SEBIM®

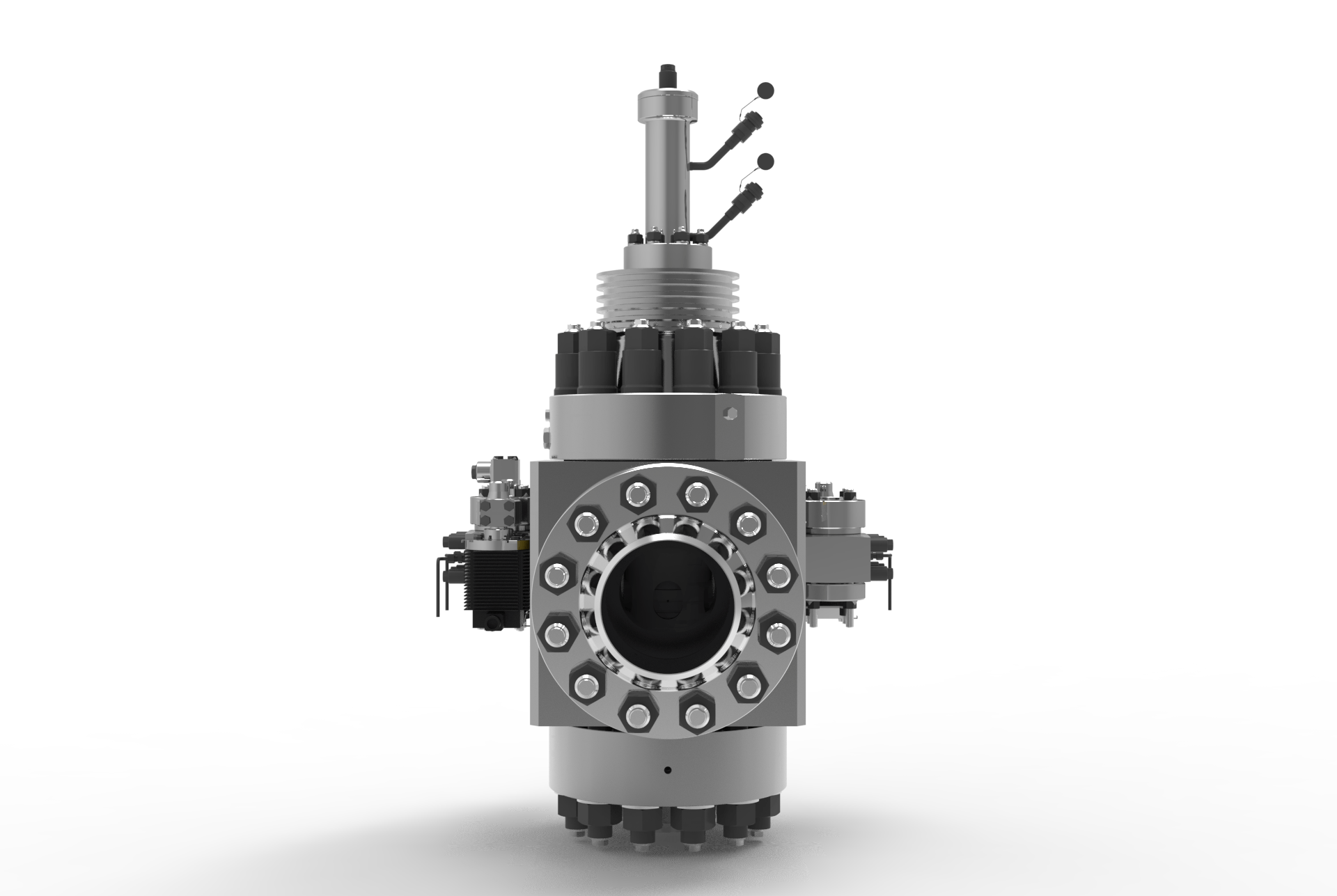

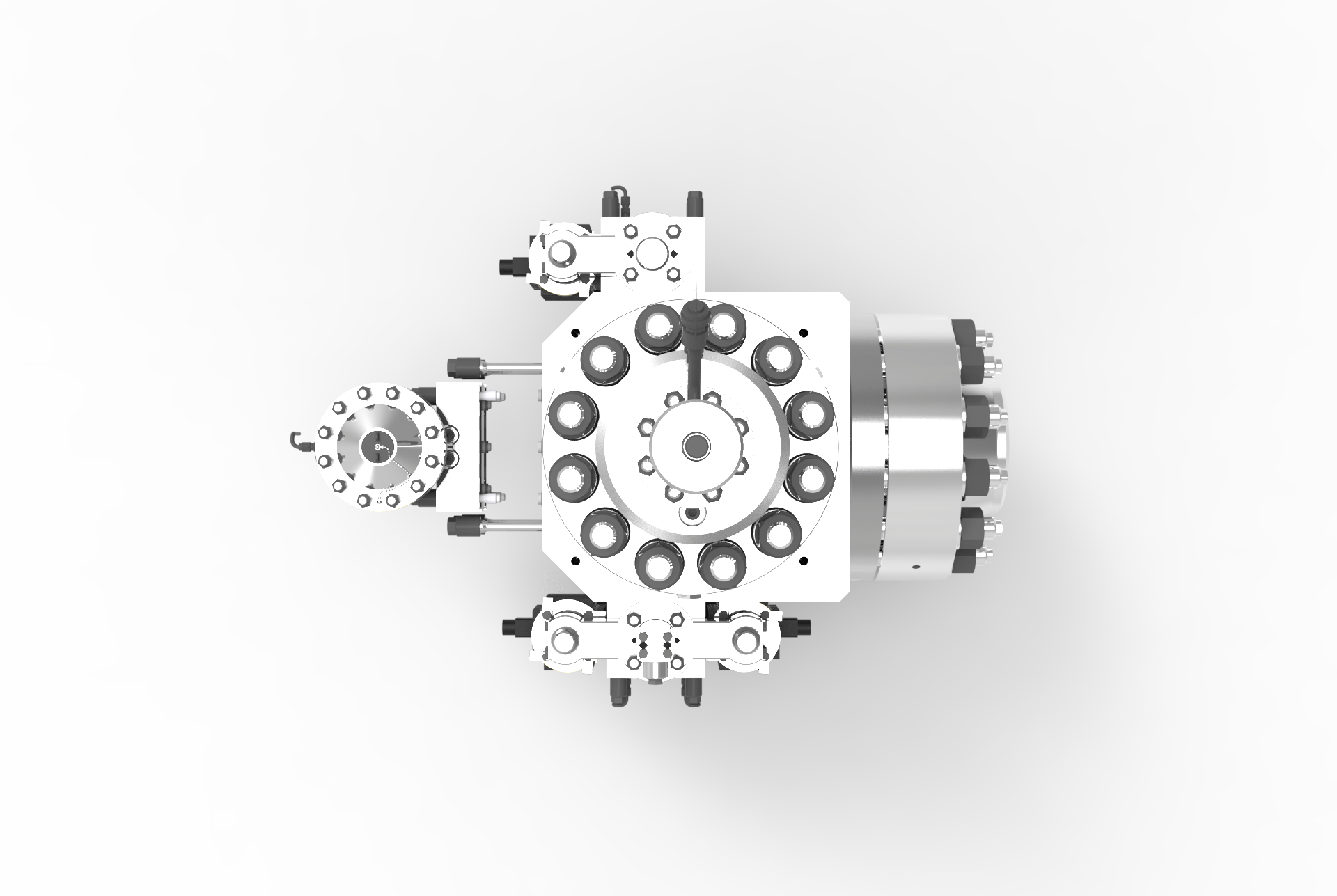

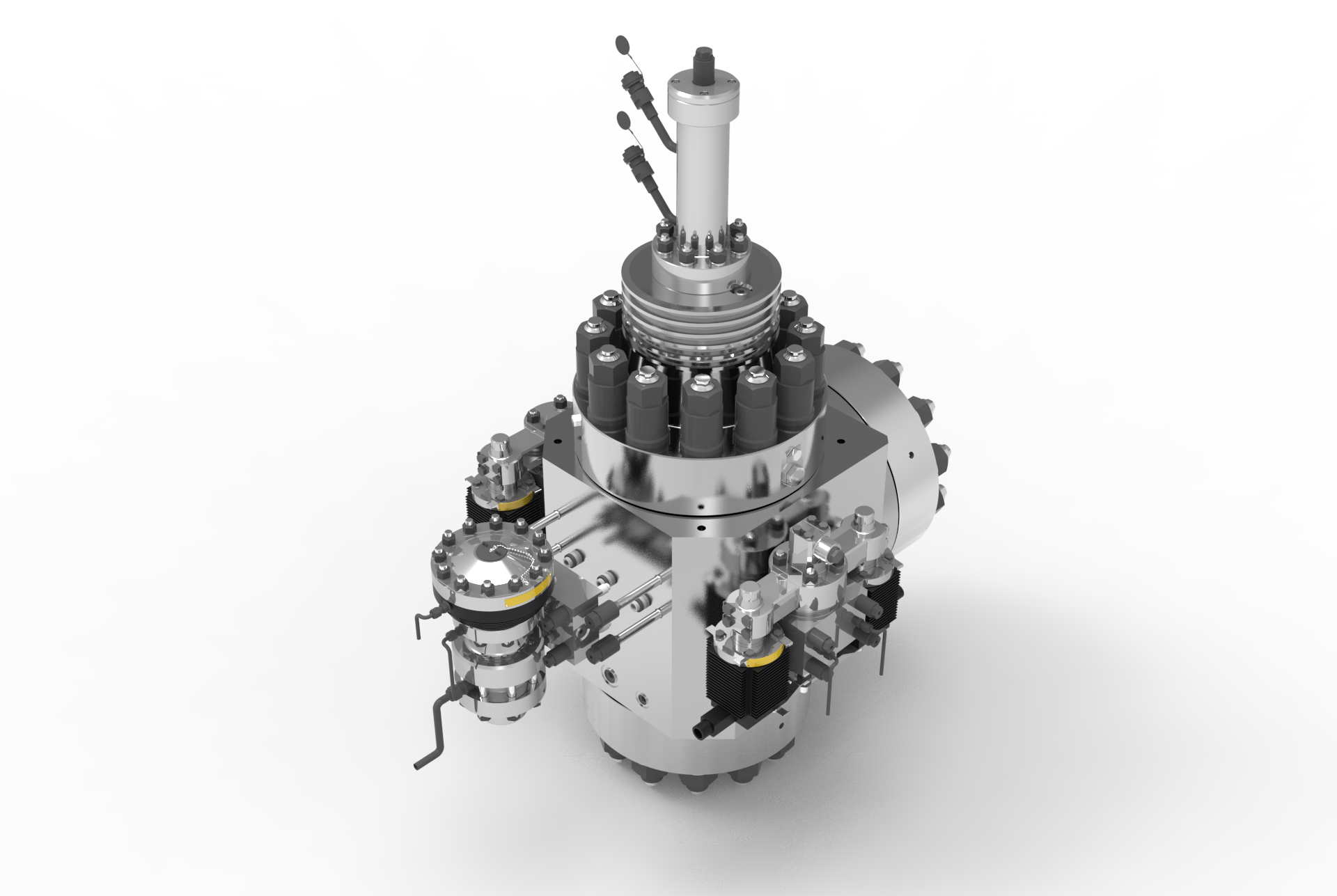

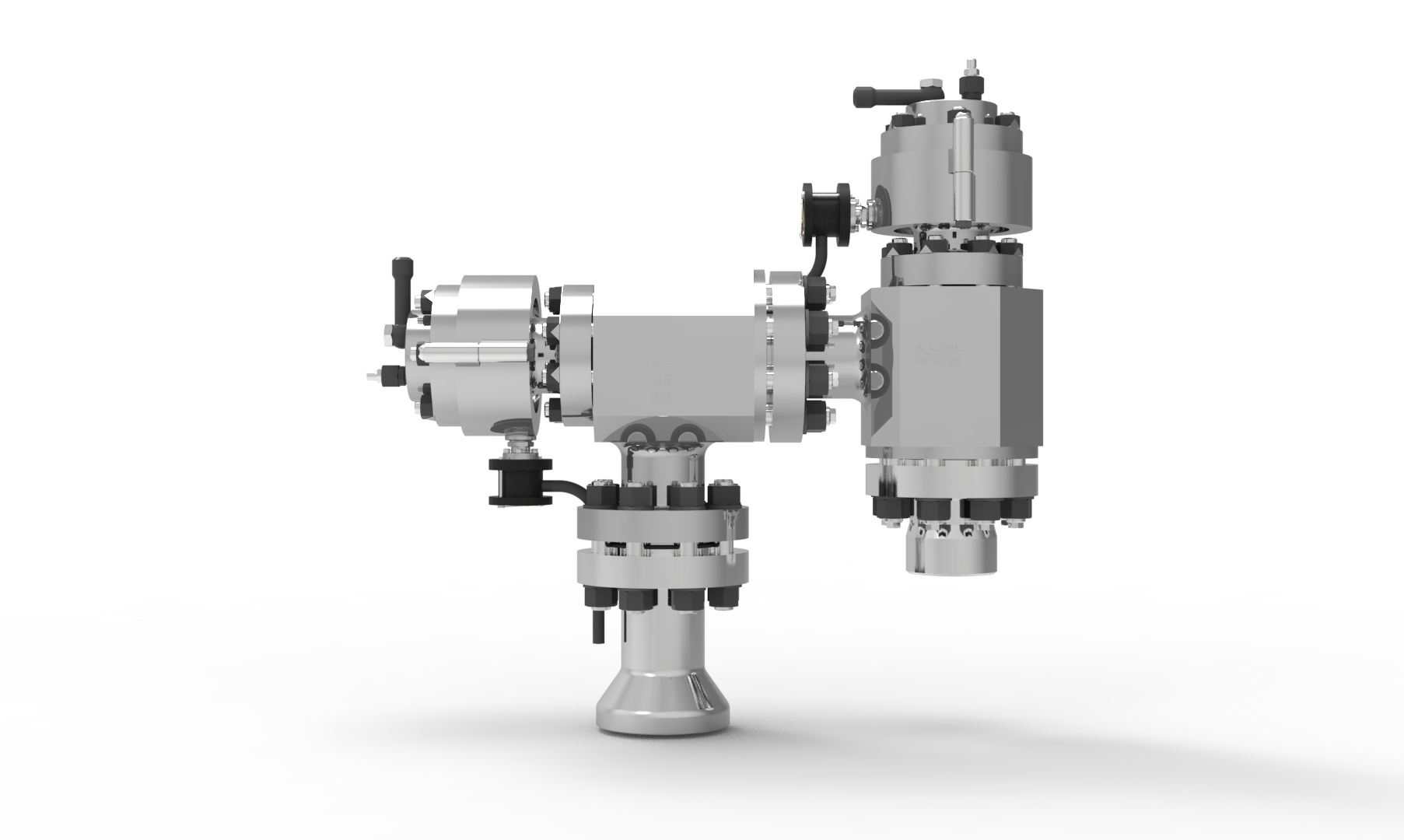

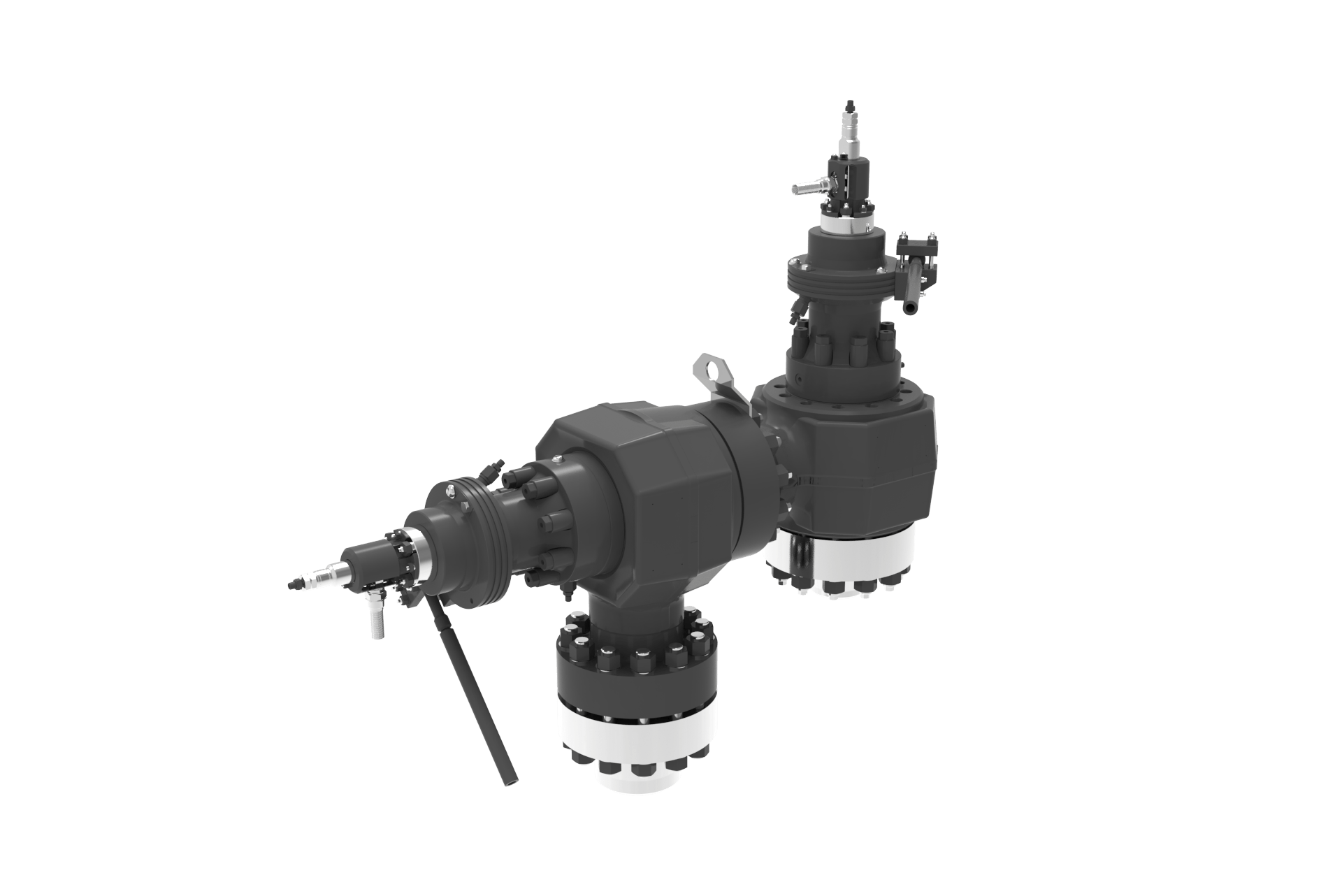

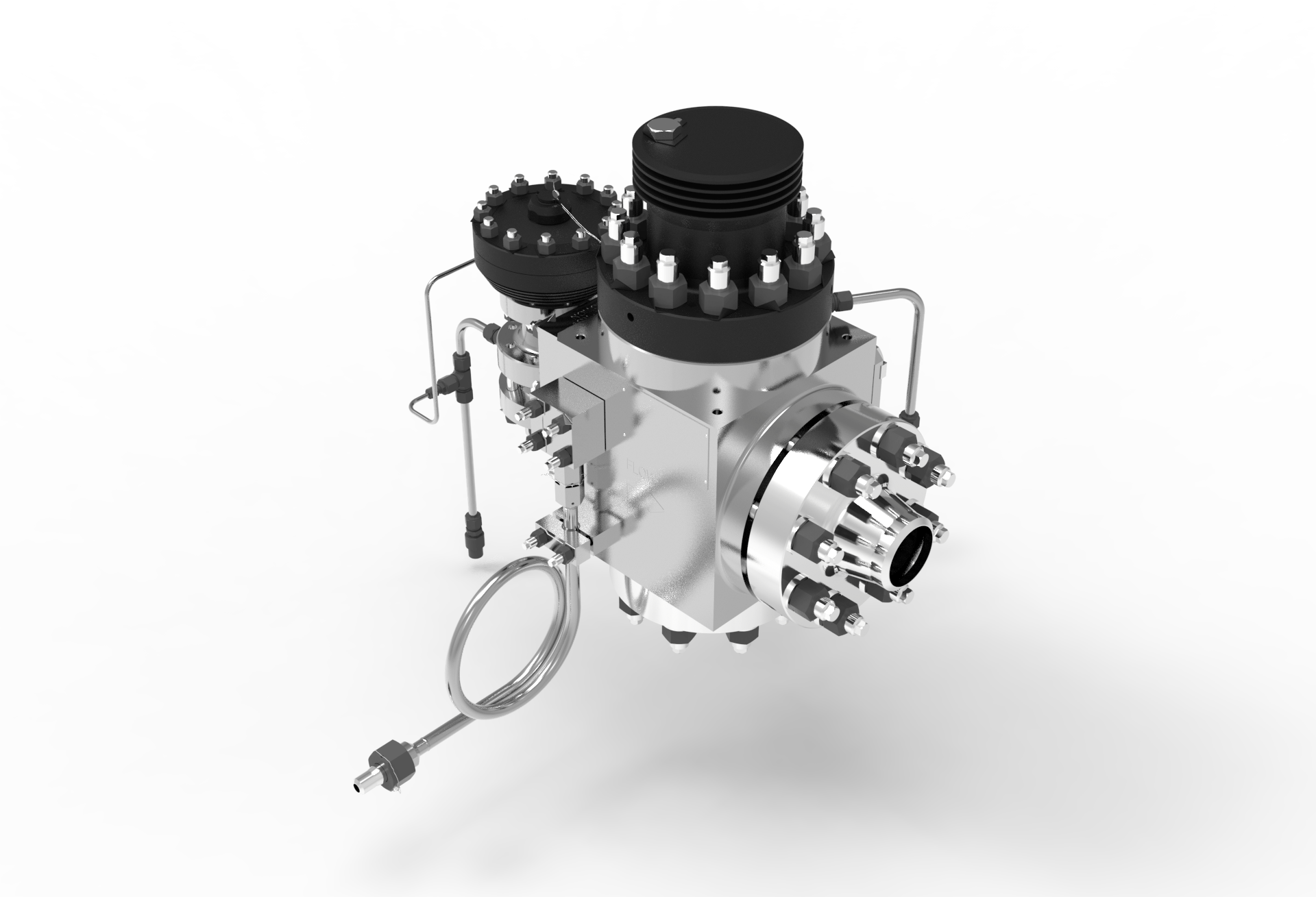

PRG 3000 Primary coolant safety valve

The SEBIM® POSV PRG 3000 is designed for overpressure protection in primary circuits of all designs of nuclear reactors, including third and fourth generations reactors.

The SEBIM® POSV type PRG 3000 series is qualified for overpressure protection of the primary circuit of the third generation pressurized water reactors (including EPR, VVER 1000 & 1200 etc.). Our PRG 3000 design is currently in operation throughout several primary loop second generation reactors.

MAIN CHARACTERISTICS

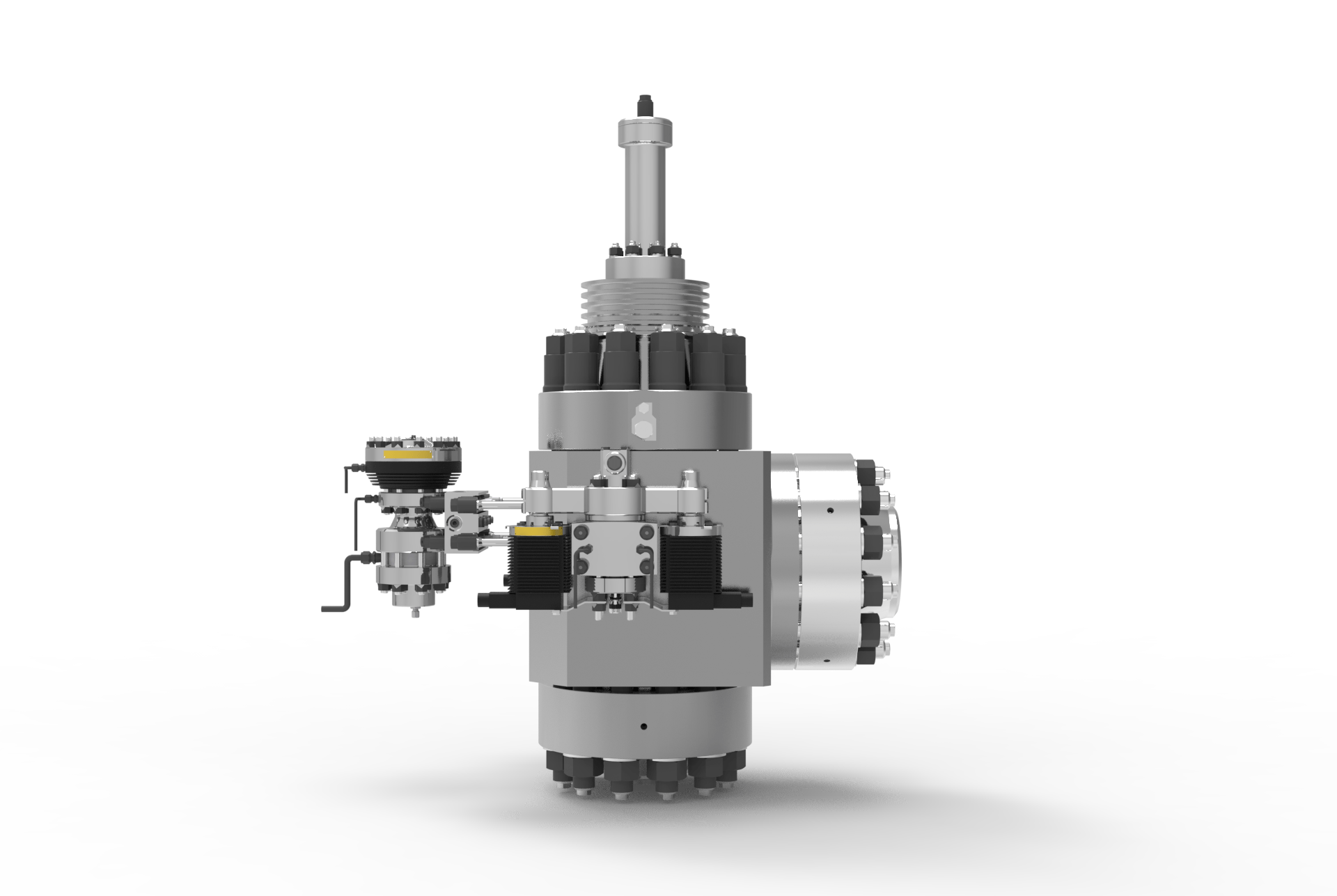

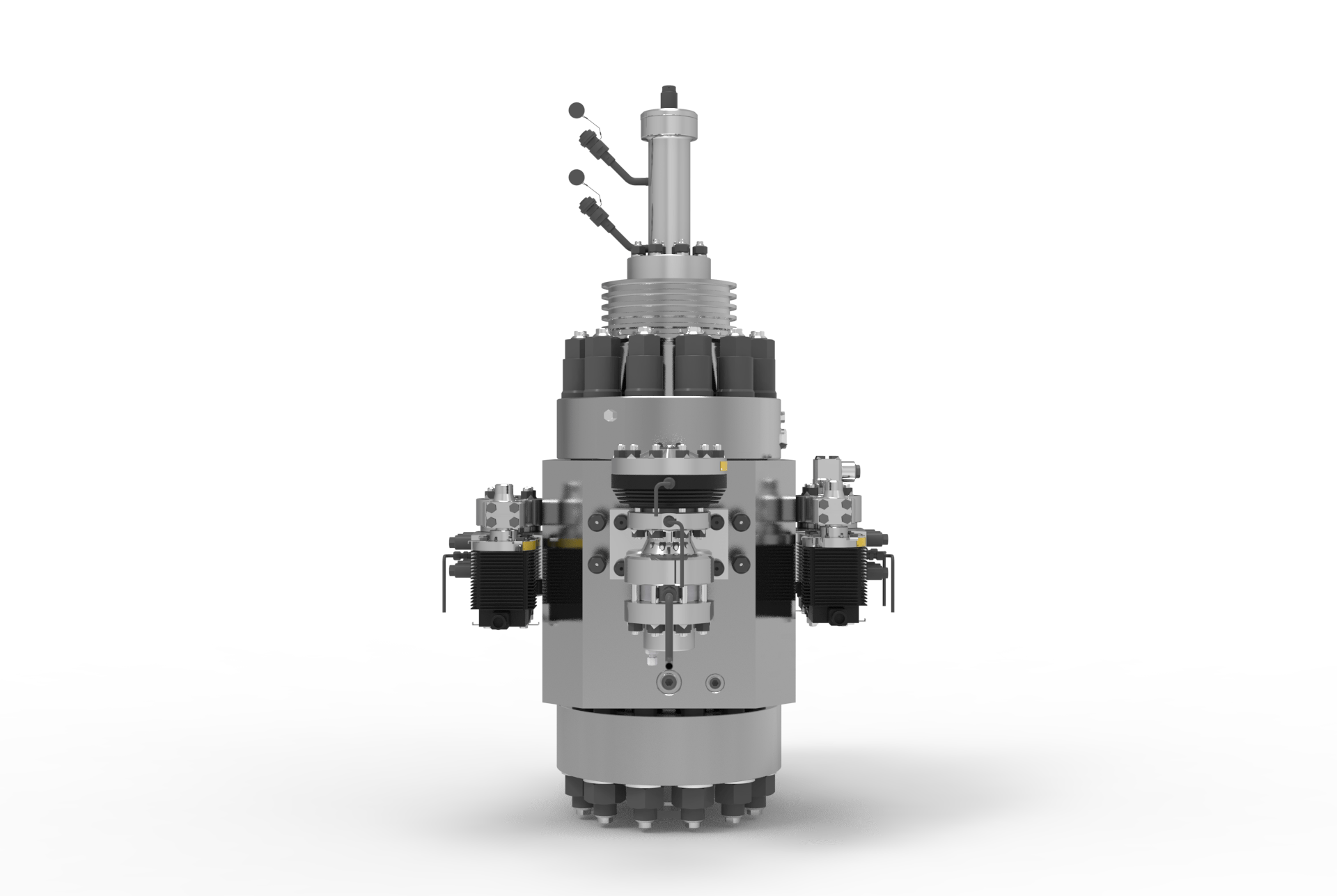

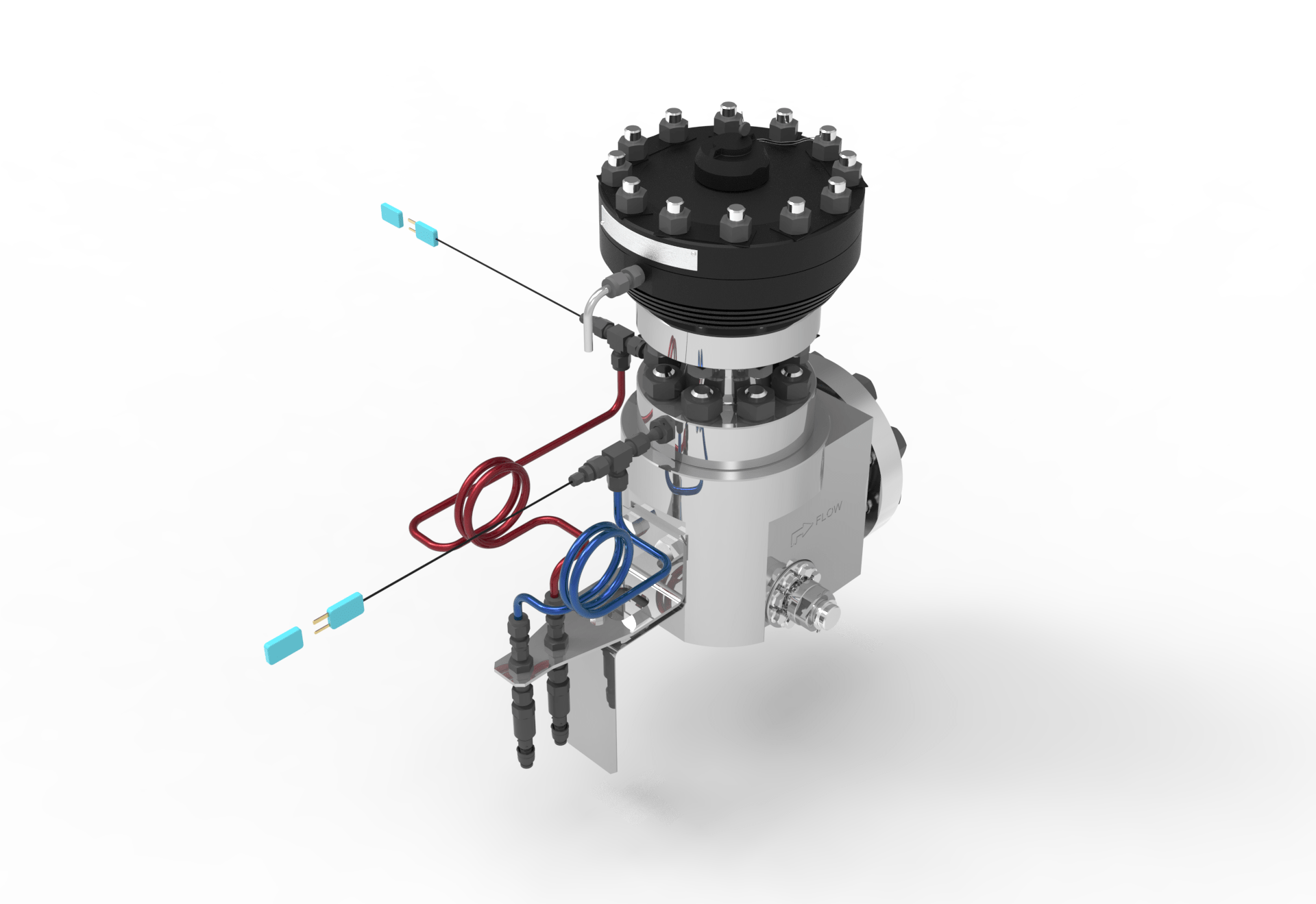

- Autonomous piloting system which uses the fluid in the protected process (no external source of energy is needed for operation)

No-Flow piloting system - Compact and tubeless design (integral through valve body drilling; reduced size and weight)

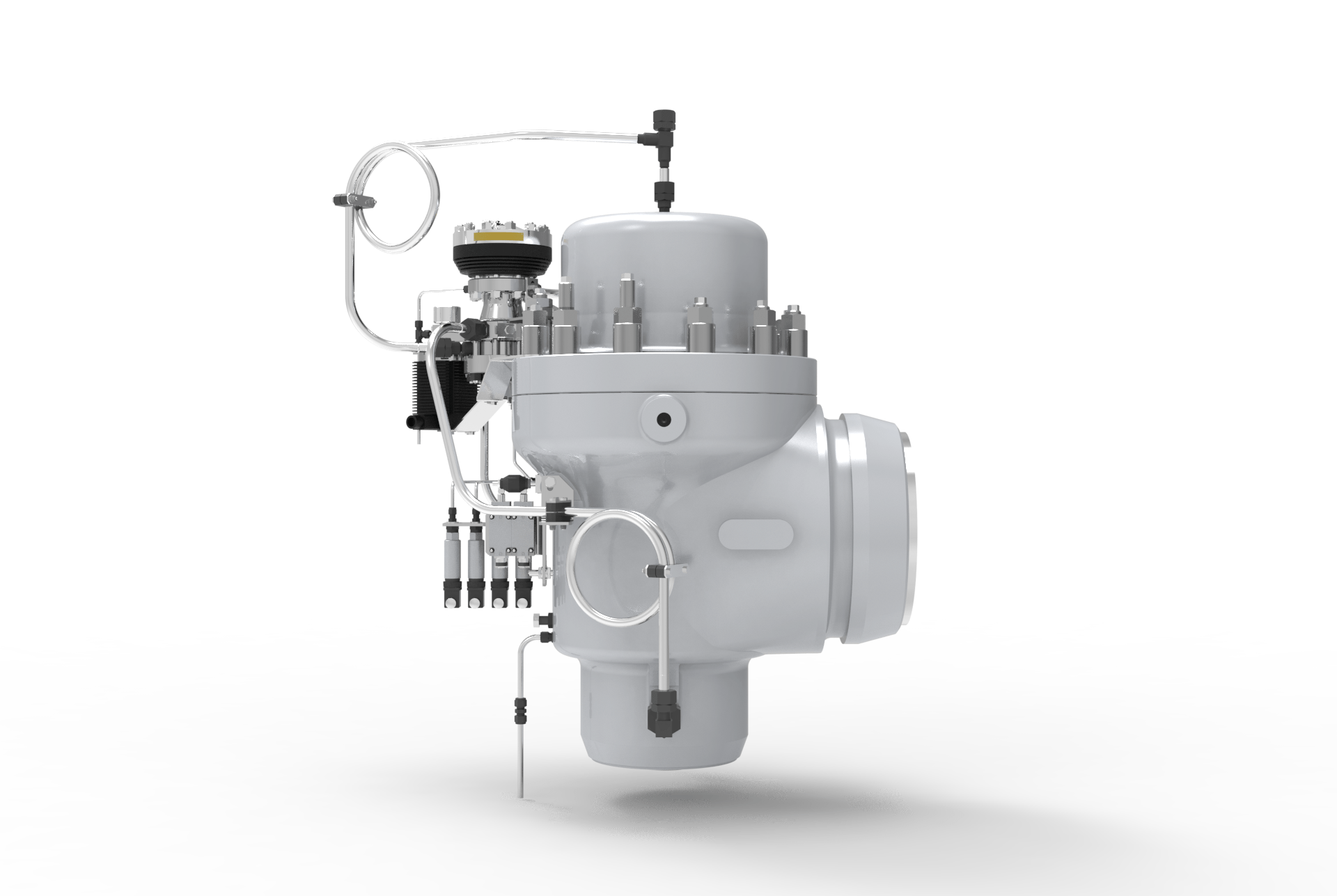

Excellent leak tightness (the disc and the nozzle are leak tight up to the point of opening and immediately again after closing)

No erosion of sealing faces, no chattering - Proven reliability

- Excellent accuracy (better than 1%)

- Repeatability (lower than 1%)

- System insensitive to back pressure

- Maintained stability even when flow capacity is below the maximum rate

KEY FEATURES & BENEFITS

- Improved capability to open the pressurizer depressurization system before reaching severe accident conditions and avoid core melting under high pressure in the primary system

- Improved capability to maintain the pressurizer depressurization in the open position system during a severe accident

Excellent operation irrespective of the type of fluid; steam, gas, liquid, or two-phases applications. - Leak tightness up to the set-pressure maximizes the operating pressure and power output

- Non-flowing pilot valve minimizes the mechanisms rate of ageing

- Soft opening & closing decreases the load on surrounding equipment

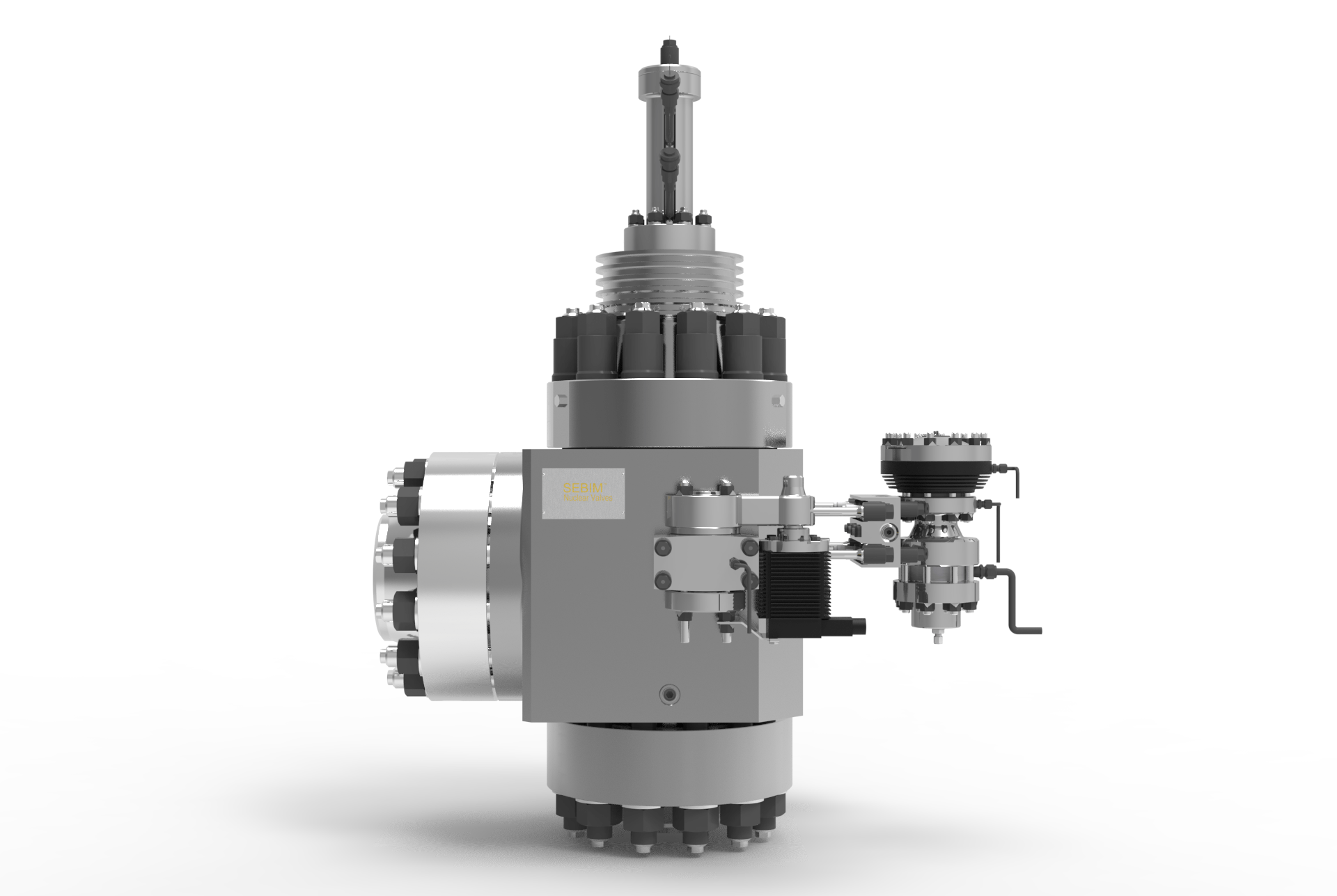

- Low or high pressure in-situ test during operation for preventative maintenance

- Stable system: no mass spring effect

- Reduced maintenance

- Proven and accurate repeatability and reliability

- Protection against cold overpressure (nuclear vessel protection within the NDTT curve)

- In the case of design basis accident conditions, improved reliability of the pressurizer depressurization system (feed and bleed, operating at low pressure conditions)

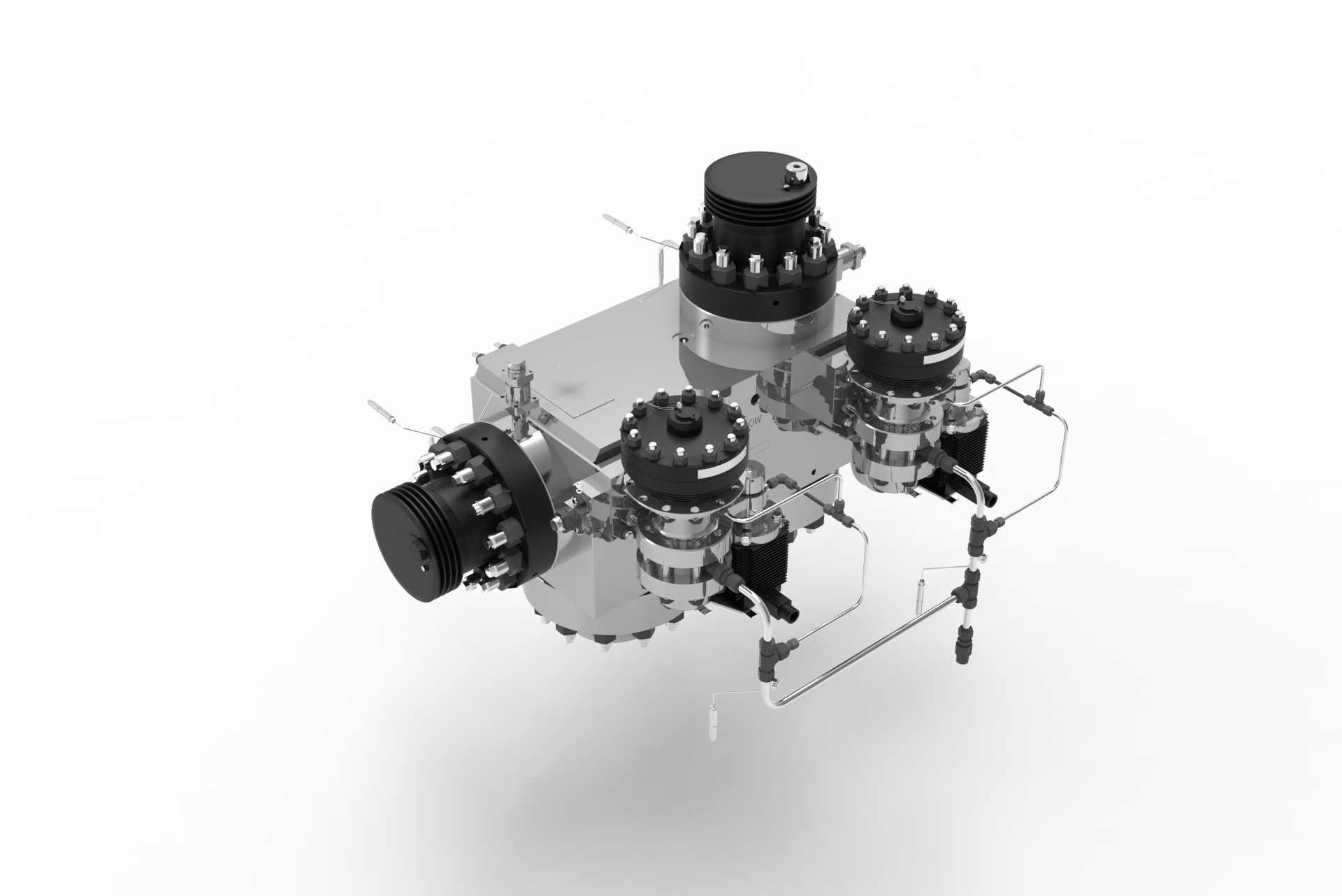

UPGRADES & ADAPTATIONS

- Steam Generator Safety Valves

- Main Steam Safety Valves

- Bleed Condenser Relief Valves

- Reactor Heat Removal Safety Valves

- Reactor volumetric and chemical control circuit overpressure protection

- Interface adaptable to the need

MAIN FUNCTIONS

- Cold and Hot condition overpressure protection on steam, water, gas, or steam & water mix applications.

- Safety functions during accidental conditions (Feed & Bleed)

- Protection of Loss of Coolant Accident; this unique feature guarantees reliable closing (Emergency Shut Off )

- Remote control (RO two signals to open)

APPLICATIONS

- Pressuriser Safety Valves

DESIGN STANDARDS

- All main standards including RCC-M level 1, ASME section III Sub. NB Class 1, OTT, IEEE, NNSAK1 – 1E qualified for applications within containment area of nuclear plants

DESIGN RATINGS

- ASME Class 150 to 2500 or customized

- ASME Class 150 to 2500 or customized

PRESSURE CLASS & POWER

- From 43 – 4350 psi (0.3 to 30 Mpa)

- 50 – 300 T/h (Saturated Steam) adaptable

SIZE RANGE & DIMENSIONS

- 0.5 – 16 inches (15 – 400mm) (DN 25 – DN400)

TEMPERATURE RANGE

- Up to 576°C (1069°F)

MATERIALS

- Stainless steel