NUCLEAR POWER

Our products were used at the first ever nuclear power plant in 1956. Today, we deliver deep expertise with an array of reactor types including 4th generation reactor projects.

WE PARTNER WITH NUCLEAR PROJECTS THROUGHOUT THEIR OPERATIONAL LIFECYCLES

For over 60 years, our products have been used in nuclear facilities, including early generation reactors.

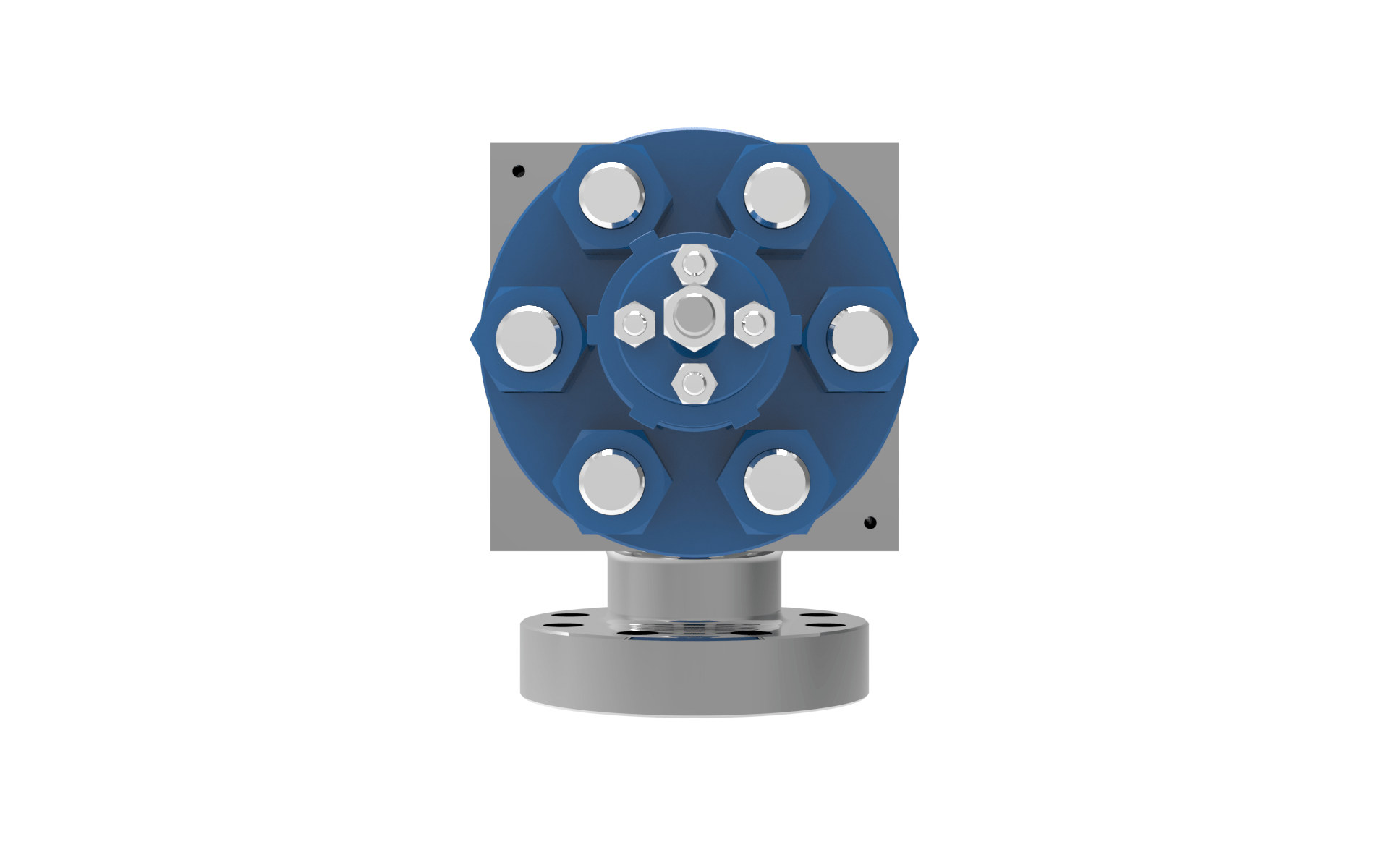

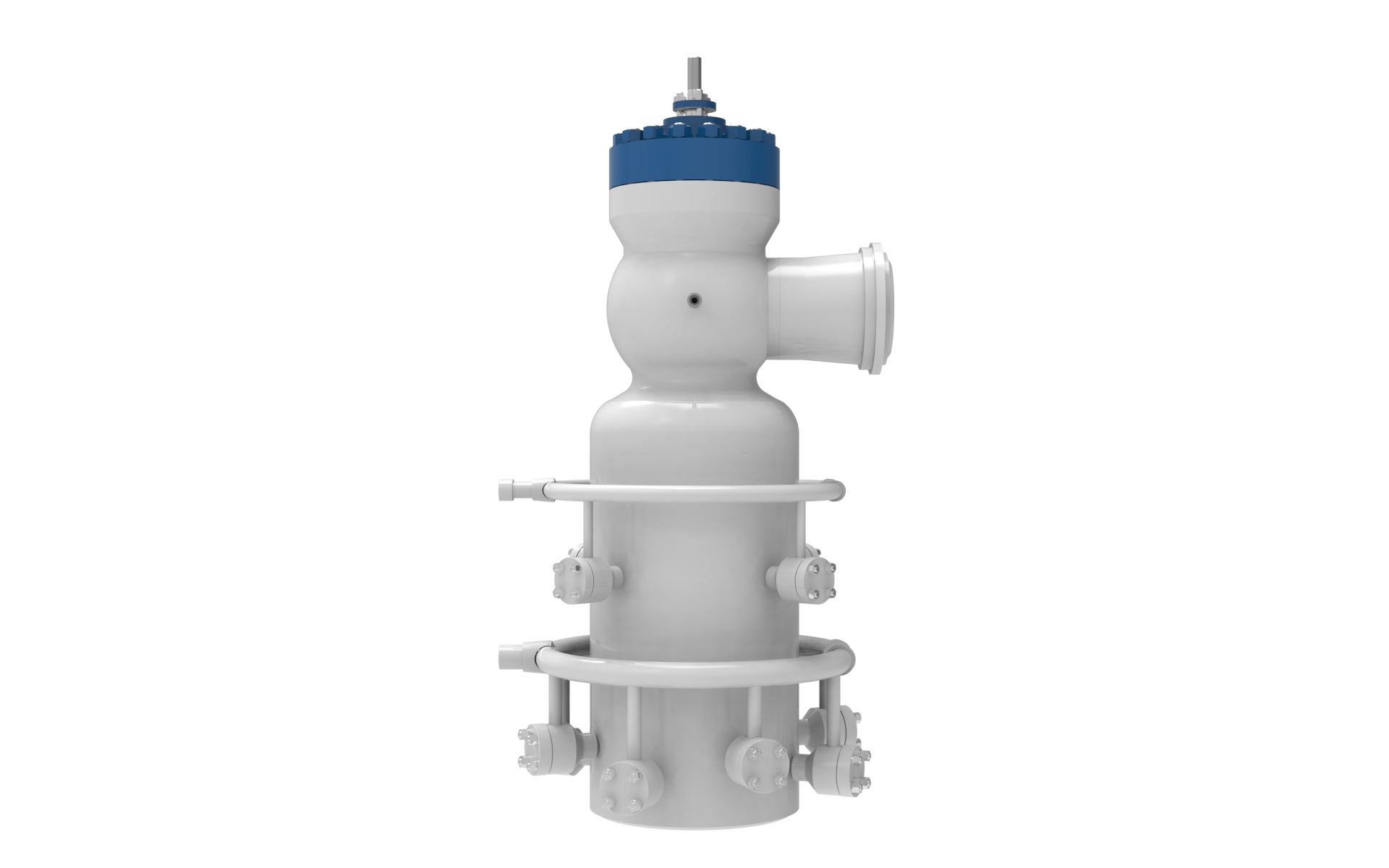

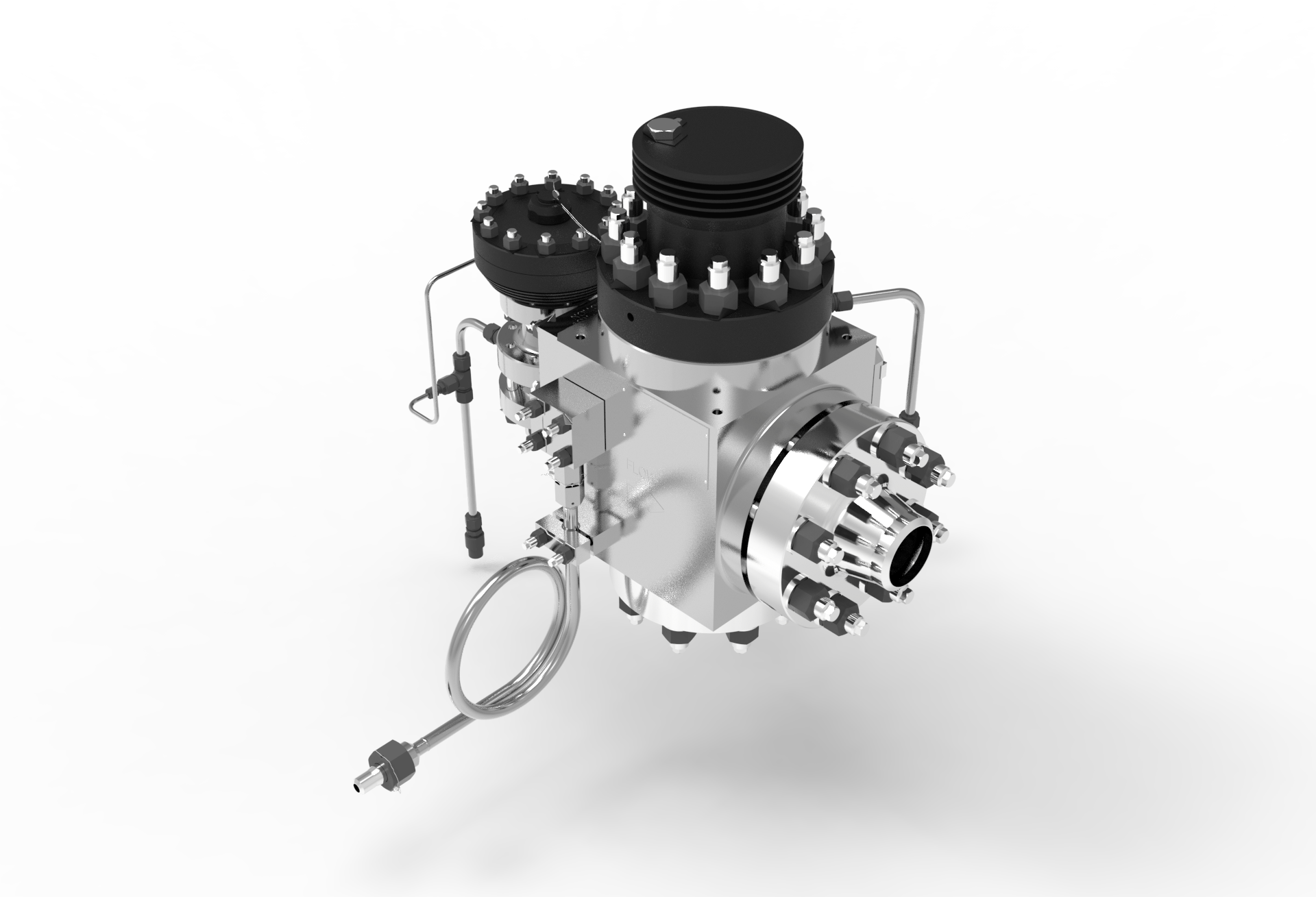

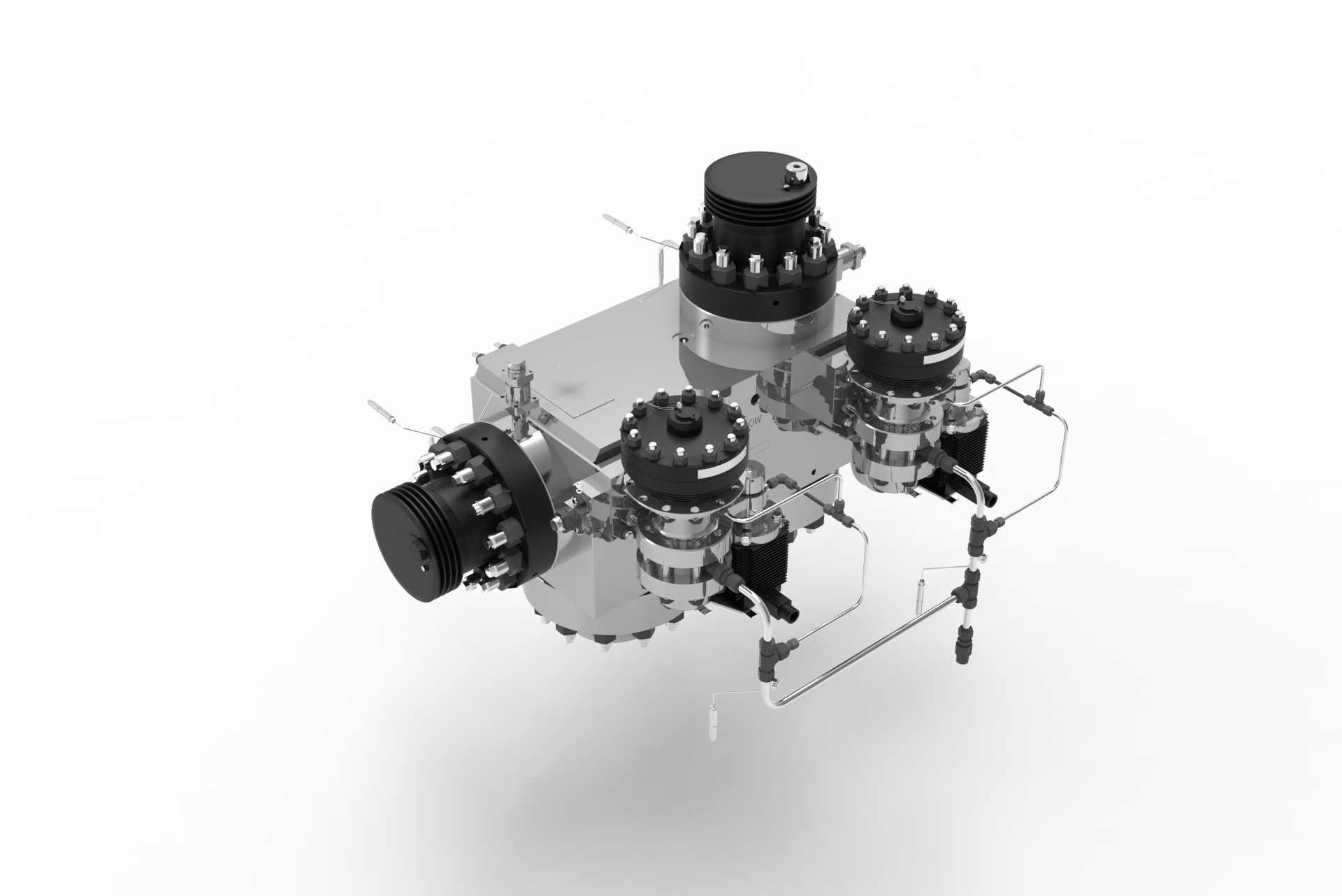

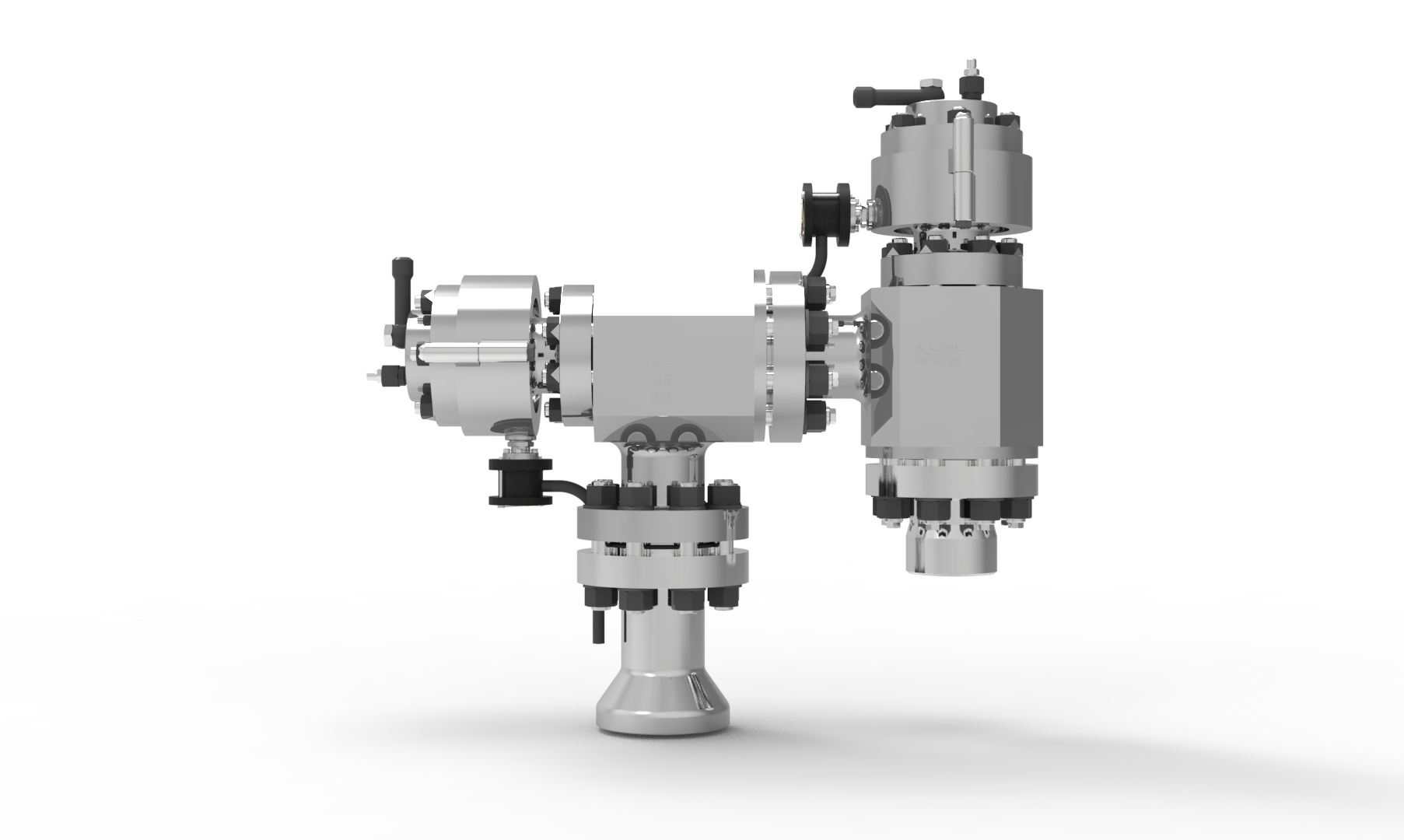

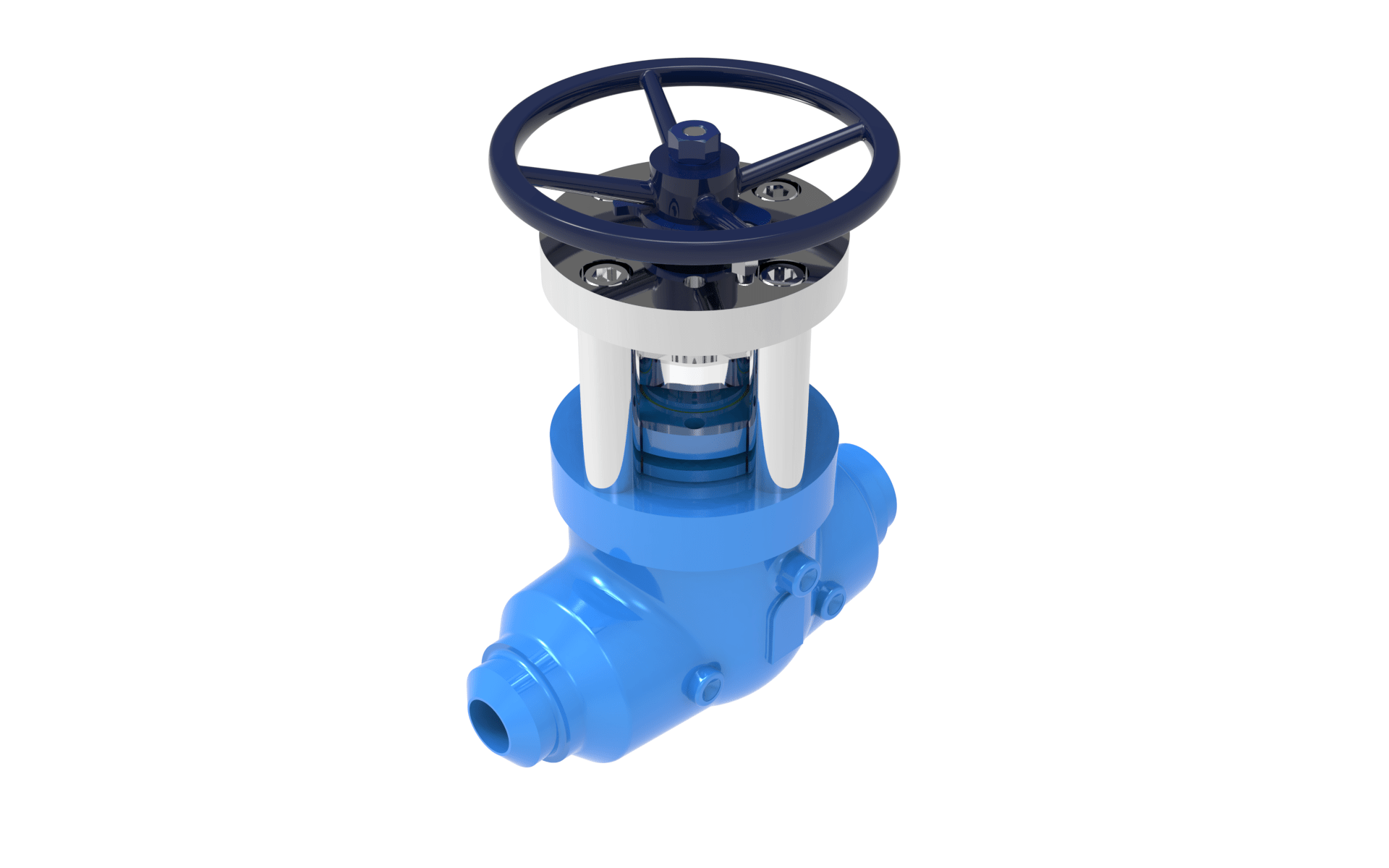

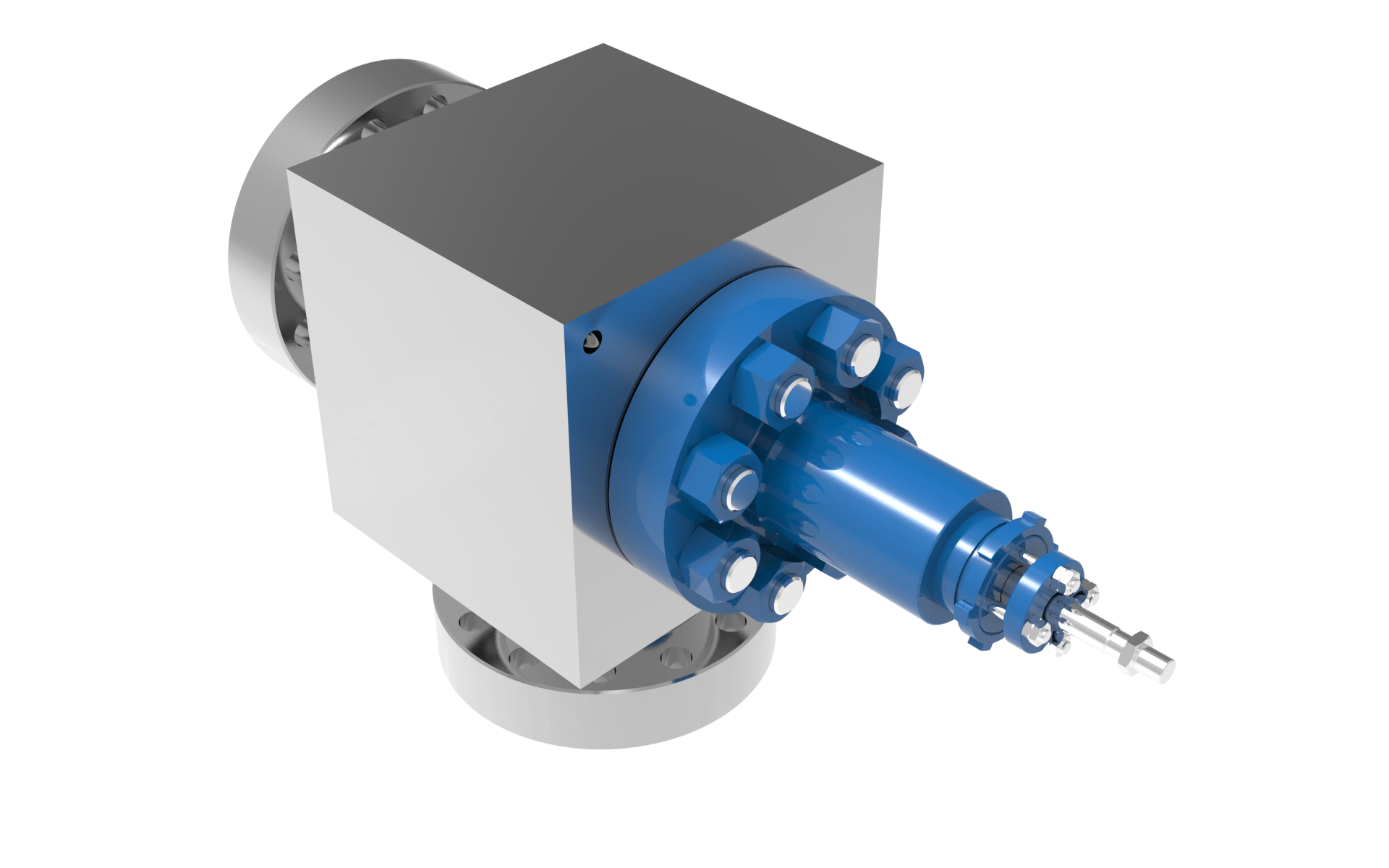

Our nuclear foundation is built on highly engineered valves and actuators from world-class brands synonymous with variety, flexibility, reliability, and trust. You’ll benefit from our unmatched experience.

UNIQUE LEVEL OF SUPPORT

Our unique level of service and support is simply unmatched, from design and manufacturing of valves on a nuclear island, to general isolation and control applications throughout the plant, to complete aftermarket solutions including maintenance, outages, upgrades, life extension projects, and through-life service.

CENTERS OF EXCELLENCE

We are exceptionally well-versed in the codes and standards of nuclear power as well as insurance considerations. We are committed to safety and can deliver compliance assurance. Our testing and training centers in Europe and the United States provide premier centers of excellence.

As the world turns to nuclear power to meet growing consumption demands, Trillium Flow Technologies™ is experienced in the nuclear industry with product lines and services that help ensure both safety and efficiency of this essential, clean energy source.

NUCLEAR POWER PRODUCTS

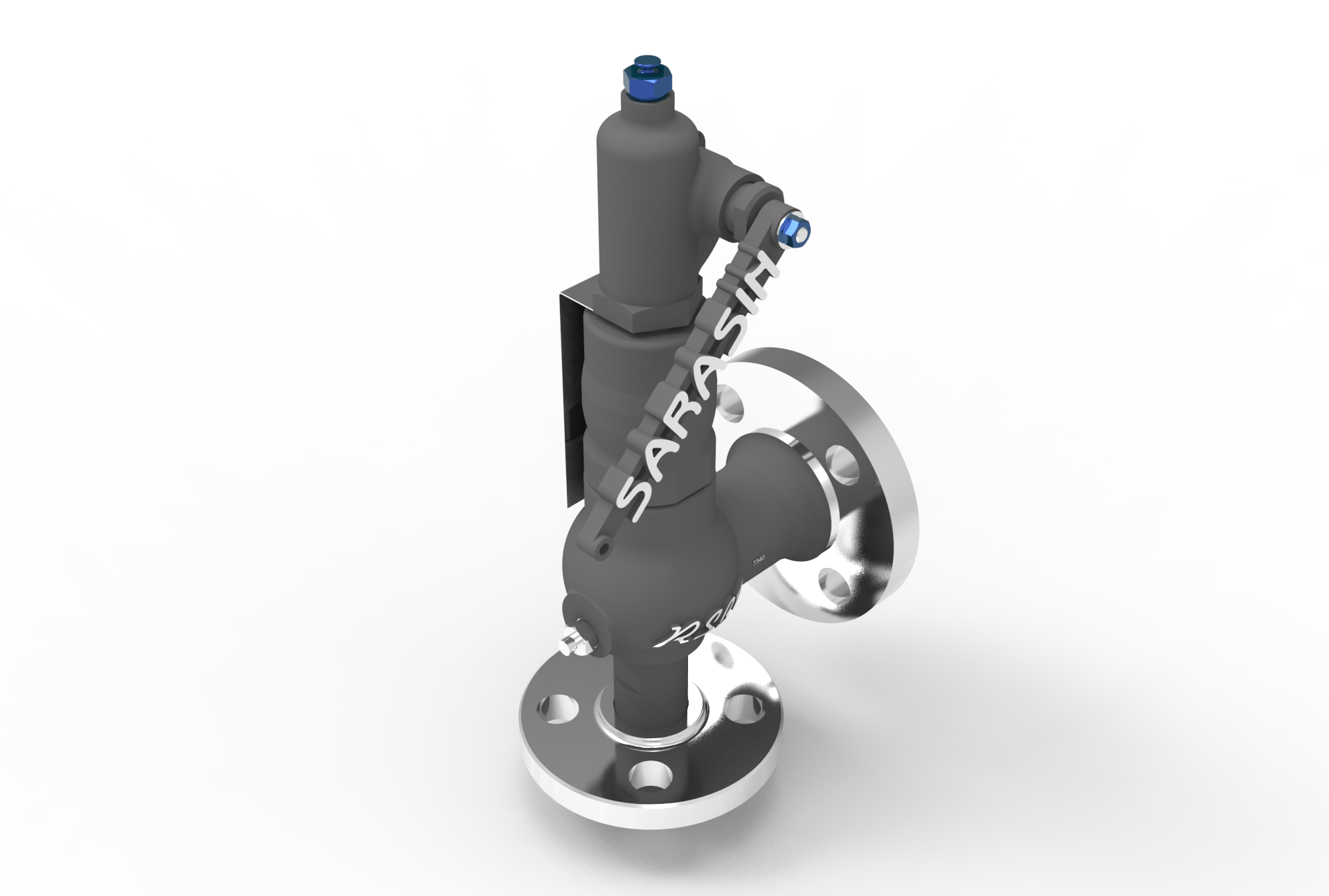

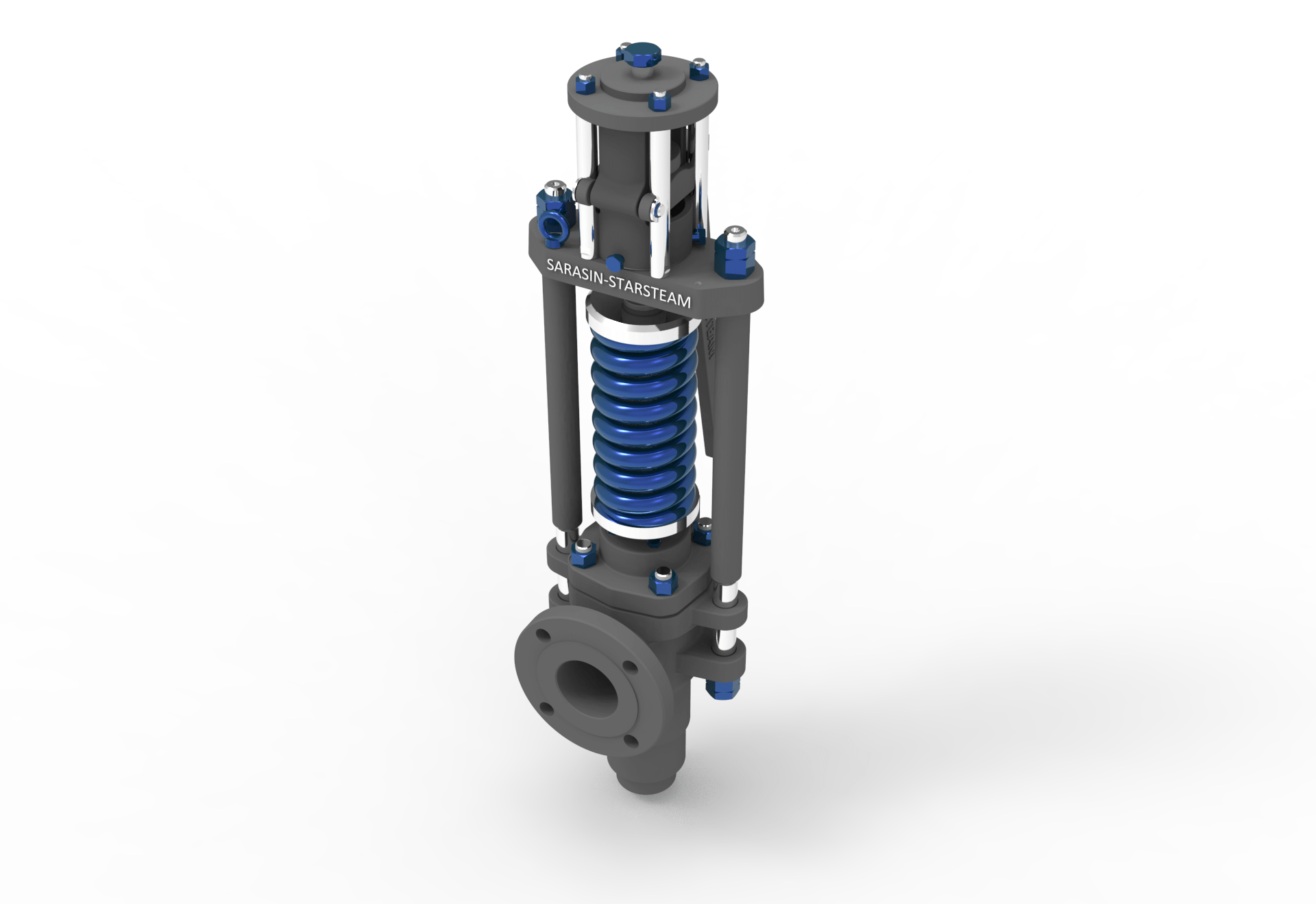

- Sarasin-RSBD®Red Point®Air,ANSI,API,ASME,Fertilizer,Food & Beverage,Gas,General Industry,Hydrogen,Industries,ISO,LNG,Media,Molten Salt,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional Power,Water & WastewaterMain_Valves,Spring Loaded Pressure Relief Valve

Main_Valves,Spring Loaded Pressure Relief Valve

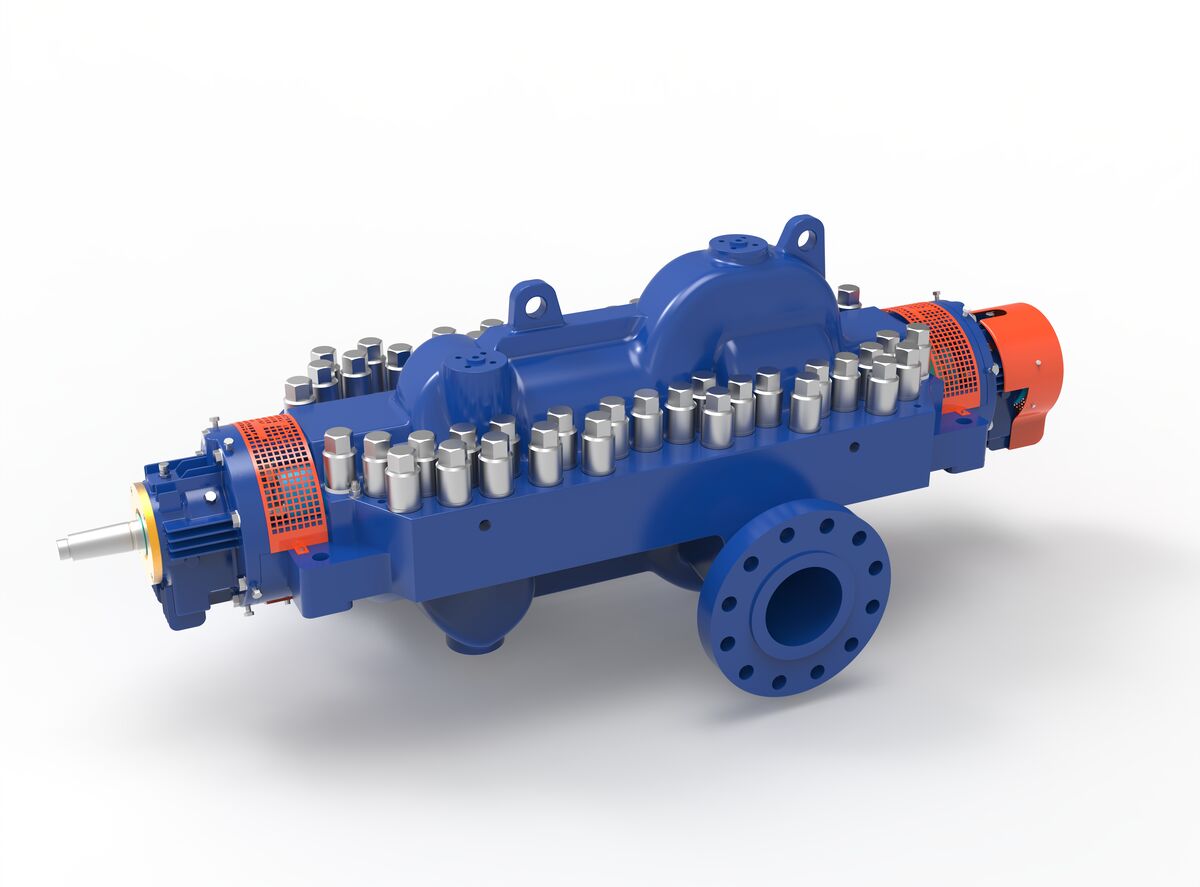

- Gabbioneta Pumps® Termomeccanica PompeRed Point®API,Desalination,Fertilizer,General Industry,Industries,Liquid,LNG,Media,Mining & Minerals,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Renewable Power,Standard,Traditional Energy,Traditional Power,Water & WastewaterBetween Bearings,Main_Pumps

Between Bearings,Main_Pumps

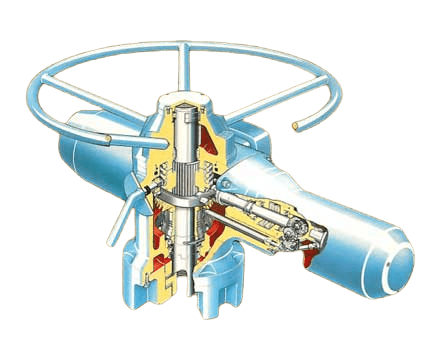

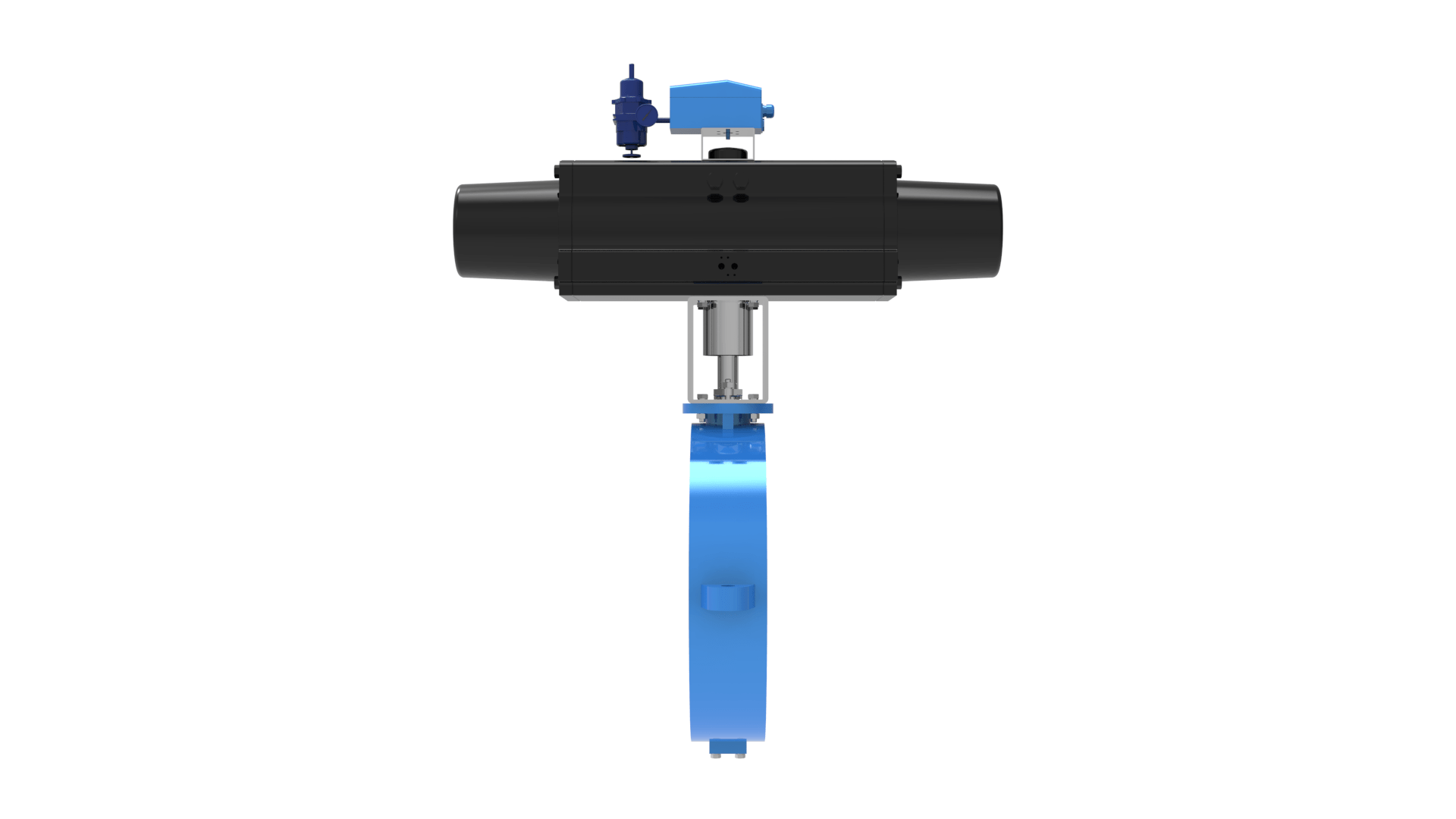

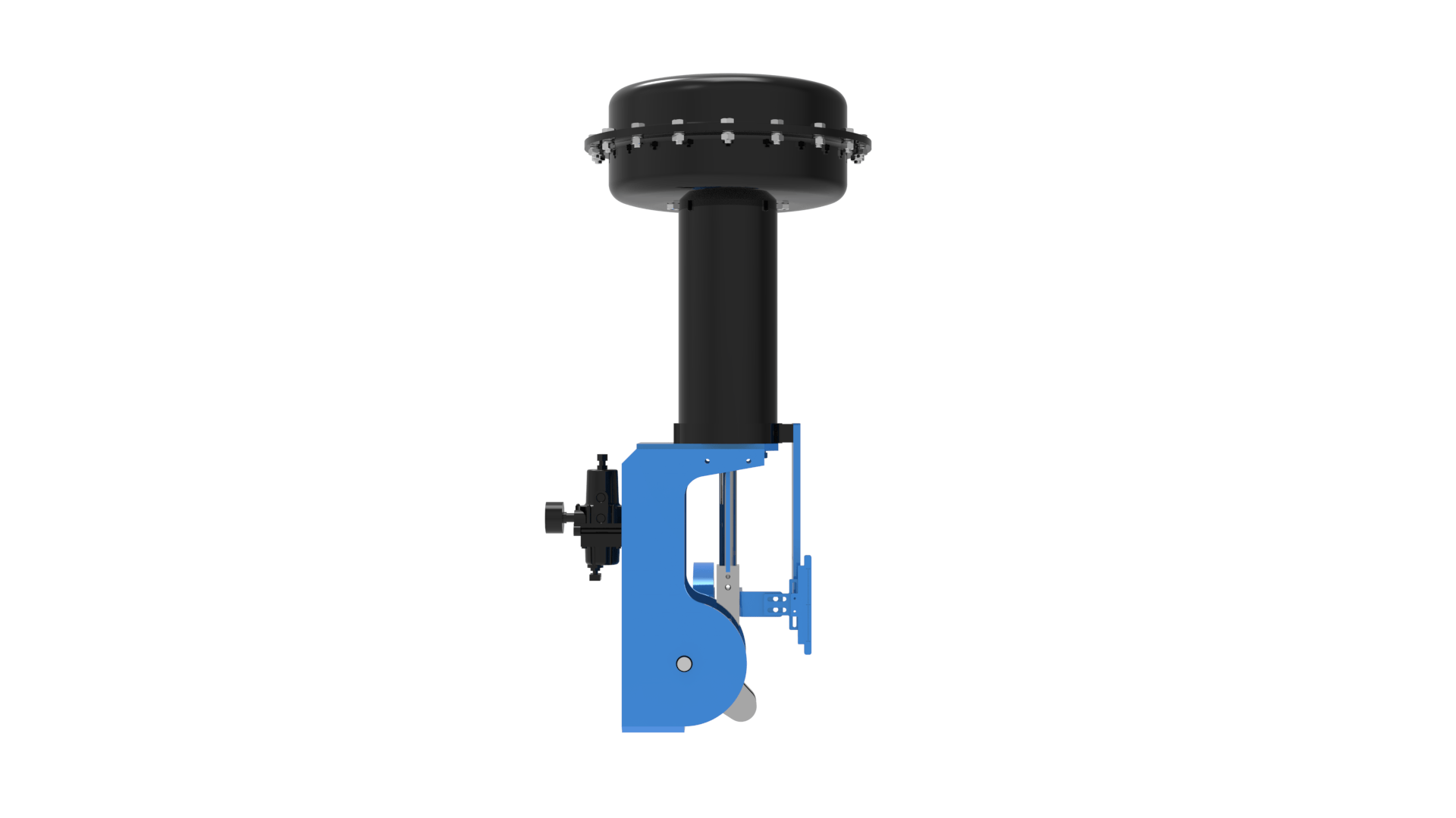

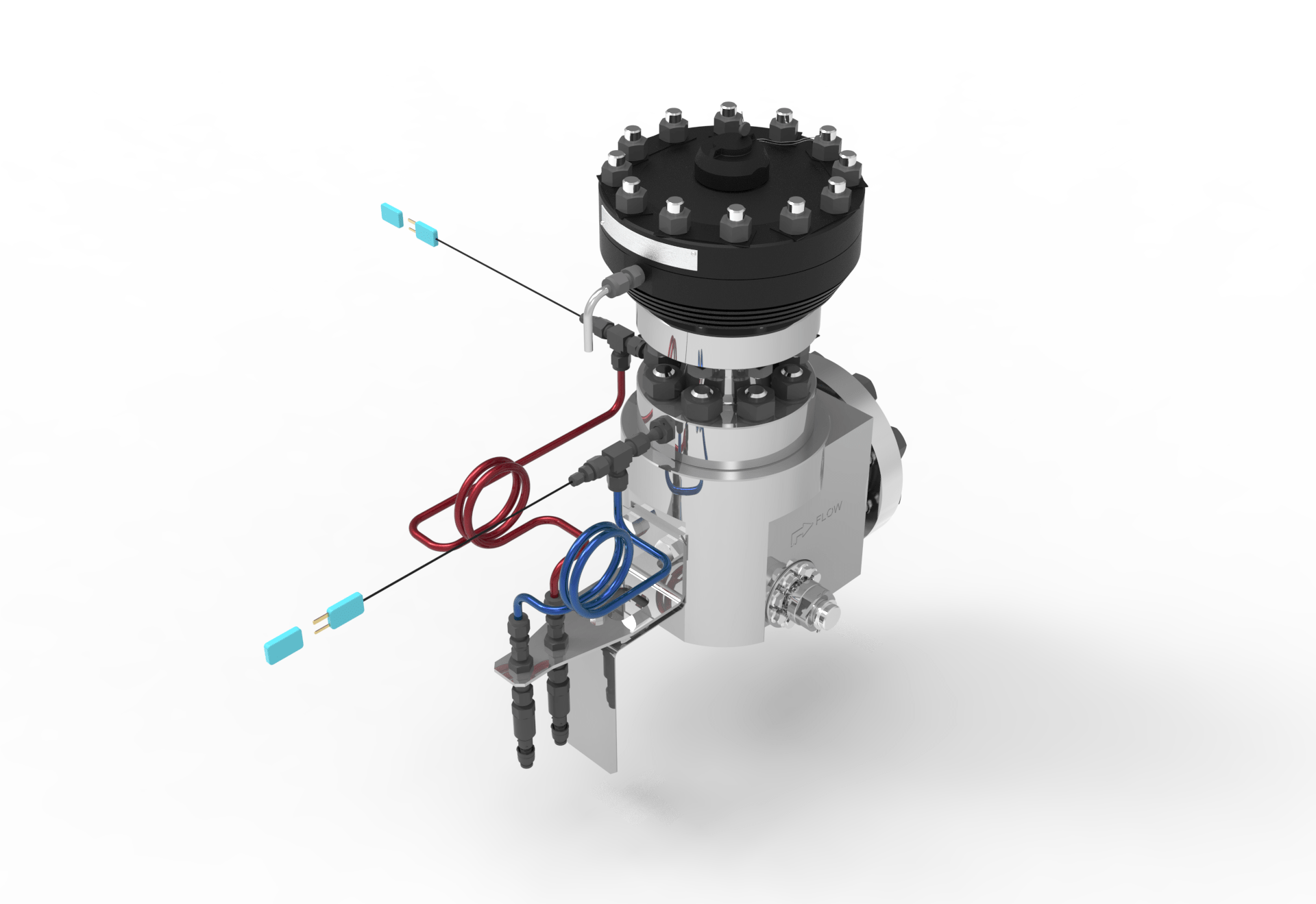

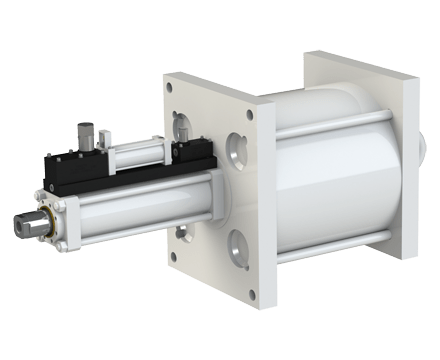

- AutoTork™Red Point®Coal Fired,Gas Fired,Industries,Media,Nonrenewable Power,Nuclear Power,Standard,Traditional Energy,Traditional PowerMain_Actuators

Main_Actuators

- Atwood & Morrill®Red Point®ASME,Coal Fired,Gas Fired,General Industry,Industries,Liquid,Media,Nonrenewable Power,Nuclear Power,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerCheck Valves,Isolation Valves,Main_Valves

Check Valves,Isolation Valves,Main_Valves

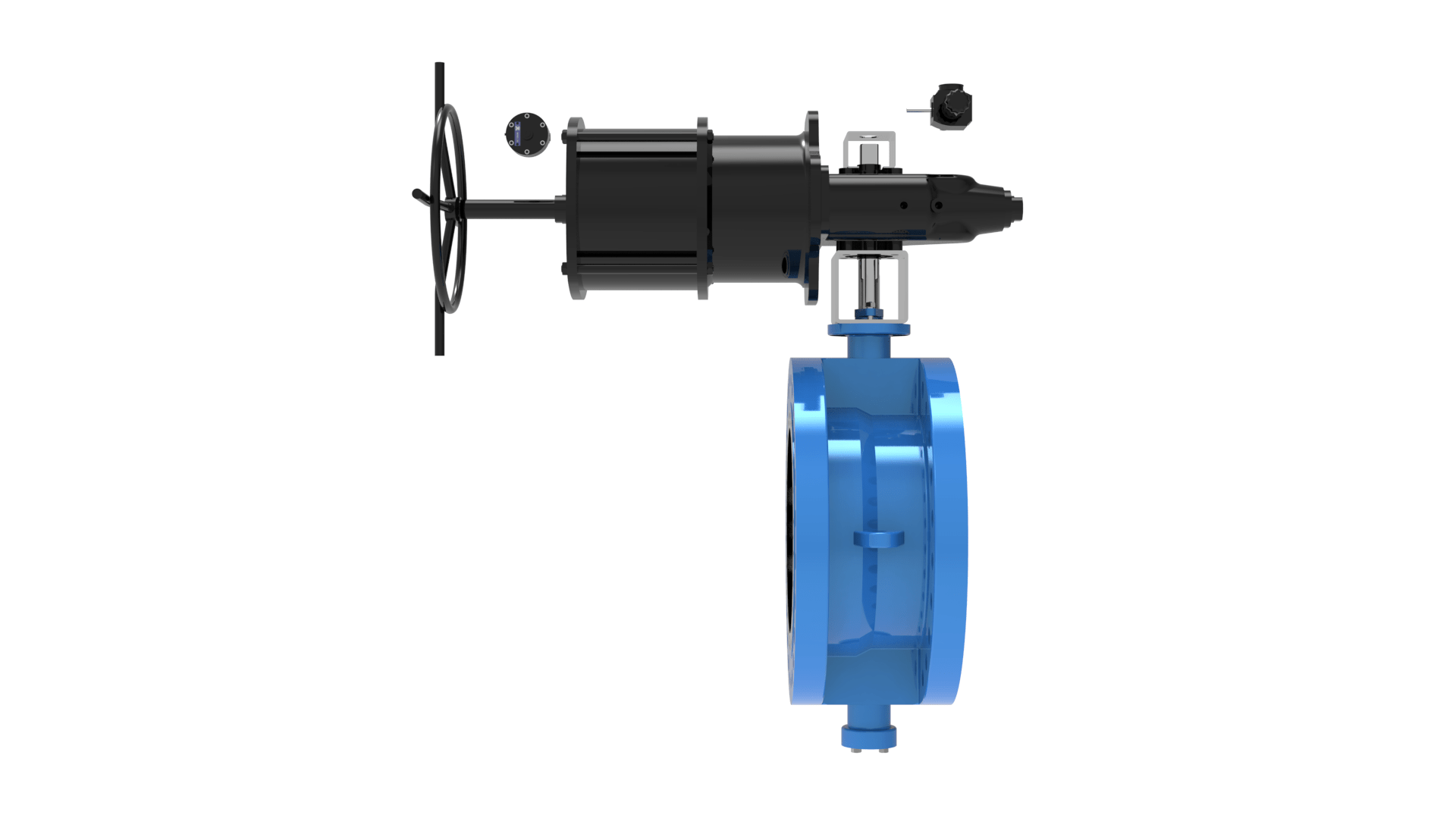

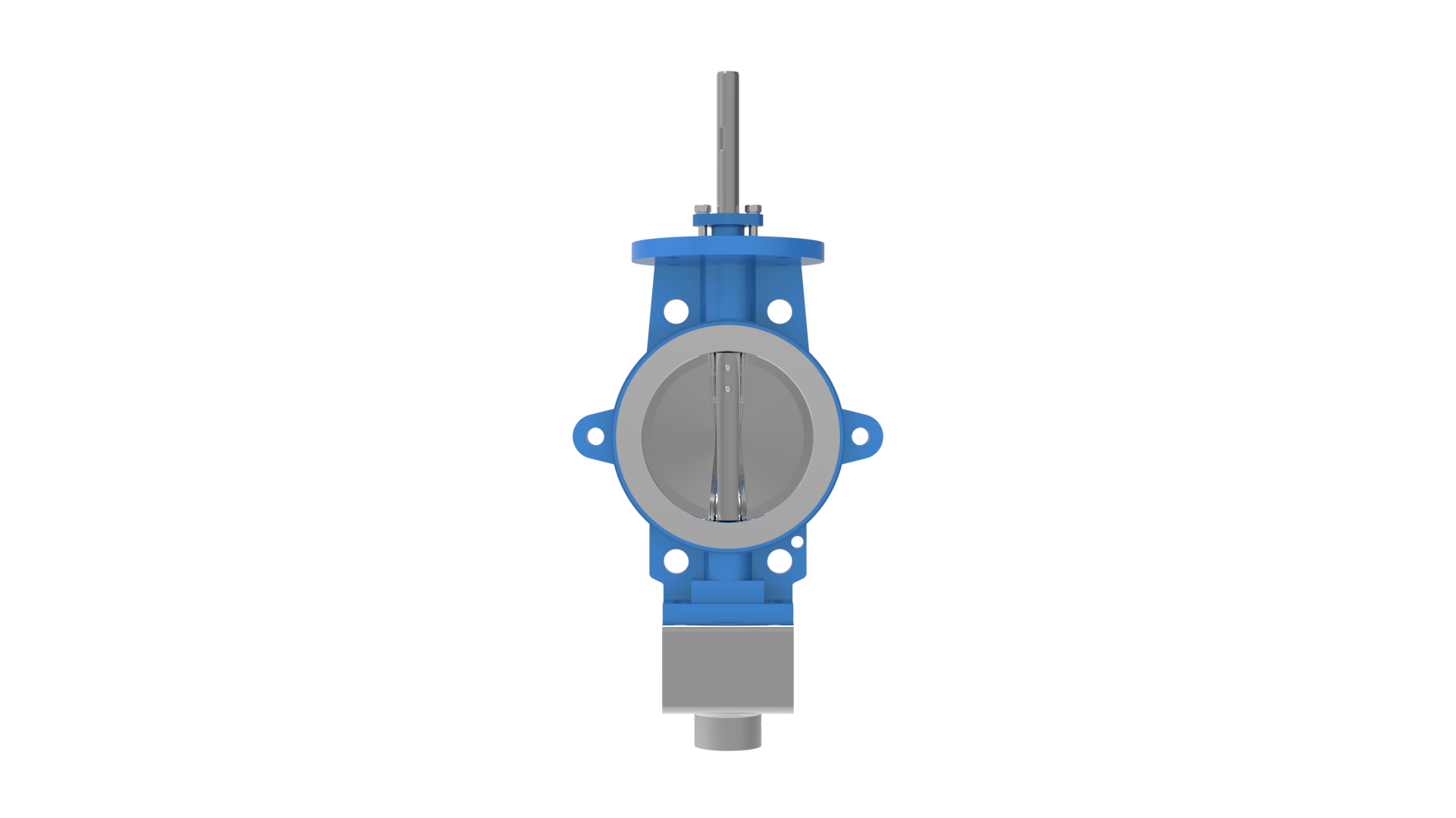

- Batley Valve®Red Point®Coal Fired,Fertilizer,Food & Beverage,Gas Fired,General Industry,Industries,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Traditional Energy,Traditional PowerButterfly Control Valves,Control Valves,Main_Valves

Butterfly Control Valves,Control Valves,Main_Valves

- Batley Valve®Red Point®ANSI,ASME,Coal Fired,Fertilizer,Food & Beverage,Gas Fired,General Industry,Industries,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Traditional Energy,Traditional Power,Water & WastewaterButterfly Control Valves,Control Valves,Main_Valves

Butterfly Control Valves,Control Valves,Main_Valves

- Batley Valve®Red Point®ANSI,ASME,Coal Fired,DIN,Fertilizer,Food & Beverage,Gas Fired,General Industry,Industries,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Traditional Energy,Traditional Power,Water & WastewaterButterfly Control Valves,Control Valves,Main_Valves

Butterfly Control Valves,Control Valves,Main_Valves

- Batley Valve®Red Point®ANSI,API,ASME,Coal Fired,DIN,Fertilizer,Food & Beverage,Gas,Gas Fired,General Industry,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Traditional Energy,Traditional PowerButterfly Control Valves,Control Valves,Main_Valves

Butterfly Control Valves,Control Valves,Main_Valves

- Batley Valve®Red Point®ANSI,API,ASME,Coal Fired,DIN,Fertilizer,Food & Beverage,Gas Fired,General Industry,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Solids Handling,Standard,Traditional Energy,Traditional PowerButterfly Control Valves,Control Valves,Main_Valves

Butterfly Control Valves,Control Valves,Main_Valves

- Batley Valve®Red Point®API,ASME,Coal Fired,DIN,Fertilizer,Food & Beverage,Gas Fired,General Industry,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Traditional Energy,Traditional Power,Water & WastewaterButterfly Control Valves,Control Valves,Main_Valves

Butterfly Control Valves,Control Valves,Main_Valves

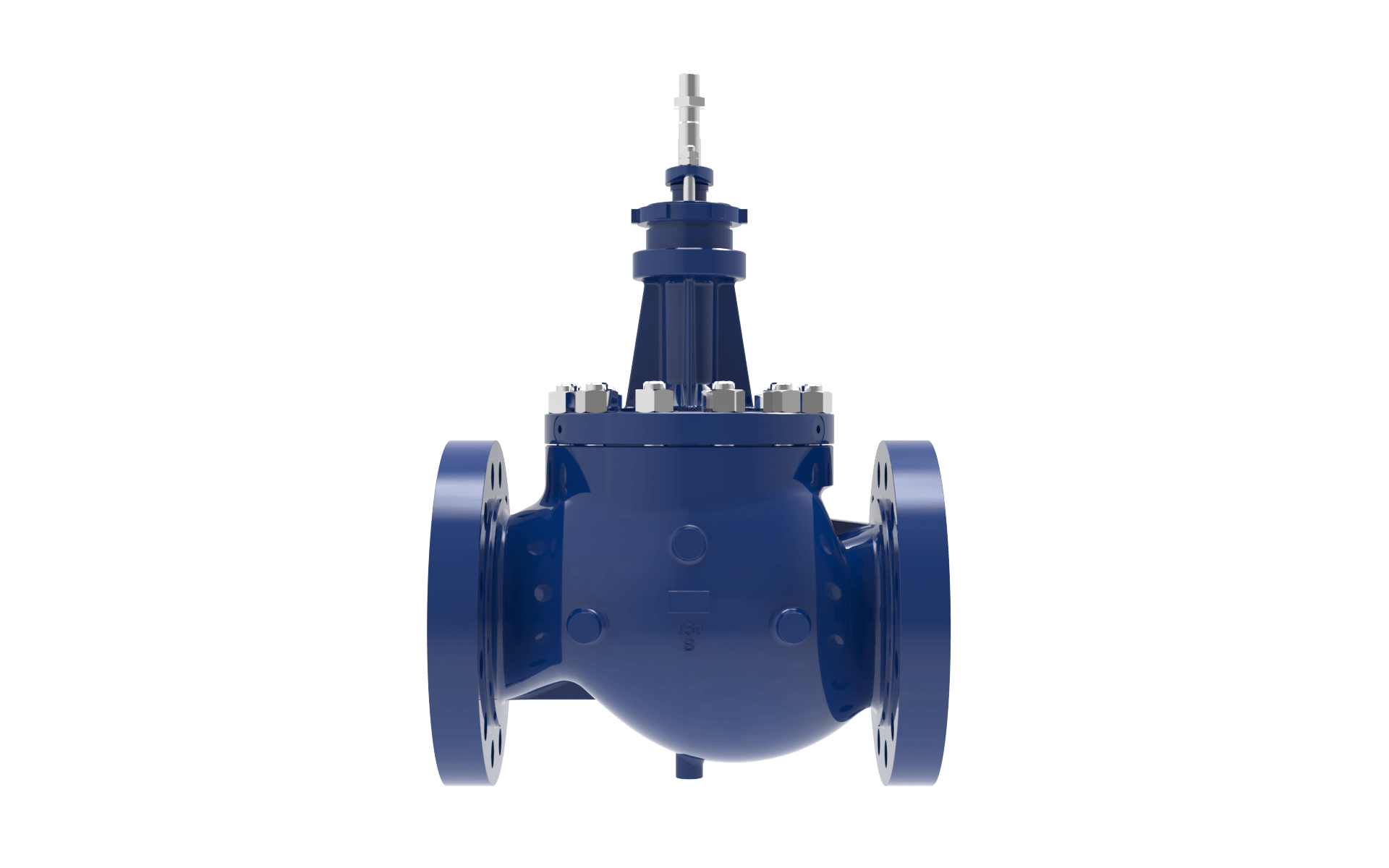

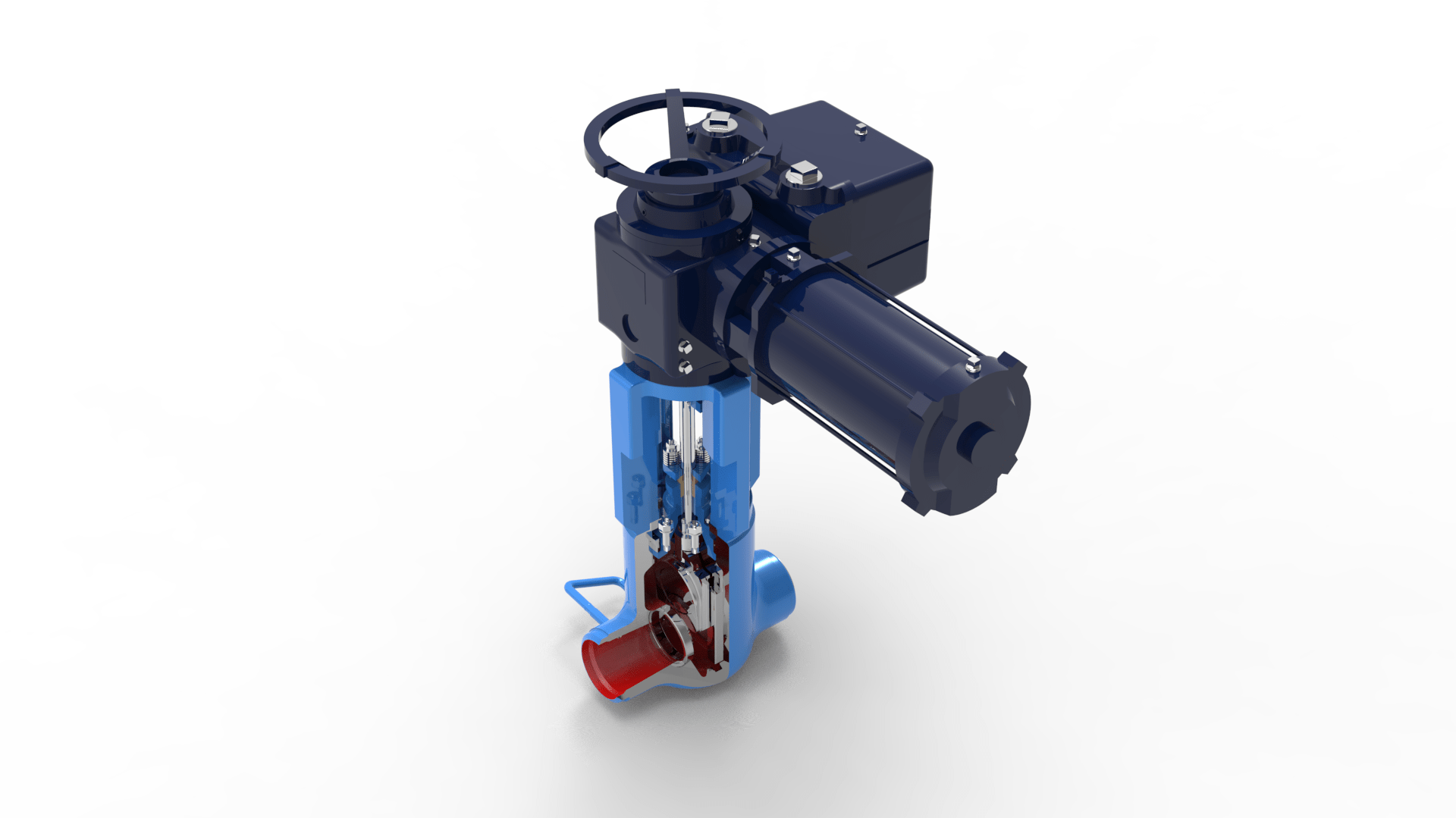

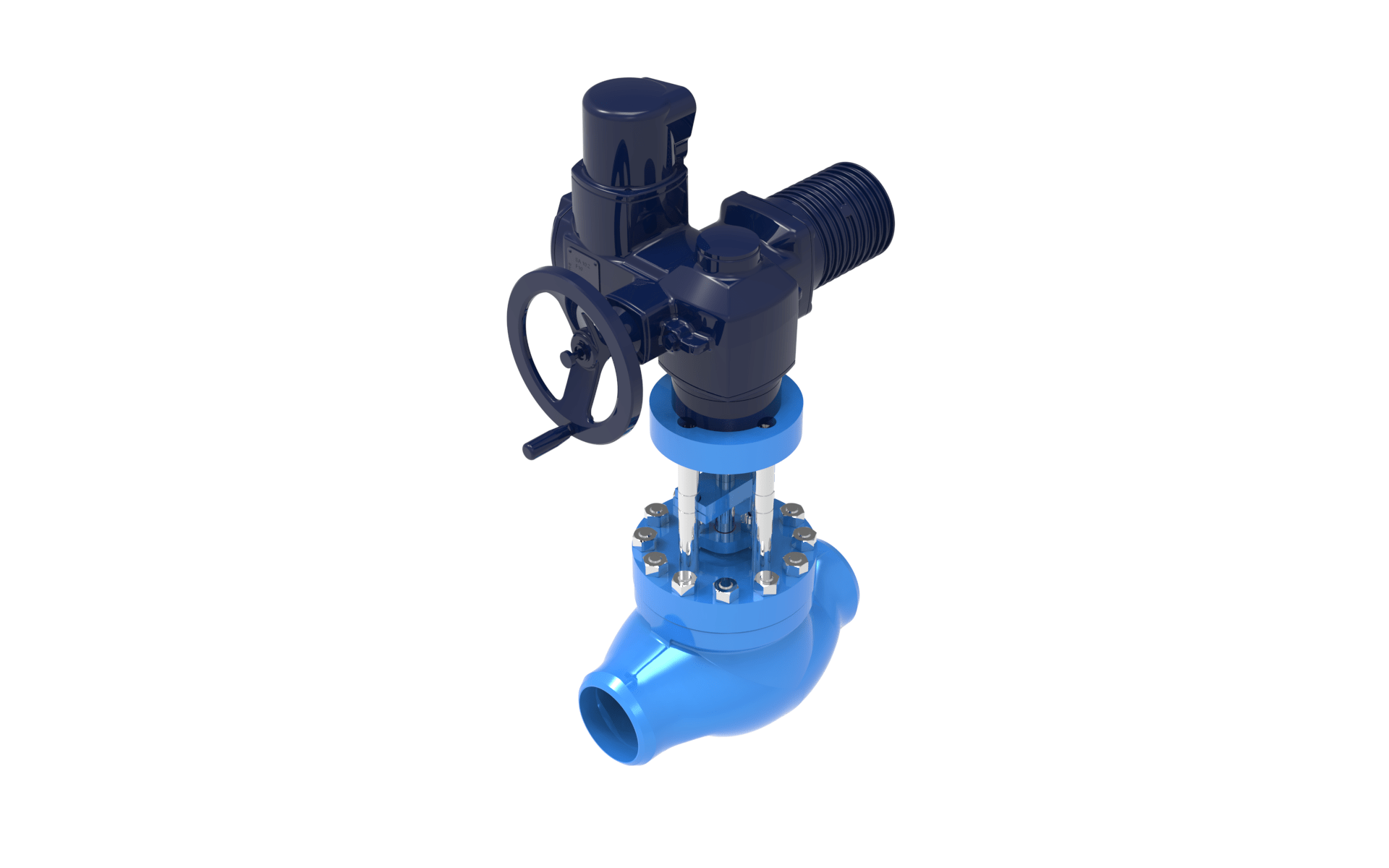

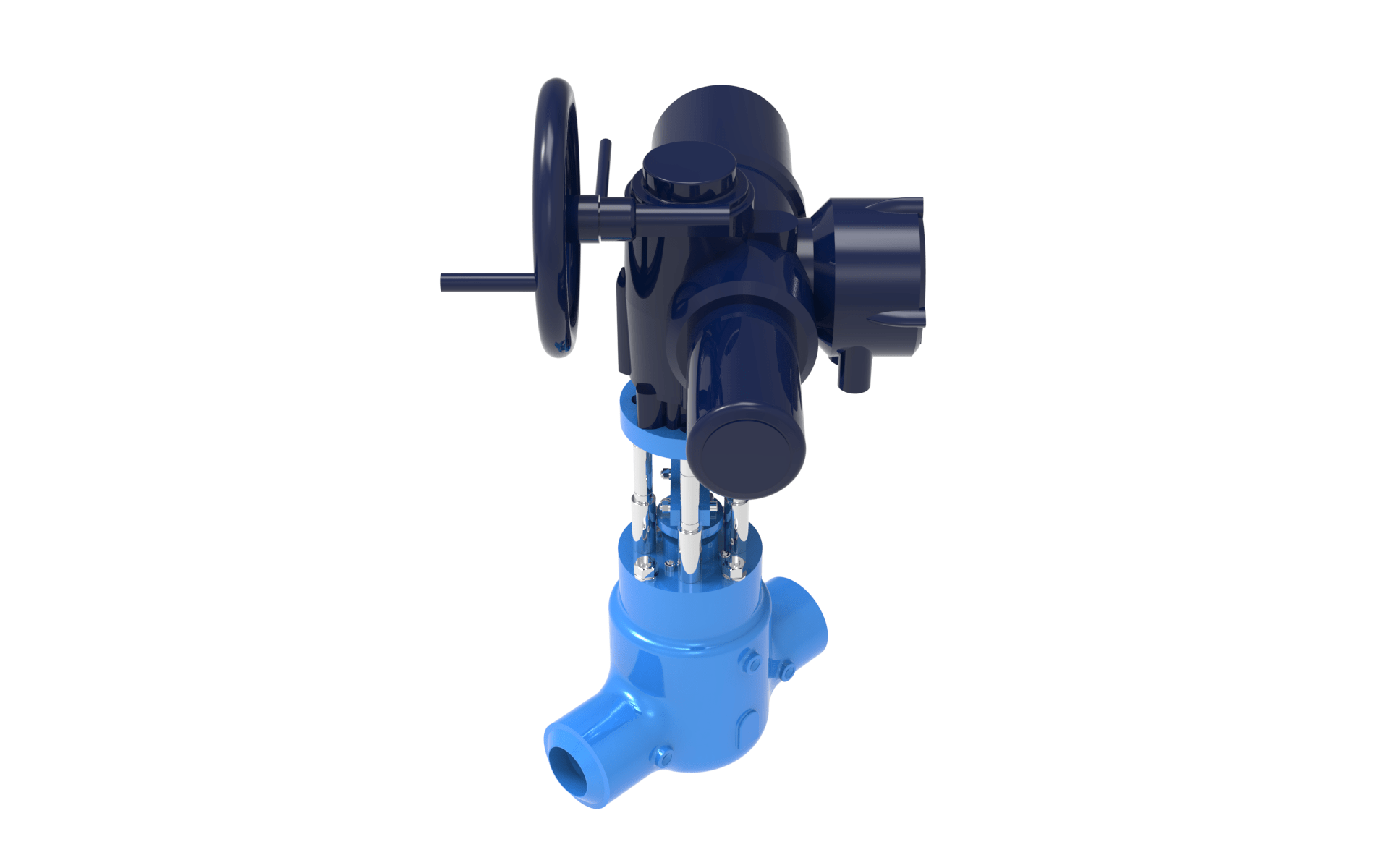

- Blakeborough®Red Point®API,ATEX,Fertilizer,Food & Beverage,Gas,General Industry,Hydrogen,Industries,ISO,LNG,Media,Mining & Minerals,Molten Salt,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerControl Valves,Globe Control Valves,Main_Valves

Control Valves,Globe Control Valves,Main_Valves

- Blakeborough®Red Point®ASME,Fertilizer,Food & Beverage,Gas,General Industry,Hydrogen,Industries,LNG,Media,Mining & Minerals,Molten Salt,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerControl Valves,Main_Steamturbines

Control Valves,Main_Steamturbines

- Blakeborough®Red Point®Air,ANSI,ASME,ATEX,Fertilizer,Food & Beverage,Gas,General Industry,Industries,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerControl Valves,Globe Control Valves,Main_Valves

Control Valves,Globe Control Valves,Main_Valves

- Blakeborough®Red Point®ANSI,Fertilizer,Food & Beverage,General Industry,Industries,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerDesuperheaters and Turbine Bypass,Main_Valves

Desuperheaters and Turbine Bypass,Main_Valves

- Blakeborough®Red Point®ANSI,Fertilizer,Food & Beverage,General Industry,Industries,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerDesuperheaters and Turbine Bypass,Main_Valves

Desuperheaters and Turbine Bypass,Main_Valves

- Blakeborough®Red Point®ANSI,API,ASME,ATEX,Fertilizer,Food & Beverage,Gas,General Industry,Hydrogen,Industries,ISO,Liquid,LNG,Media,Mining & Minerals,Molten Salt,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerControl Valves,Globe Control Valves,Main_Valves

Control Valves,Globe Control Valves,Main_Valves

- Blakeborough®Red Point®ANSI,API,ASME,ATEX,Gas,General Industry,Hydrogen,Industries,ISO,Liquid,LNG,Media,Mining & Minerals,Molten Salt,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,SMR,Solids Handling,StandardChoke Valves,Main_Valves

Choke Valves,Main_Valves

- Blakeborough®Red Point®ANSI,General Industry,Industries,Media,Nonrenewable Power,Nuclear Power,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerControl Valves,Globe Control Valves,Main_Valves

Control Valves,Globe Control Valves,Main_Valves

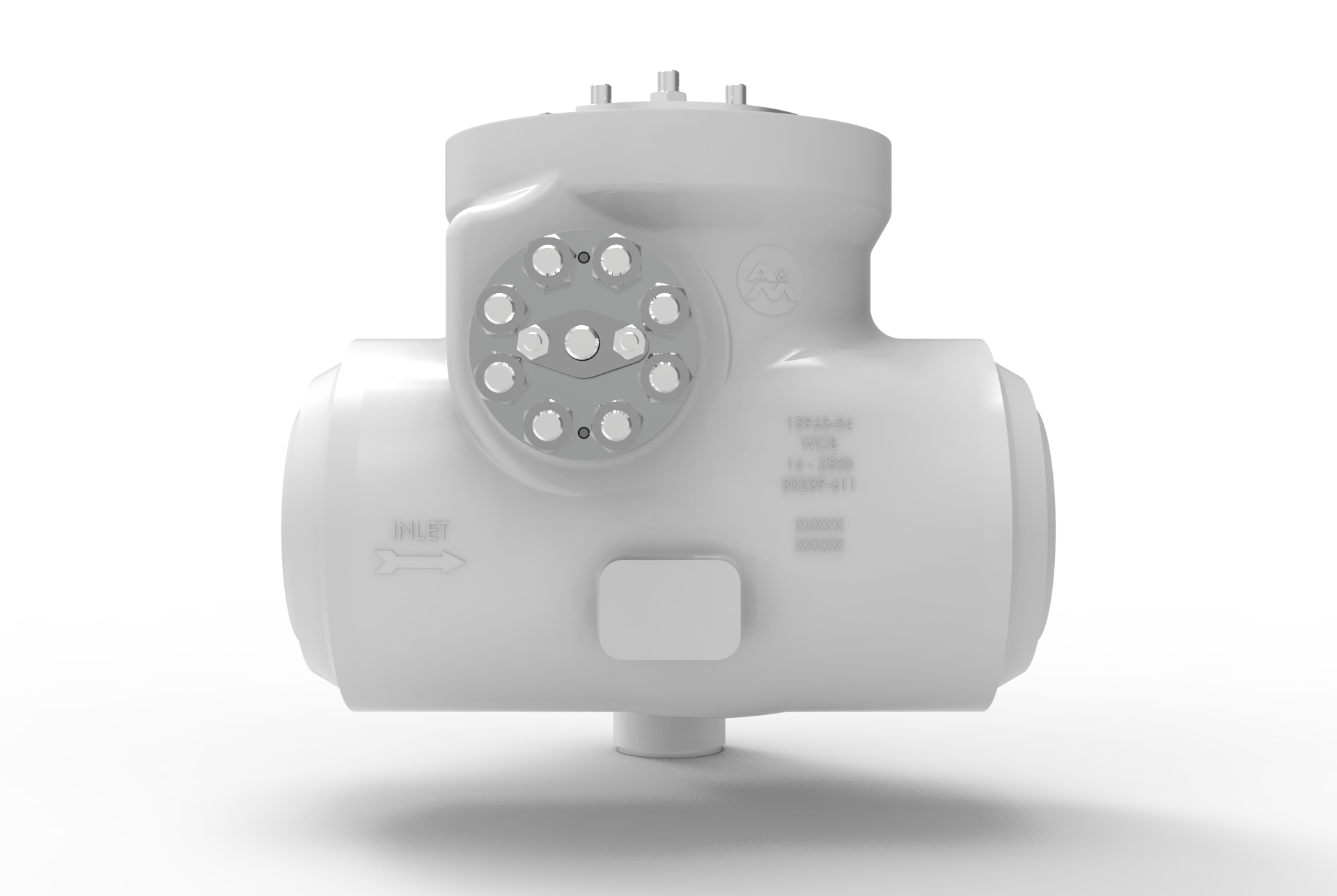

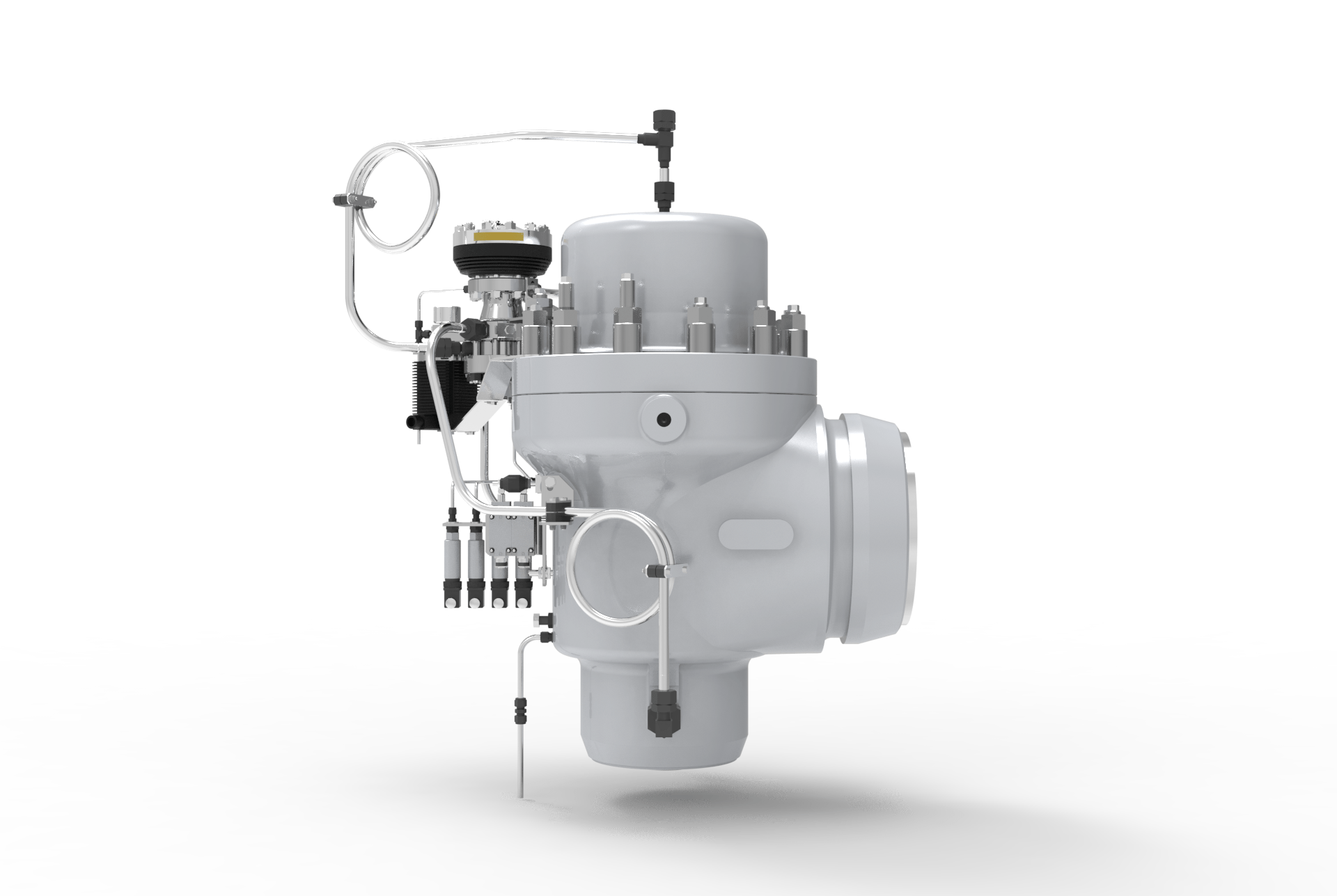

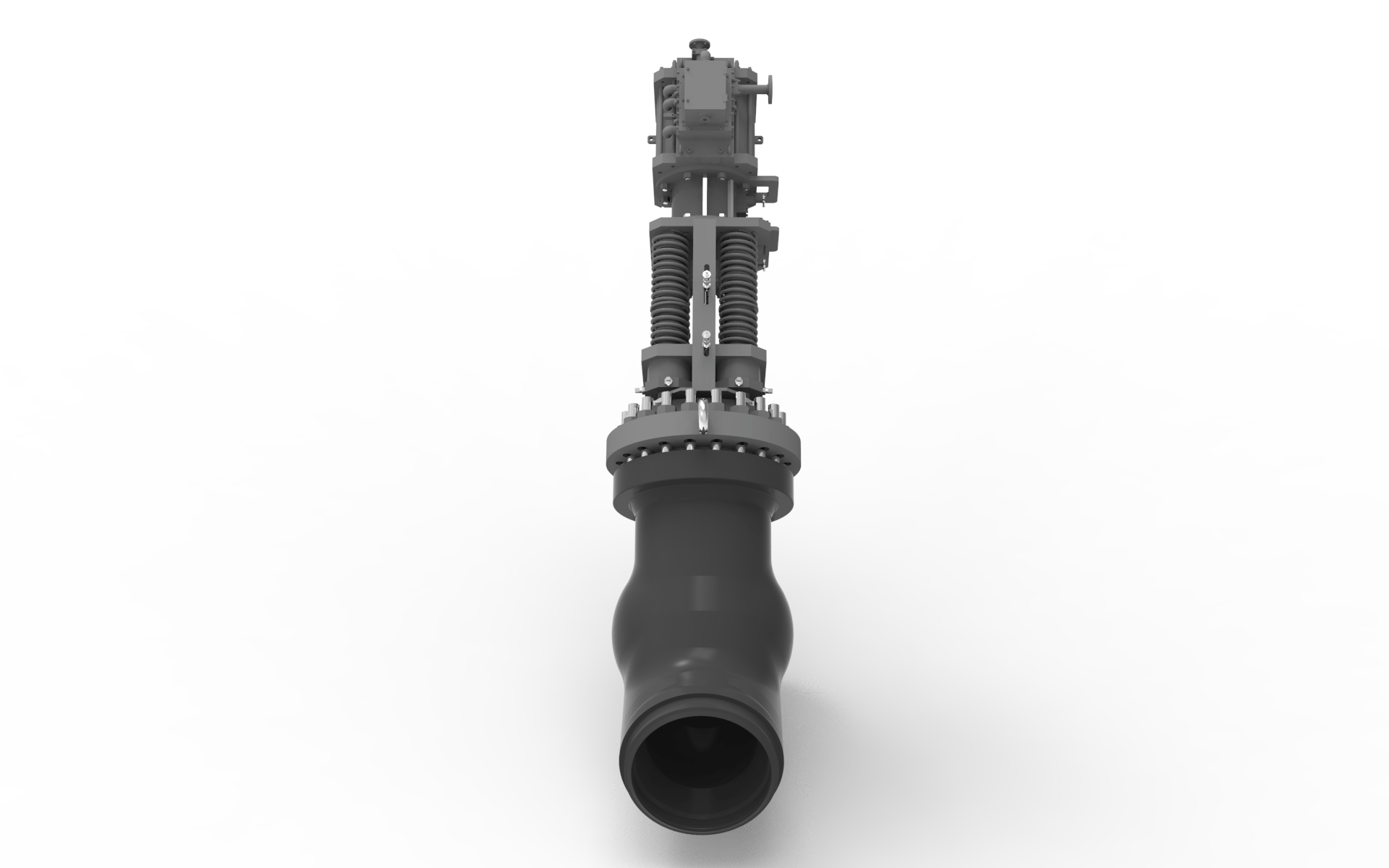

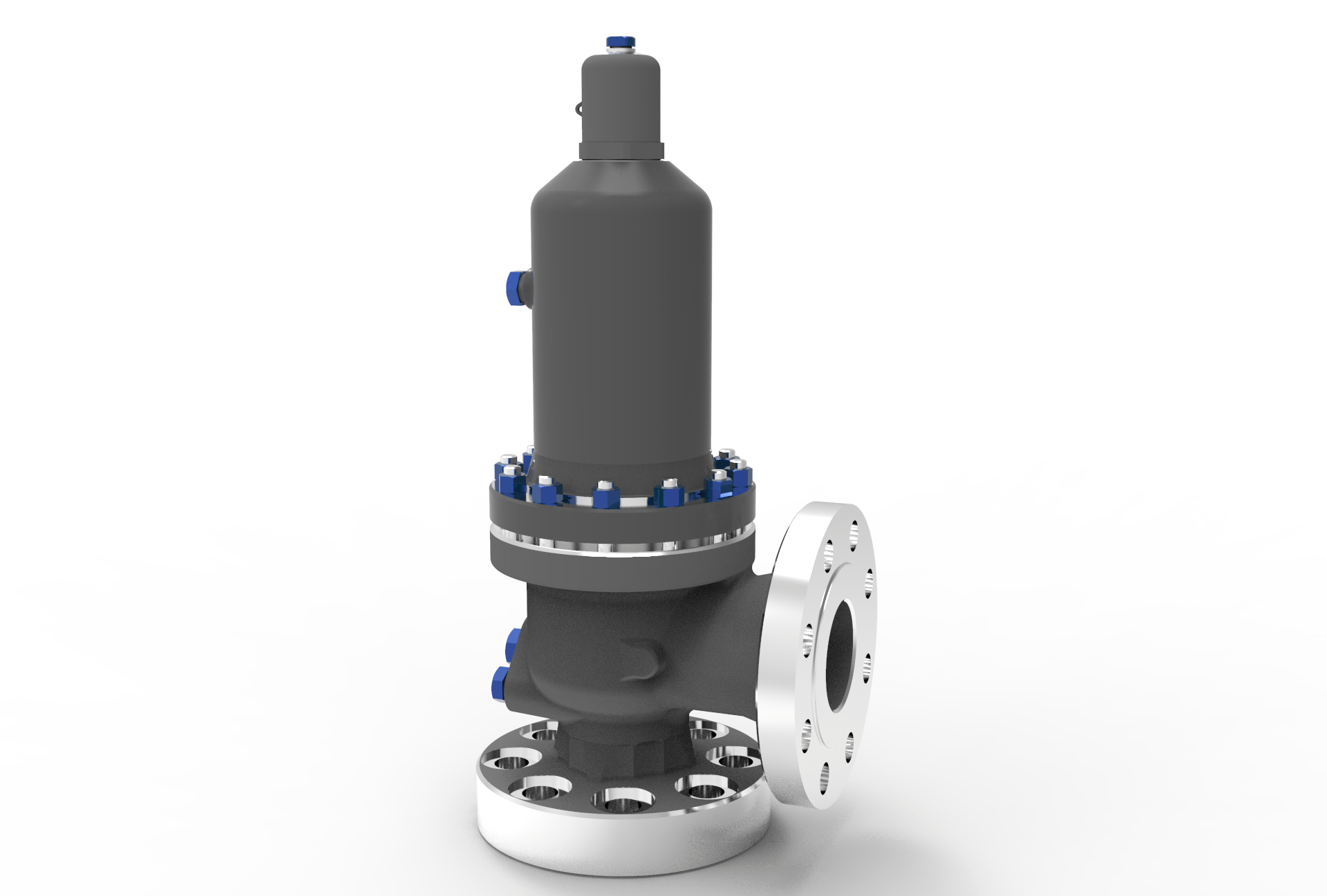

- SEBIM®Red Point®Nuclear PowerMain_Valves,Pilot Operated Pressure Relief Valves

Main_Valves,Pilot Operated Pressure Relief Valves

- SEBIM®Red Point®ASME,Gas,Industries,Liquid,Media,Nuclear Power,SMR,Standard,SteamMain_Valves,Pilot Operated Pressure Relief Valves

Main_Valves,Pilot Operated Pressure Relief Valves

- SEBIM®Red Point®ASME,Gas,Industries,Liquid,Media,Nuclear Power,SMR,Standard,SteamMain_Valves,Pilot Operated Pressure Relief Valves

Main_Valves,Pilot Operated Pressure Relief Valves

- Red Point®Red Point®API,ASME,Fertilizer,Gas,General Industry,Hydrogen,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Traditional Energy,Traditional PowerBall Valves,Main_Valves

Ball Valves,Main_Valves

- Red Point®Red Point®API,ASME,Fertilizer,Gas,General Industry,Hydrogen,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Traditional Energy,Traditional PowerBall Valves,Main_Valves

Ball Valves,Main_Valves

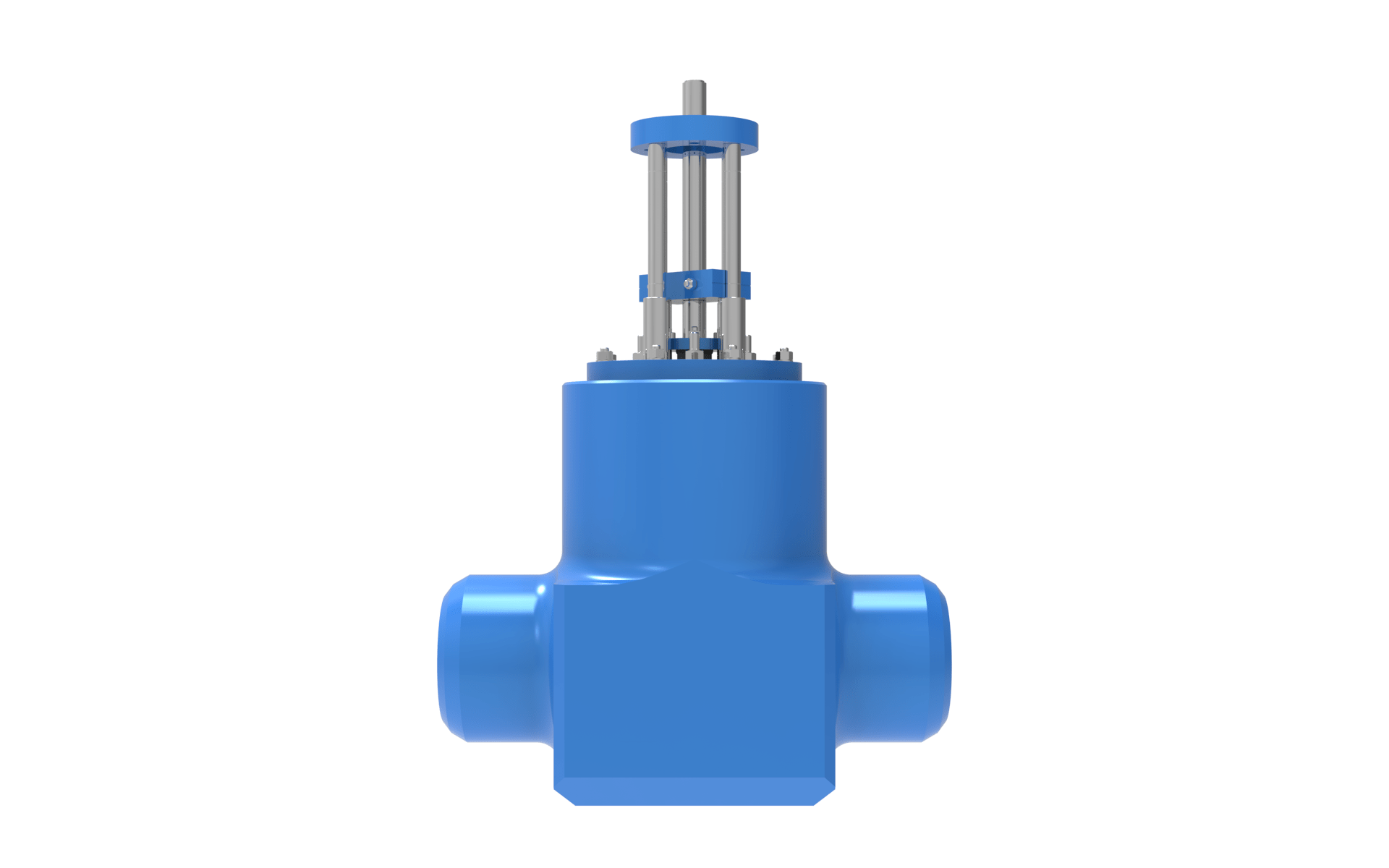

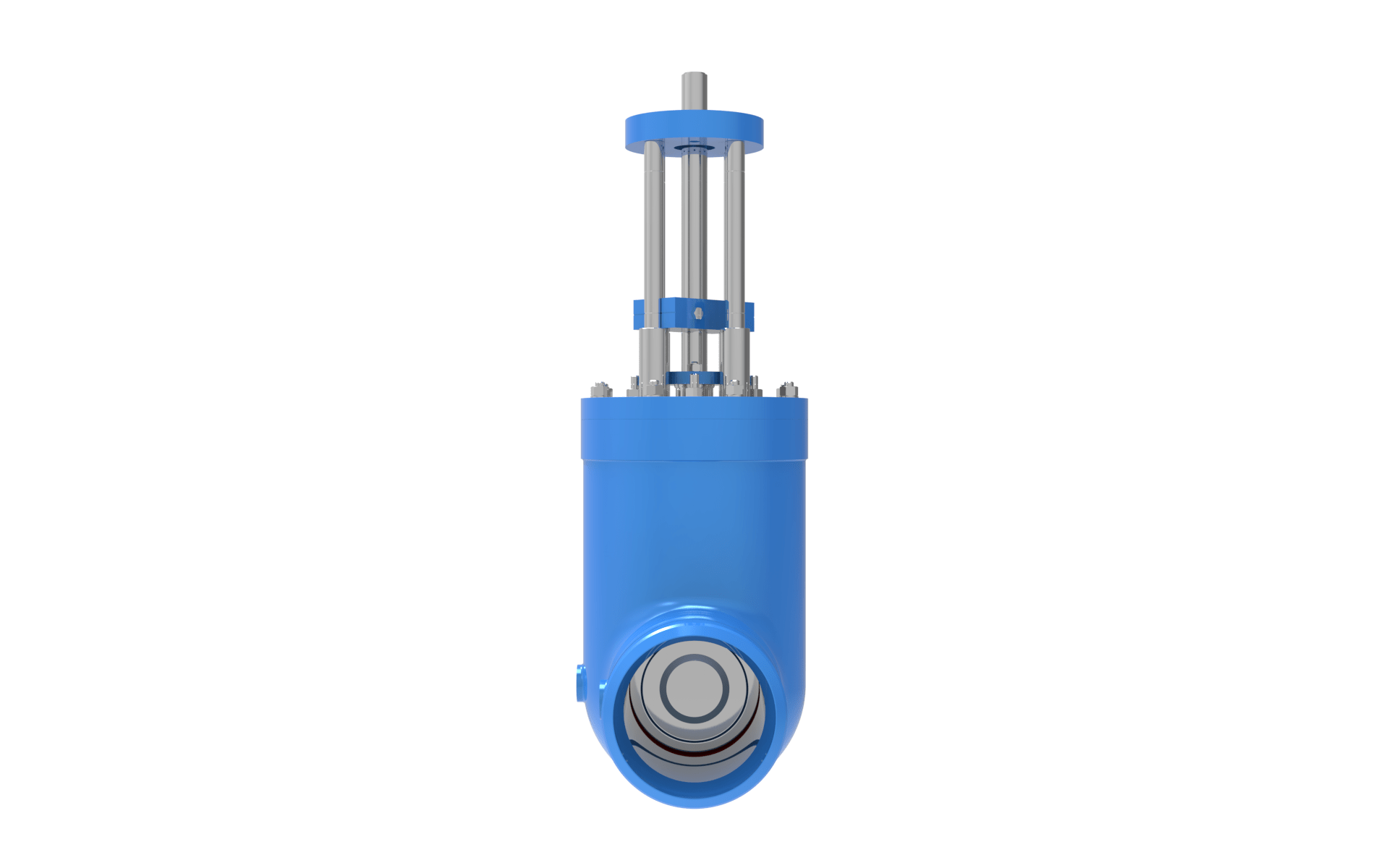

- Hopkinsons®Red Point®ASME,Fertilizer,Food & Beverage,General Industry,Industries,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas - Downstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerGate Valves,Isolation Valves,Main_Steamturbines

Gate Valves,Isolation Valves,Main_Steamturbines

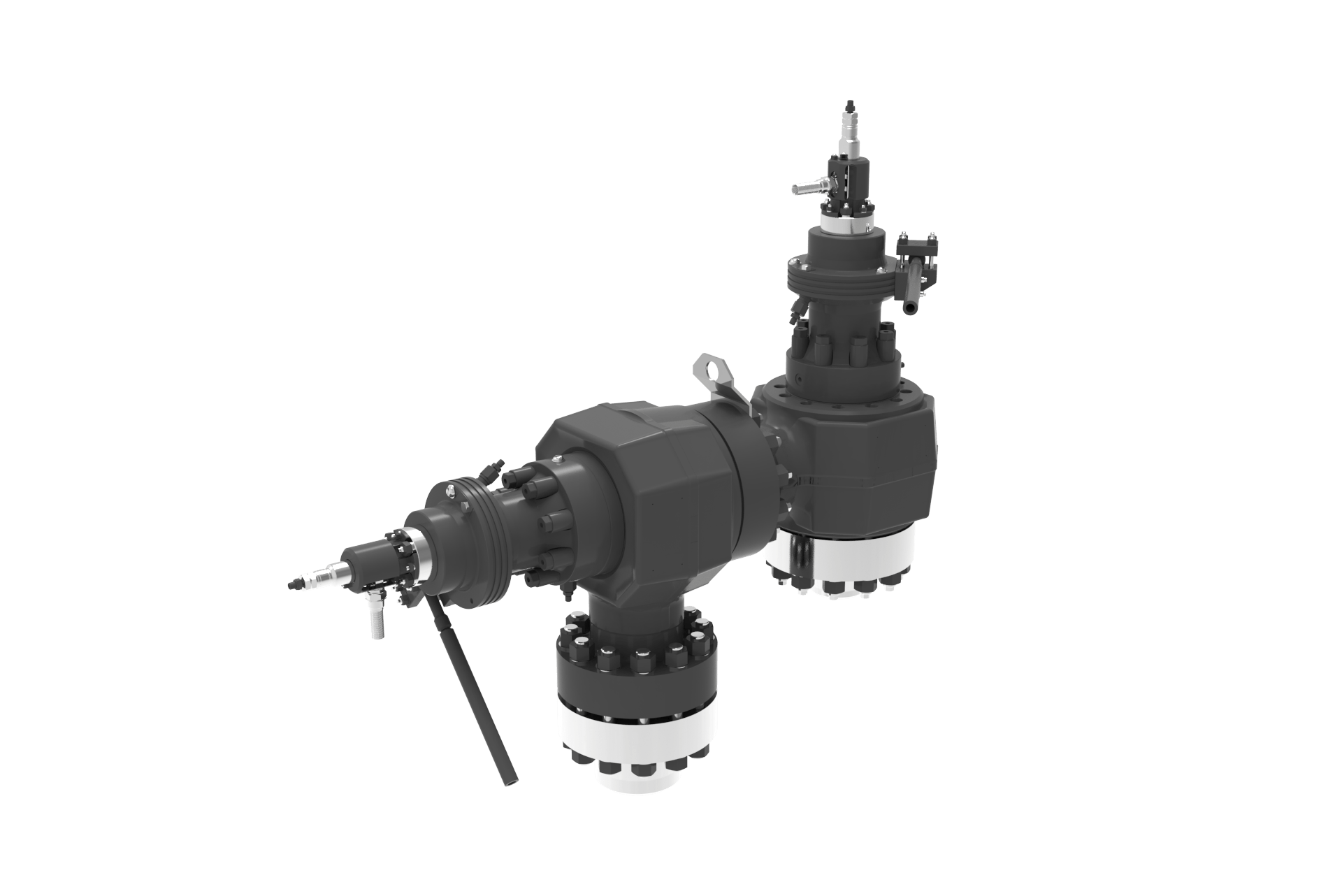

- Atwood & Morrill®Red Point®ASME,Coal Fired,Gas Fired,General Industry,Industries,Media,Nonrenewable Power,Nuclear Power,PWR,Renewable Power,SMR,Standard,Steam,Traditional PowerCheck Valves,Gate Valves,Isolation Valves,Main_Valves

Check Valves,Gate Valves,Isolation Valves,Main_Valves

- Hopkinsons®Red Point®ASME,Fertilizer,Food & Beverage,General Industry,Industries,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas - Downstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerIsolation Valves,Main_Valves,Parallel Slide Valves

Isolation Valves,Main_Valves,Parallel Slide Valves

- Hopkinsons®Red Point®ASME,Fertilizer,Food & Beverage,General Industry,Industries,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerGate Valves,Isolation Valves,Main_Valves

Gate Valves,Isolation Valves,Main_Valves

- Hopkinsons®Red Point®ASME,Fertilizer,Food & Beverage,General Industry,Industries,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas - Downstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerGlobe Valves,Isolation Valves,Main_Valves

Globe Valves,Isolation Valves,Main_Valves

- SEBIM®Red Point®ASME,Industries,Media,Nuclear Power,SMR,Standard,SteamMain_Valves,Pilot Operated Pressure Relief Valves

Main_Valves,Pilot Operated Pressure Relief Valves

- Hopkinsons®Red Point®ASME,Fertilizer,Food & Beverage,General Industry,Industries,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,PWR,Renewable Power,SMR,Standard,Traditional Energy,Traditional PowerGate Valves,Isolation Valves,Main_Valves

Gate Valves,Isolation Valves,Main_Valves

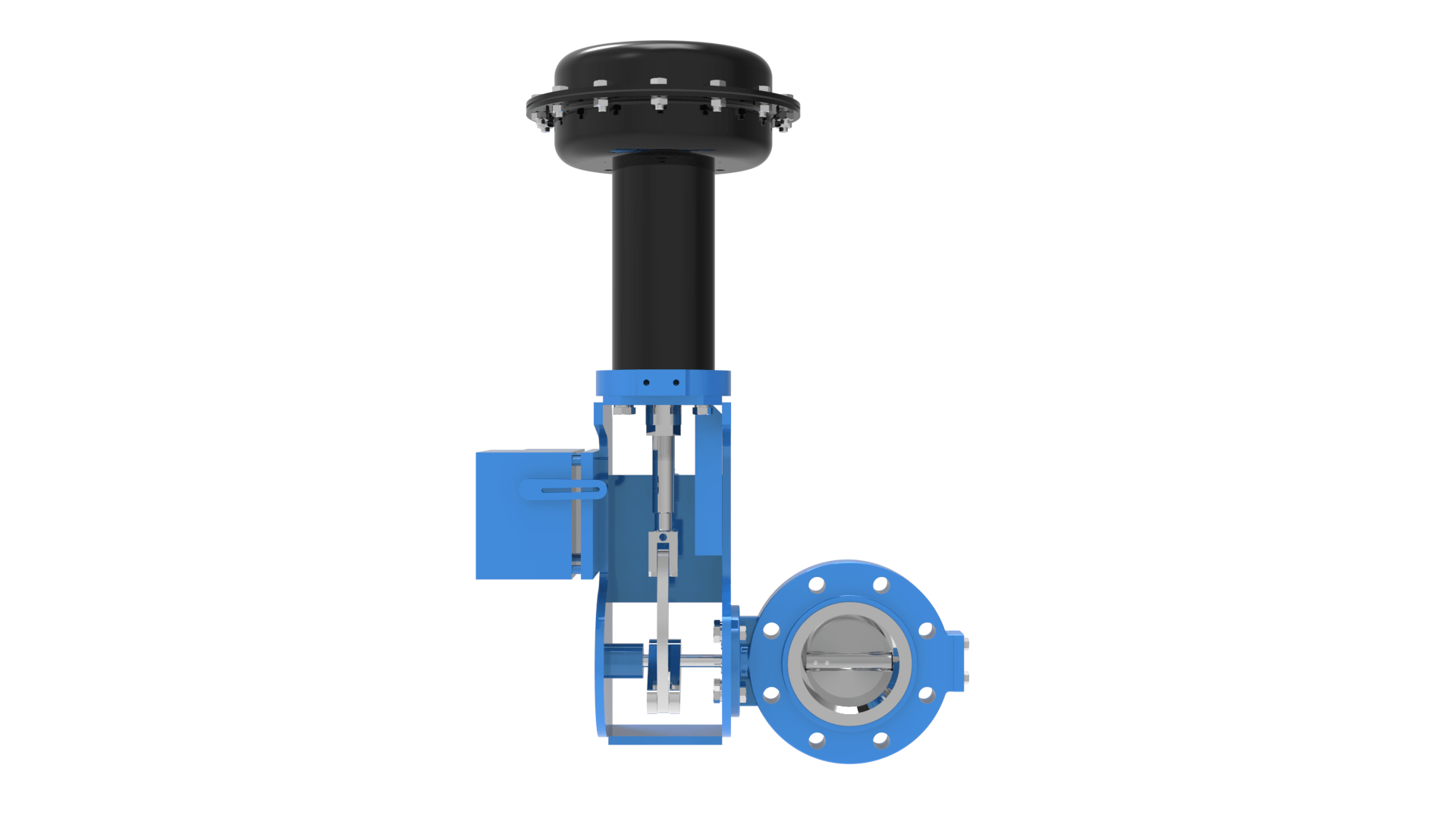

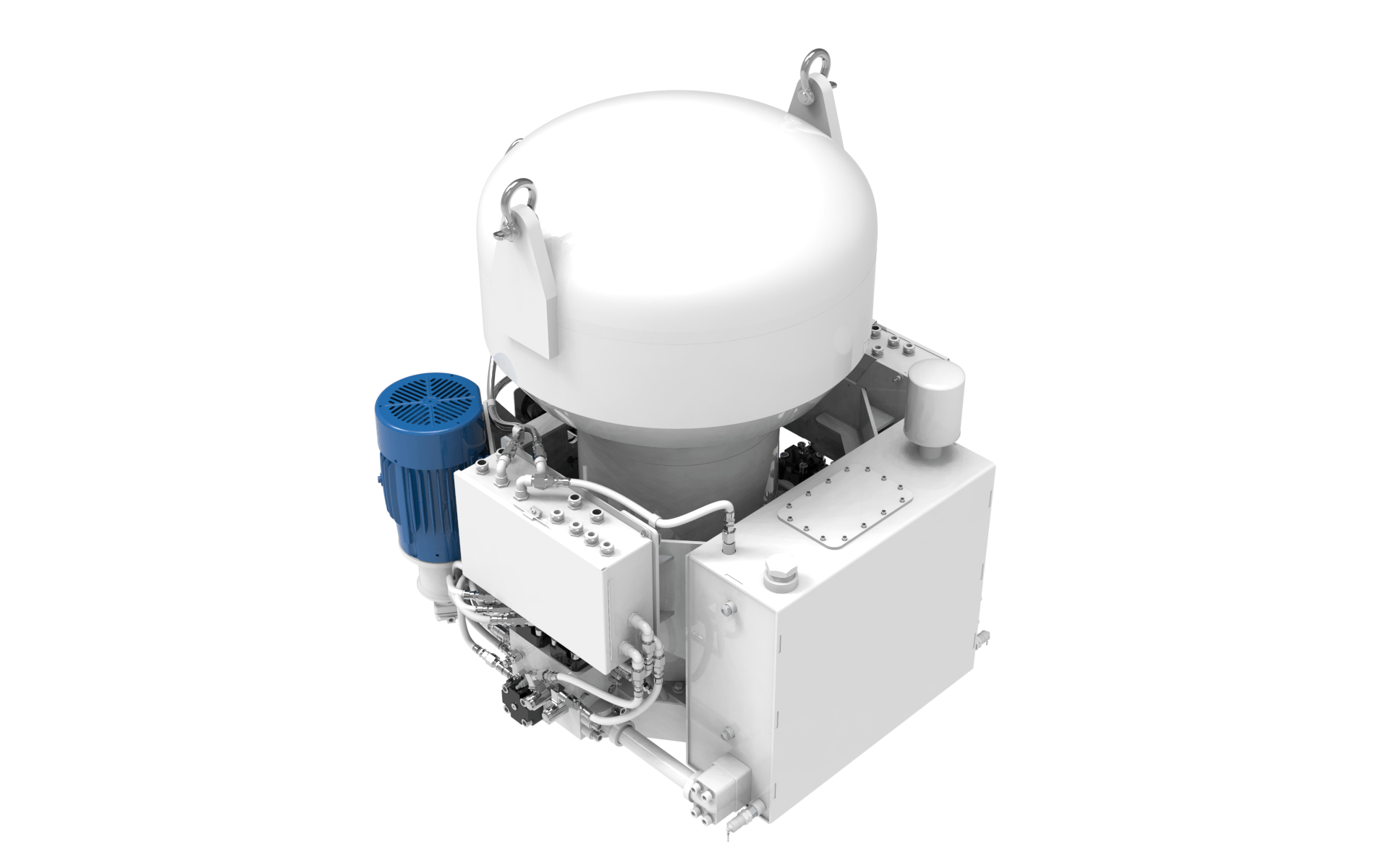

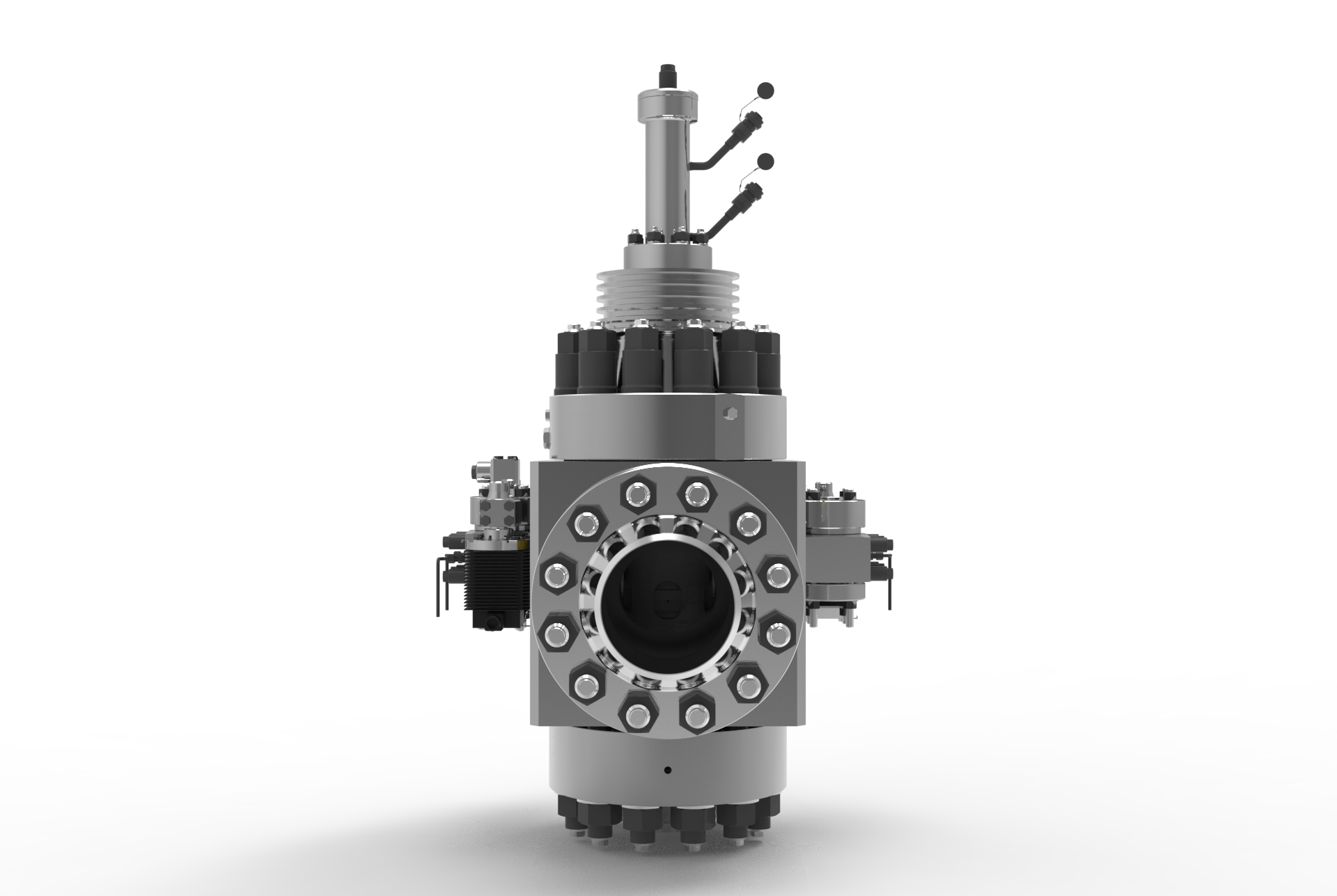

- HillerRed Point®Industries,Media,Nuclear Power,PWR,SMR,StandardMain_Actuators

Main_Actuators

- Atwood & Morrill®Red Point®ASME,Coal Fired,Gas Fired,Industries,Media,Nuclear Power,PWR,SMR,Standard,SteamCheck Valves,Gate Valves,Isolation Valves,Main_Valves

Check Valves,Gate Valves,Isolation Valves,Main_Valves

- Red Point®Red Point®API,ASME,Fertilizer,Gas,General Industry,Hydrogen,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Traditional Energy,Traditional PowerBall Valves,Main_Valves

Ball Valves,Main_Valves

- HillerRed Point®Industries,Media,Nuclear Power,PWR,SMR,StandardMain_Actuators

Main_Actuators

- HillerRed Point®Industries,Media,Nuclear Power,PWR,SMR,StandardMain_Actuators

Main_Actuators

- Termomeccanica PompeRed Point®ASME,Desalination,General Industry,Industries,ISO,Liquid,Media,Nuclear Power,Standard,Traditional Energy,Water & WastewaterMain_Pumps,Vertical

Main_Pumps,Vertical

- SEBIM®Red Point®Nuclear PowerMain_Valves,Pilot Operated Pressure Relief Valves

Main_Valves,Pilot Operated Pressure Relief Valves

- SEBIM®Red Point®ASME,Gas,Industries,Liquid,Media,Nuclear Power,SMR,Standard,SteamMain_Valves,Pilot Operated Pressure Relief Valves

Main_Valves,Pilot Operated Pressure Relief Valves

- Sarasin-RSBD®Red Point®Air,ANSI,API,ASME,Fertilizer,Food & Beverage,Gas,General Industry,Hydrogen,Industries,ISO,Liquid,LNG,Media,Molten Salt,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional Power,Water & WastewaterMain_Valves,Spring Loaded Pressure Relief Valve

Main_Valves,Spring Loaded Pressure Relief Valve

- Sarasin-RSBD®Red Point®ASME,General Industry,Industries,ISO,Media,Nonrenewable Power,Nuclear Power,Oil & Gas,Renewable Power,Standard,Steam,Traditional Energy,Traditional PowerMain_Valves,Spring Loaded Pressure Relief Valve

Main_Valves,Spring Loaded Pressure Relief Valve

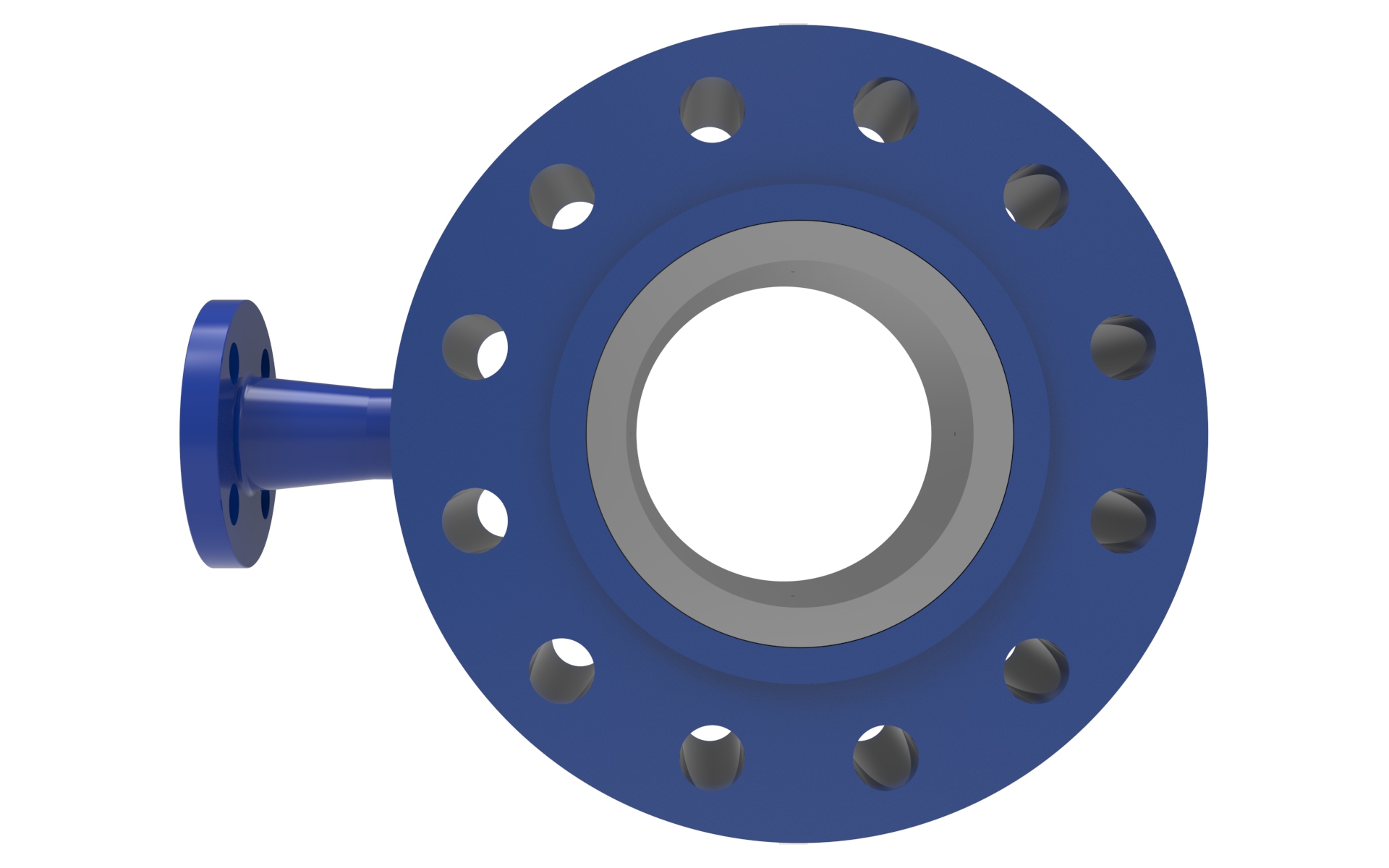

- Red Point®Red Point®API,ASME,Fertilizer,Gas,General Industry,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,SMR,Standard,Traditional Energy,Traditional PowerMain_Valves,Tailor-made Valves

Main_Valves,Tailor-made Valves

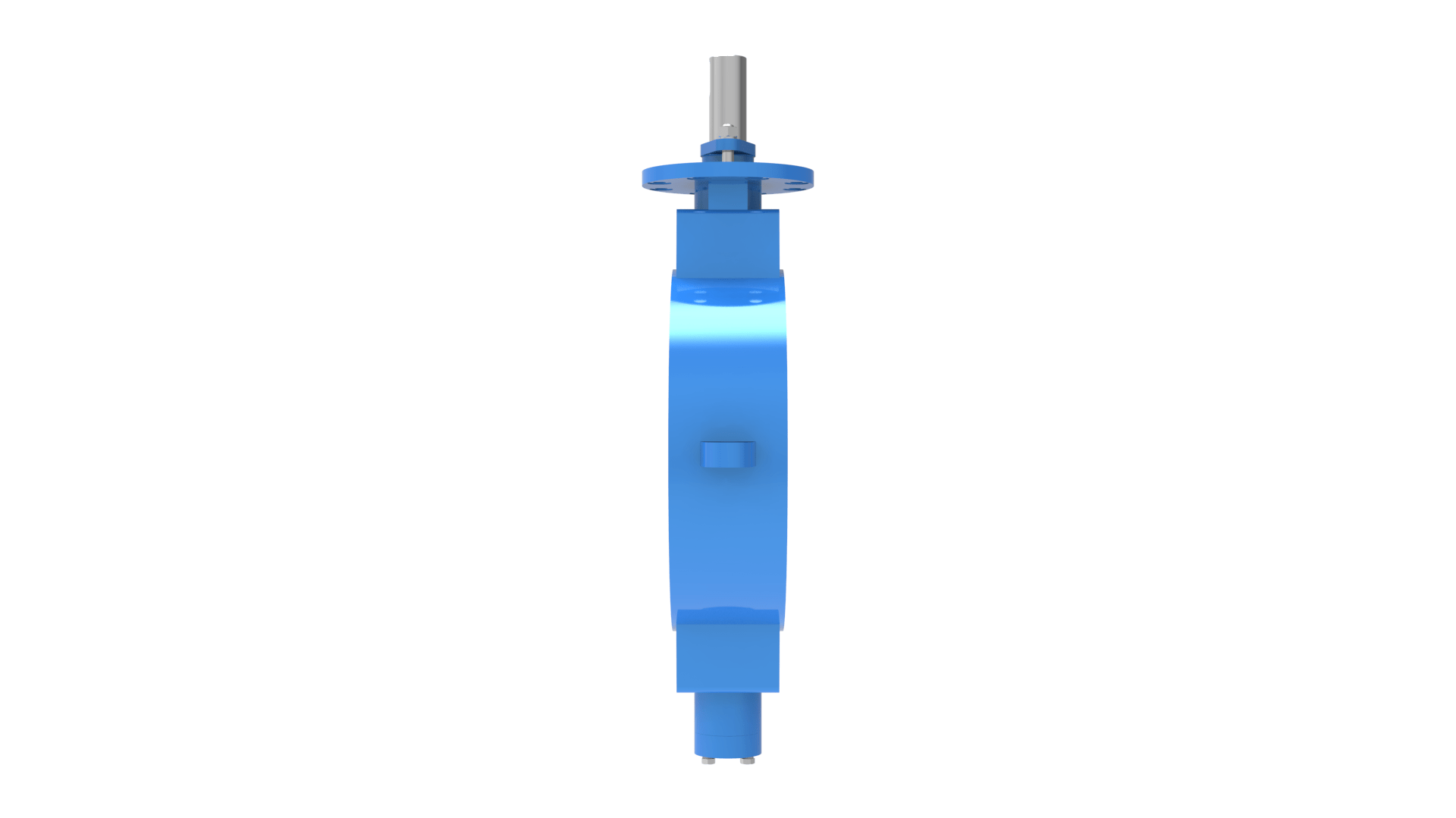

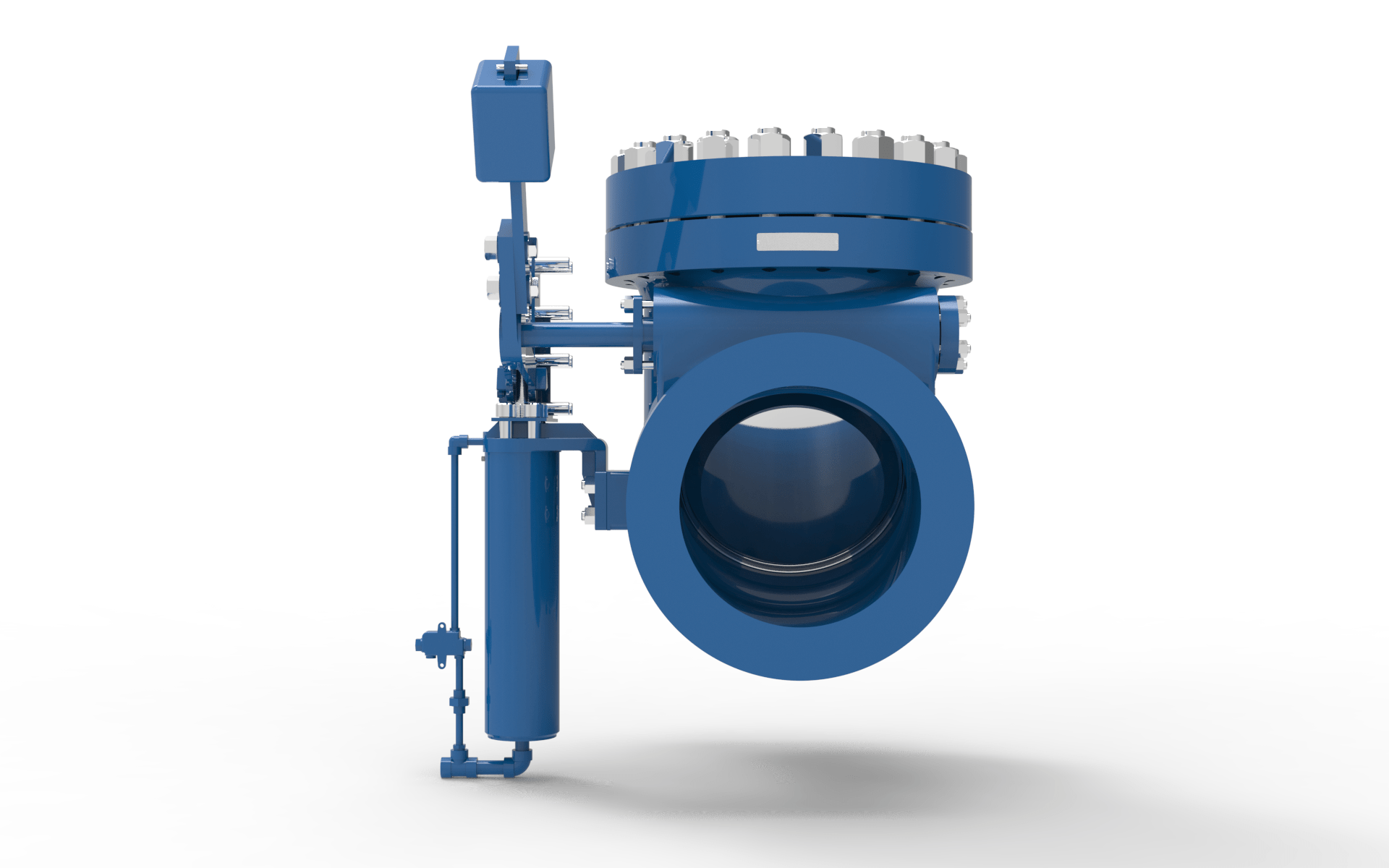

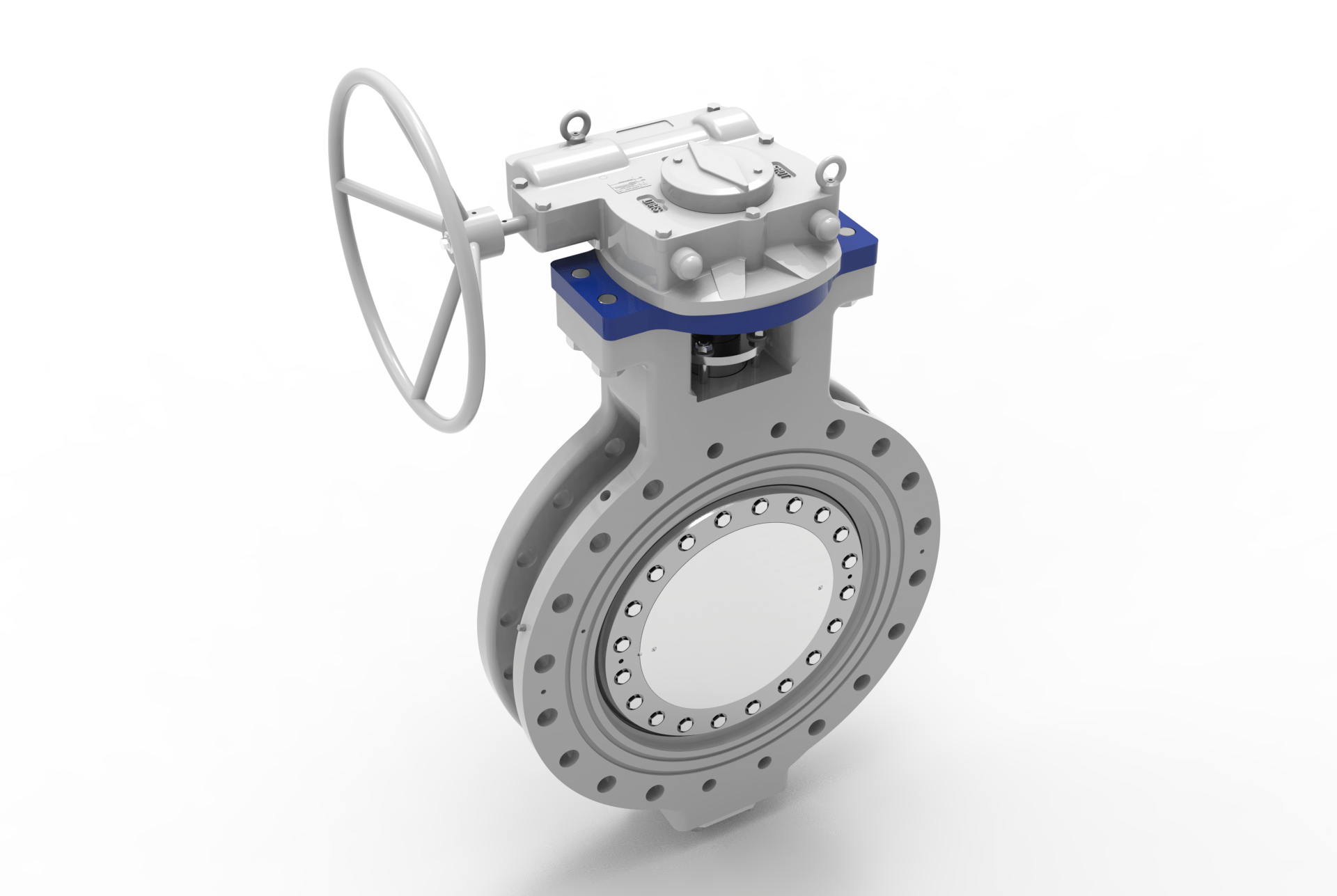

- Tricentric®Red Point®ASME,Fertilizer,Gas,General Industry,Industries,Liquid,Media,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional Power,Water & WastewaterButterfly Control Valves,Butterfly Valves,Control Valves,Isolation Valves,Main_Valves

Butterfly Control Valves,Butterfly Valves,Control Valves,Isolation Valves,Main_Valves

- Hopkinsons®Red Point®ASME,Fertilizer,Food & Beverage,General Industry,Industries,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerIsolation Valves,Main_Valves

Isolation Valves,Main_Valves

- Atwood & Morrill®Red Point®ASME,Coal Fired,Gas Fired,General Industry,Industries,Liquid,Media,Nonrenewable Power,Nuclear Power,Oil & Gas - Downstream,PWR,Renewable Power,Standard,Steam,Traditional Energy,Traditional PowerCheck Valves,Gate Valves,Isolation Valves,Main_Valves

Check Valves,Gate Valves,Isolation Valves,Main_Valves

- Blakeborough®Red Point®Fertilizer,Food & Beverage,Gas,General Industry,Industries,ISA,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Traditional Energy,Traditional PowerControl Valves,Globe Control Valves,Main_Valves

Control Valves,Globe Control Valves,Main_Valves