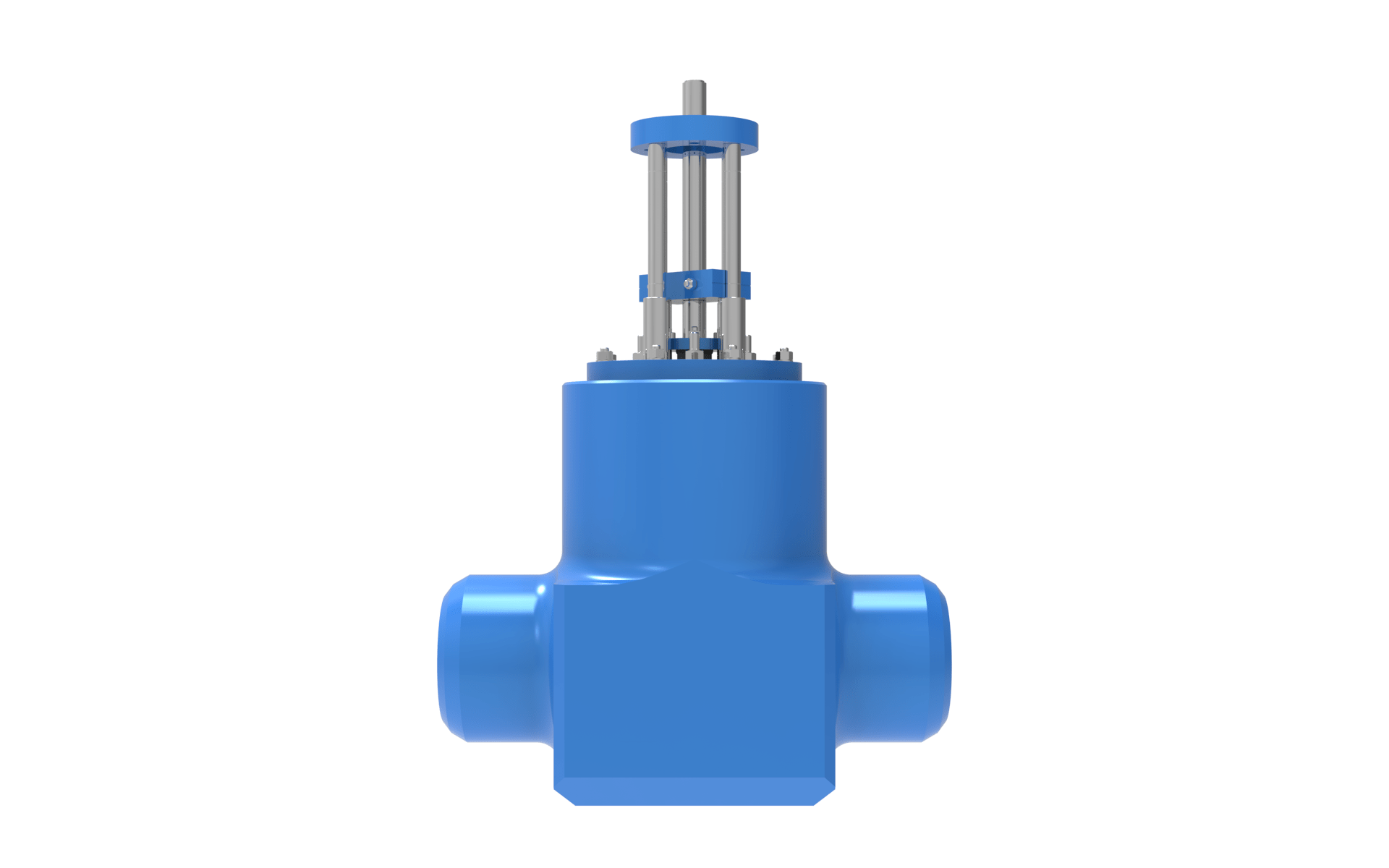

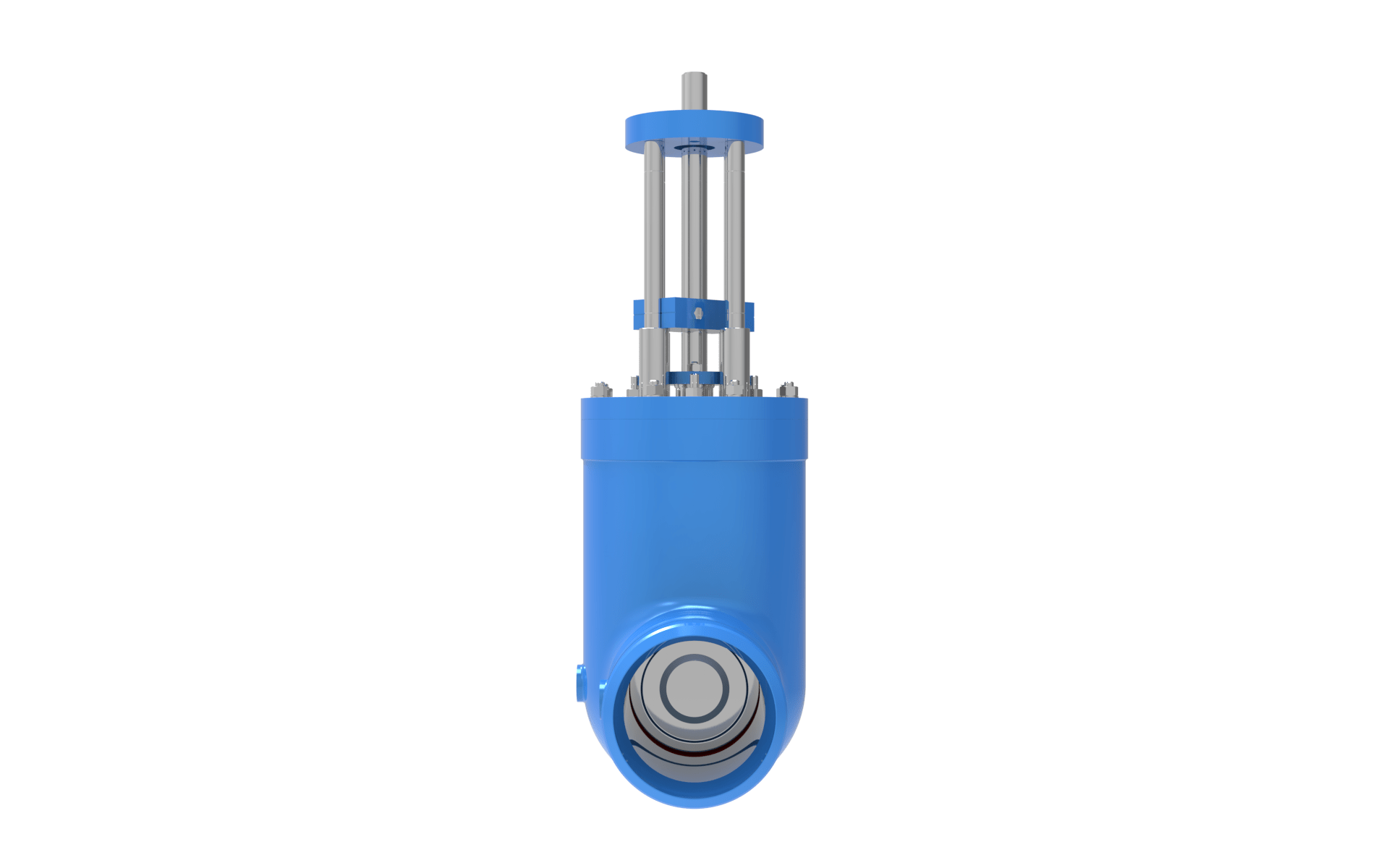

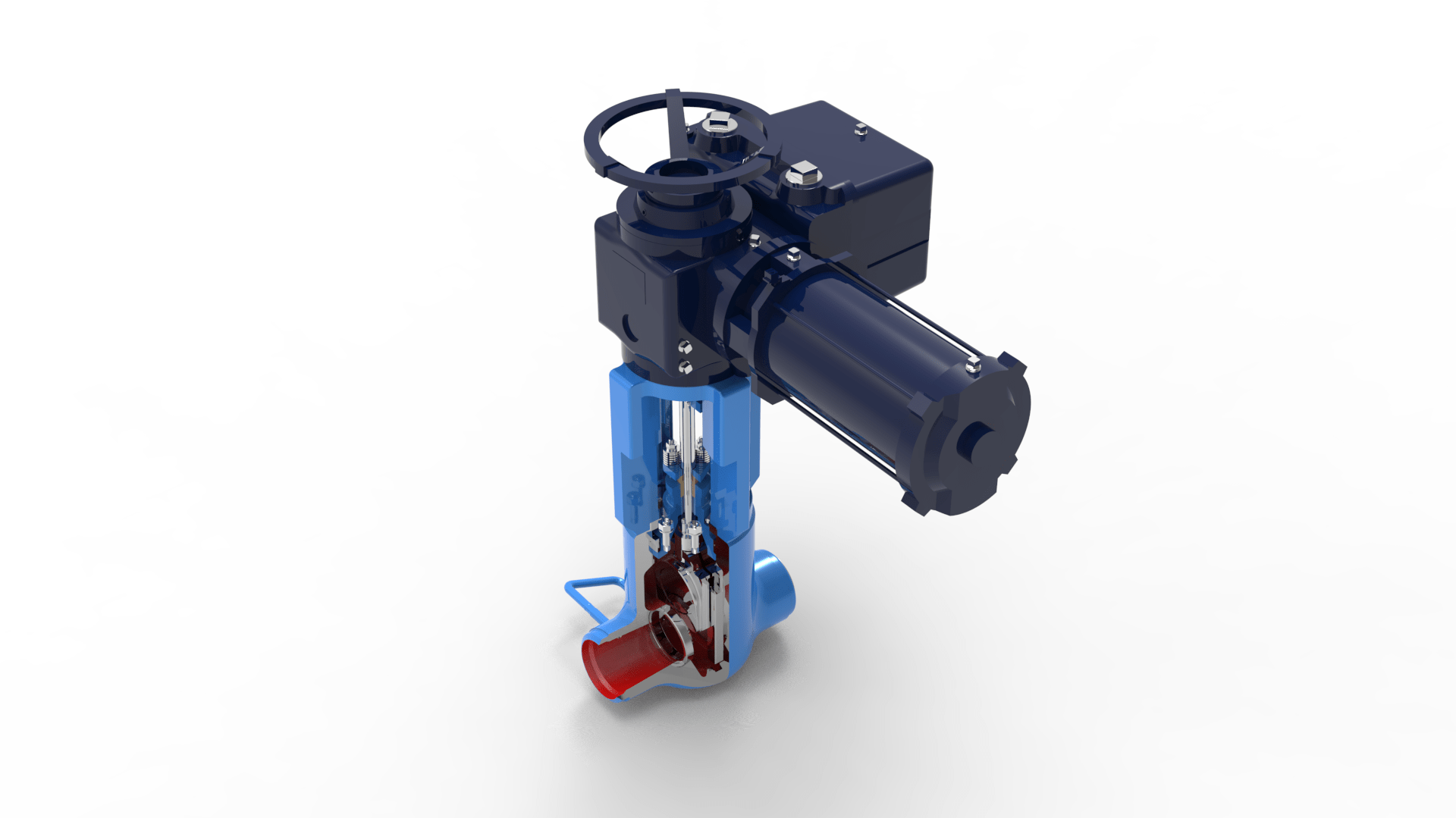

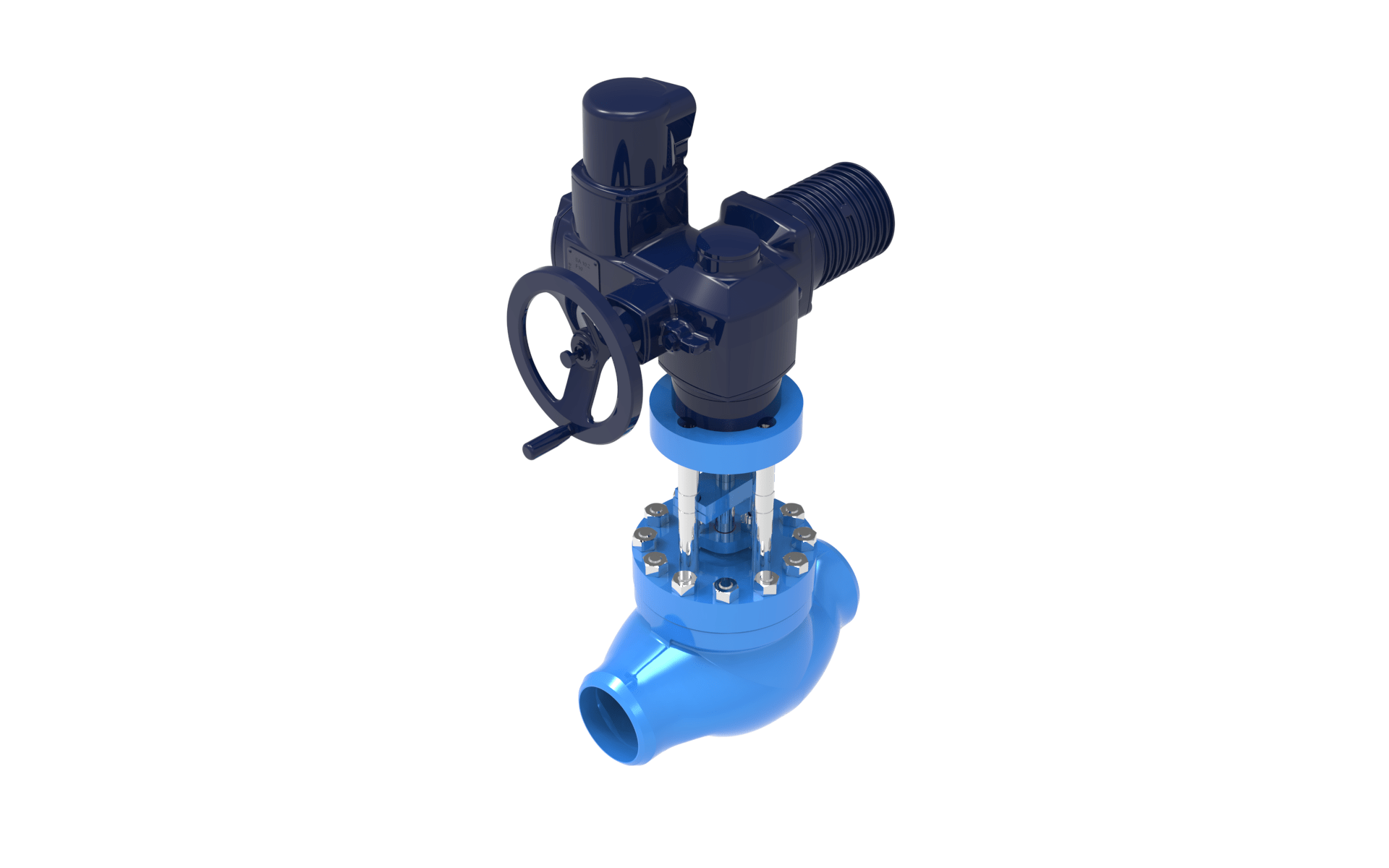

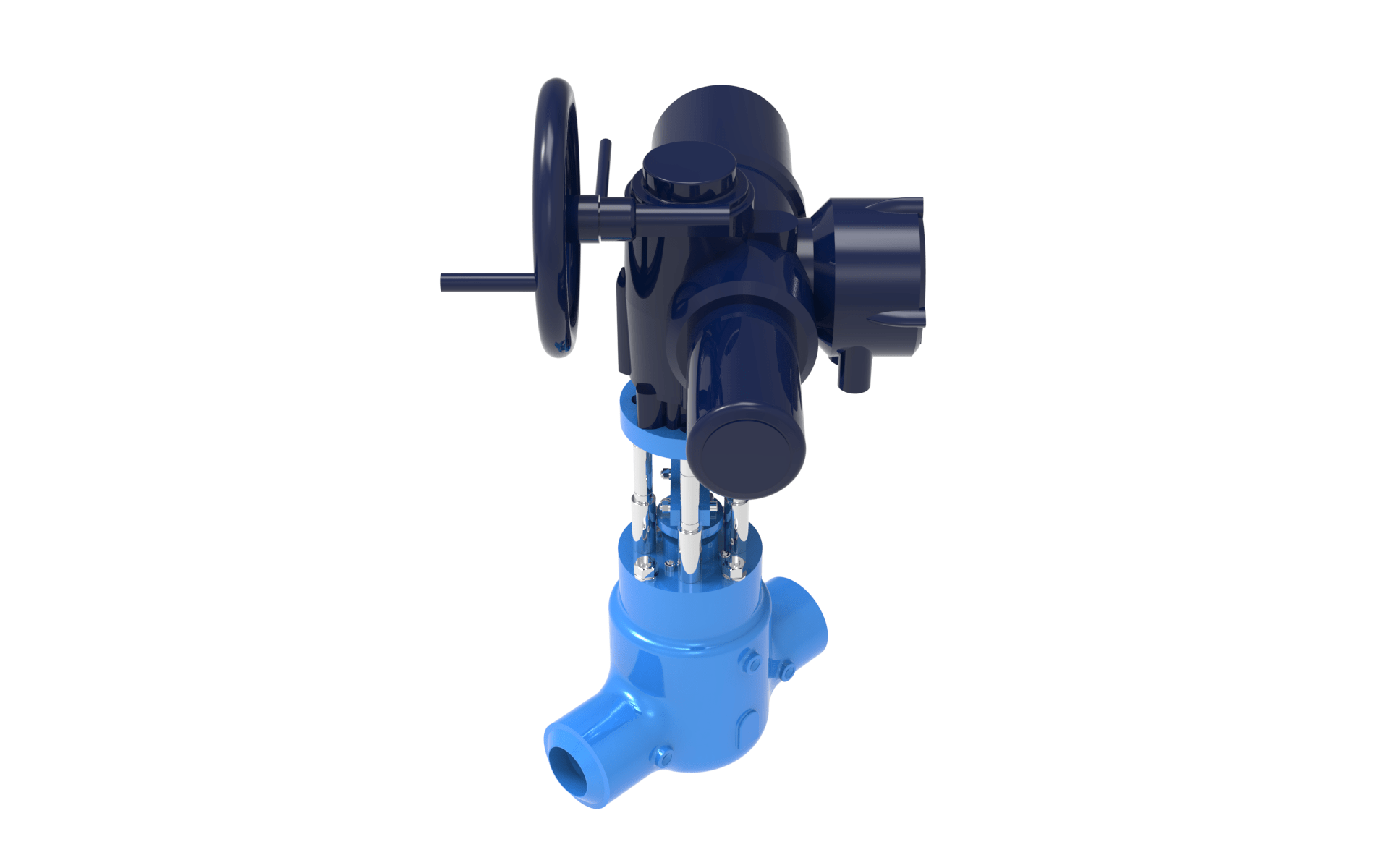

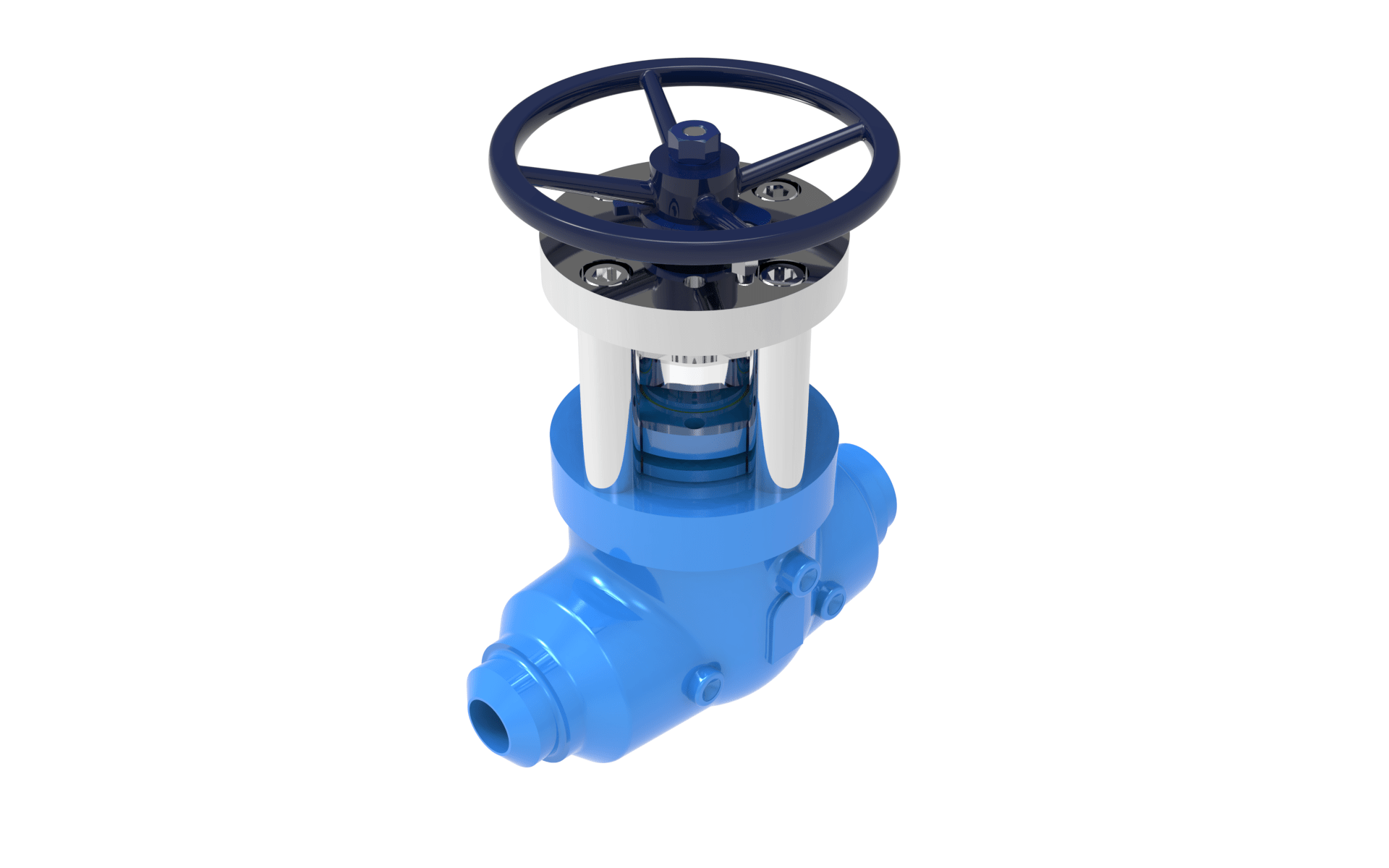

Trillium Flow Technologies™ Hopkinsons® brand delivers highly engineered valves known for long life and reliability. Hopkinsons® parallel slide valves and venturi parallel slide valves are considered the standard in the areas of isolation, protection, and process control.

HIGHLY ENGINEERED VALVES FOR LONG LIFE AND RELIABILITY

The Hopkinsons® brand started in 1843, when Joseph Hopkinsons began making valves and mountings in an upstairs room of a cottage in Huddersfield, England. Joseph Hopkinsons was a visionary who believed in the power of engineering during an era characterized by a strong cultural backlash against mechanization. His determination began what is today one of Trillium Flow Technologies™ prominent legacy brands.

Today, Trillium Flow Technologies™ Hopkinsons® brand delivers highly engineered valves known for long life and reliability. From our factories in Elland, England, Ipswich, Massachusetts, and Suzhou, China we design and manufacture versatile valves used in countless installations – from boilers to power plants to oil and gas to petrochemicals. We also design and manufacture boiler mountings and reheat isolation devices.

THE ENERGY OF TODAY AND TOMORROW

In addition to conventional energy applications, Hopkinsons® valves are frequently used for isolation, control, pressure limitation, instrumentation and draining, and in combined cycle gas turbine power plants.

As a Trillium Flow Technologies™ legacy brand, Hopkinsons® delivers real solutions that deliver long-term success and confidence.