GET INDUSTRY UPDATES

Thank you. Check your email for details on your request..

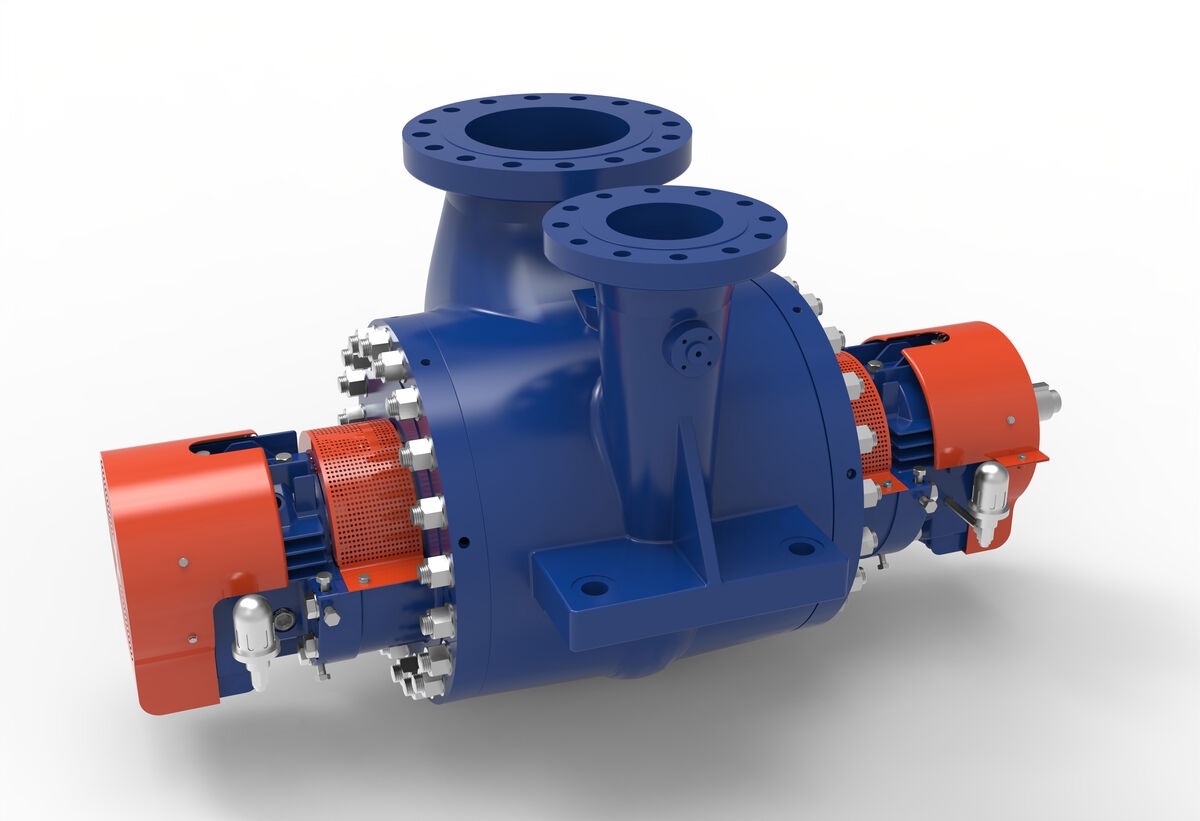

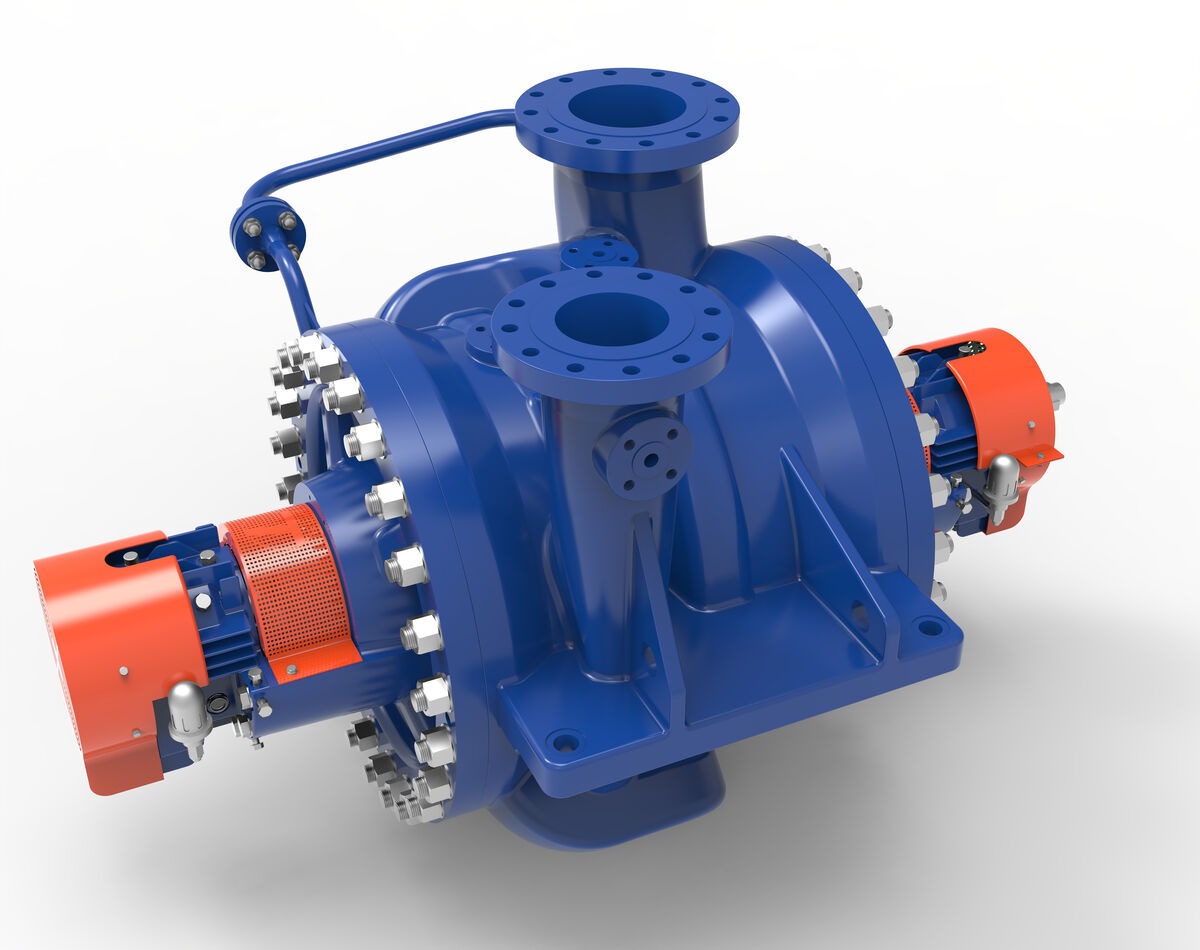

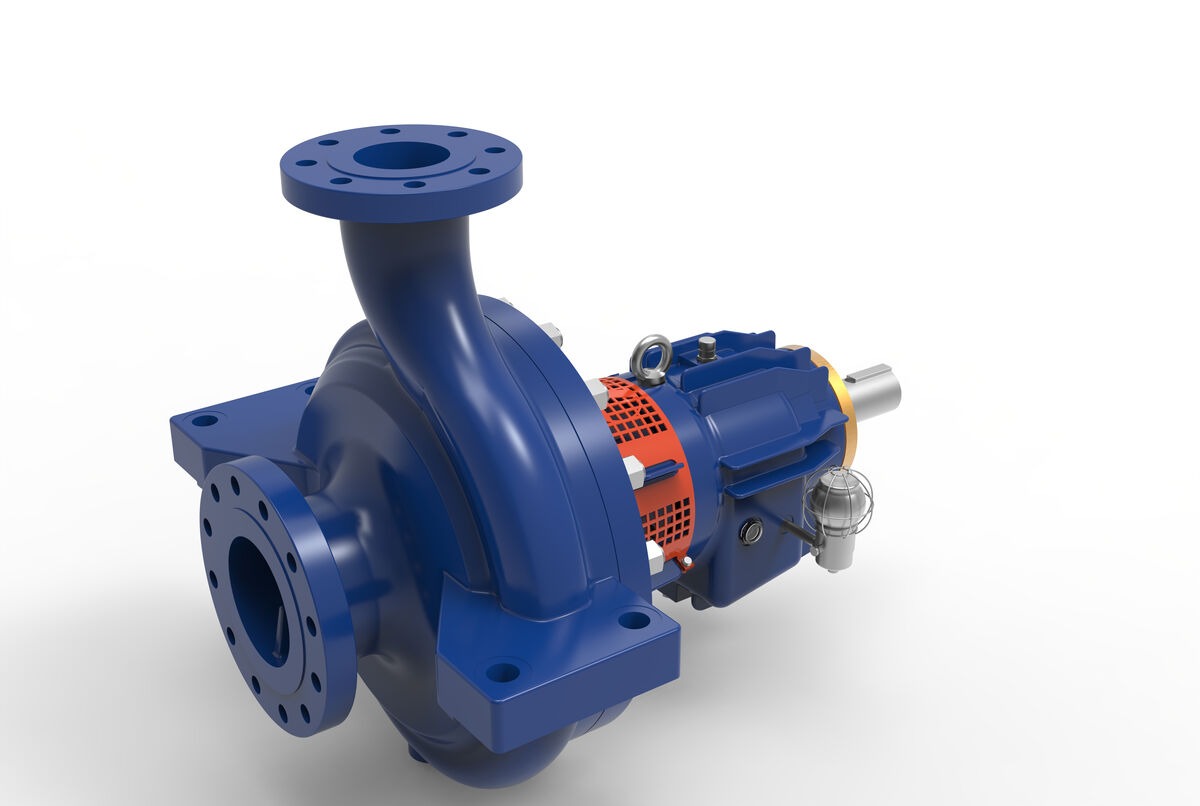

Trillium Flow Technologies™, founded on a legacy of premier products and service, will continue to provide mission critical valves, pumps, and aftermarket services in oil and gas, power generation, water and wastewater, and general industry.

HEADQUARTERS

Westpoint House, 5 Redwood Place

East Kilbride, Glasgow, G74 5PB, UK

12848 Queensbury Lane #208

Houston, Texas 77024 USA

Red Point® Valves have joined the Trillium Flow Technologies® family of performance-engineered flow control products. Welcome to TrilliumFlow.com, the single source for Red Point® product details.

Rest assured that our commitment to you, our customers, remains unchanged. The Red Point® brand will continue to engineer, manufacture, and deliver tailor-made valves within short timeframes and are proud to be aligned alongside Trillium’s global brands.

COPYRIGHT © 2025 TRILLIUM FLOW TECHNOLOGIES™