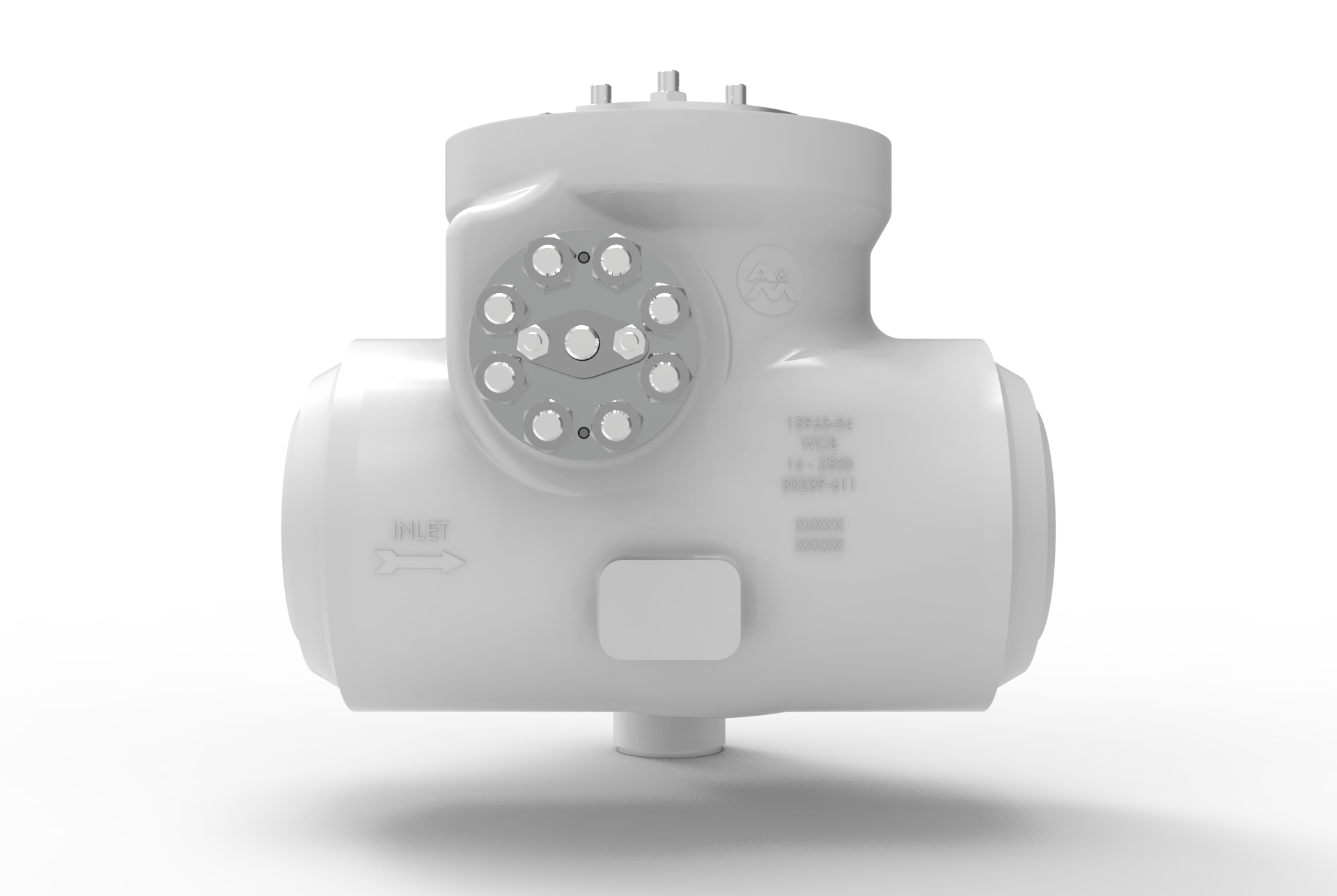

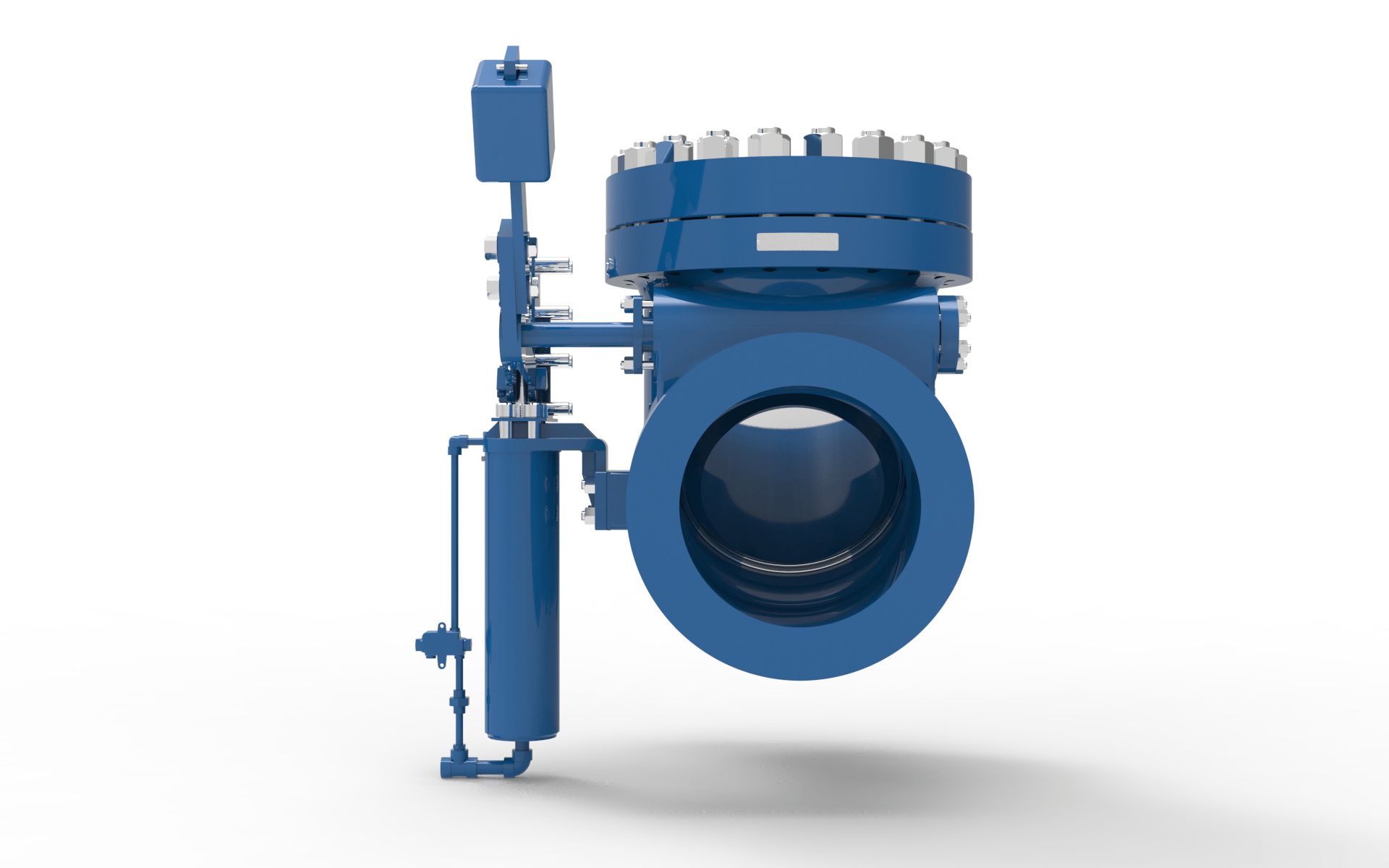

Atwood & Morrill®

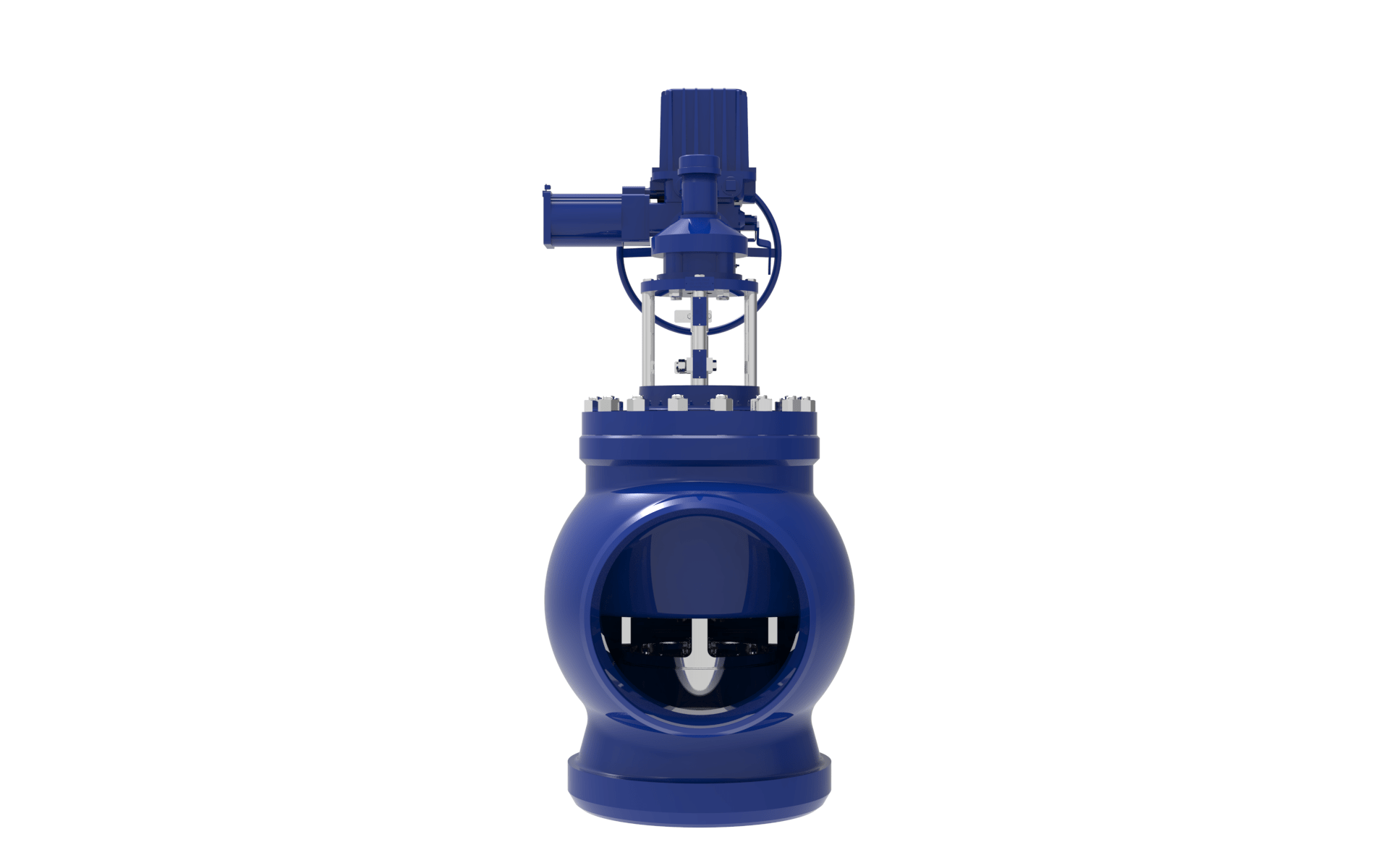

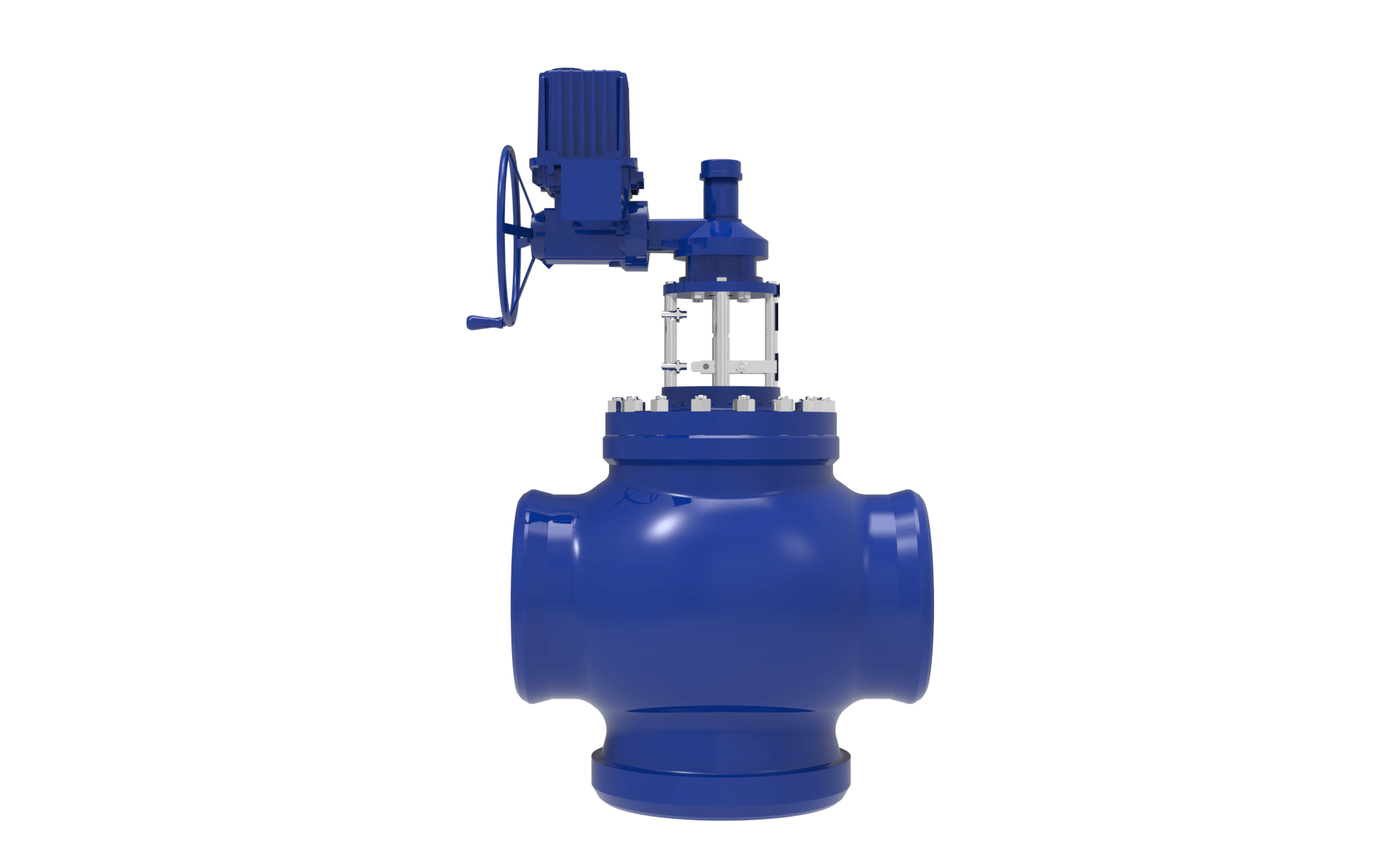

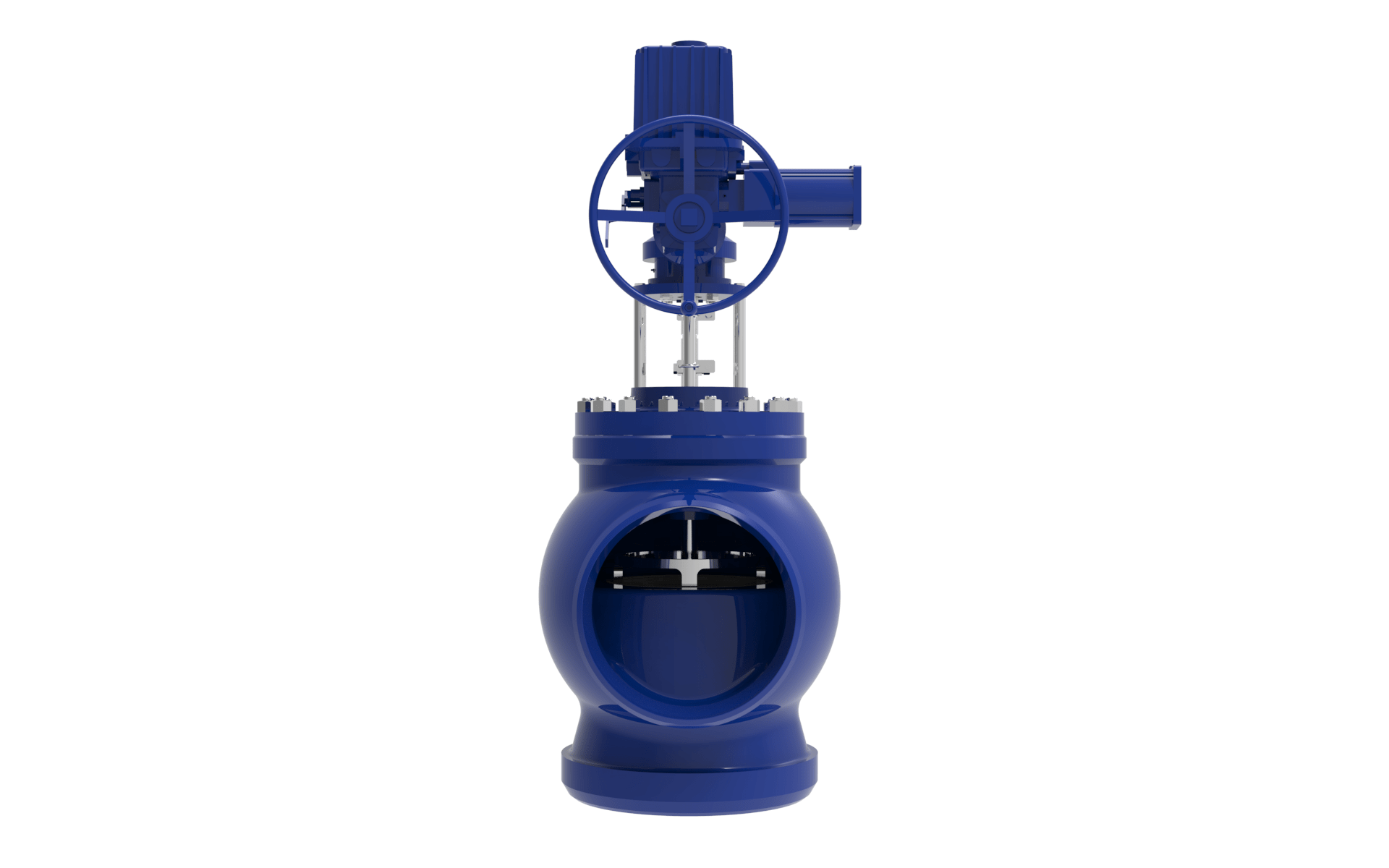

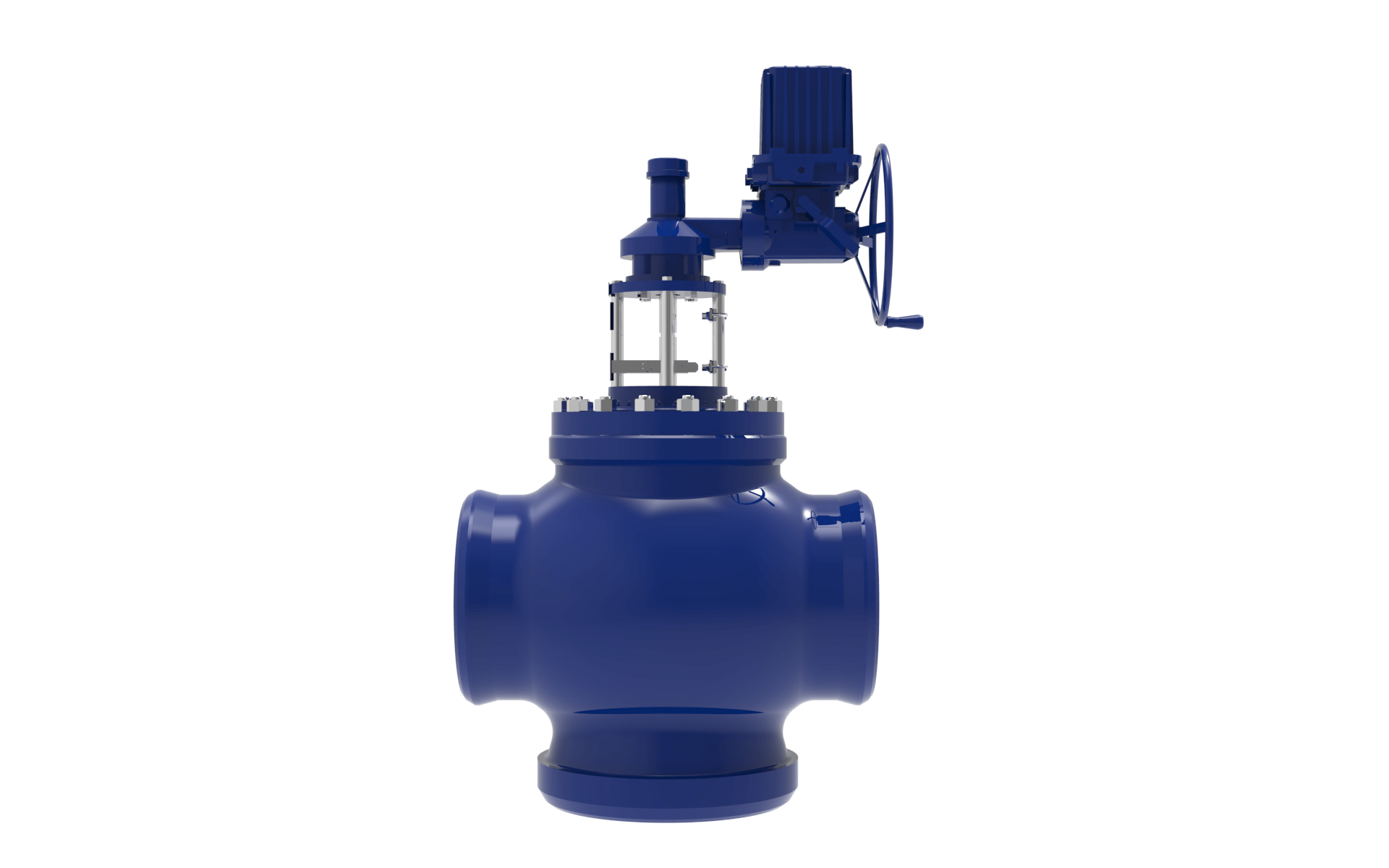

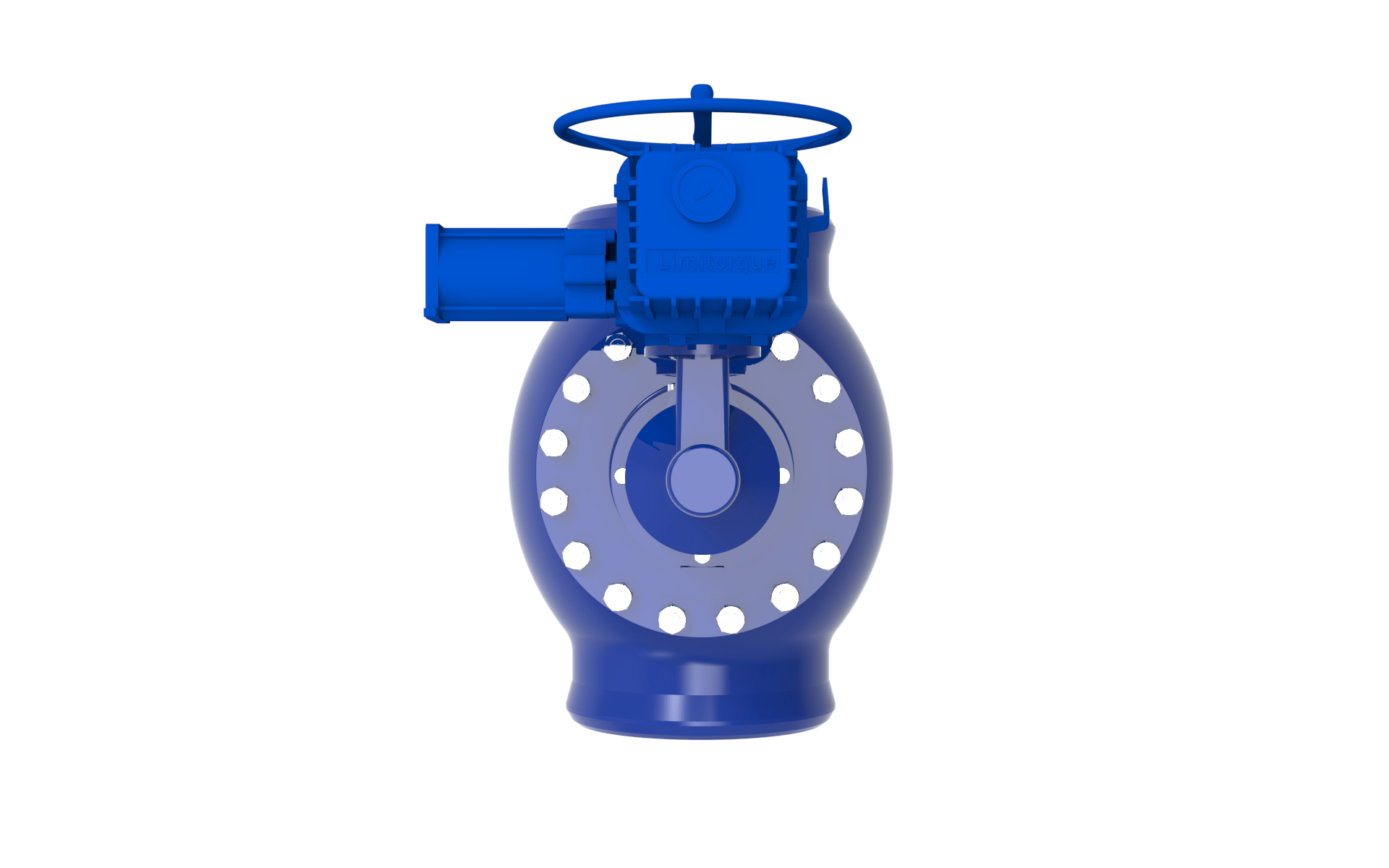

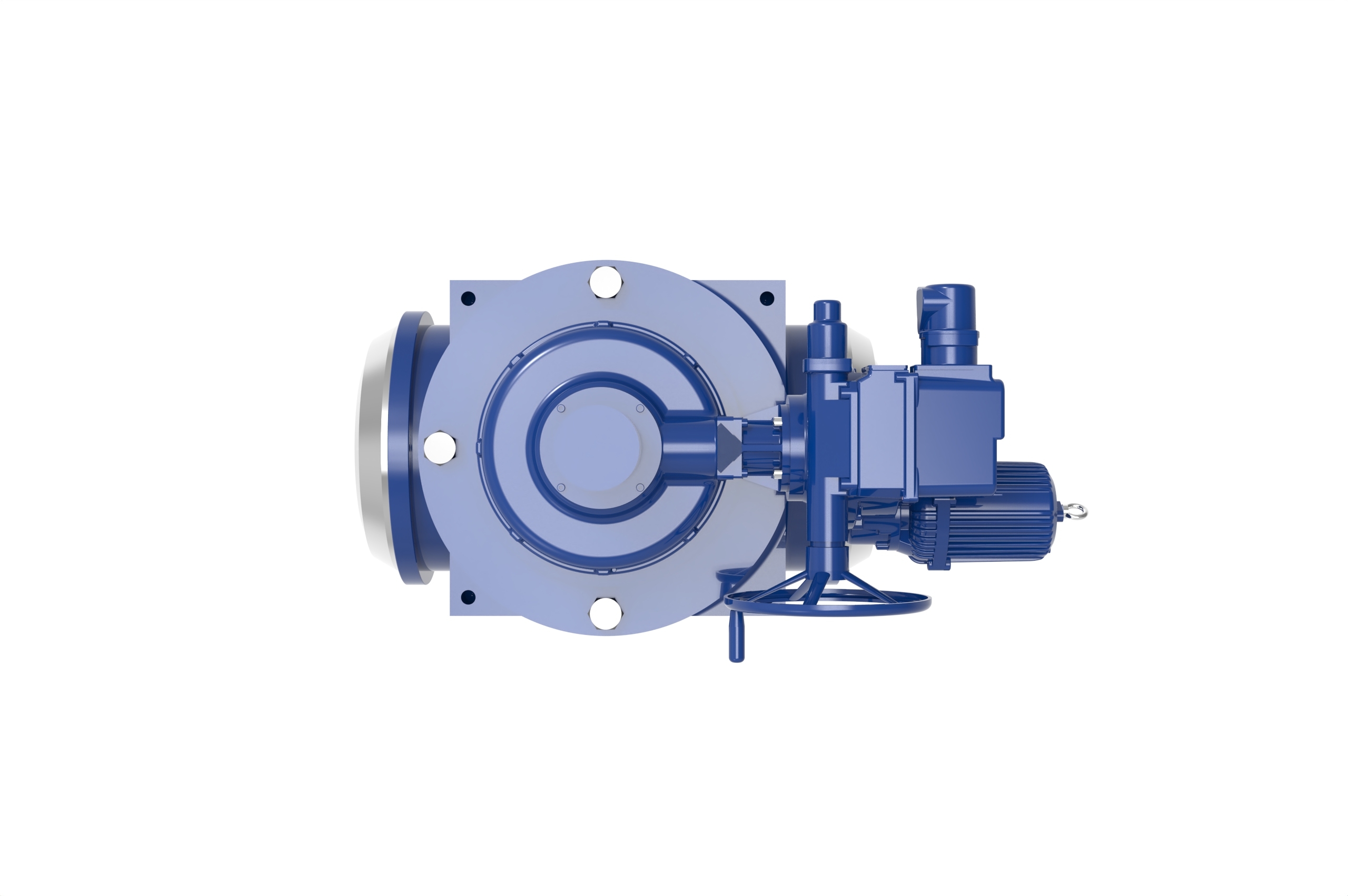

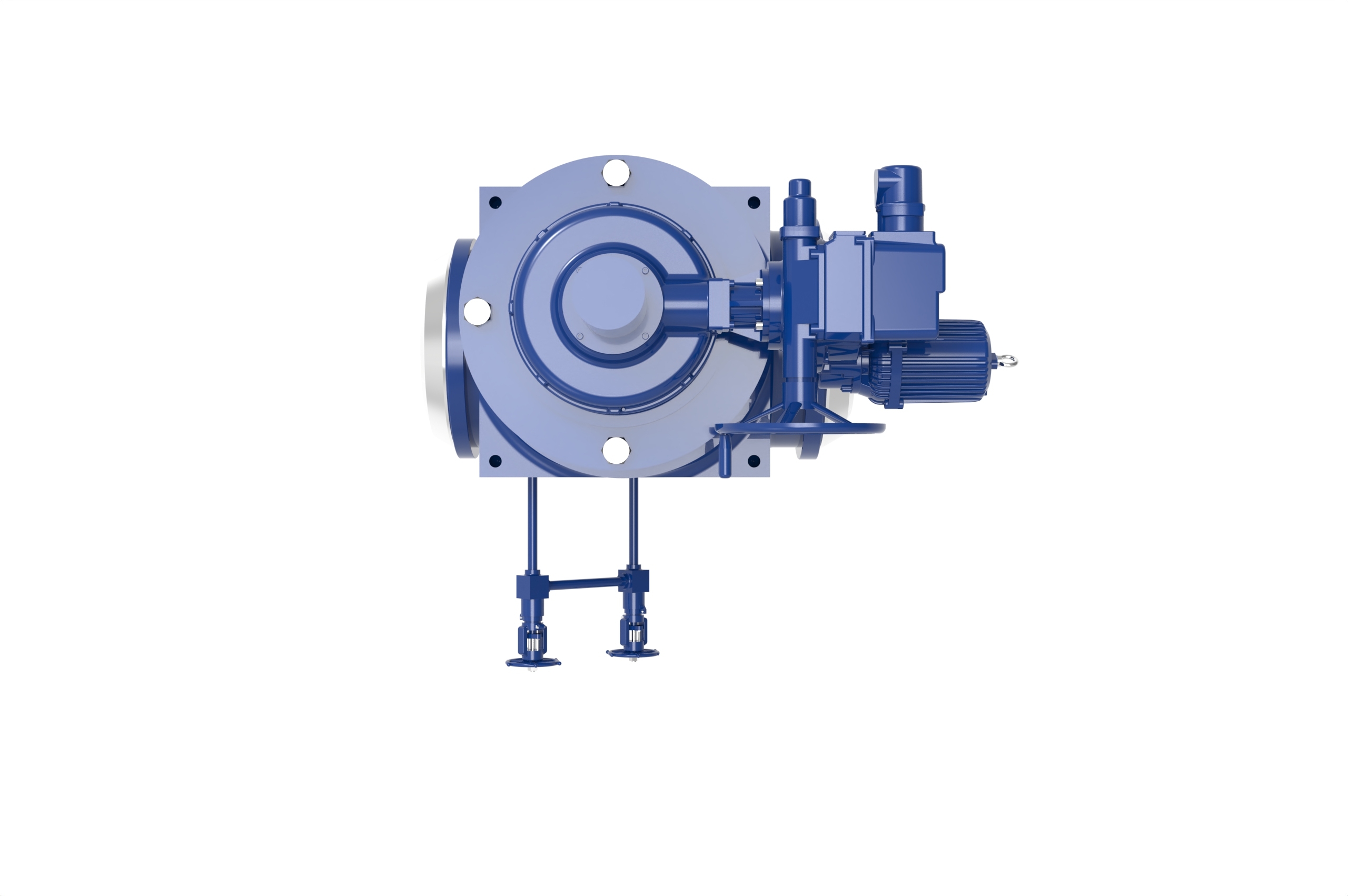

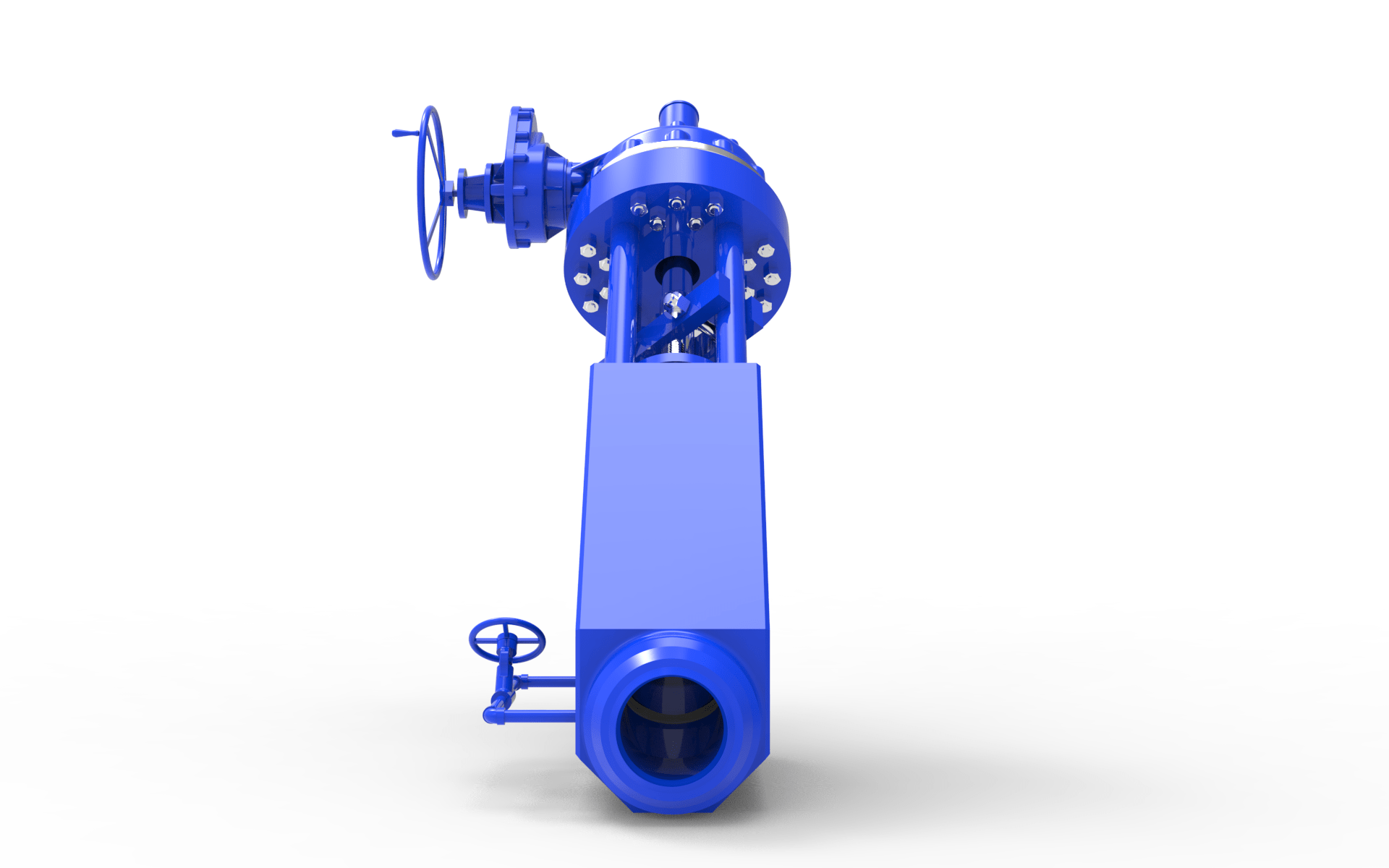

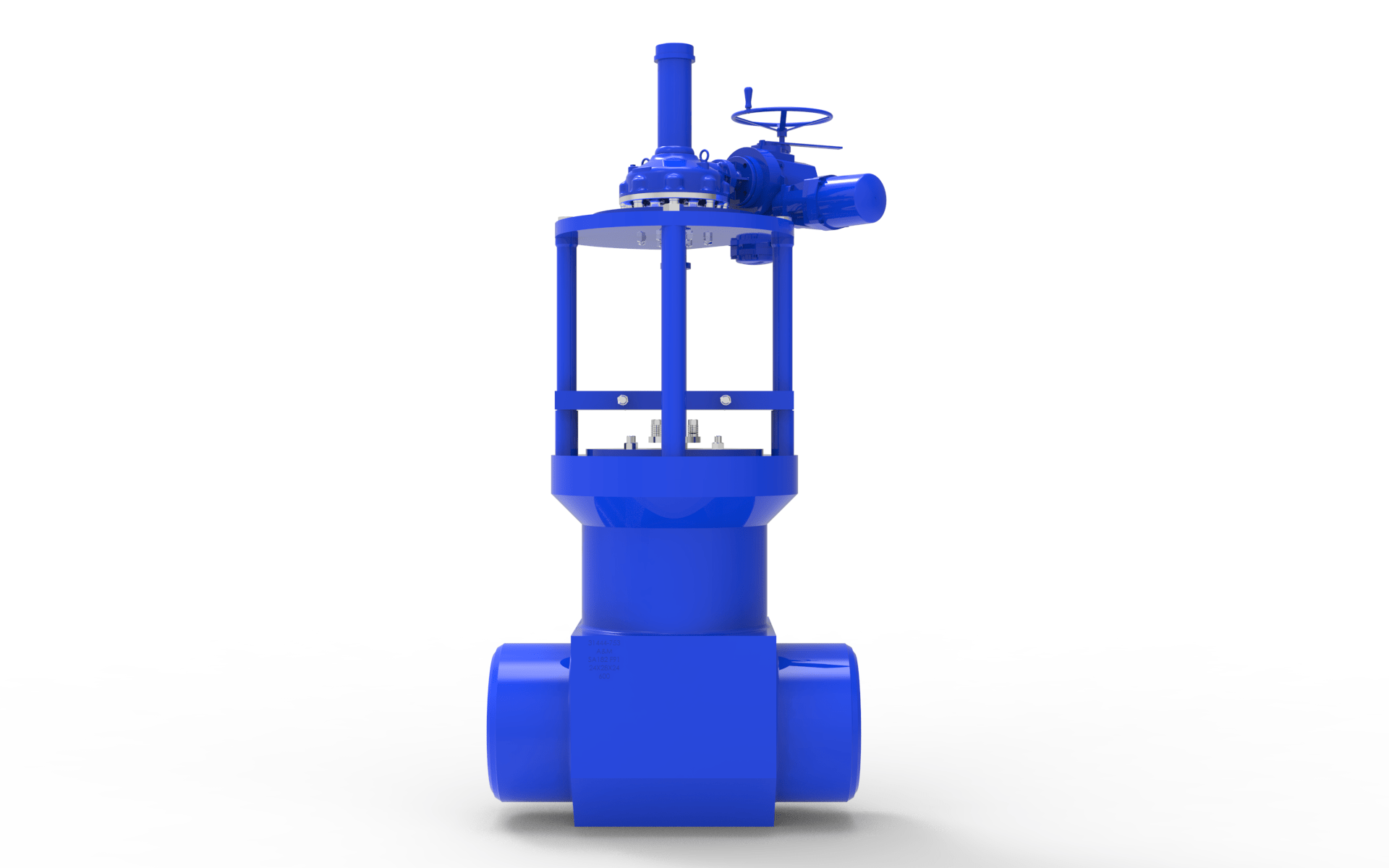

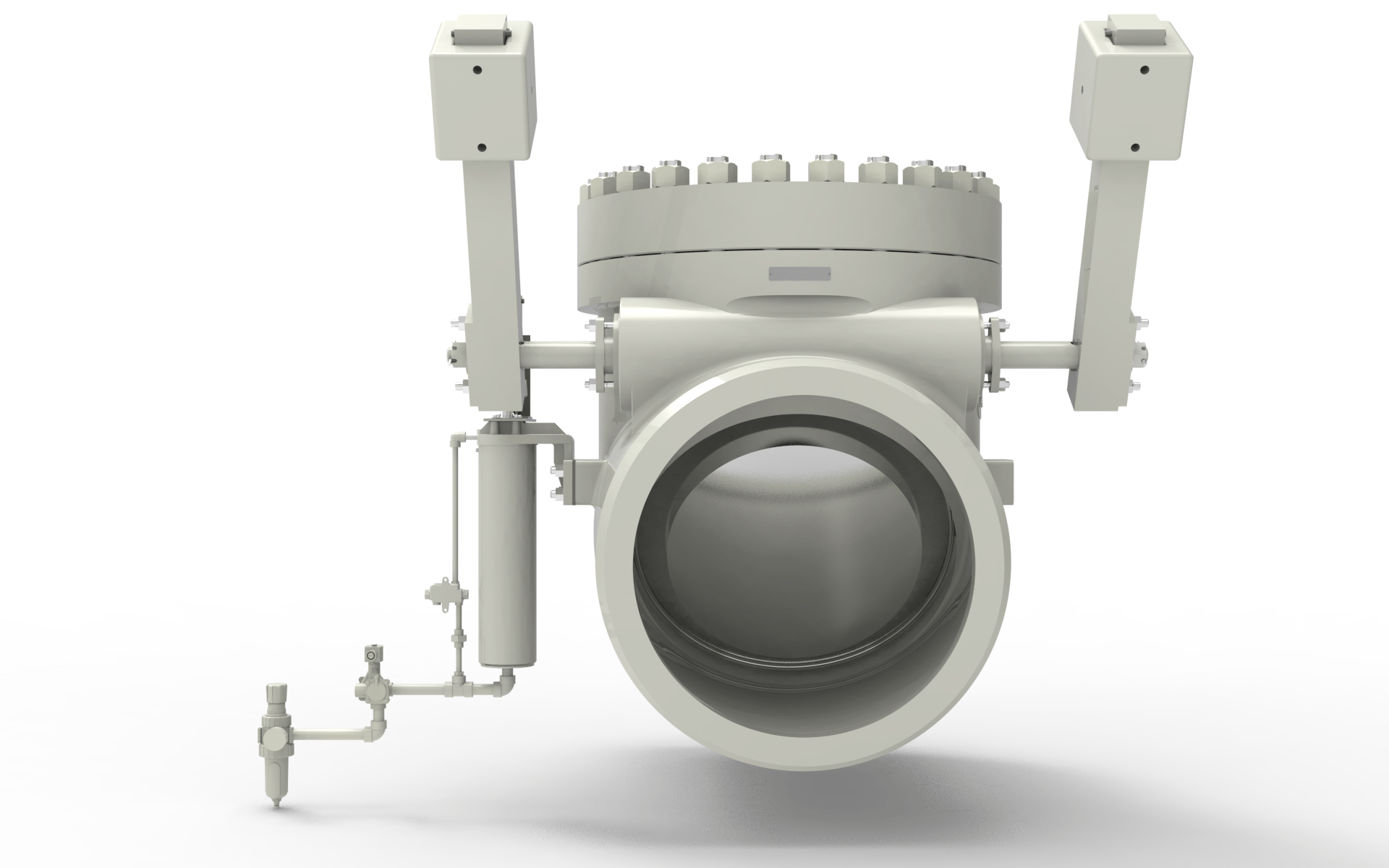

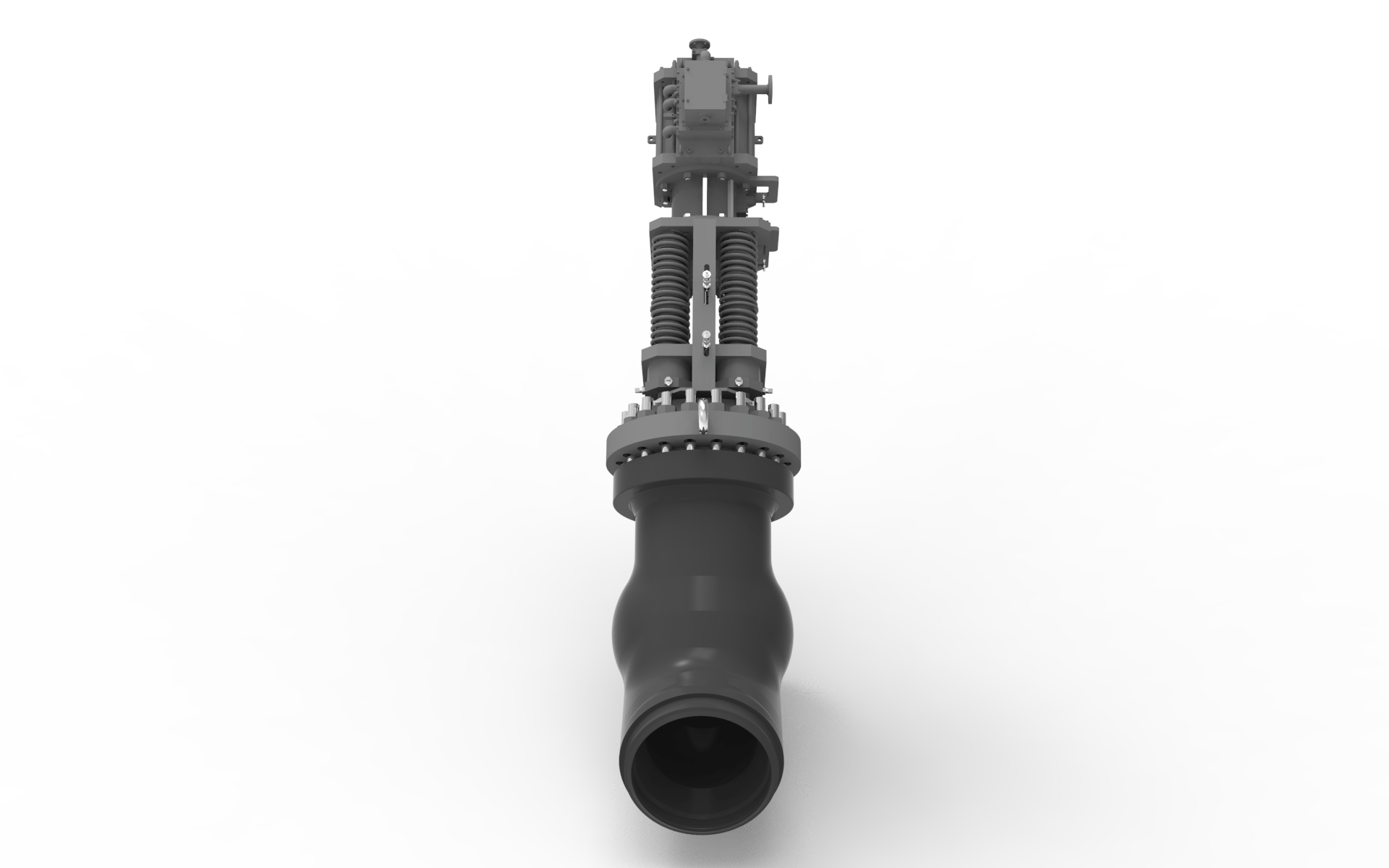

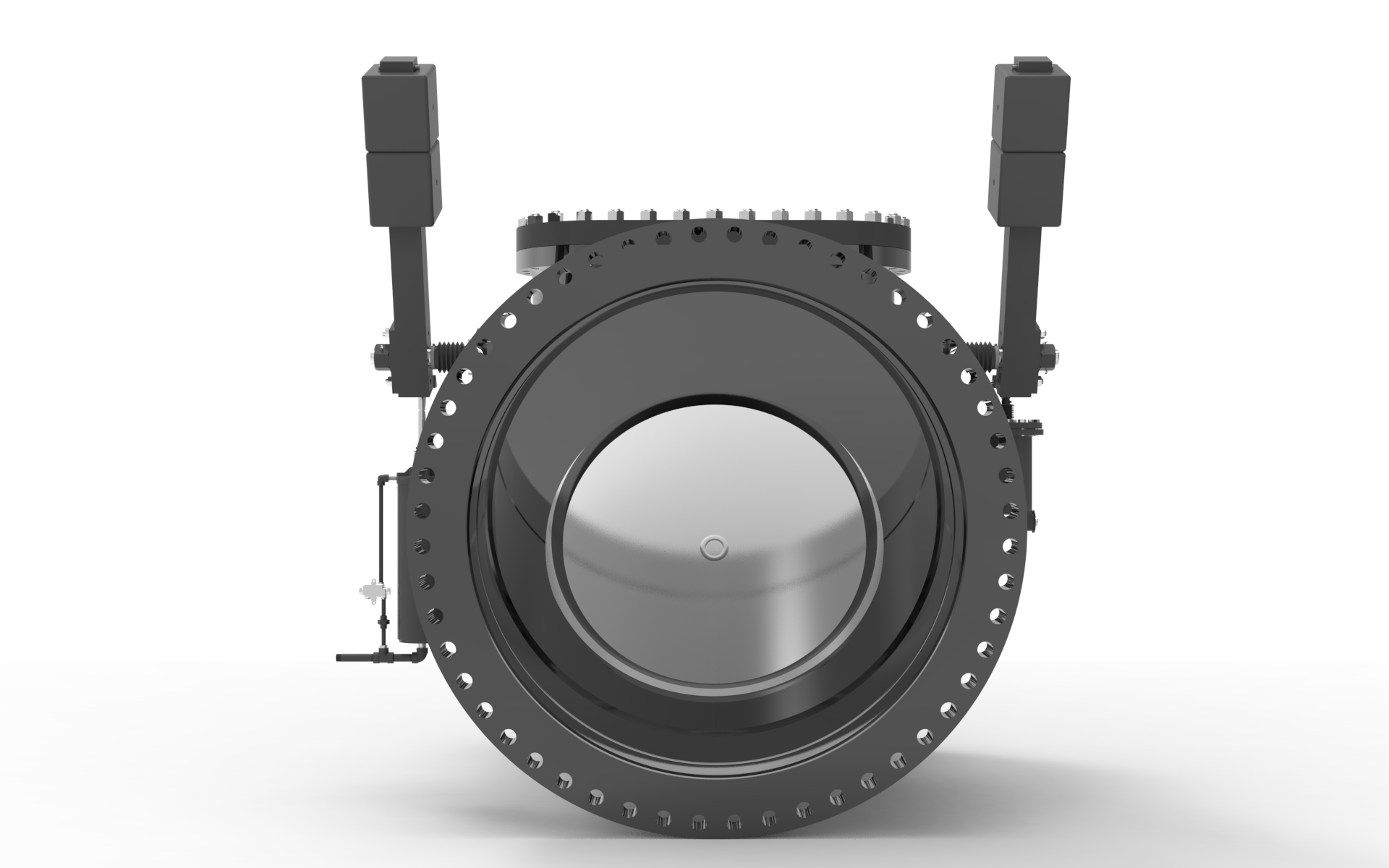

Three Way Valves

KEY FEATURES & BENEFITS

- Allows two different flow patterns from the same valve

- Full flow maintained through valve stroke

- Simplifies piping layout

- Eliminates one motor operator connection

- Significant installation and maintenance cost savings

- Cage guided poppet to stabilize

- In-line “T” body design

- Flat seats for easier maintenance

APPLICATIONS

- High pressure feedwater heater bypass

- Low pressure feedwater heater bypass

- Dual safety valve installations

- Continuous process applications

- HRSG economiser

- Bulk storage tank switching

DESIGN STANDARD

- ASME B16.34

PRESSURE CLASS RANGE

- ASME 150, 300, 1500, 2500

SIZE RANGE

- 6 – 24 inches (150 – 600 mm)

TEMPERATURE RANGE

- Up to 1,200ºF

MATERIALS

- Cast carbon, Alloy steel, Stainless steel, or Forged options available

END CONFIGURATION

- Weld End

UPGRADES & ADAPTATIONS

- Poppet guidance upgrades, Live loaded packing, Replace hard seal with graphite seal