Red Point®

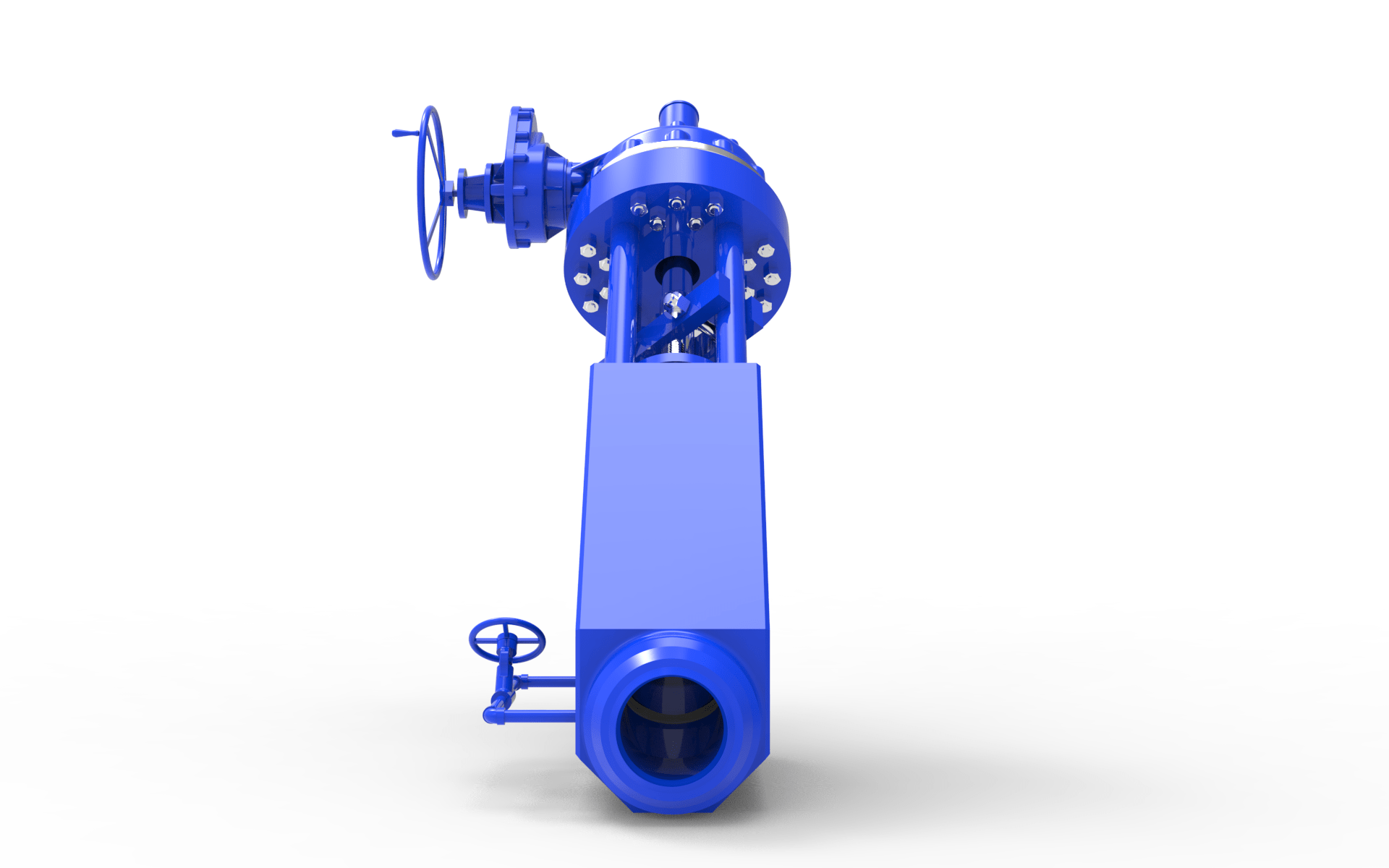

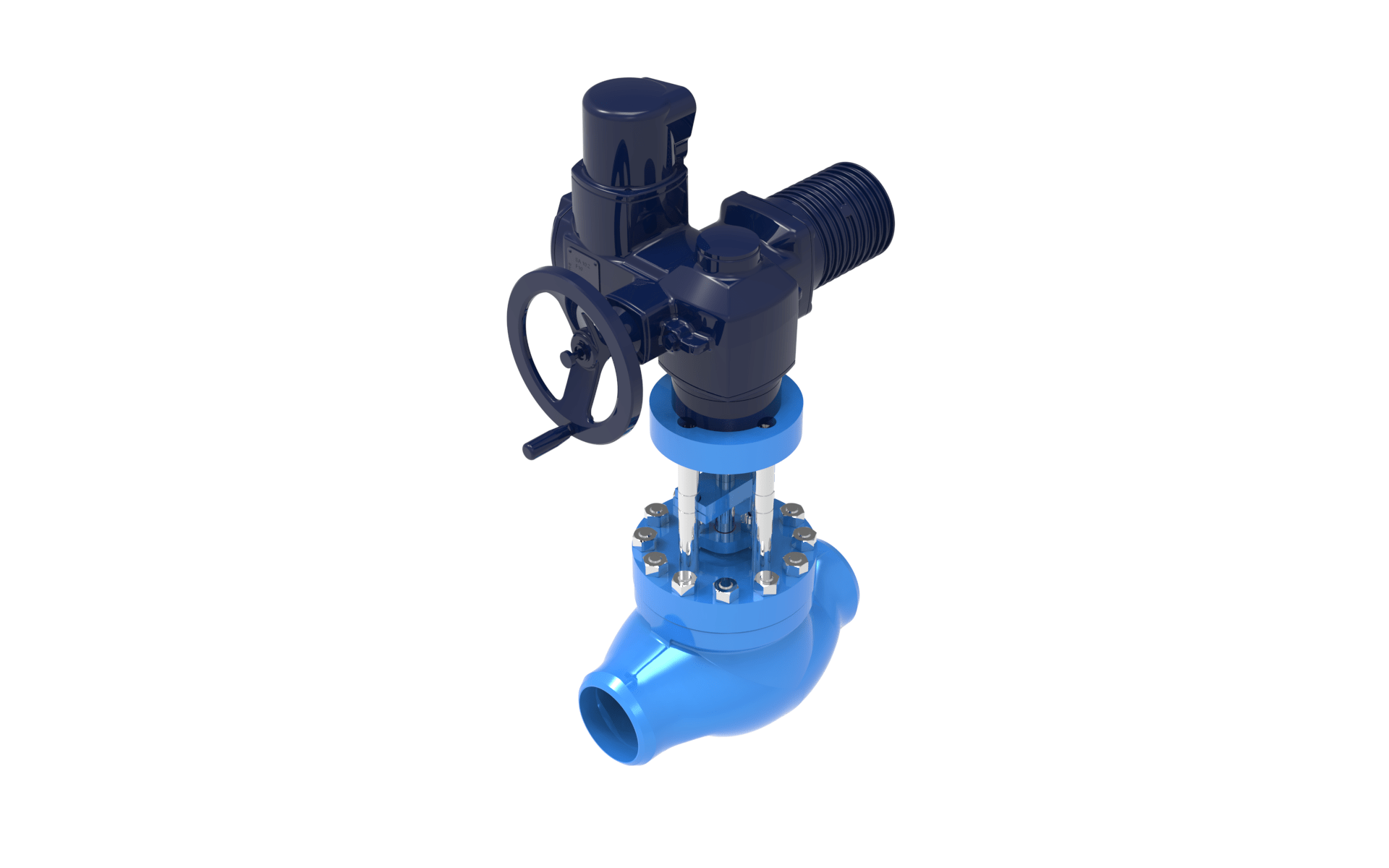

Angle Type Globe Valves

The angle globe valve is a modification of the basic standard pattern globe valve where the ends are at an angle of 90 degrees. The Red Point® angle globe valves have a streamlined curved bore to create optimal flow and lower CV value. They are used in applications that have periods of pulsating flow because of their capability to handle the slugging effect of this type of flow. To avoid accumulation and crystallization of the medium, packing flushing and heating steam jackets can be added to the valve design.

Our angle globe valves are available as forged or cast valves featuring exotic material options with short delivery times.

Type of disc

- Plug

- Needle

- Swivel

- Regulating Disc

Pattern

- Straight

- Angle

- Y-type

Options

- Extended Bonnet

- Bellow Sealed

- Heating Jacket

- Screw-Down/Non-Return

Operated

- Handwheel

- Actuator Operated

- Bare Stem

Design & testing

- All available international standards according to API, EN, ISO

- Fire safe design

Pressure range

Forged Valves:

- ANSI 125 to 4,500 lbs

- ISO PN 10 to PN 640

Cast Valves:

- ANSI 125 to 2,500 lbs

- ISO PN 10 to PN 400

Construction

- Bolted,

- Welded

- Extended

- Pressure Seal Bonnet

End connections

- Flanged,

- BW

- SW

- THR

- HUB

Seating options

- Soft or Metal Seated

- Renewable

- HF

Bellow seal materials

- 304, 321, 316Ti, Alloy 625, C276

Size & bore

Forged Valves:

- ANSI 1” – 6”

- DN 25 to DN 100

Cast Valves:

- ANSI 6” to 16”

- DN 10 to DN 400