Centrifugal pumps are the most common type of pumps used across any industry. These applications range from small-scale pumps within cars and household appliances to large industrial use such as oil and gas, water, power, and nuclear stations.

What are the functions of a centrifugal pump, and how is it made?

A centrifugal pump is a machine that uses the rotation of its impeller to impart velocity into a liquid. The speed and diameter of the impeller determines the amount of fluid moved and ultimately the pressure created.

The main components of a centrifugal pump are:

-

- Case – usually cast

- Impellers – usually cast

- Shaft – usually forged bar

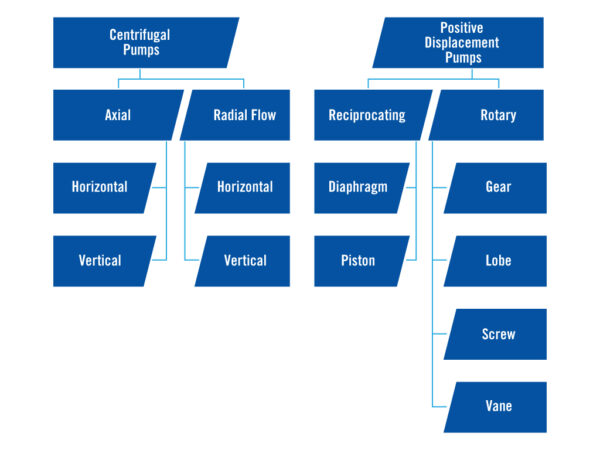

At the highest level, pumps can be split into categories as shown below. Within each section of pumps are many subgroups. API pump classifications are the most commonly used for centrifugal pumps.

The benefits of a centrifugal pump

When compared to positive displacement pumps, centrifugal pumps have the following advantages:

-

- No pressure pulsations

- Considerably higher flow capabilities

- Often lower cost

- Generally more reliable operation

What makes Trillium’s centrifugal pumps different?

Our pump brands have been around for centuries and provide an extensive range to suit almost every application. We invest in new product development and global service support for the entire lifecycle of the pumps.