Red Point®

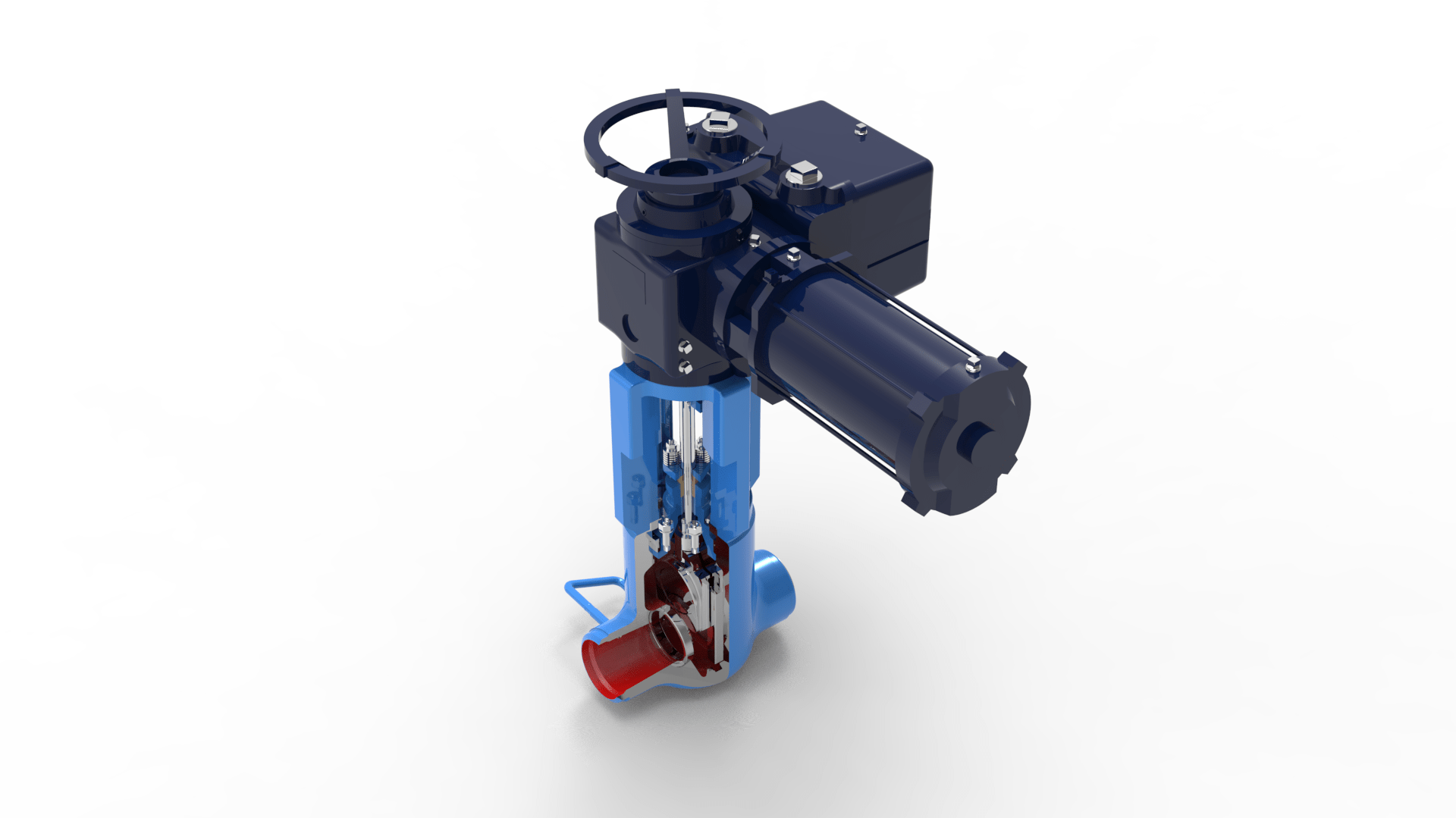

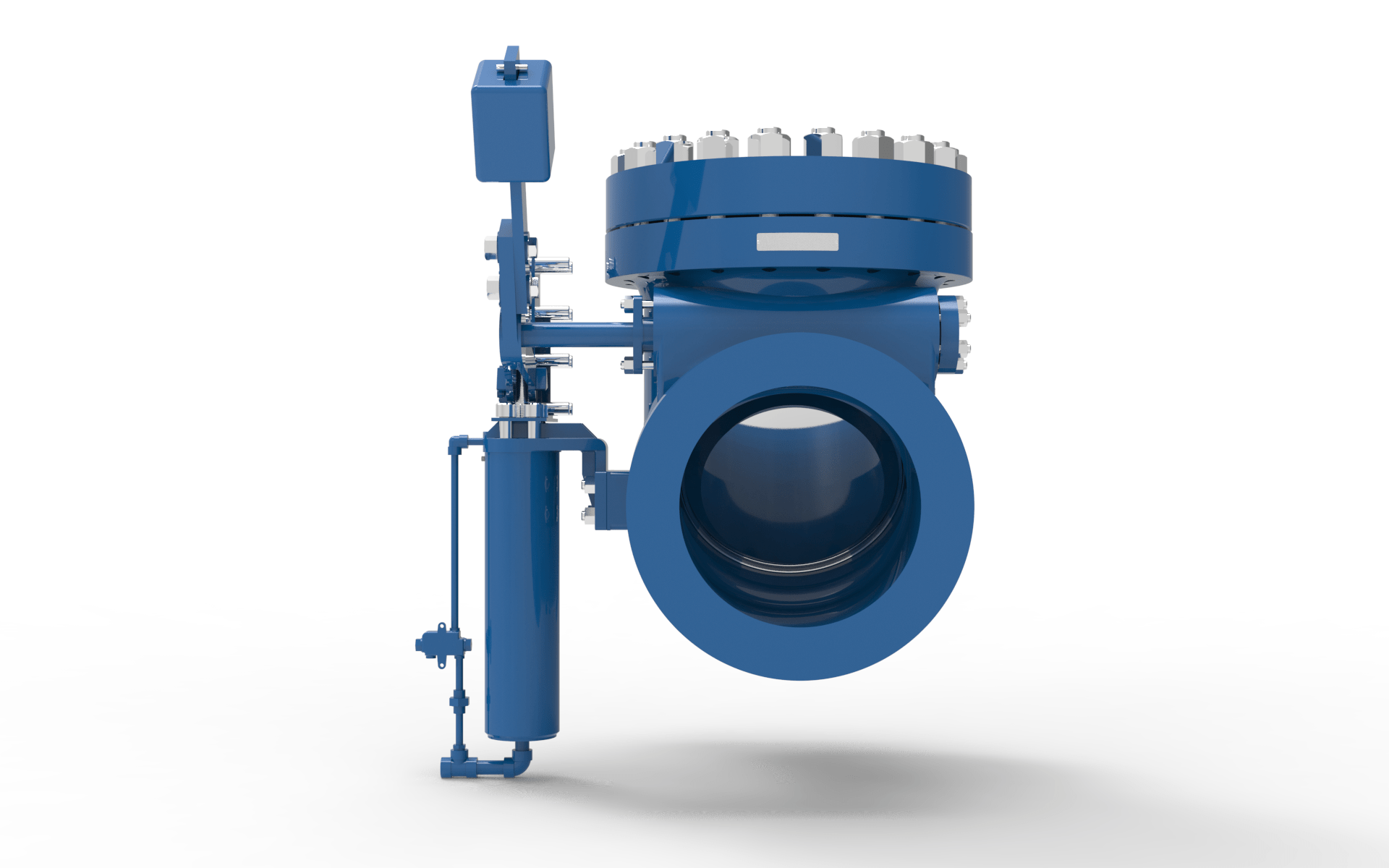

Through Conduit Gate Valves

Through conduit gate valves are used in applications like: offshore platforms, onshore terminals, transmission lines.

Commonly used types of medium in these applications are: non-corrosive liquids, gas, water, sour service, hydrocarbon liquids or gas.

Our through conduit gate valves are available as forged or cast valves featuring exotic material options with short delivery times.

Type of wedge

- Solid Slab

- Expanding Wedge

End connections

- Flanged

- BW

- SW

- THR

- HUB

- PE

Options

- Extended Bonnet

- Bellow Sealed

- Heating Jacket

- DBB Configuration

Bellow seal materials

- 304

- 321

- 316Ti

- Alloy 625

- C276

Size & bore

Forged Valves:

- ANSI 1” – 6”

- DN 25 to DN 100

Cast Valves:

- ANSI 6” to 16”

- DN 10 to DN 400

Construction

- Pressure Seal Bonnet

Operated

- Handwheel

- Gear

- Bare Stem

- Actuator

Through Conduit

- Expanding wedge or slab gate construction

Design & testing

- All available international standards according to API, EN, ISO

Pressure range

Forged Valves:

- ANSI 125 to 4,500 lbs

- ISO PN 10 to PN 640

Cast Valves:

- ANSI 125 to 2,500 lbs

- ISO PN 10 to PN 400