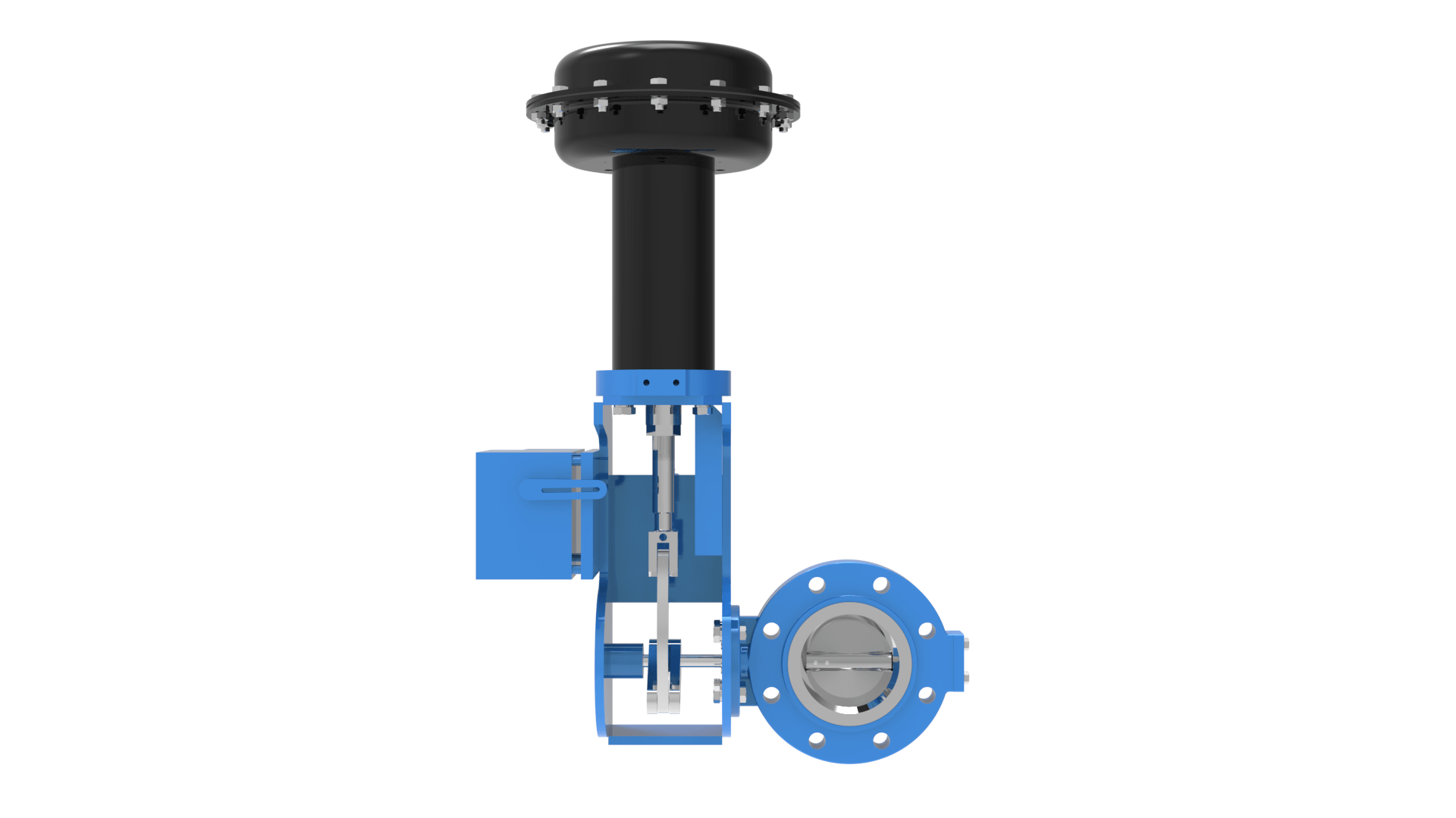

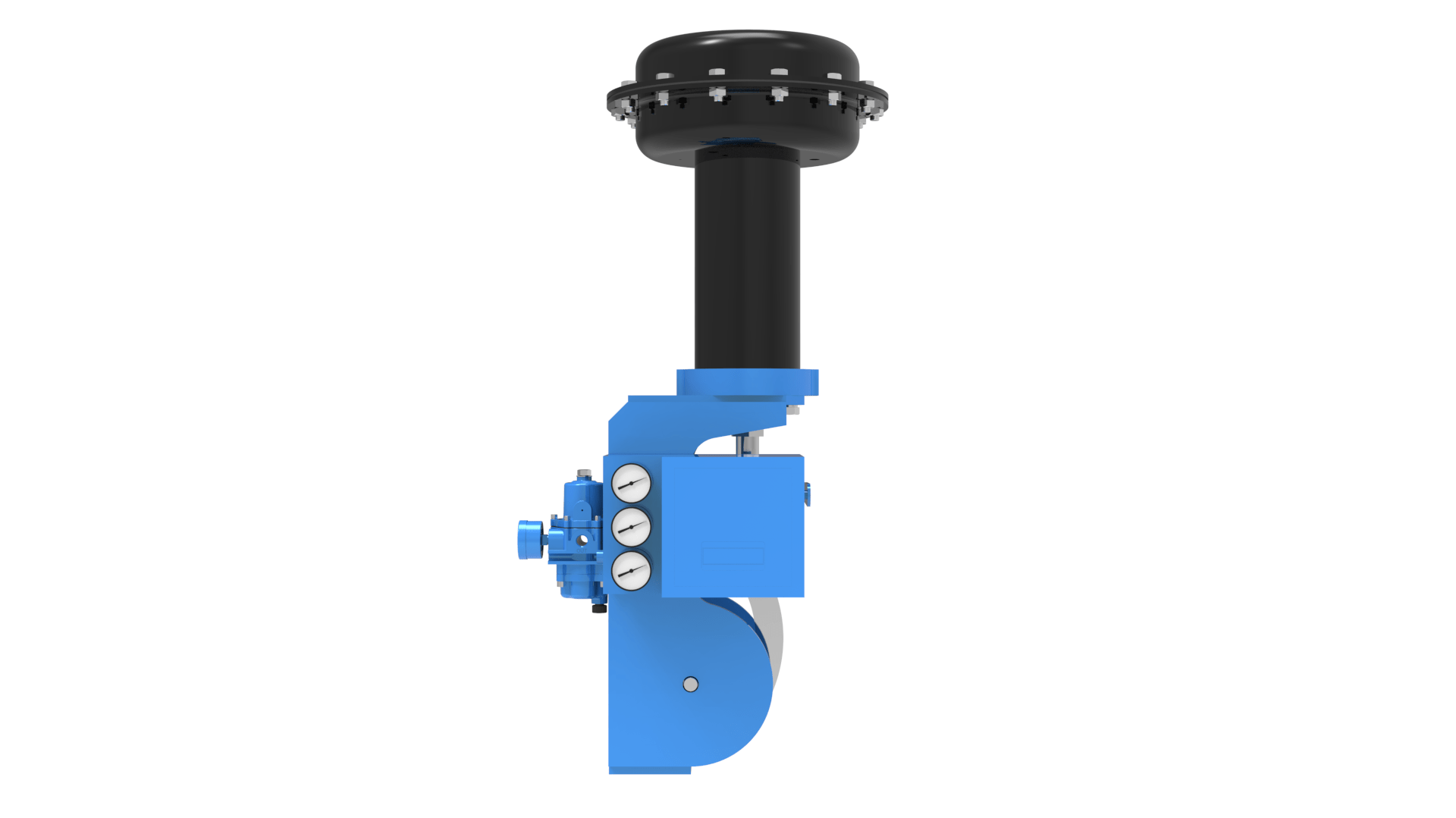

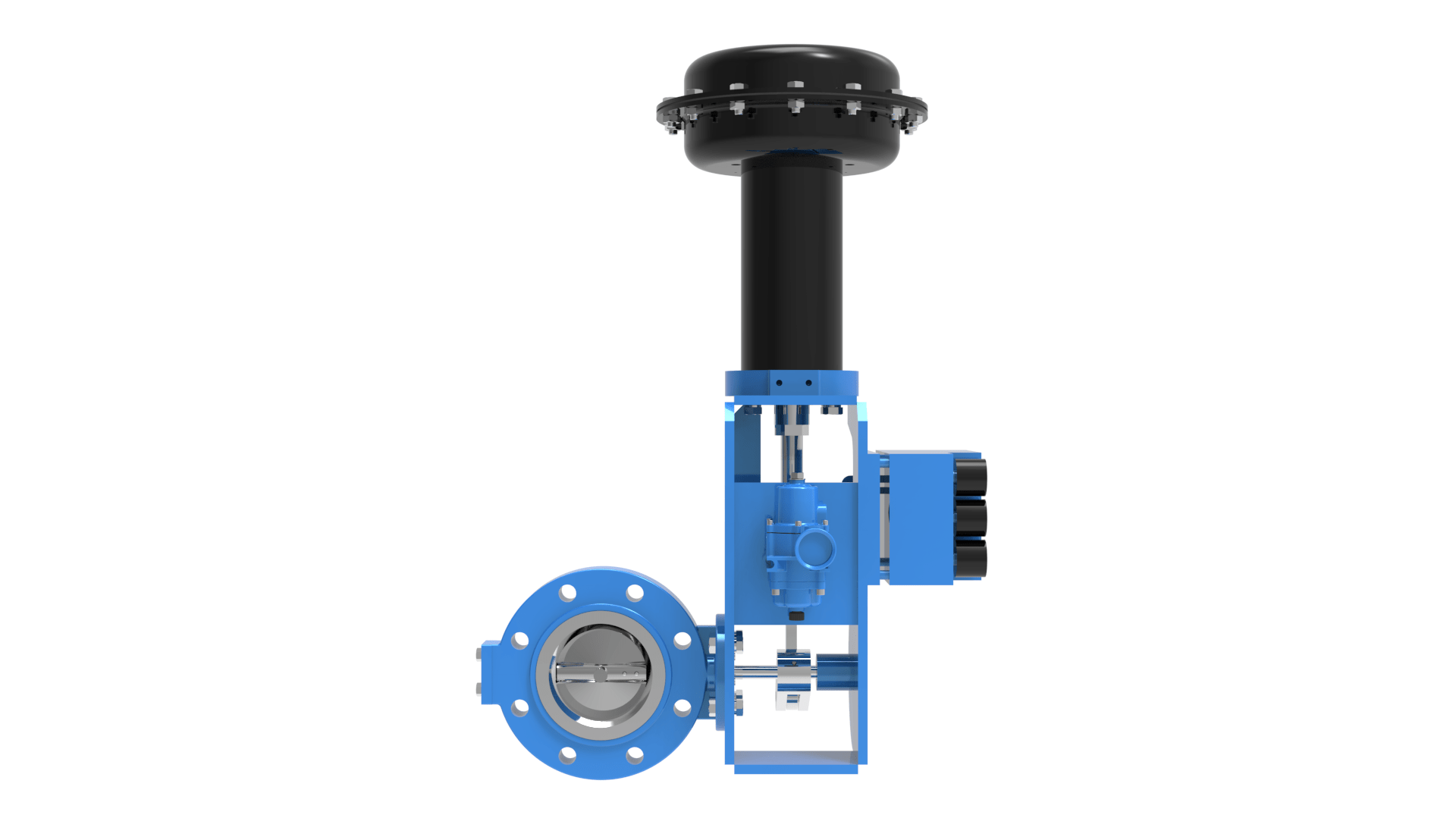

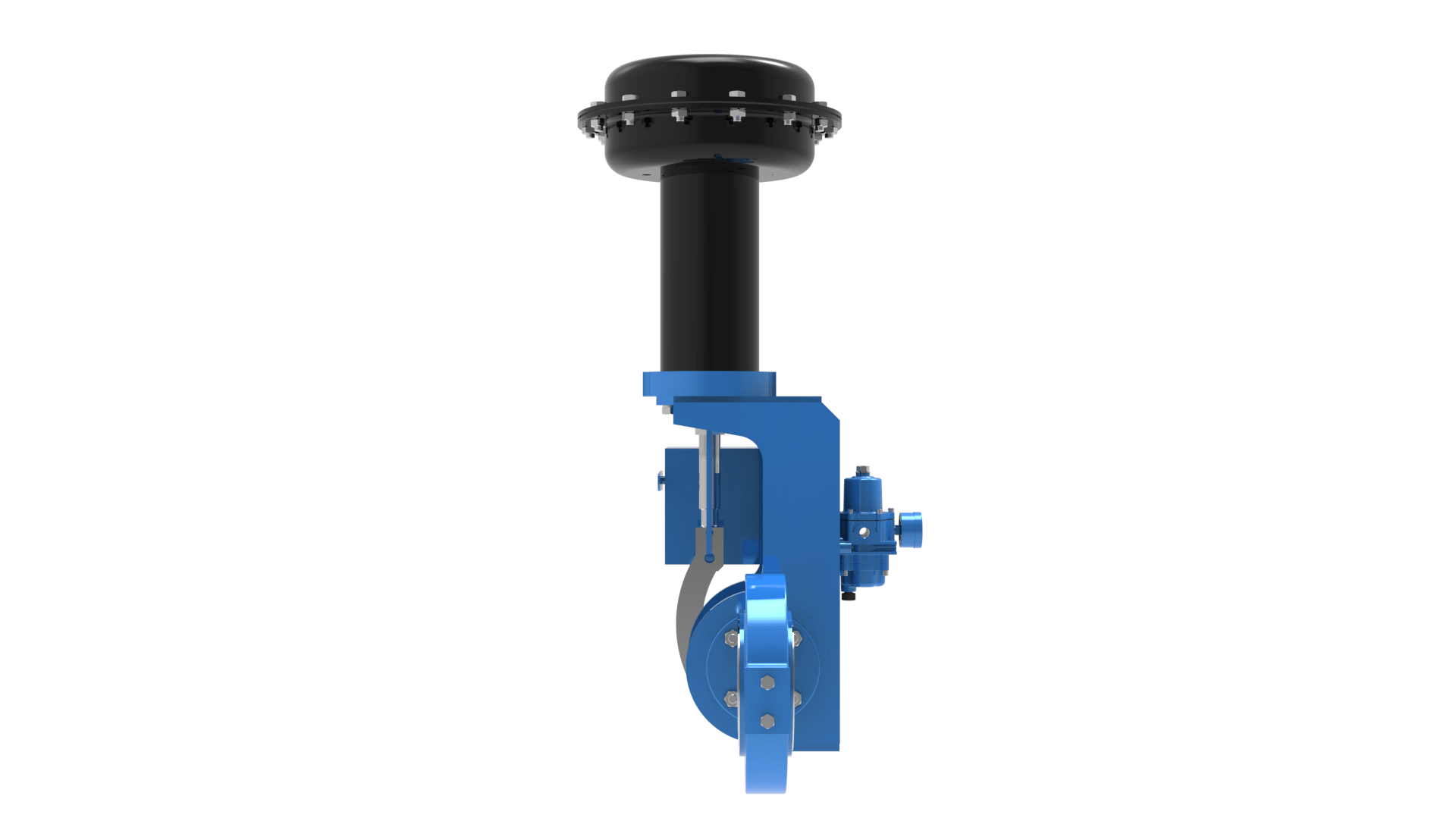

Batley Valve®

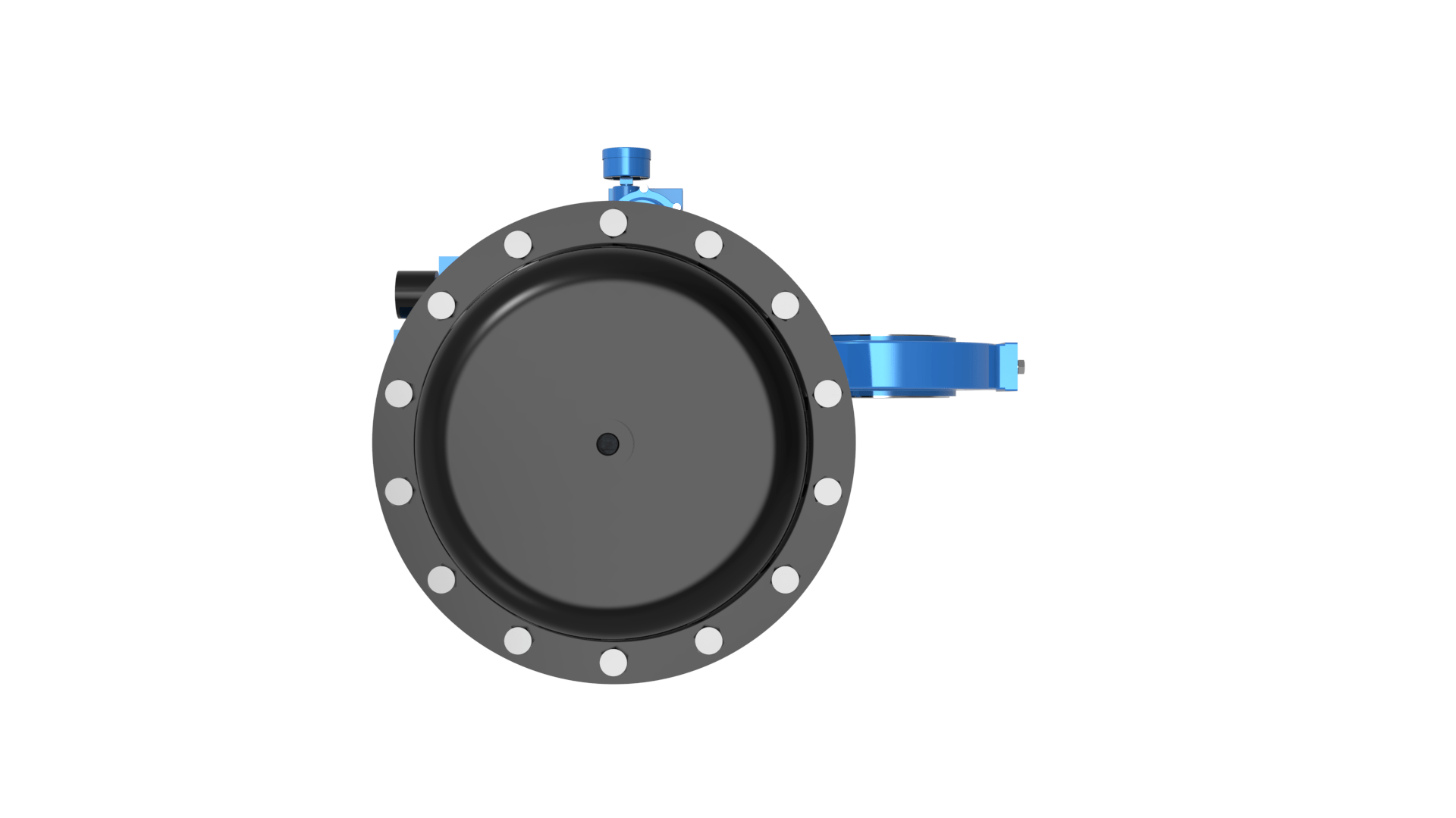

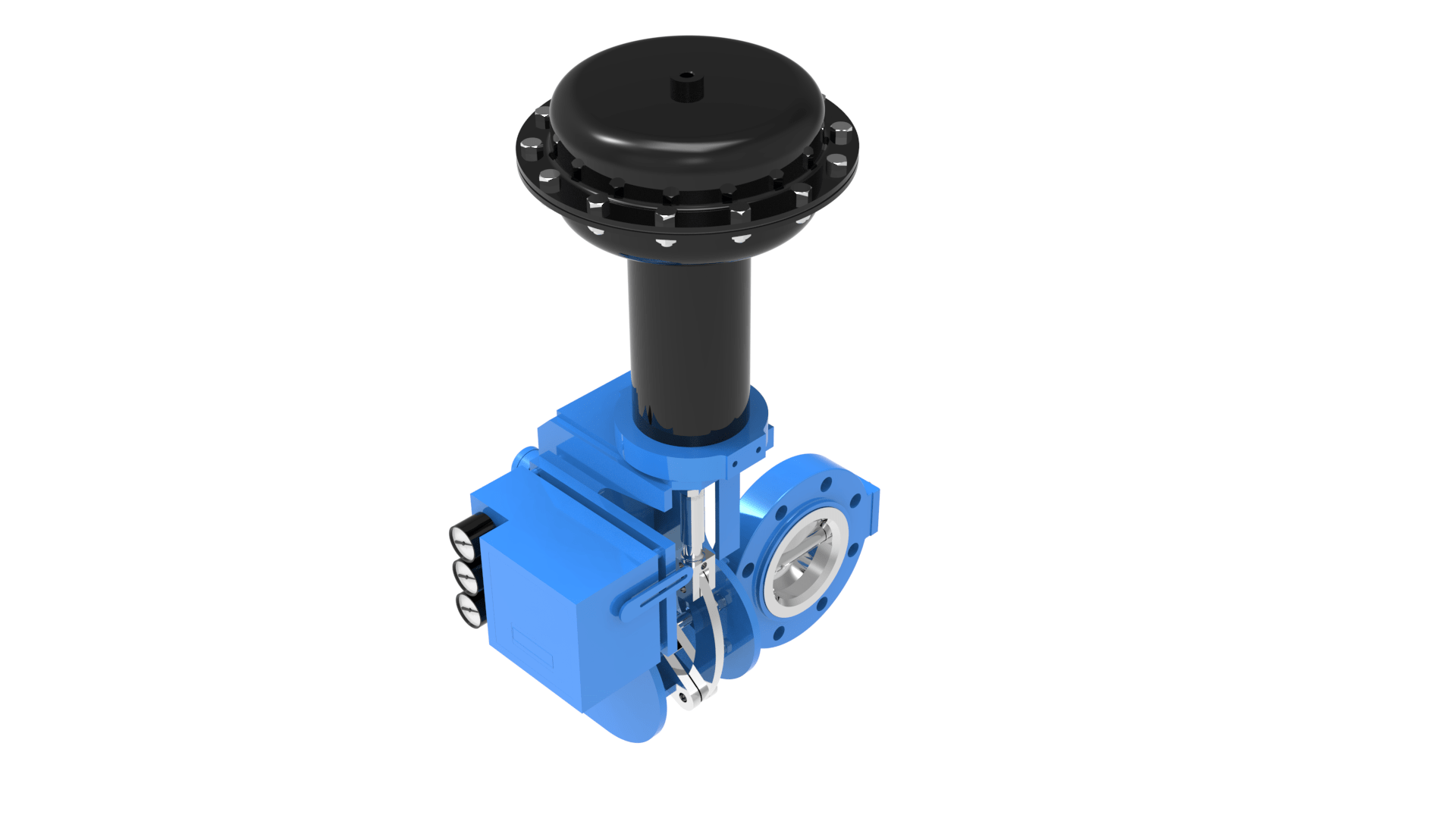

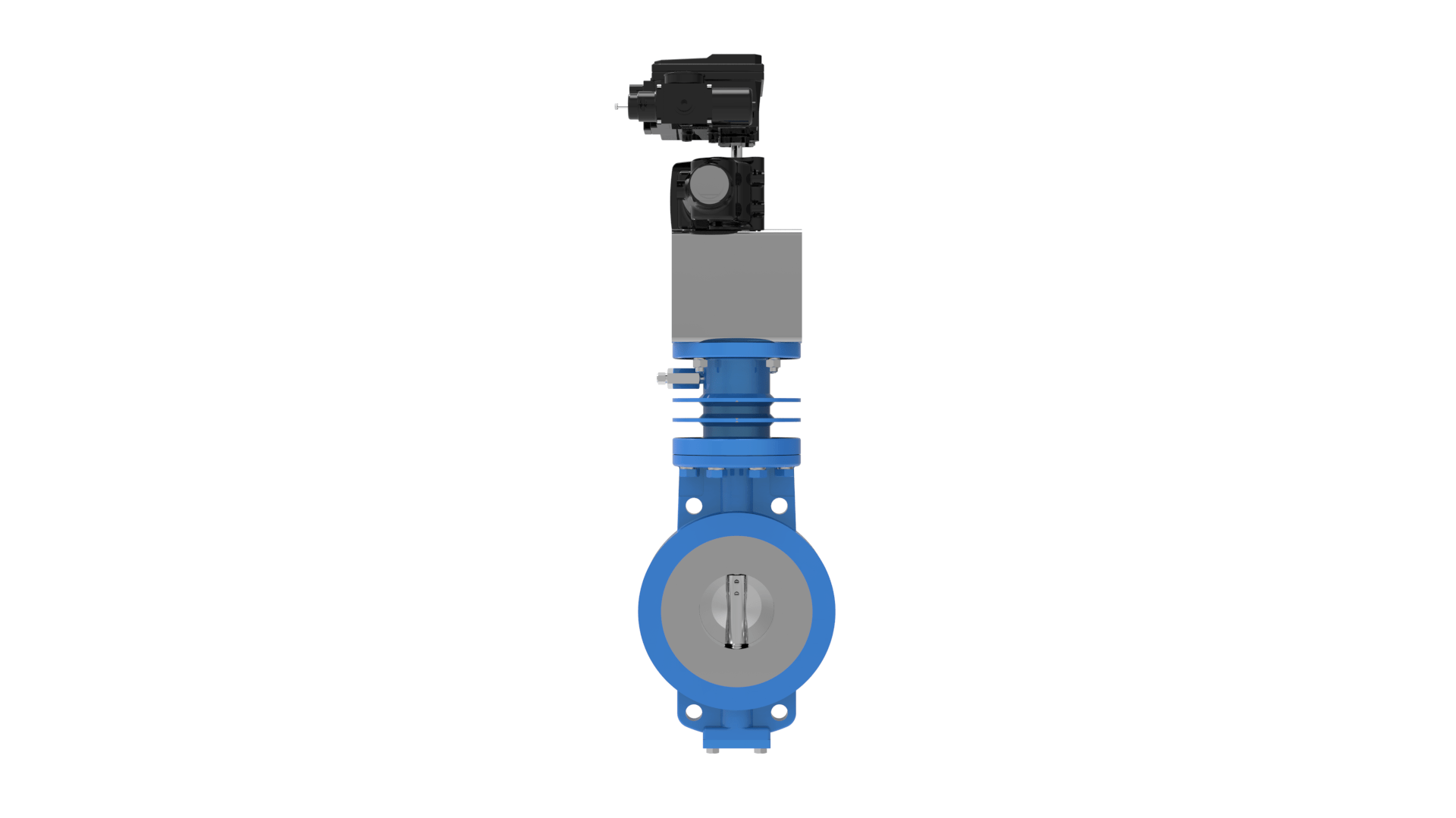

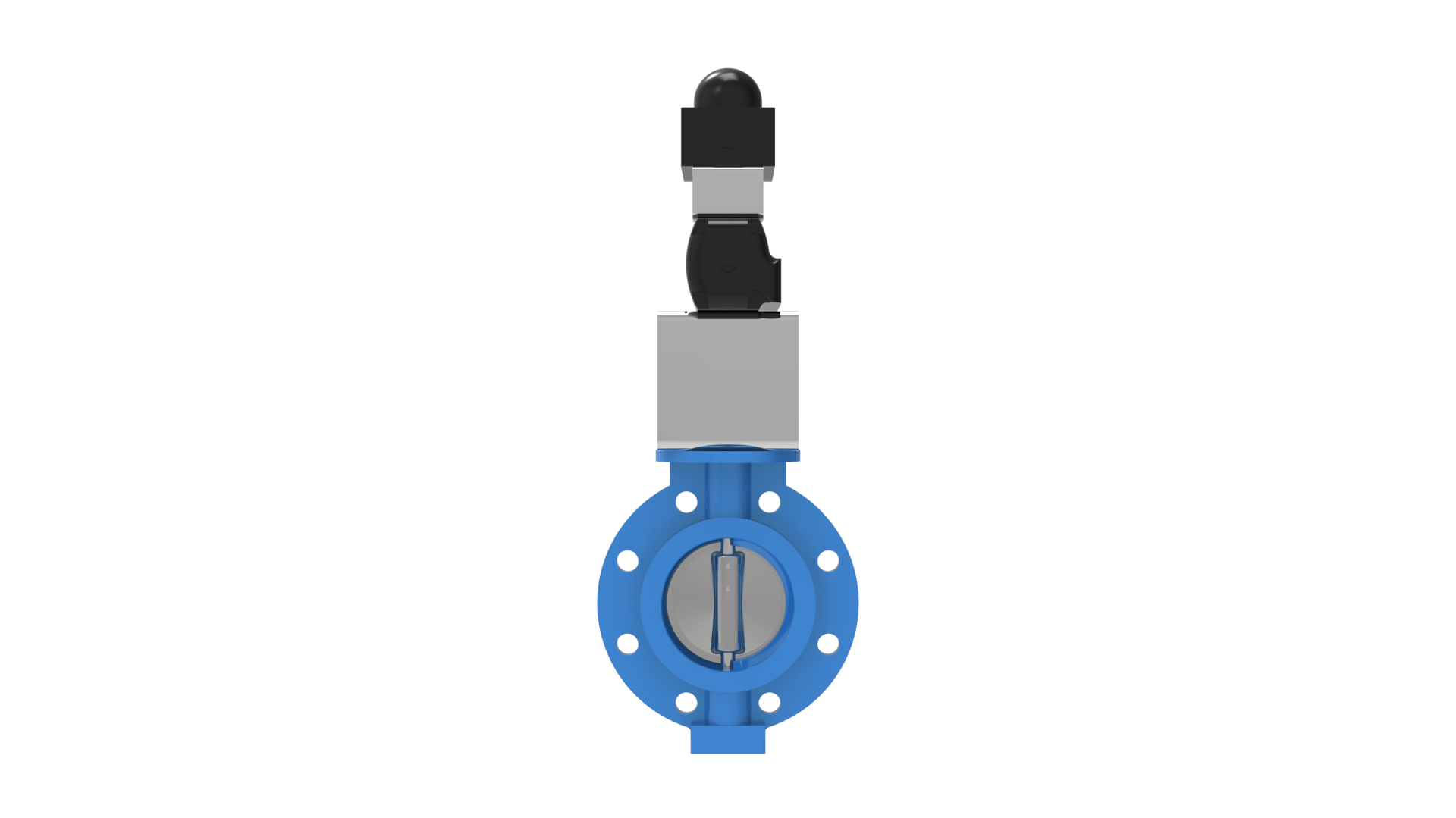

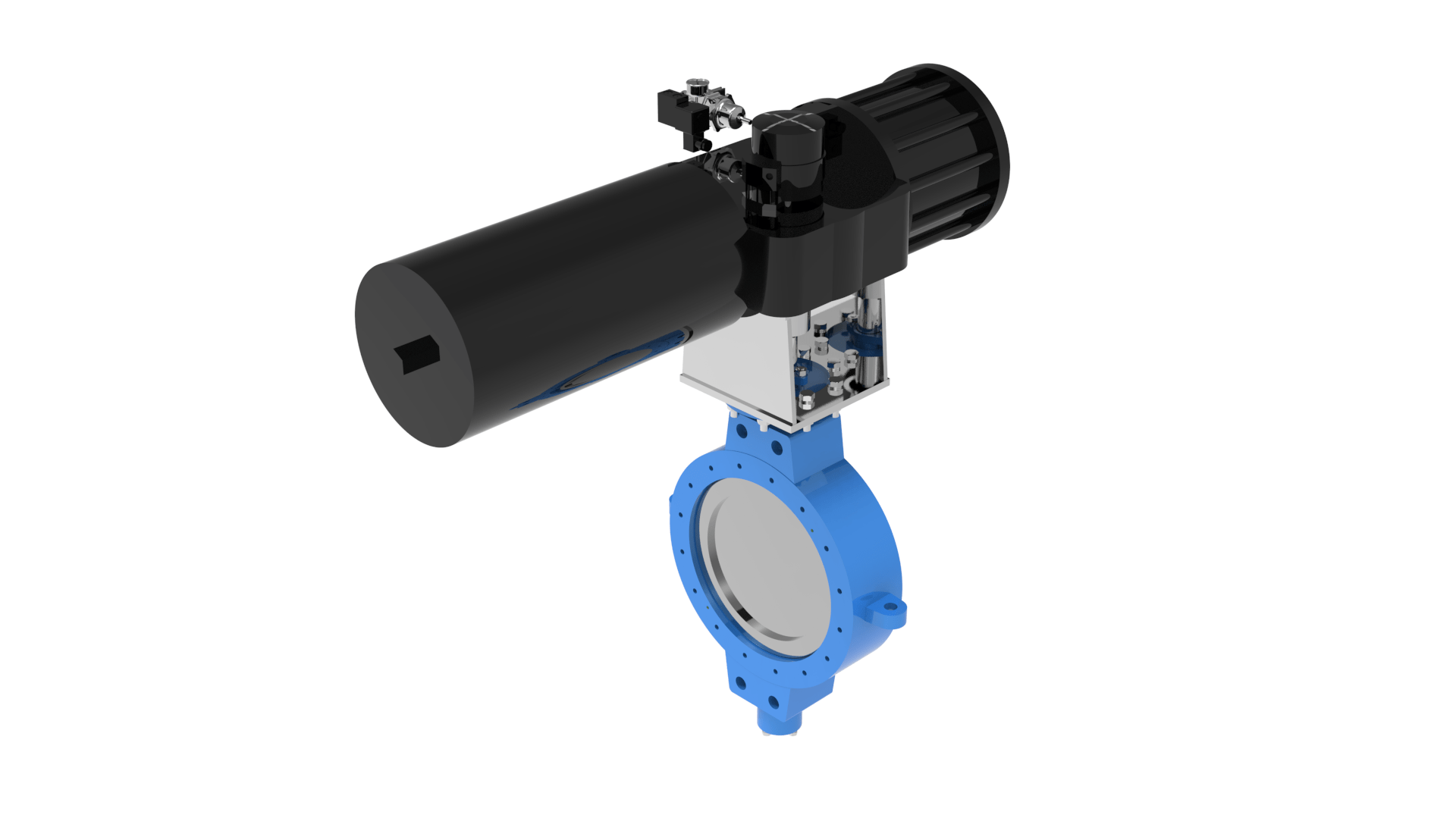

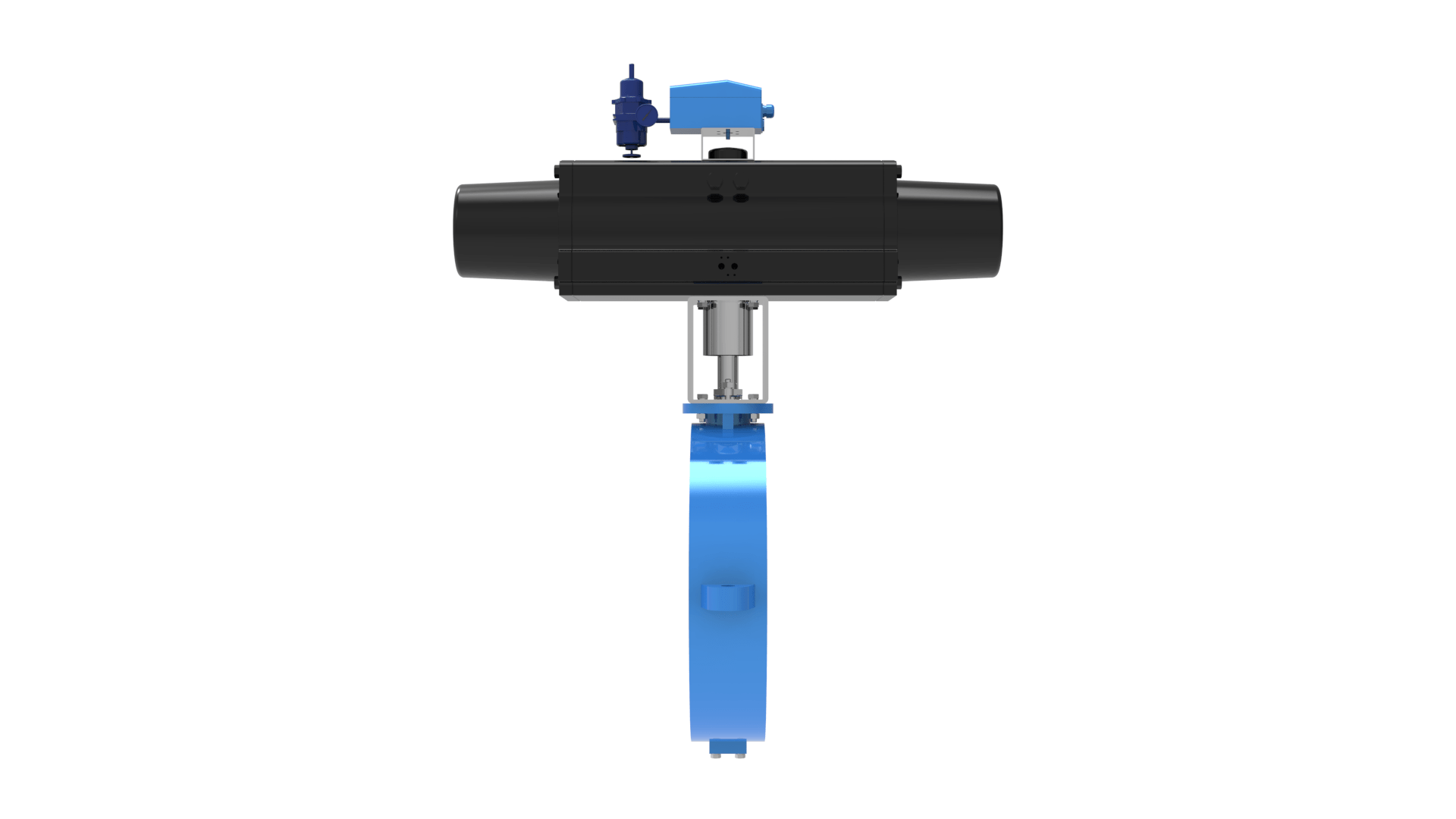

BV 16000 SpoolSeal

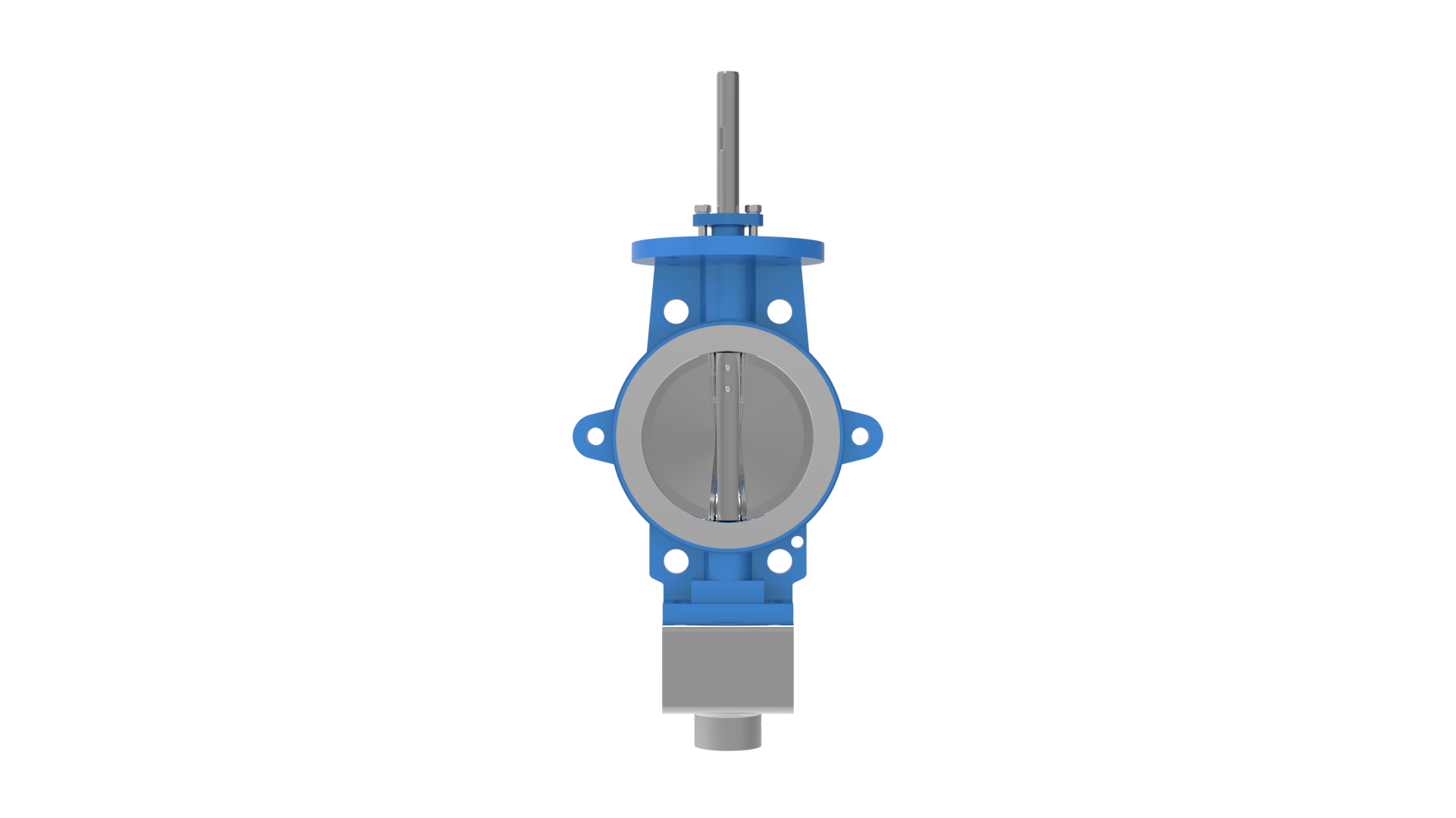

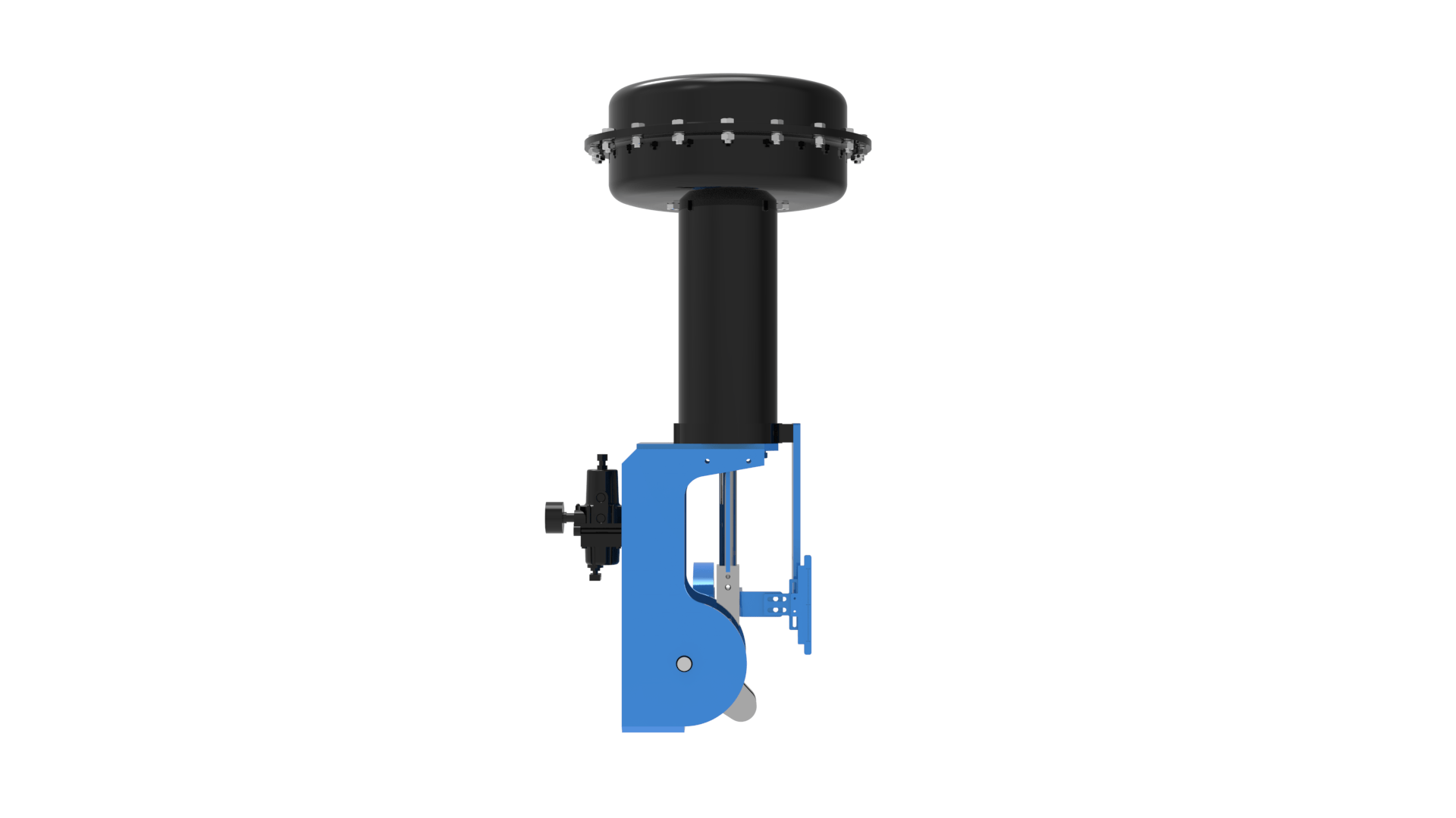

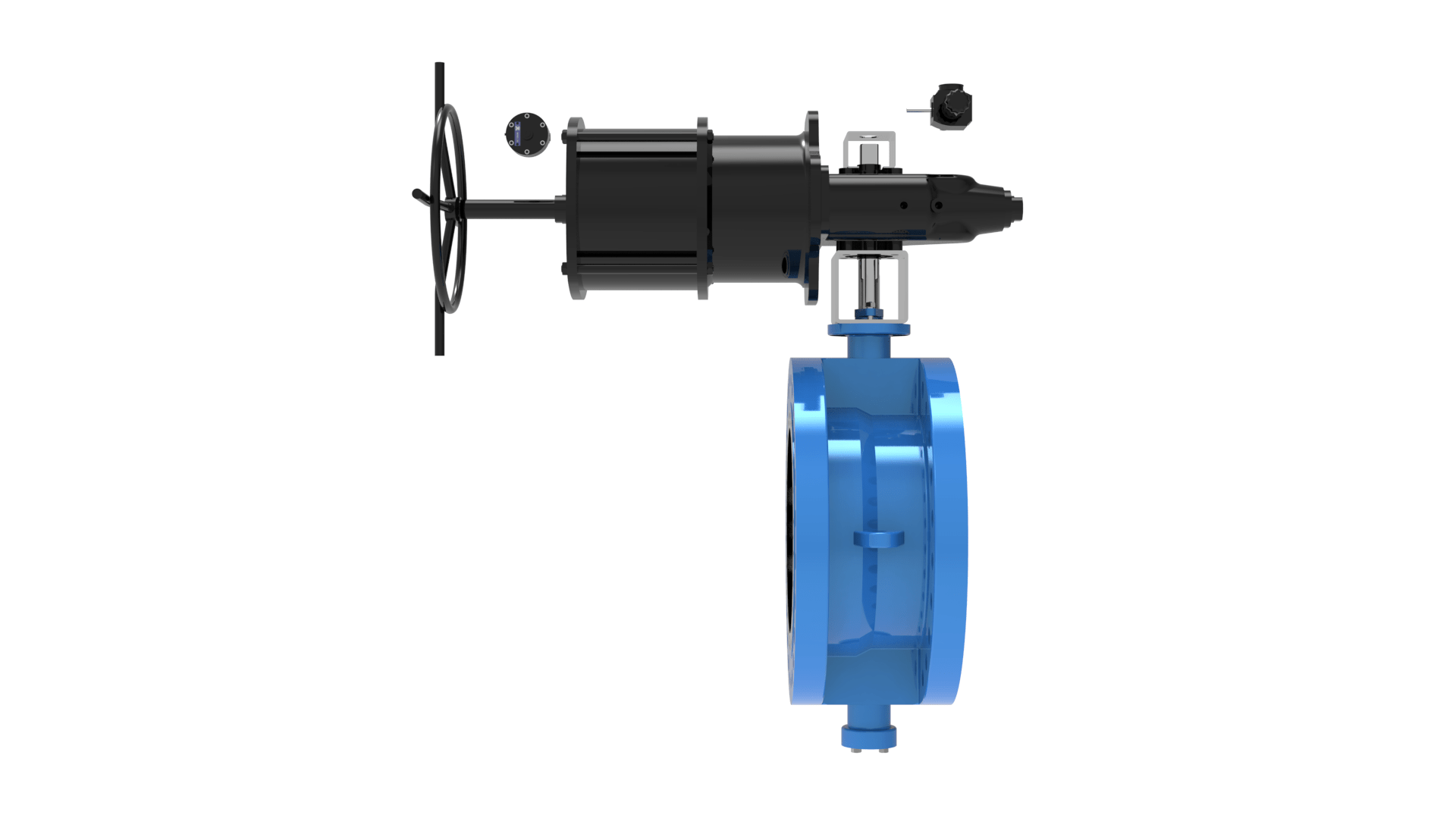

The Batley Valve® BV 16000 SpoolSeal butterfly control valve incorporates the use of a replaceable rubber liner for body protection. The valves are normally supplied complete with our own manual, diaphragm, cylinder or electric actuator. The rubber lining is of snap-in type which locks into a body recess and is available in various grades of rubber.

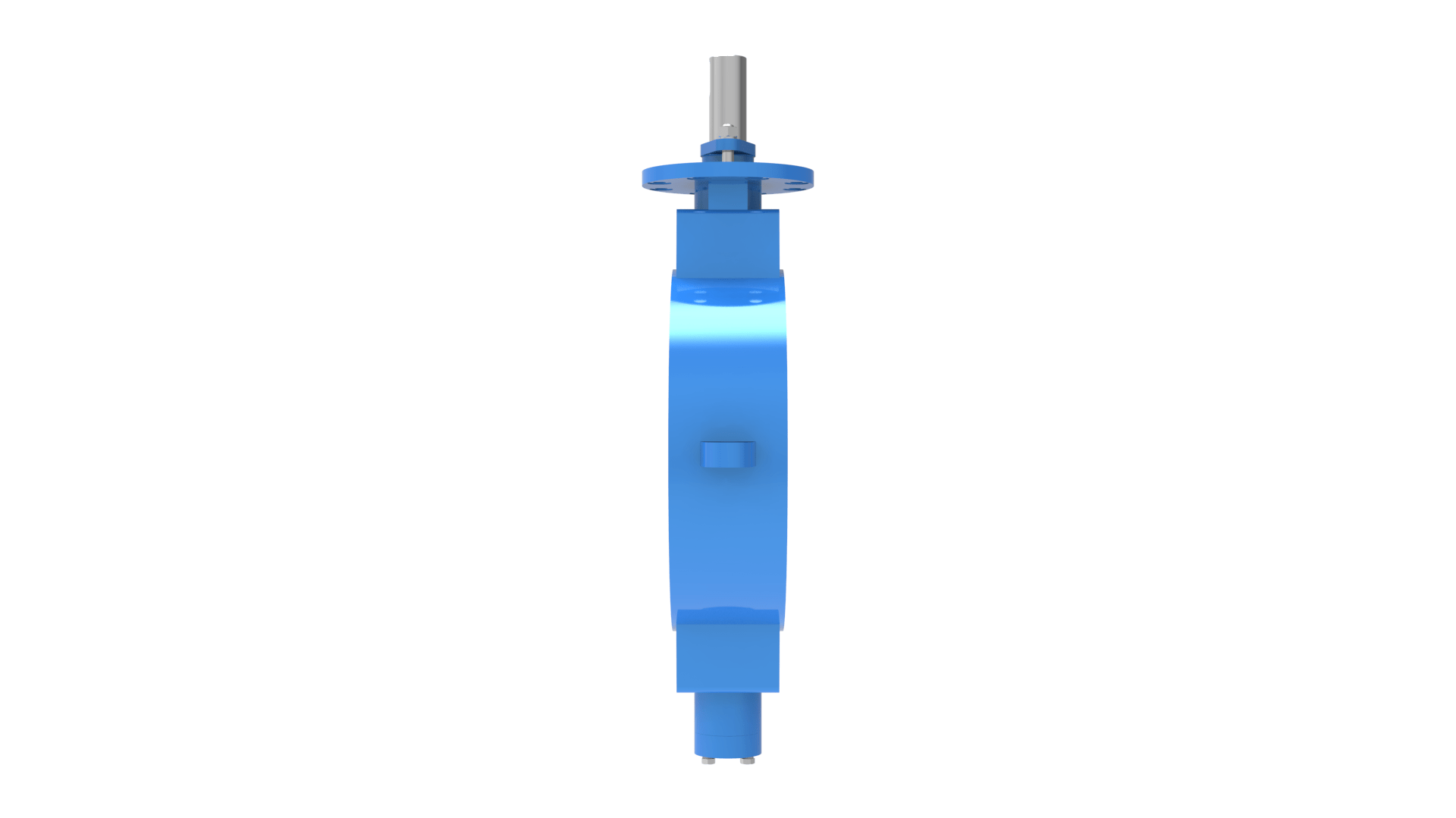

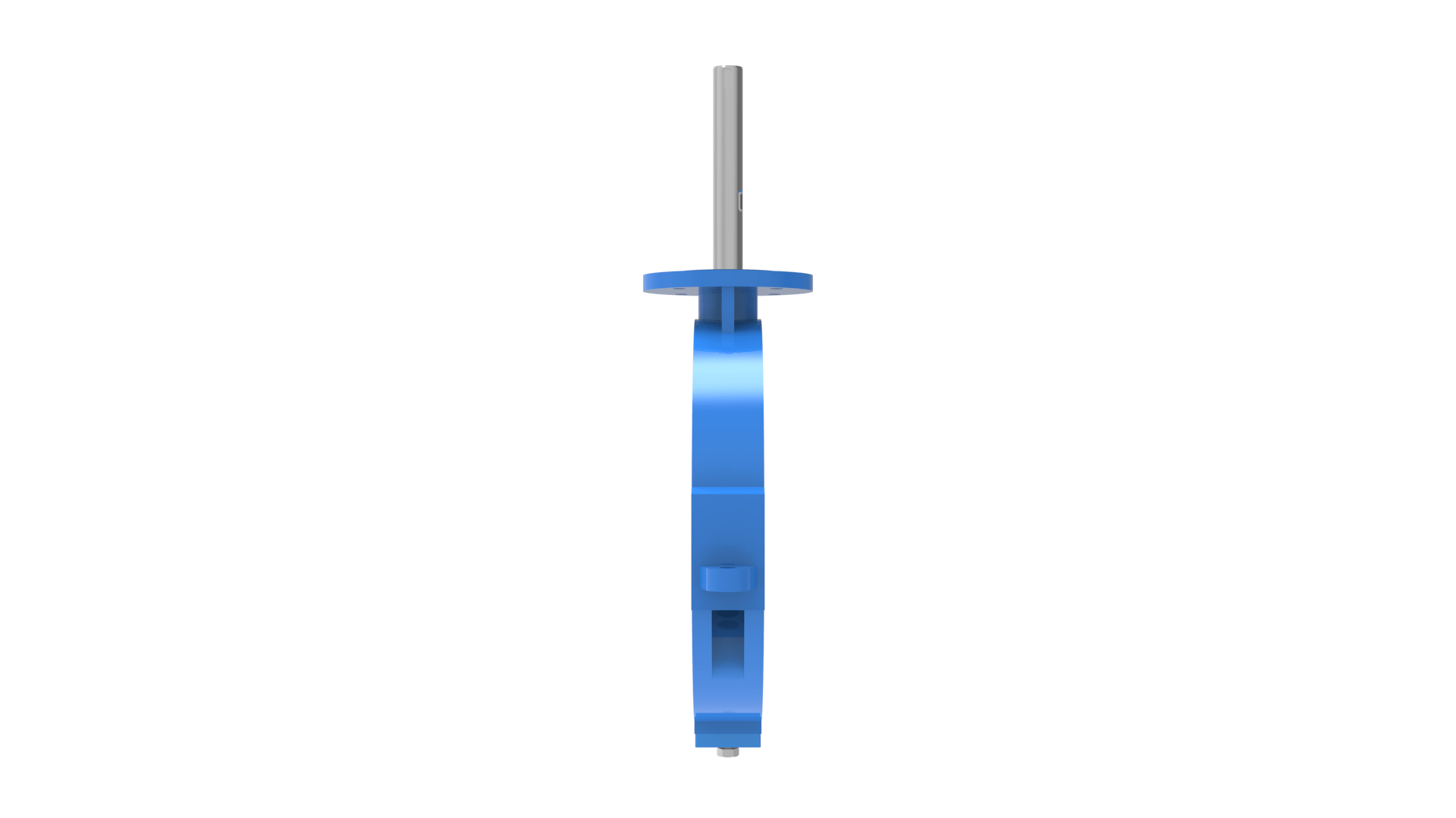

The streamlined shape of the vane provides minimum resistance to flow and the swing through action prevents damage to the liner should the valve overtravel. The body is of solid ring type accurately machined for liner retention, vane and spindle alignment to ensure positive shut-off combined with lower seating torques.

KEY FEATURES/BENEFITS

- Packing features a secondary seal is a viton ‘O’ Ring, acting as a back-up to the primary seal which is incorporated in the liner.

- Prevents ingress of dirt from the atmosphere.

- Bubble tight shut-off up to 10 Bars depending upon valve size.

BODY

- Wafer, Lugged connections.

- Ring thickness is in excess of the British Standard and ANSI code ratings.

- PTFE-faced, self lubricating bearings are fitted to accomplish high loading and low friction.

BLANK END GASKET

- High quality, non asbestos flat gasket. The split end of the taper pin is opened out to prevent any possibility of working loose.

- The rubber liner includes moulded-in primary ‘O’ ring 1 which prevents leakage along the spindle and in addition an ‘O’ ring 2 moulded to the liner hub which acts to prevent leakage passing behind the liner.

- For valves on vacuum service the liner is chemically bonded or vulcanised to the body.

APPLICATIONS

- Desalination and Water Treatment Plants

- Chemicals & Corrosive services

DESIGN STANDARDS

- ANSI B16.34

DESIGN RATINGS

- ASME 150 to 300

SIZE RANGE/ DIMENSIONS

- 50mm to 600mm (2″” to 24″”)

TEMPERATURE RANGE

- 40ºC to 140ºC (-40ºF to 284ºF)

MATERIALS

- Carbon Steel

- Stainless Steel

- Duplex

- Super Duplex

- Hastalloy

- Inconel

- Monel

UPGRADES/ADAPTATIONS

- Customised vane coatings to enhance durability

- Actuator customised models

CAPACITY

- Up to 25150