Red Point®

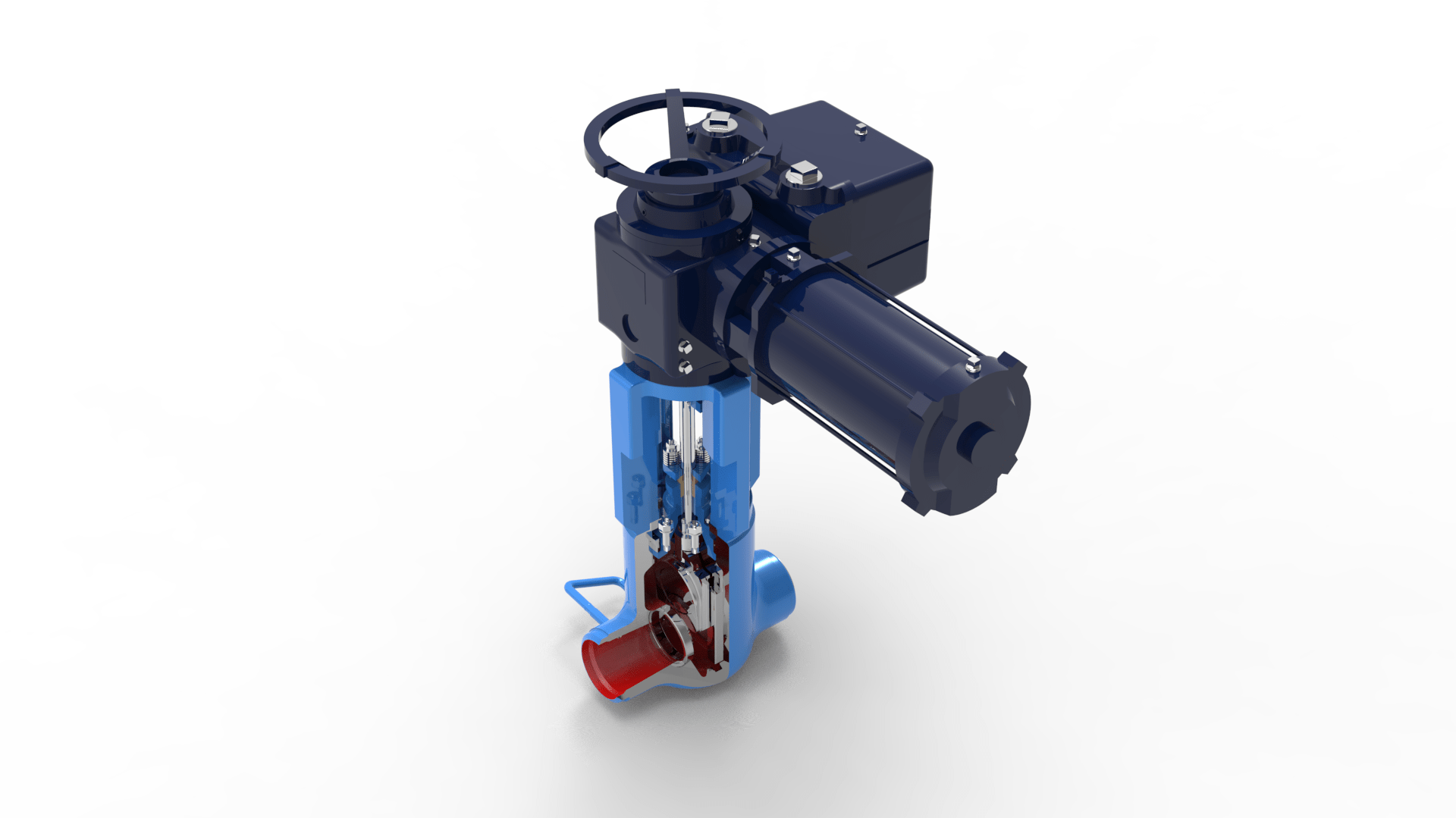

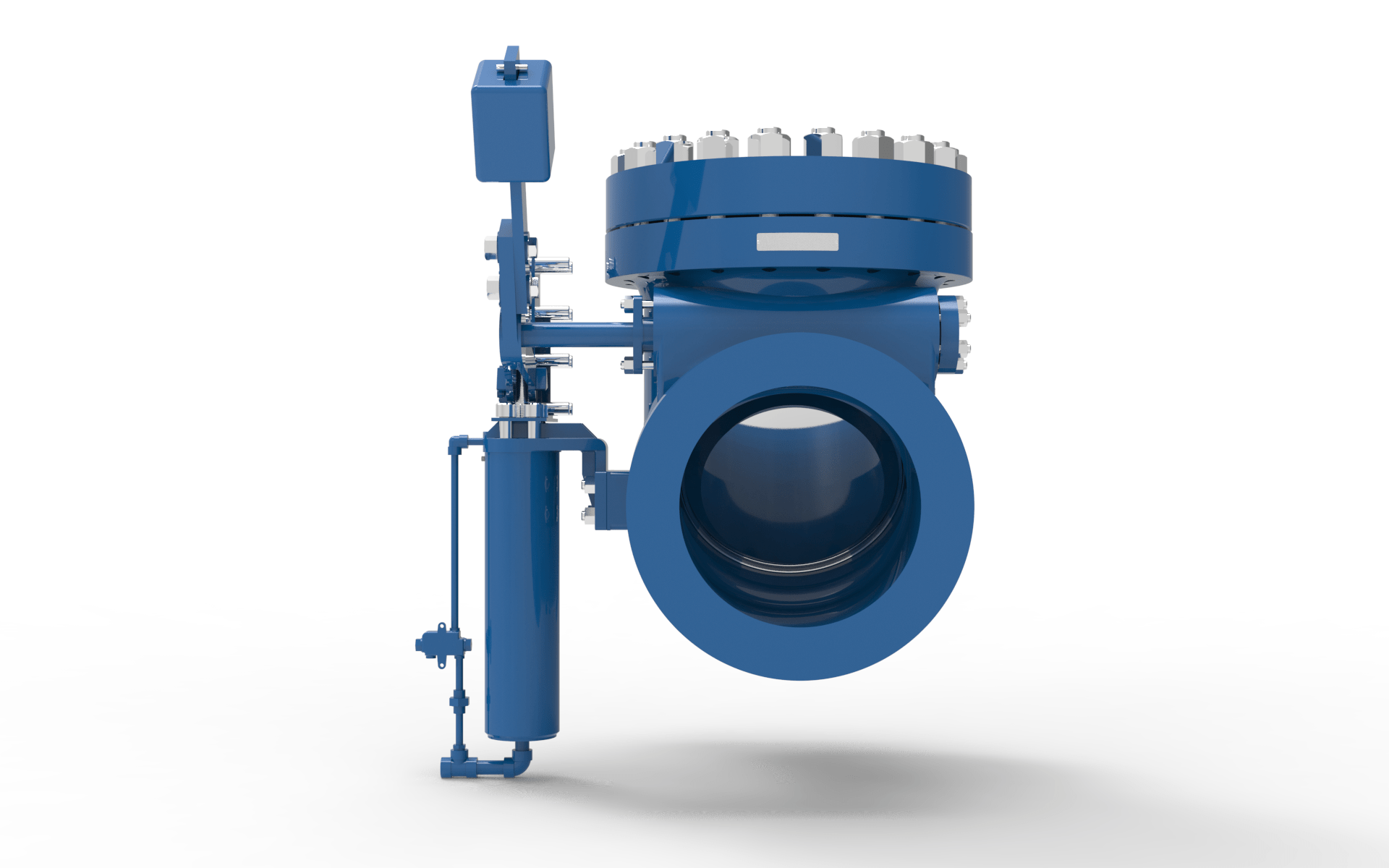

Bellow Sealed Gate Valves

In particular chemical processes the fluids in the pipes are often toxic, radioactive and hazardous. Bellow sealed valves are used to prevent leakage of any toxic chemical to the atmosphere. The bellow can be supplied in different materials like 316Ti, 321, C276 or Alloy 625. Body material can be selected from all available materials.

Our bellow sealed gate valves are available as forged or cast valves featuring exotic material options with short delivery times.

Advantages are:

- Long cycle life bellows – 3000 cycles

- Non-rotating stem prevents torsion of bellows.

- Two secondary stem seals: a) Backseat in open position; b) Graphite packing.

- Seating faces hardfaced with CoCr alloy, ground and lapped.

Type of wedge

- Flexible

- Solid

Construction

- Bolted

- Welded

- Extended

End connections

- Flanged

- BW

- SW

- THR

- HUB

- PE

Operated

- Handwheel

- Gear

- Bare Stem

- Actuator

Options

- Extended Bonnet

- Bellow Sealed

- Heating Jacket

- DBB Configuration

Bellow seal materials

- 304

- 321

- 316Ti

- Alloy 625

- C276

Design & testing

- All available international standards according to API, EN, ISO

- Thoroughly degreased and cleaned for O2 services

Size & bore

Forged Valves:

- ANSI 1” – 6”

- DN 25 to DN 100

Cast Valves:

- ANSI 6” to 16”

- DN 10 to DN 400

Pressure range

Forged Valves:

- ANSI 125 to 4,500 lbs

- ISO PN 10 to PN 640

Cast Valves:

- ANSI 125 to 2,500 lbs

- ISO PN 10 to PN 400