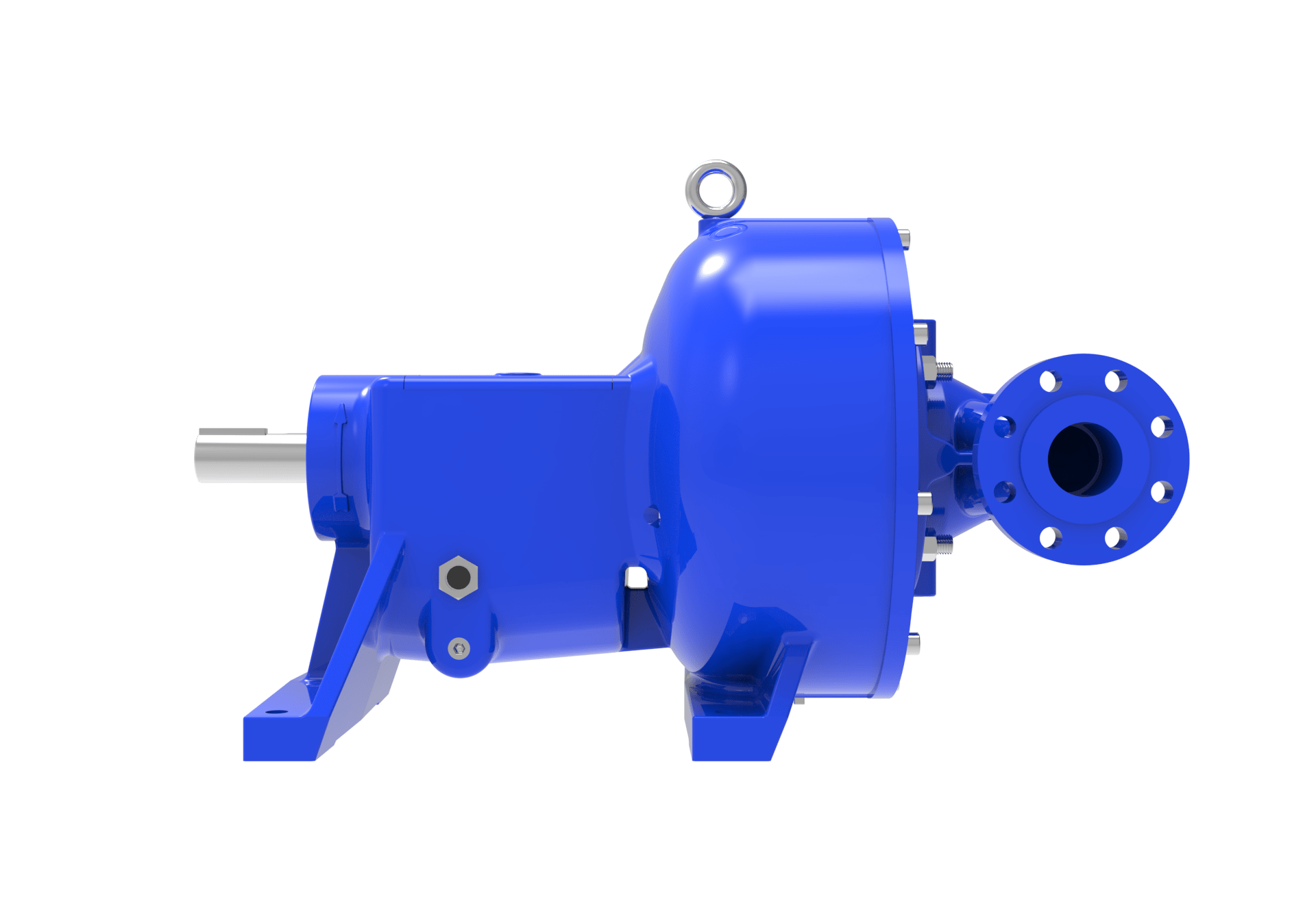

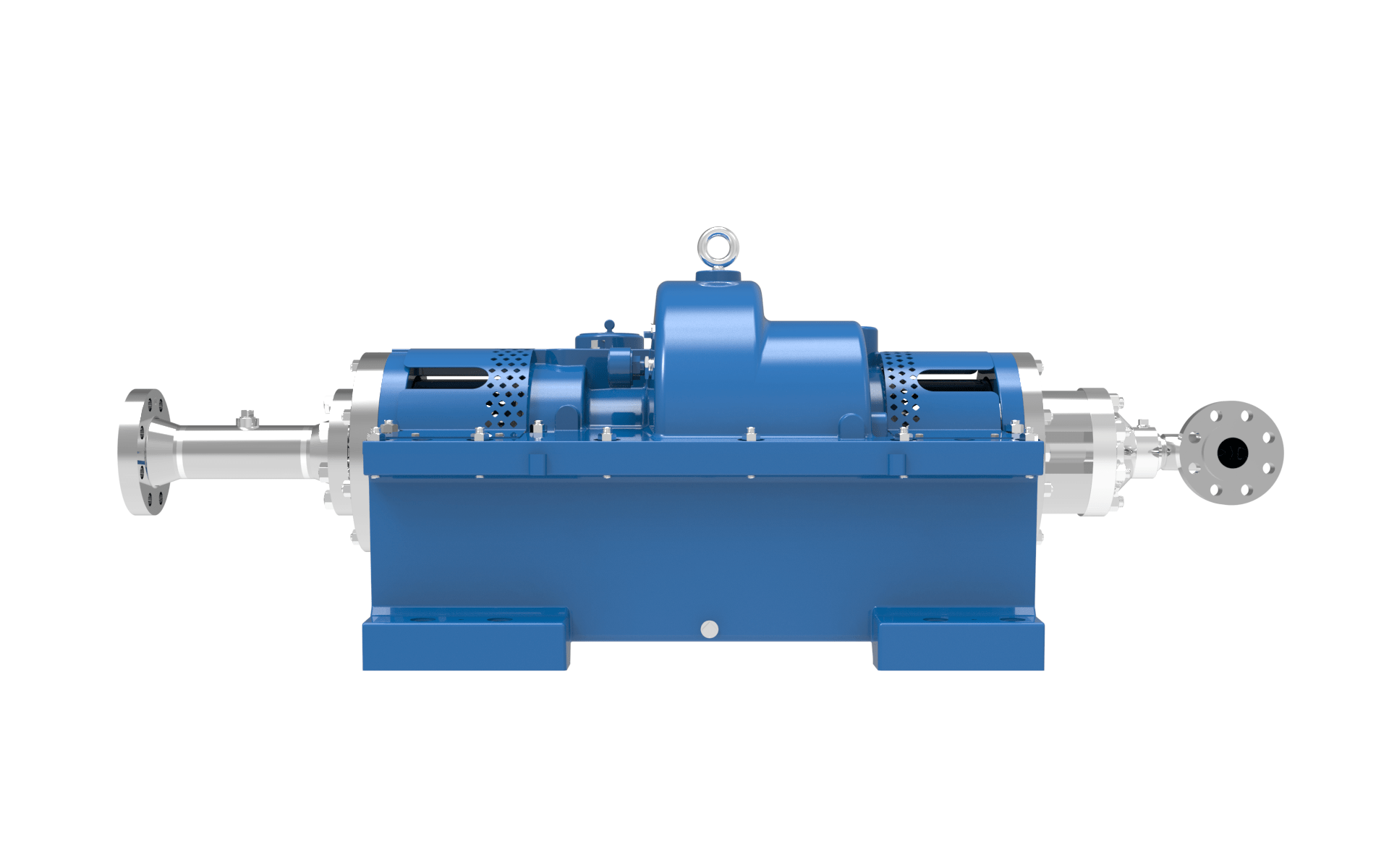

Roto-Jet®

The Roto-Jet® brand encompasses high-pressure, single-stage centrifugal pumps with advanced pitot tube technology that are successful for demanding low-flow, high-head applications.

THE BACKWARD PUMP

Roto-Jet® is built on the pitot tube pump concept which, because of its unique rotating case design, is sometimes referred to as “the backward pump”. Over the decades, the pitot tube’s simple design and versatile performance have achieved a reputation as the solution to many high-pressure pumping problems.

SIMPLE YET EFFECTIVE

The operating characteristics of the Roto-Jet® pump are simple and similar to a conventional centrifugal pump. Energy is added to the fluid via the rotor, and the stationary pitot tube converts the fluid velocity energy into static pressure.

Features and Benefits:

- No external lube system required

- No wear rings or close running clearances

- Robust design is insensitive to process upsets

- Pulsation free flow over the entire head-flow curve

- Reduced life cycle cost by optimizing hydraulic efficiency

- Process seals exposed only to suction pressure for maximum seal life

- High heads achieved in a single stage at low operating speeds compared to other low-flow, high-head pumps

As part of the Trillium Flow Technologies™ legacy brand portfolio, our Roto-Jet® high-pressure pitot tube pumps, including the Roto-Jet® RO-FT model, offer proven, field-tested pumps with a steadfast reputation for quality engineering and reliability. It’s all backed by Trillium Flow Technologies™ unique level of service and support. Roto-Jet® delivers success and confidence straight to you!