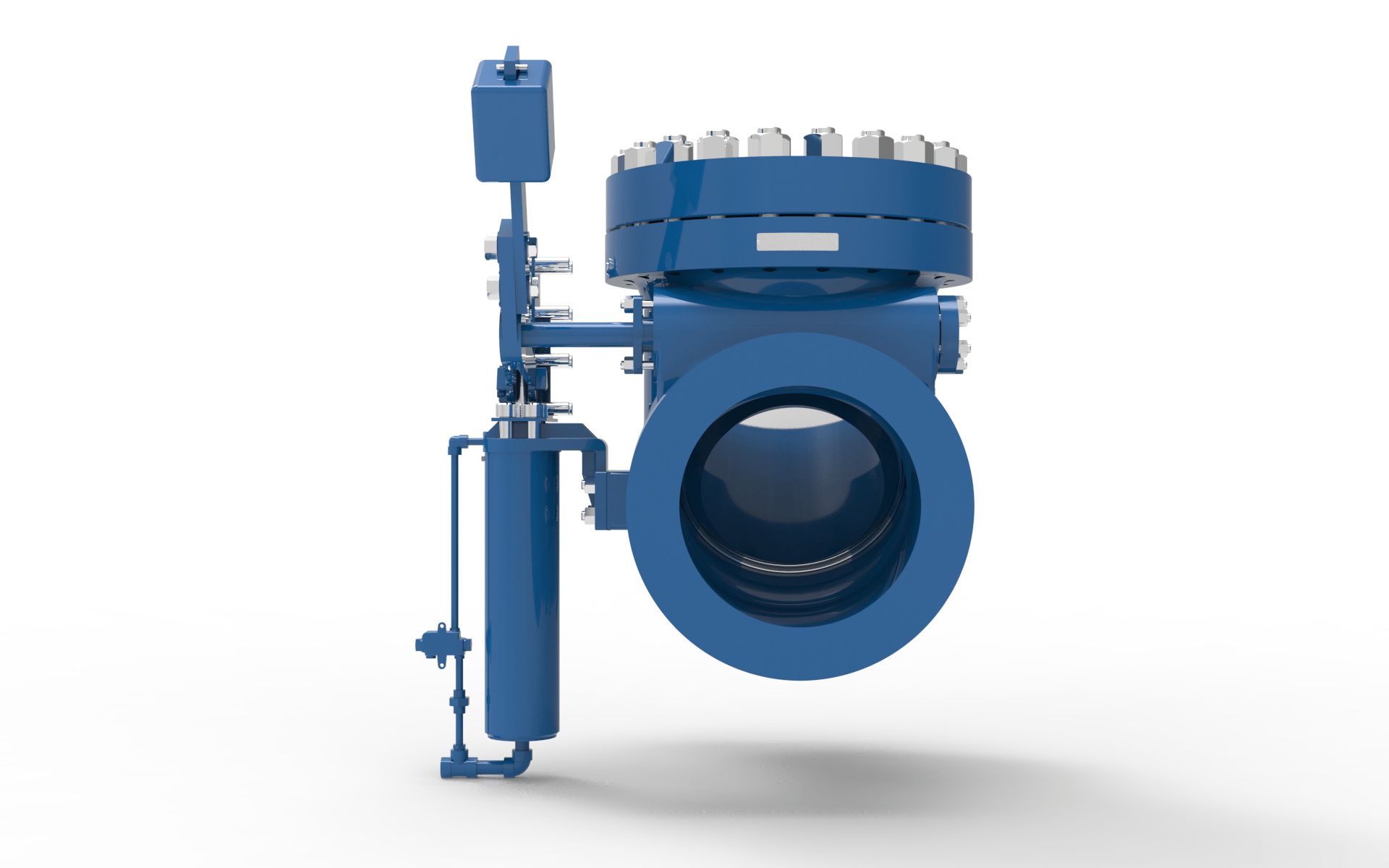

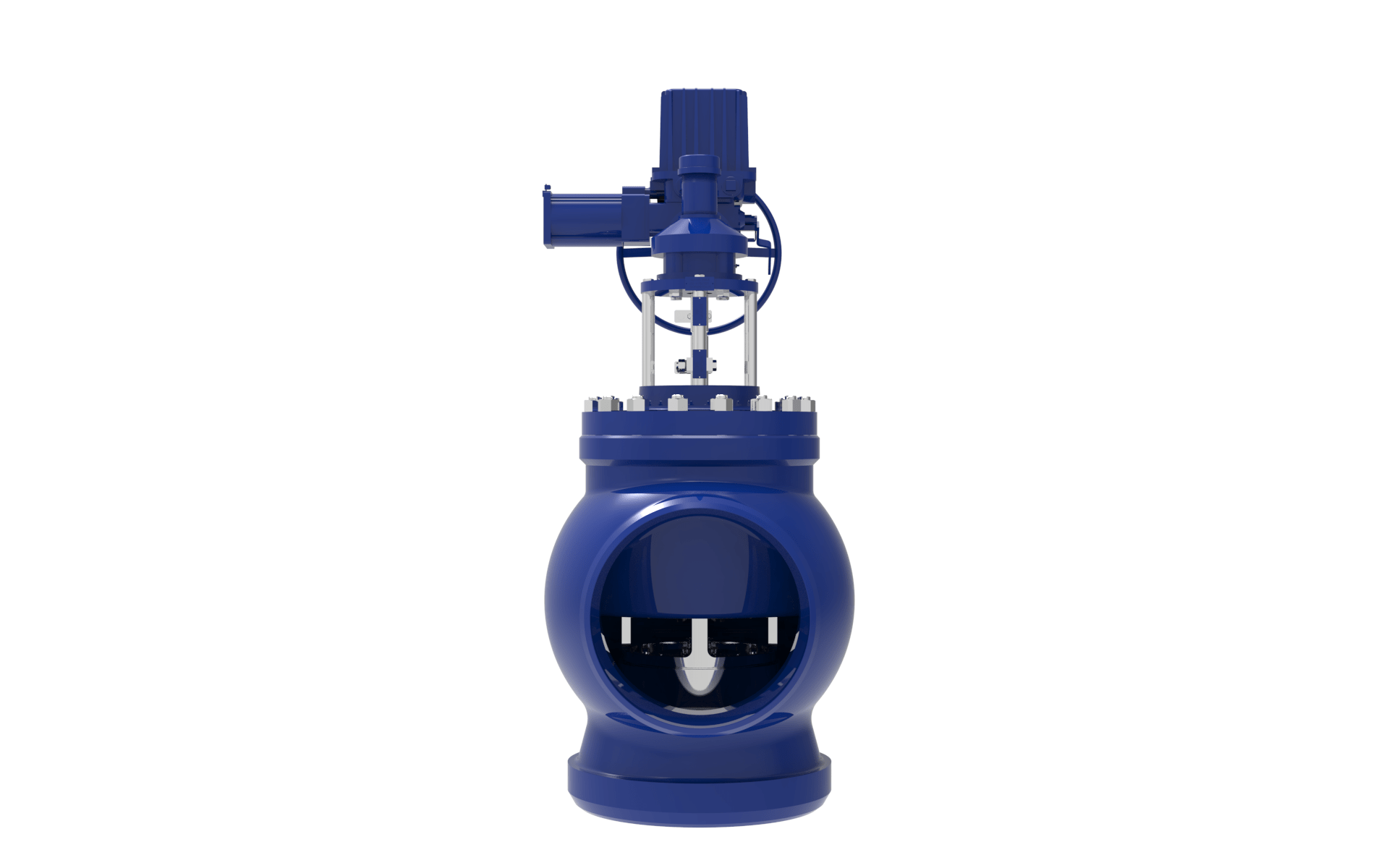

Atwood & Morrill®

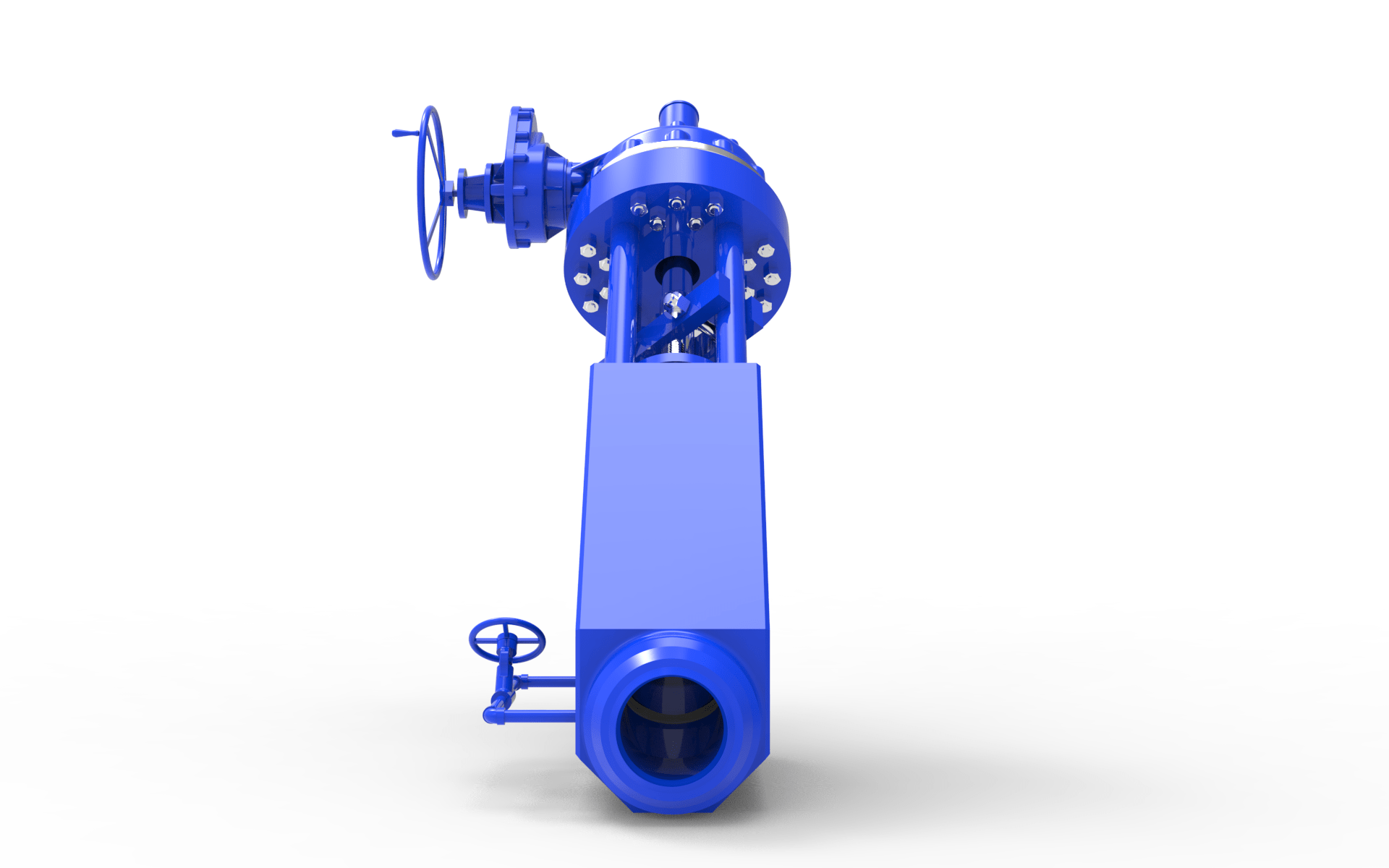

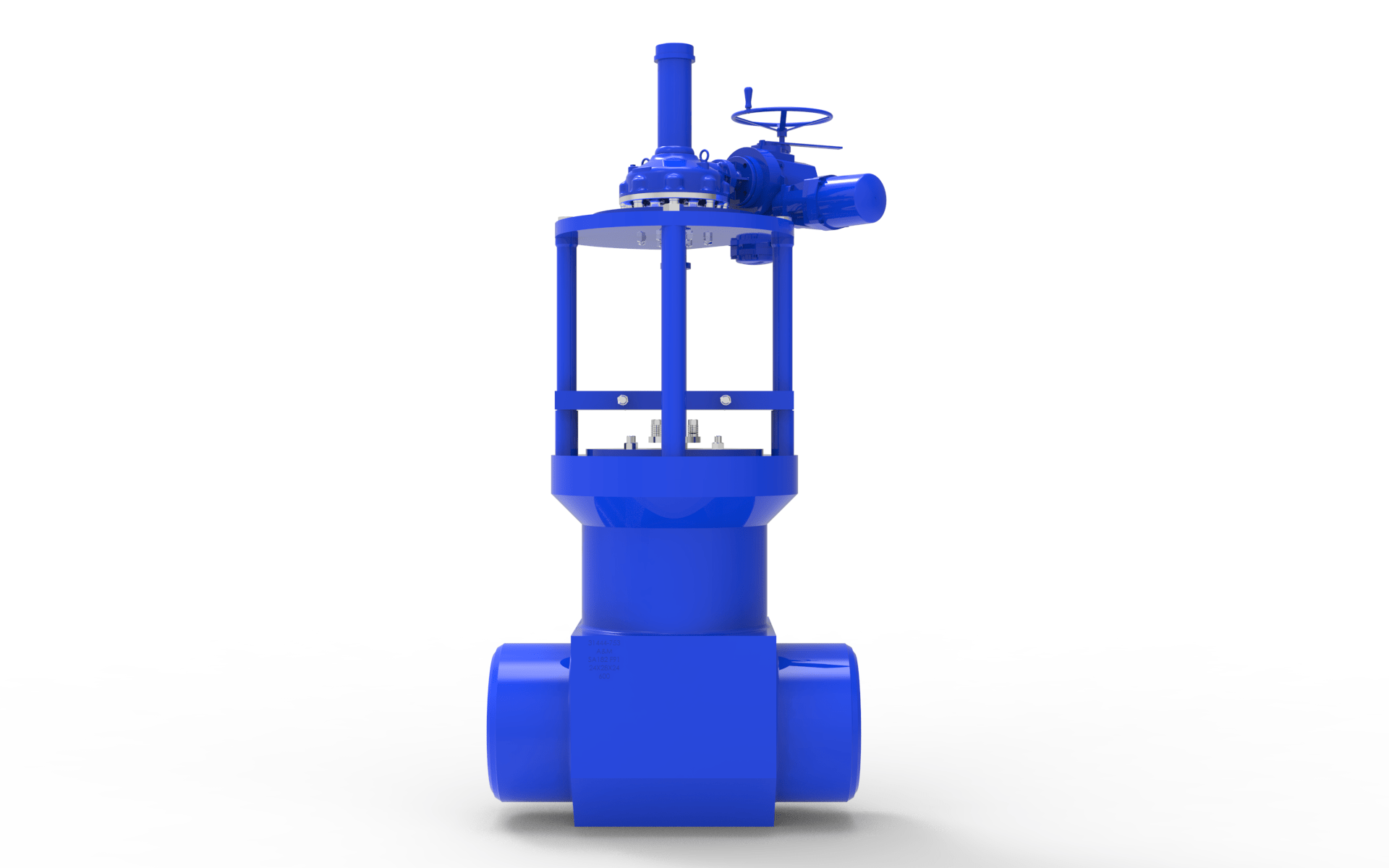

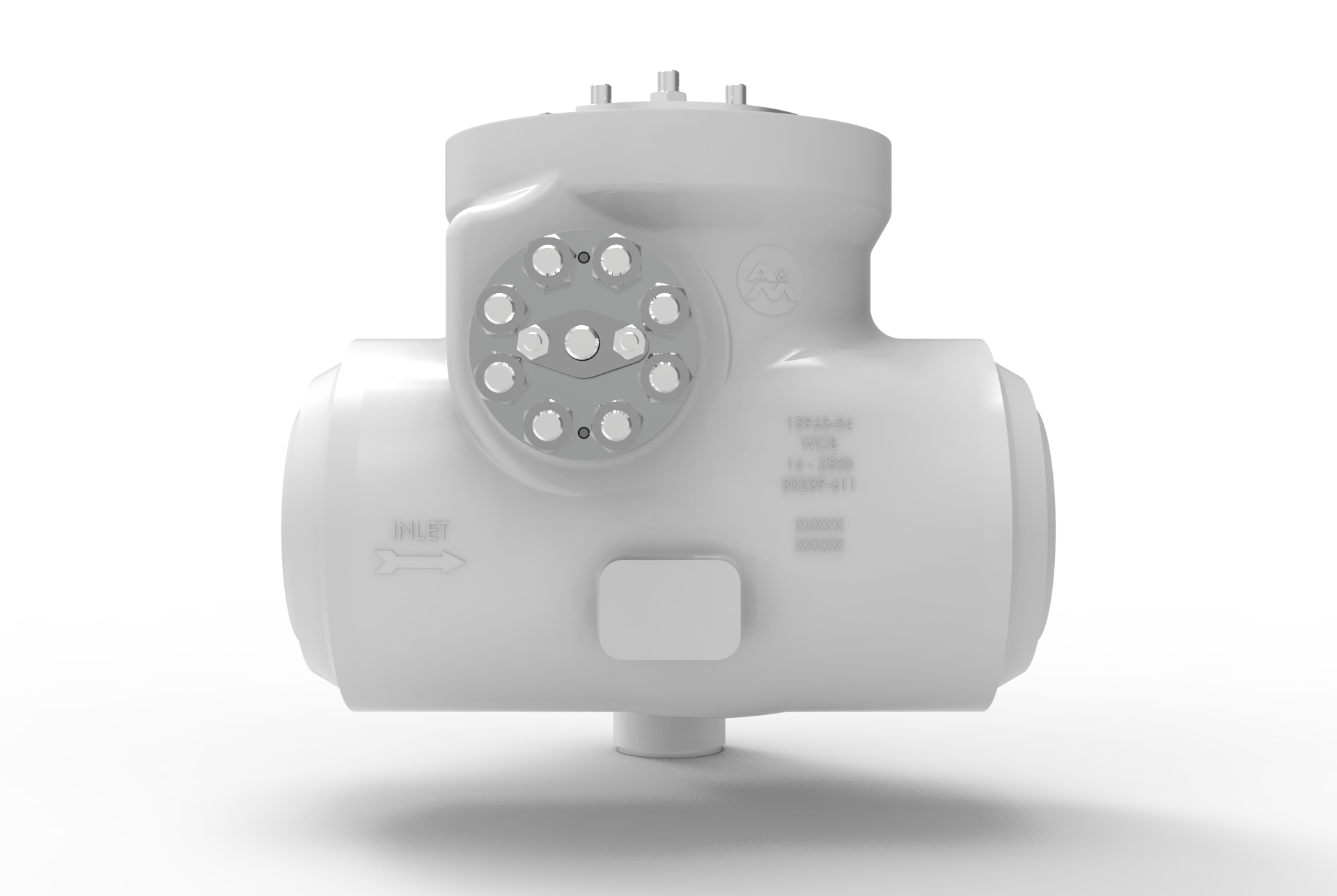

FREE FLOW® Reverse Current Valve

FREE FLOW® Reverse Current valves are designed to give maximum protection to extraction steam turbines. Their rapid, tight closure ensures that the high level of energy found in feedwater heaters or process lines is quickly isolated from the turbine in the event of a load rejection.

KEY FEATURES & BENEFITS

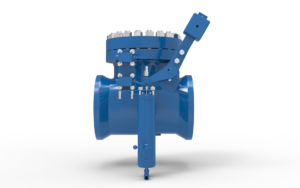

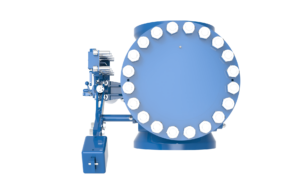

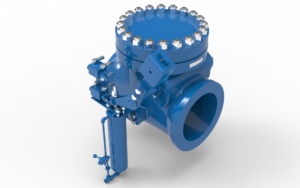

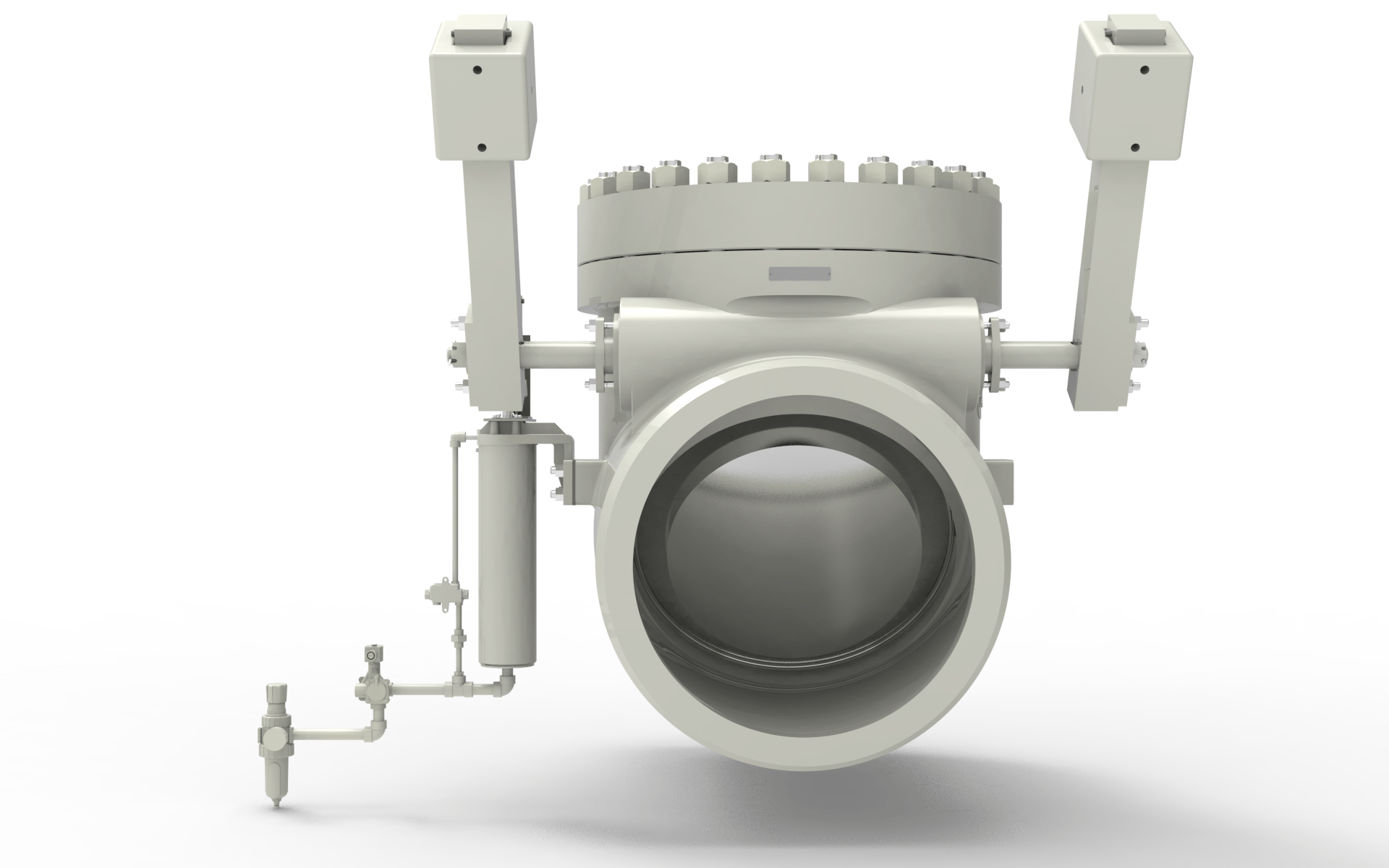

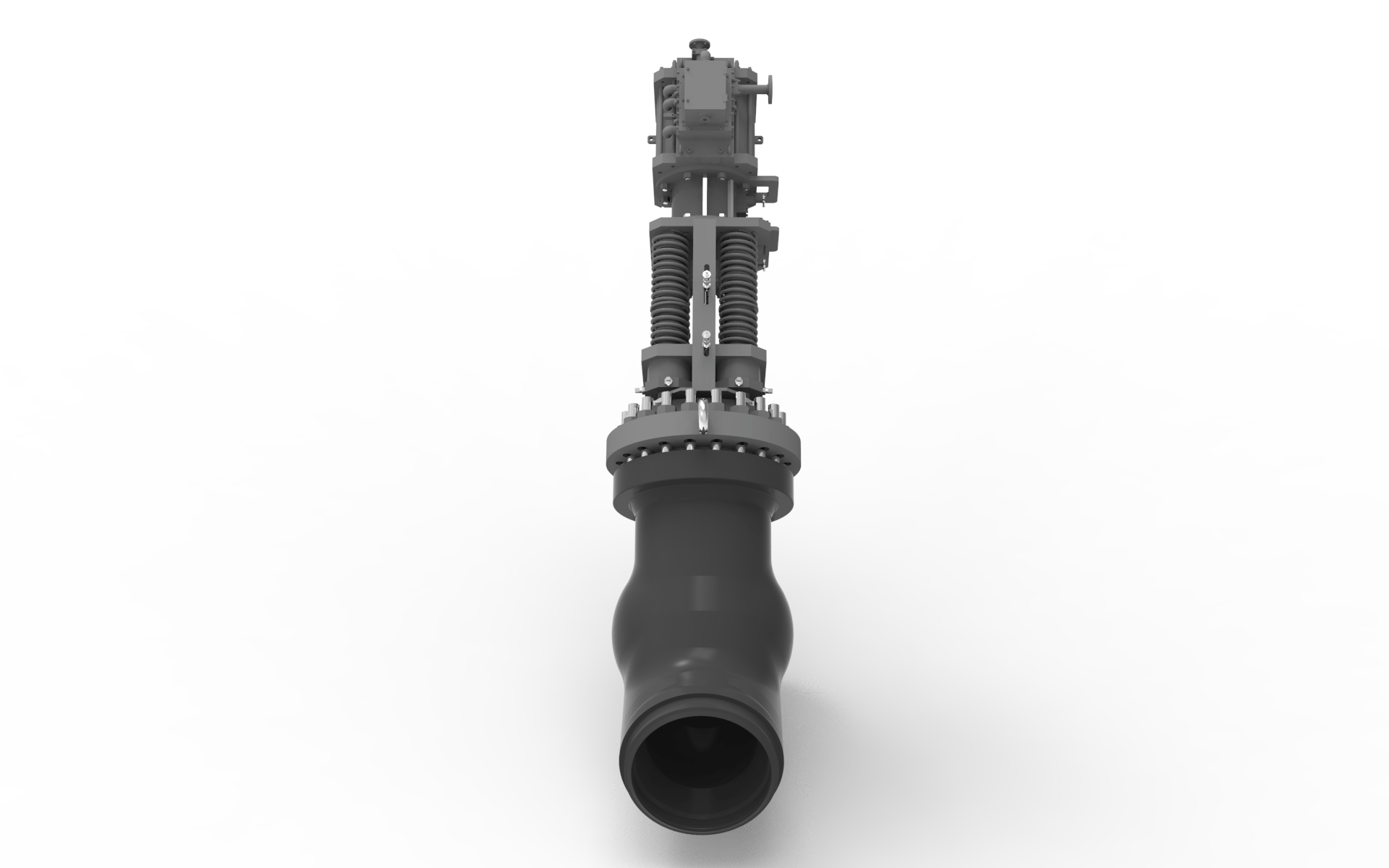

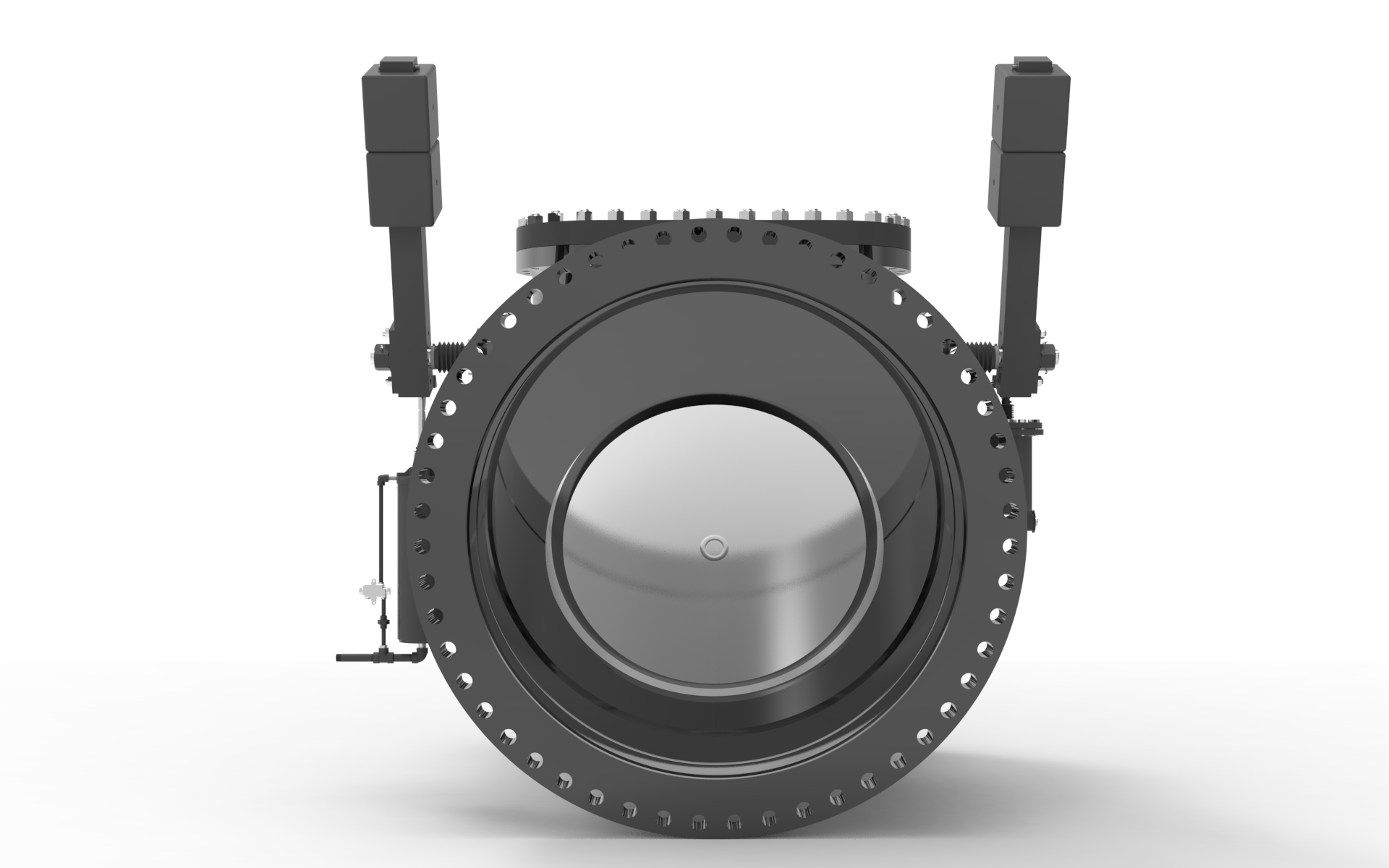

- Free swinging disc allows independent movement of the disc with assured closure upon loss or reversal of flow. Inclined seat design optimizes performance with low pressure drop and fast closure.

- Self-aligning disc & disc arm assures repeatable tight sealing.

- Air cylinder provides closing moment to shaft upon control room signal.

- Lost motion feature enables valve disc to close independently of the air cylinder position.

SPECIFICATION

- Design standards: ASME B16.34

- Pressure class range: ASME Class 150 to 2500

- Size range: 3 – 48 inches (80 – 1100 mm) & larger

- Temperature range: Up to 1,200ºF

- Materials: Carbon steel, alloy steel, stainless steel, F91 Austenitic stainless steel

- Upgrades & Adaptations: Air cylinder modification, Packing upgrade, Mechanical seal replacement, Live load packing

APPLICATIONS

- Steam turbine protection

- Extraction steam non-return

- Bleeder trip & bled steam non-return