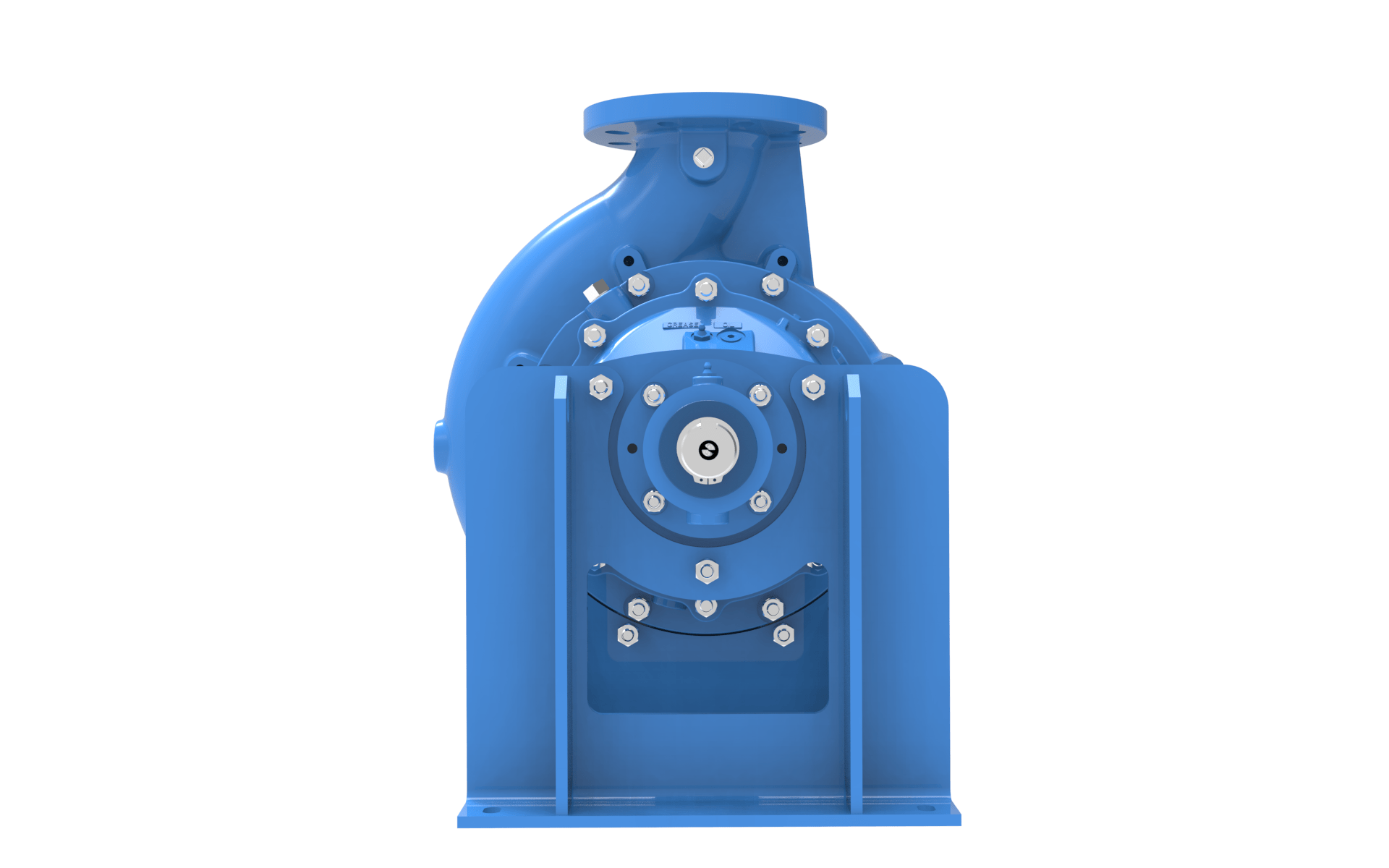

WEMCO®

Screw-Flow

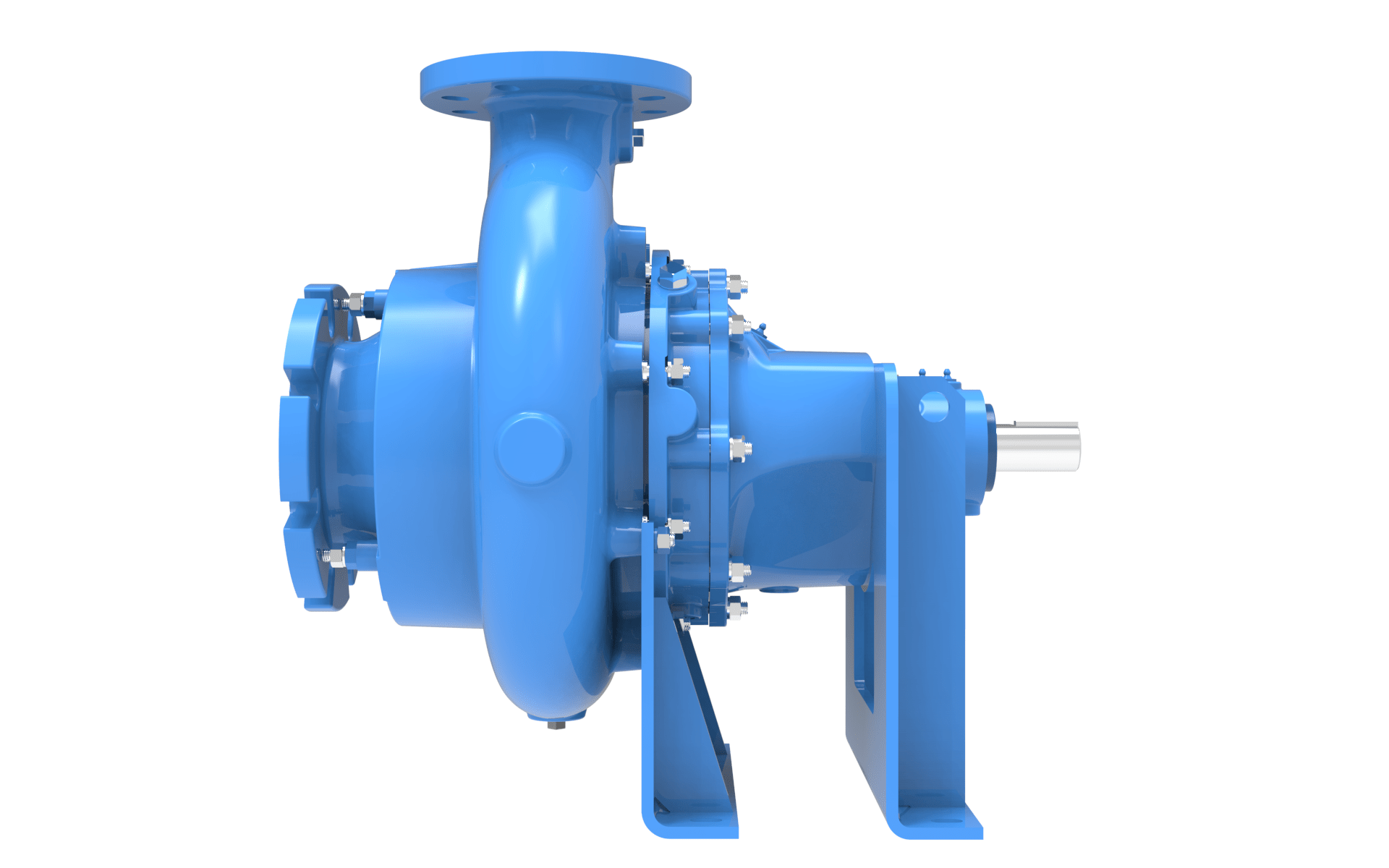

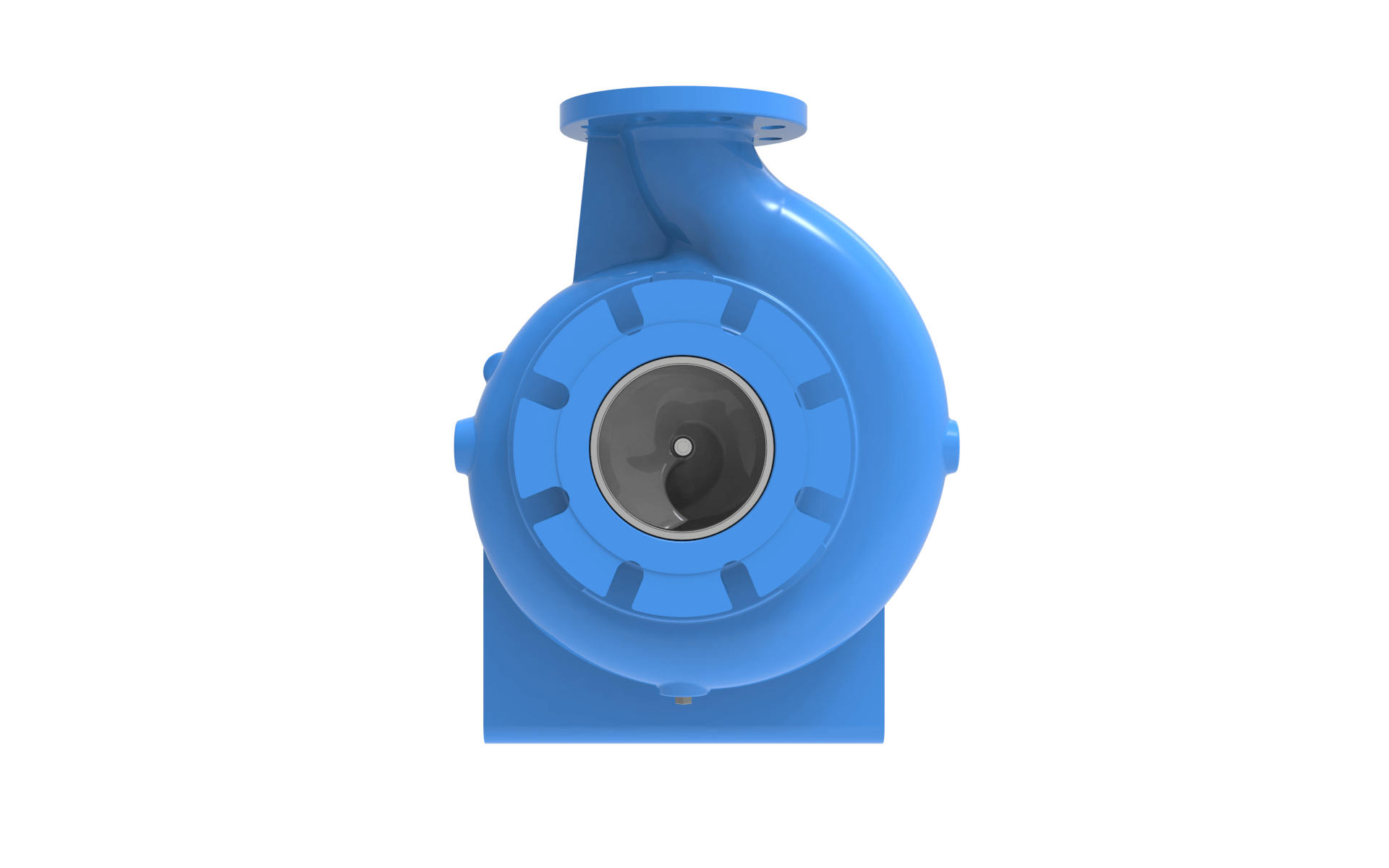

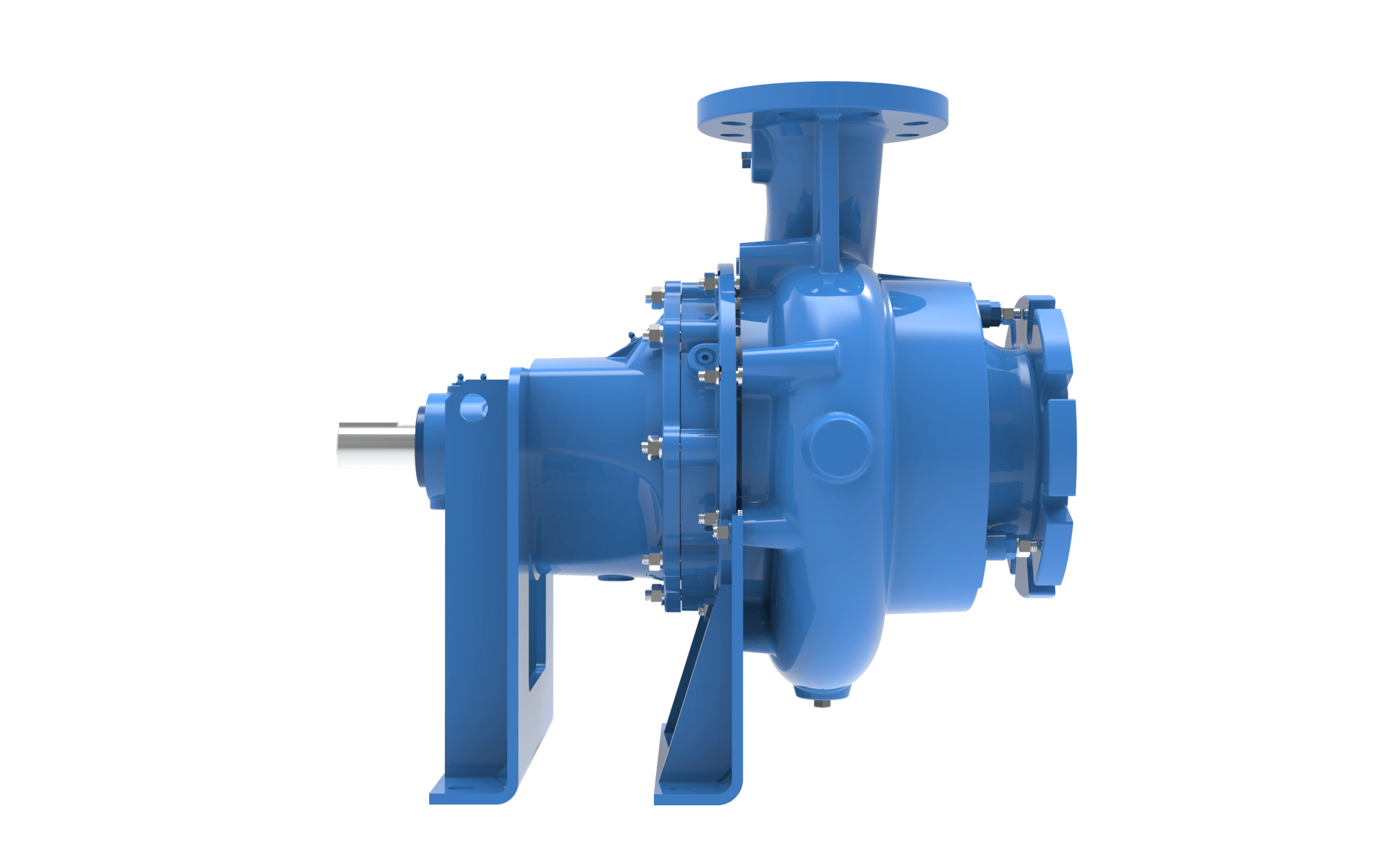

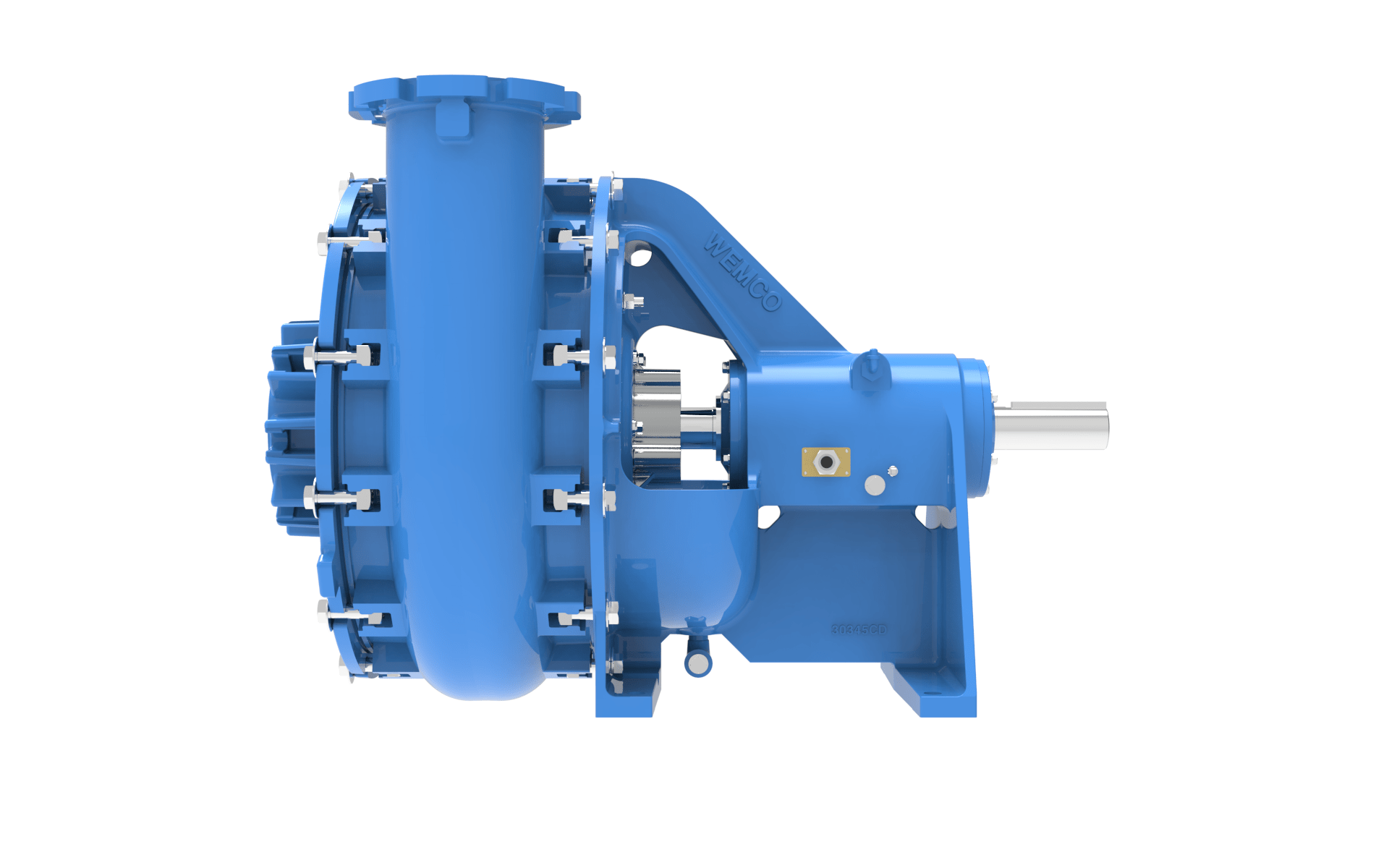

The WEMCO® Screw-Flow centrifugal pump is equipped with a classic single vane screw centrifugal impeller.

WEMCO® applies advanced pump design technology to increase product performance, reduce cost, and improve lead time. The long-established screw centrifugal design provides clog-resistant pumping for trouble free movement of solids, fibrous, and stringy materials. The steep head-capacity curve produced by the impeller provides additional head to help push through any partial blockages.

KEY FEATURES & BENEFITS

- High efficiency

- Low NPSH requirements

- Steep head & capacity curve

- Adjustable liners

- Solids passage: 2.5 – 7.38 inch

- High Chrome Iron impeller & liner

- Many sealing arrangements available, including flushed packing, flushed mechanical seals, and flushless tandem seals.

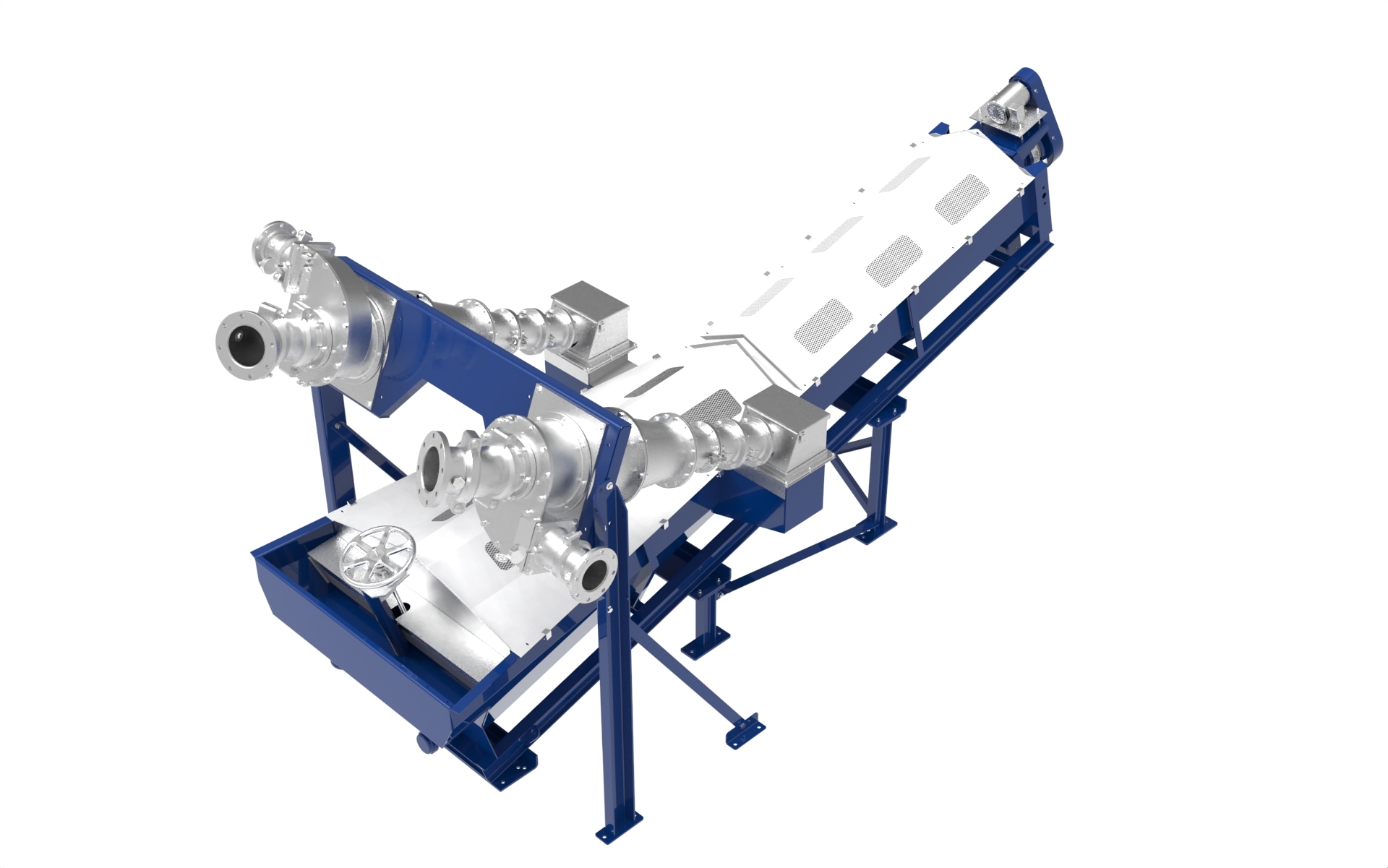

APPLICATIONS

- Sludges

- Raw & unscreened sewage

- Paper stock & wood chips

- Wet well cleanup

- Crystalline compounds

- Bacterial Floc

- Easily damaged fruits & vegetables

- Coal

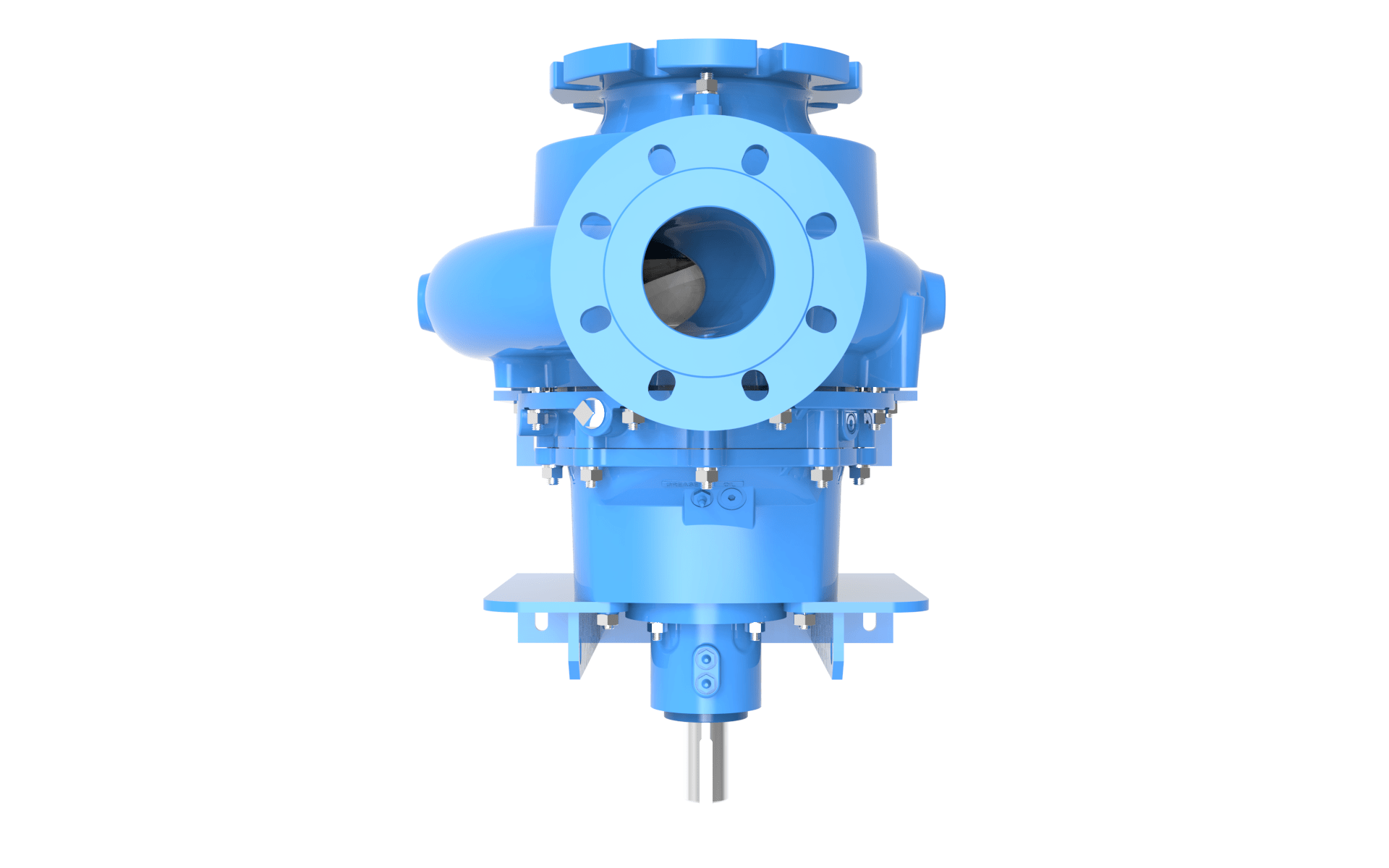

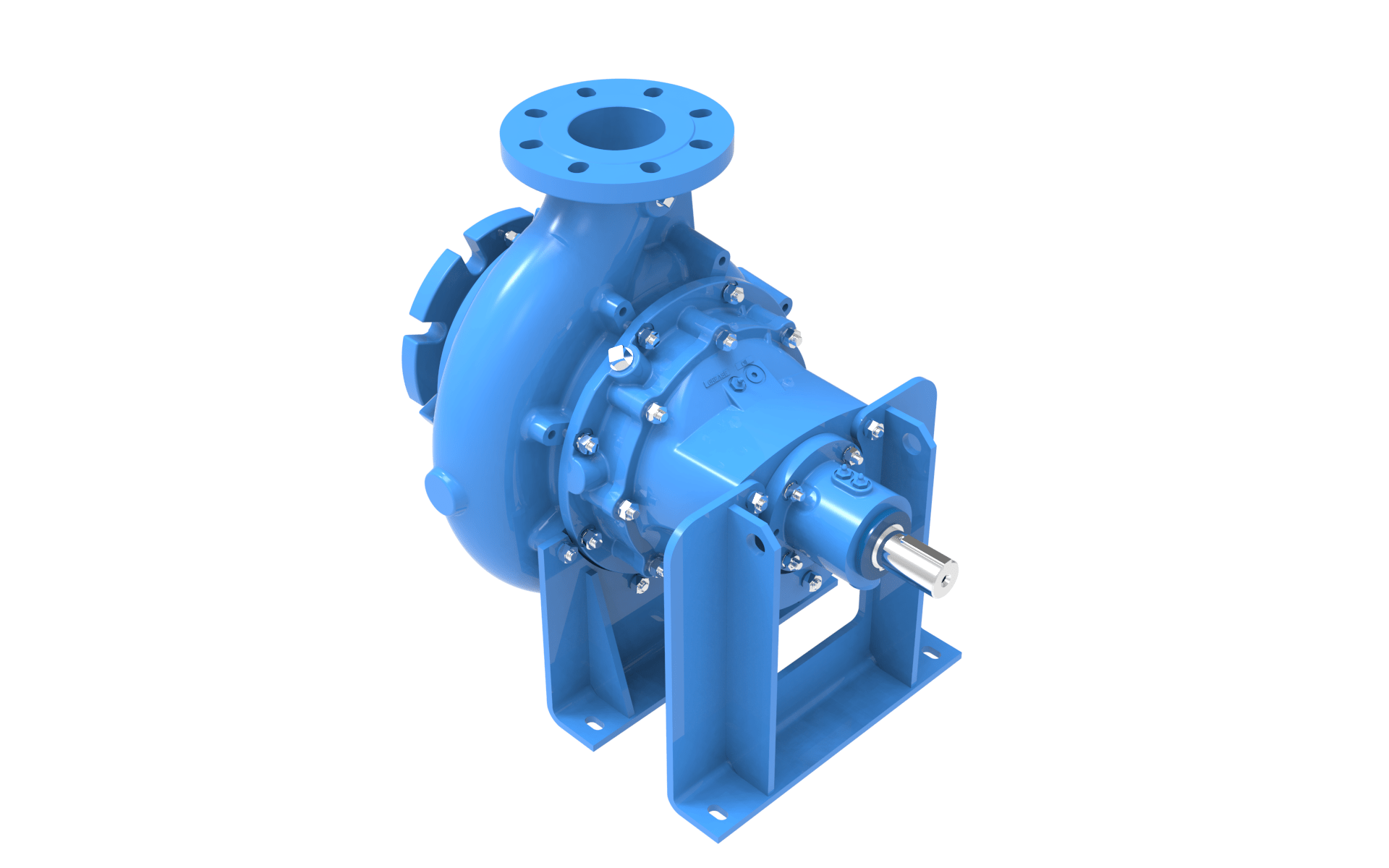

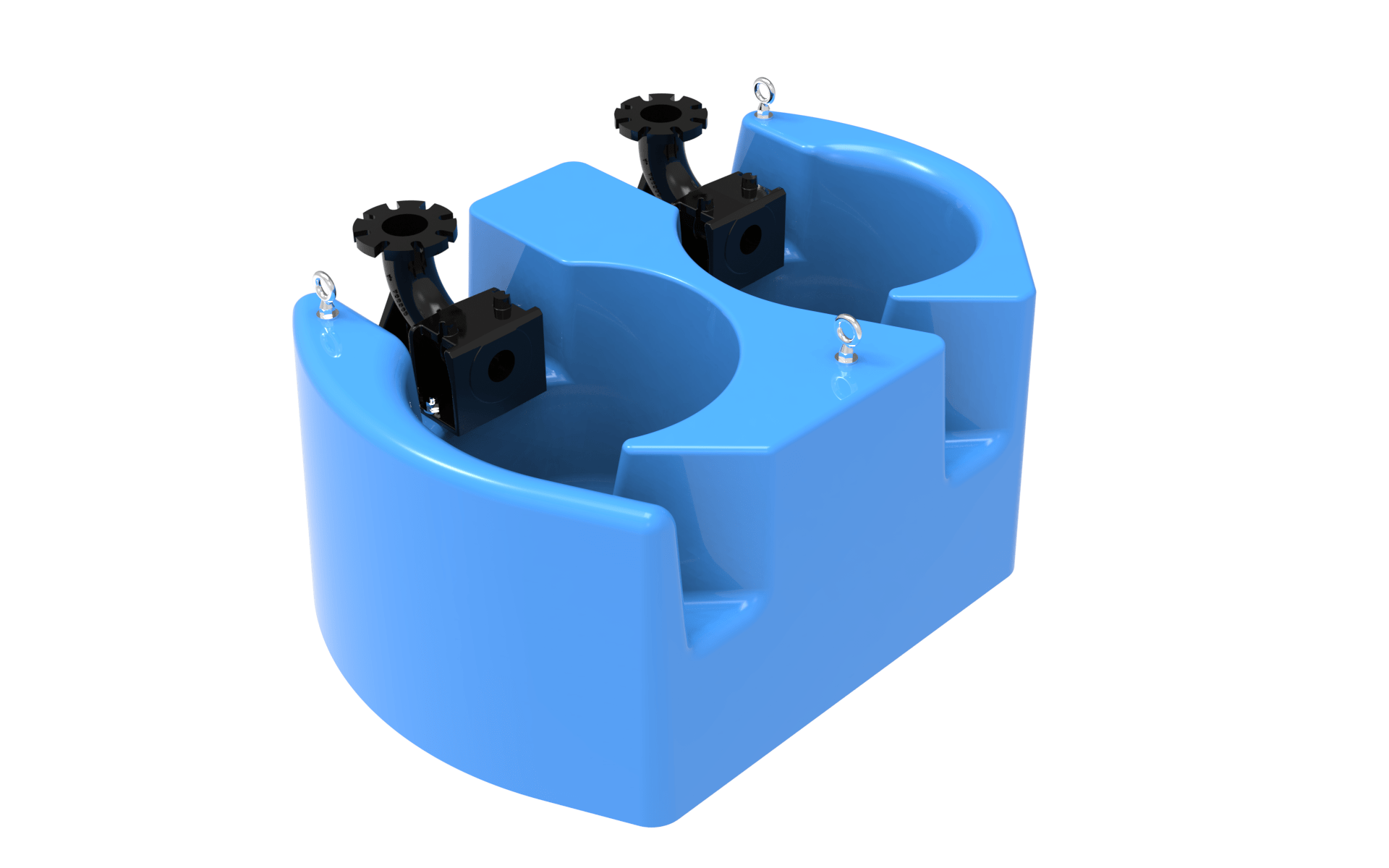

- Configurations

- Horizontal

- Vertical

- Submersible

- Prerotation

SIZE RANGE & DIMENSIONS

- 3 – 16 inch

PRESSURE CLASS & POWER

- Up to 300 ft. (91 m)

TEMPERATURE RANGE

- 32°F – 180°F (0°C – 82°C)

CAPACITY

- 15,000 GPM (31400 m3/h)

ADVANTAGES OF THE WEMCO® SCREW-FLOW CENTRIFUGAL PUMP

- Low NPSH: The screw portion of the WEMCO® Screw-Flow Centrifugal impeller performs as an inducer, pulling liquid into the impeller, resulting in low NPSH requirements.

SOLIDS HANDLING

- The single vane impeller of the WEMCO® Screw-Flow centrifugal pump creates a single channel flow, allowing for larger solids passage. The large solids passage provides better solids handling capabilities than any other pump type. The steep head-capacity curve provides ample reserve pressure to clear temporary clogs.

SLUDGE HANDLING POSITIVE SUCTION

- The combination of a low NPSH requirement and large solids channels provides a powerful pump for handling thick sludges. The steep head-capacity curve of the WEMCO® Screw-Flow centrifugal pump also allows for pumping of varying sludge consistencies without the need to change speed. An additional benefit is the reserved head for clearing temporary line blockages.

ADJUSTABLE LINER

- Consistent impeller to liner clearance is imperative to the performance of the pump. As the pump components wear, clearance between the impeller and liner can be adjusted to ensure optimal performance.