TRADITIONAL POWER

Trillium Flow Technologies™ supports flow control applications in the traditional power industry. In fact, we’ve been in the business for well over a century.

WE SUPPORT TRADITIONAL POWER

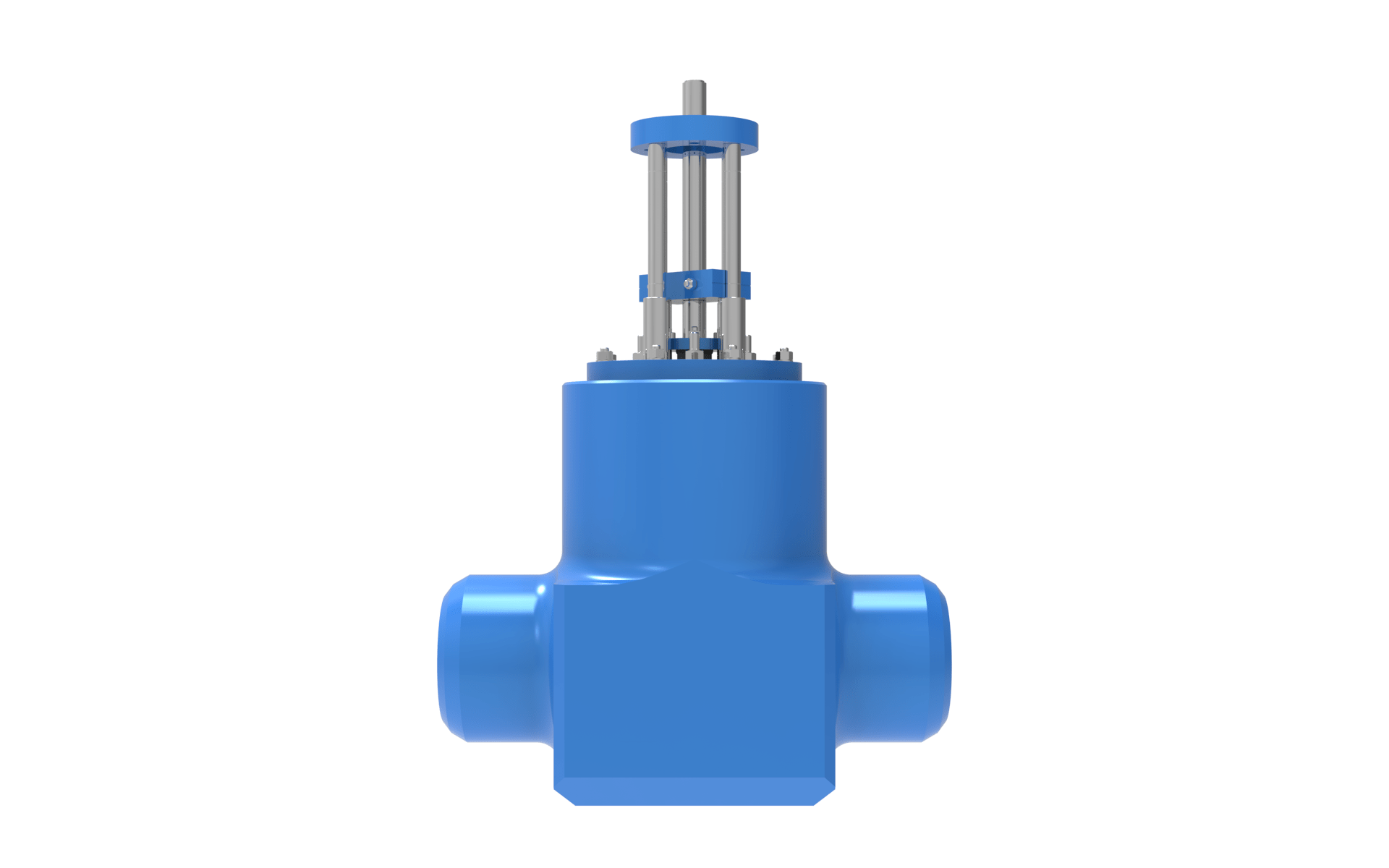

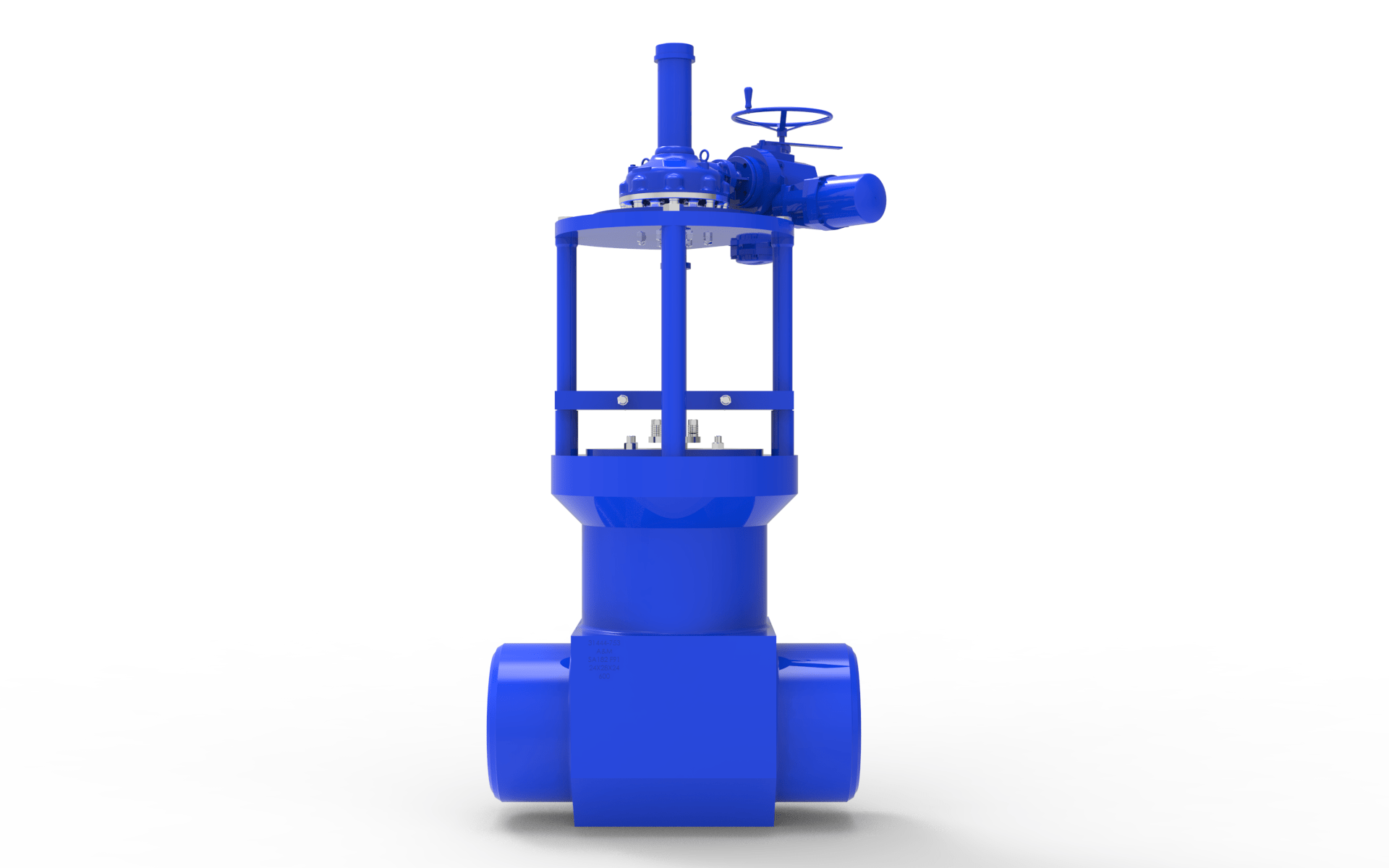

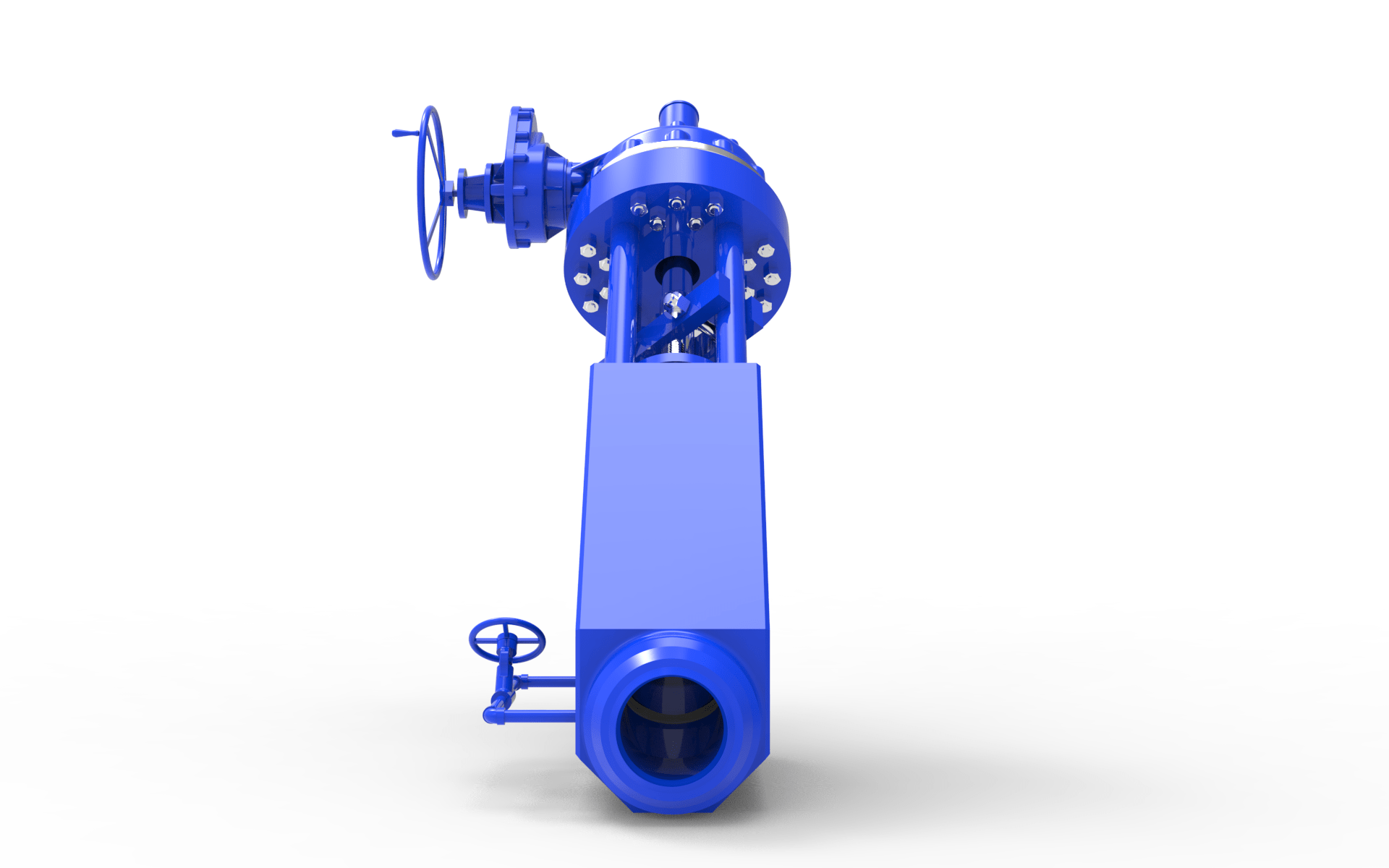

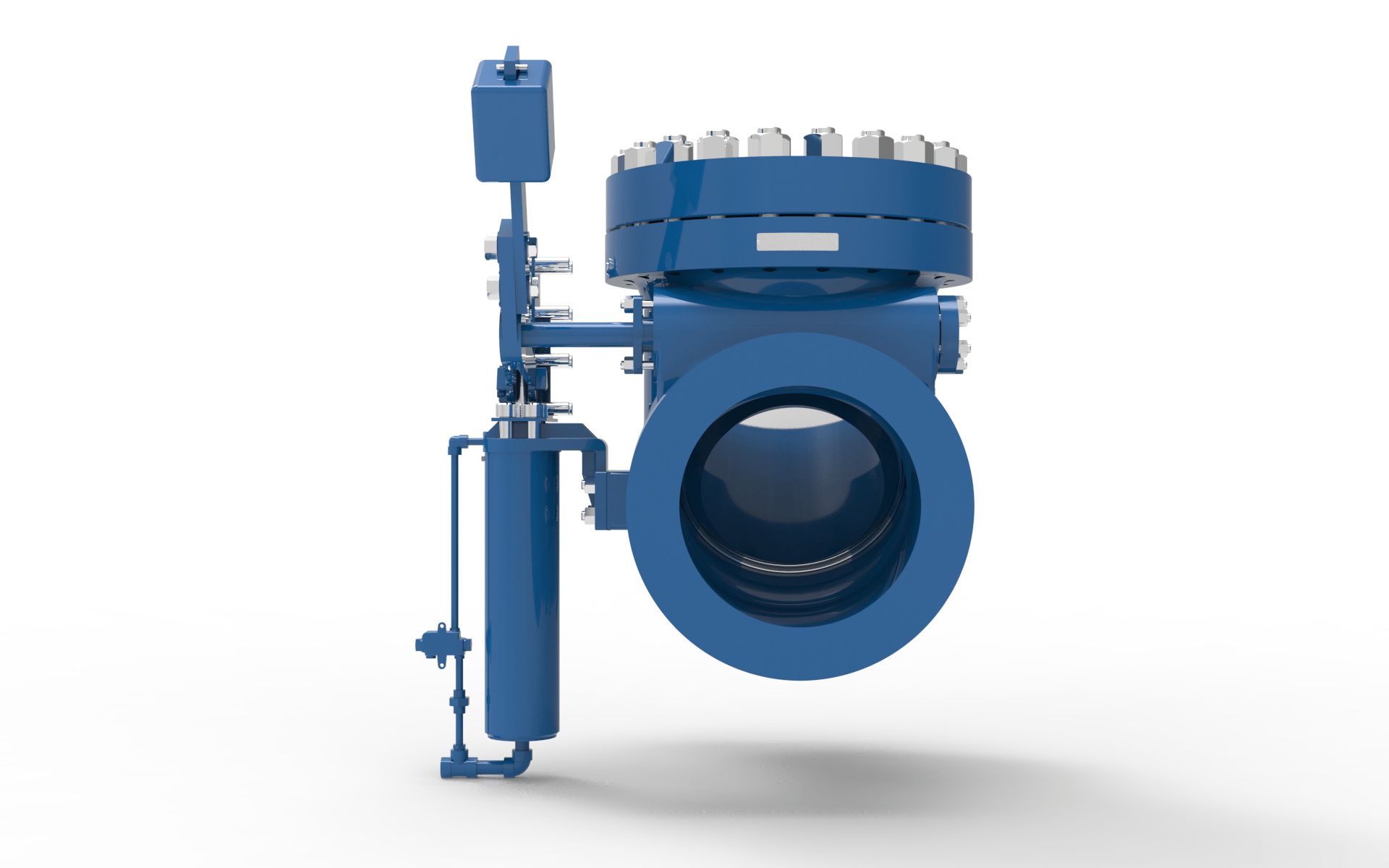

Our approach begins with designing and manufacturing exceptional valve product lines built to last. We follow this up with remarkable longevity and reliability with a unique level of support, aftermarket services, and through-life service.

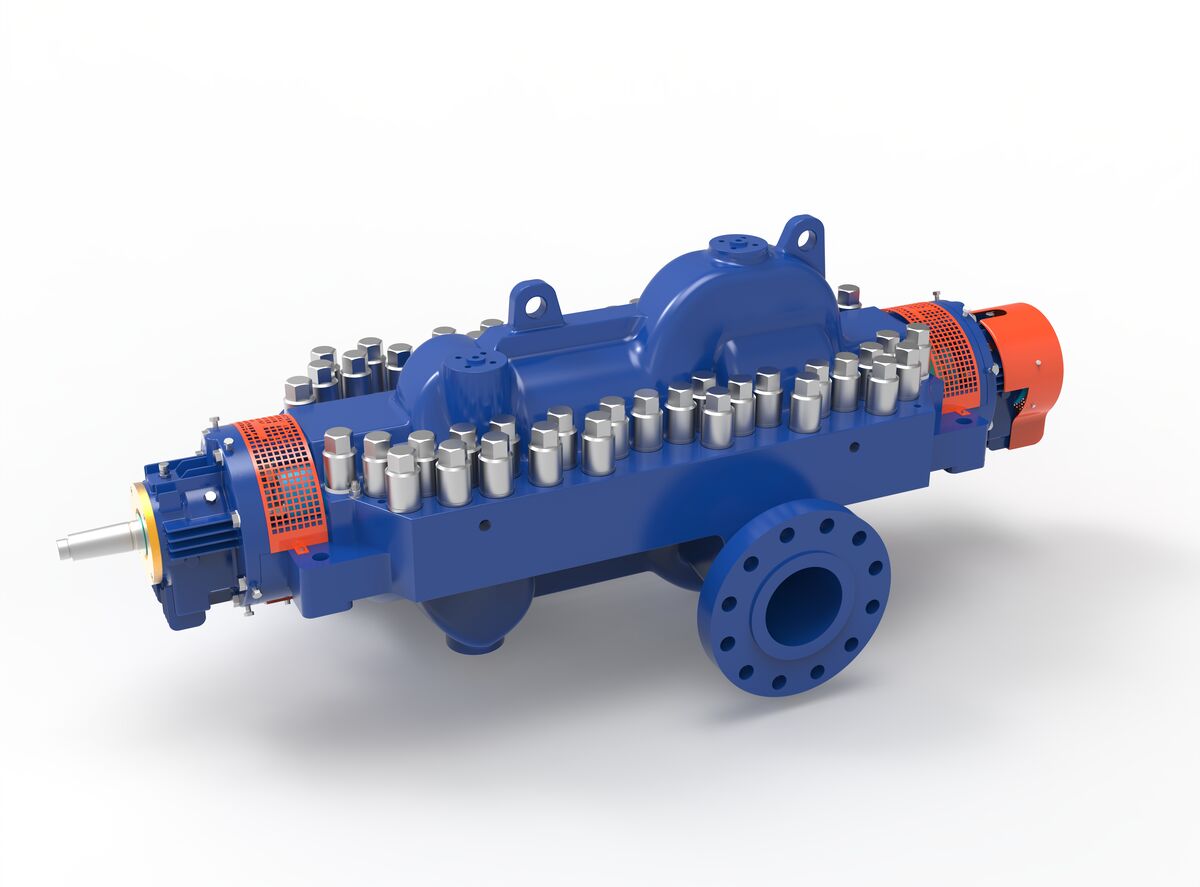

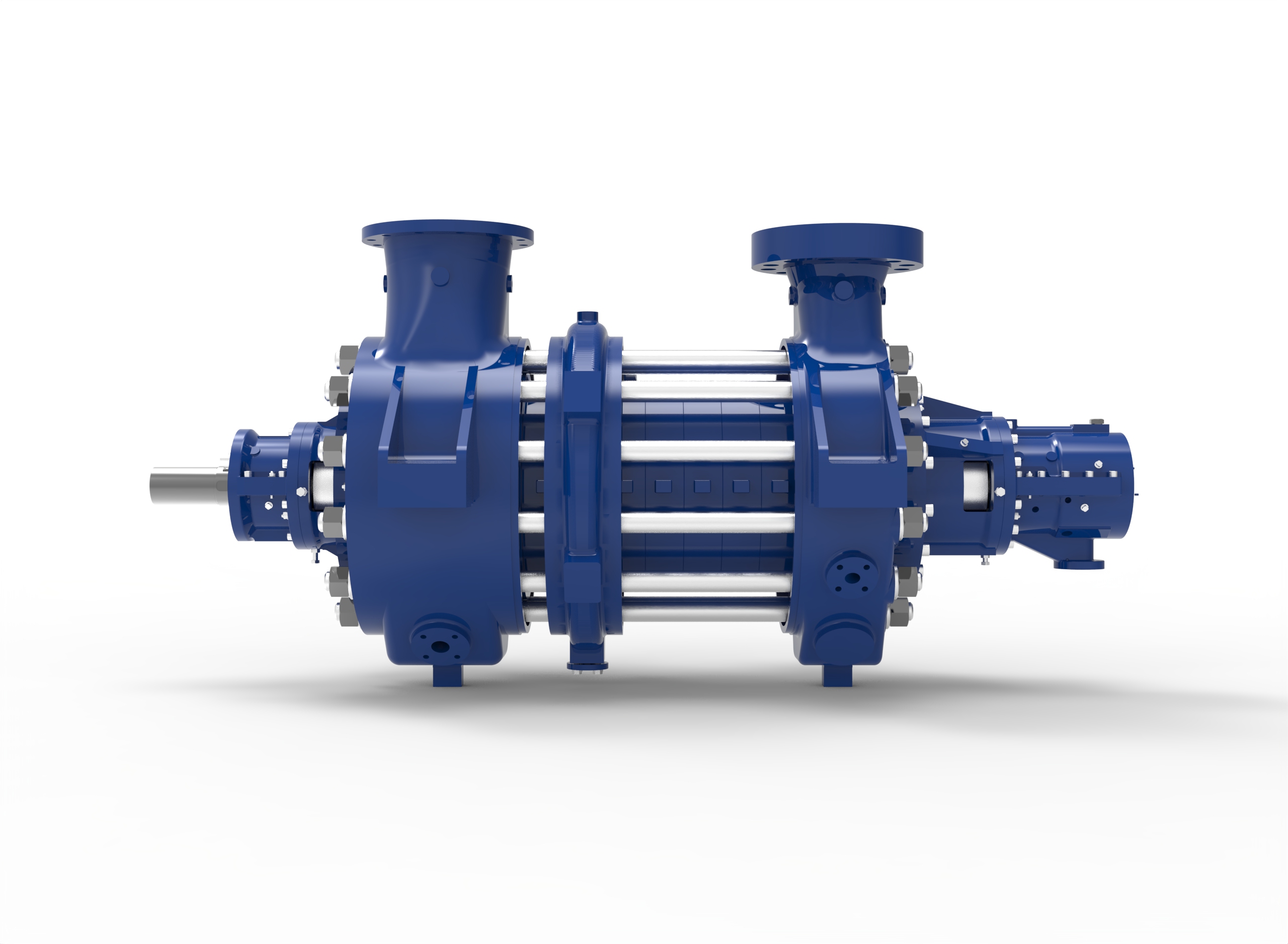

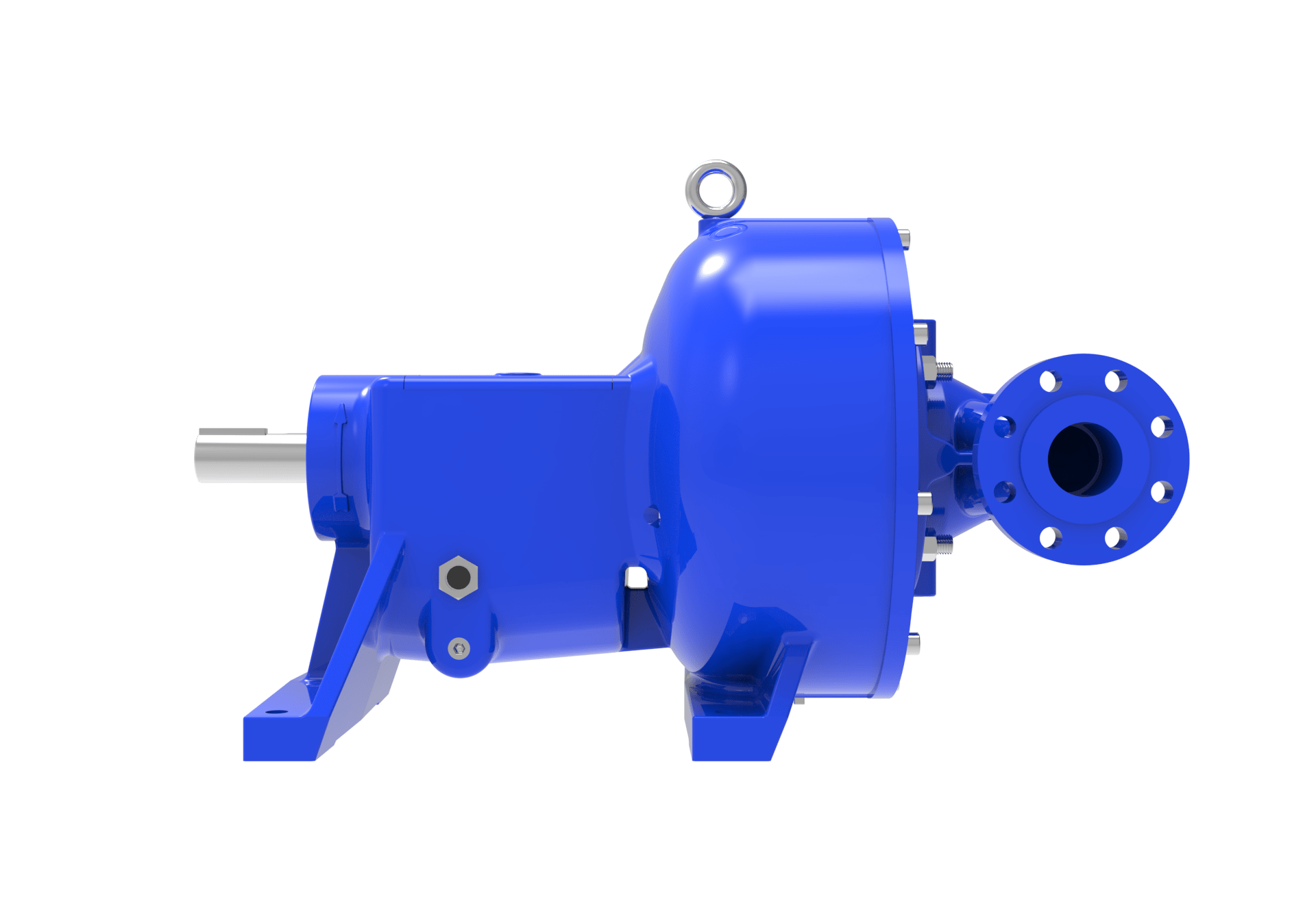

Our pump solutions support both conventional steam & combined cycle power plants including all main and auxiliary services such as boiler feed water, condensate extraction, circulating cooling, and close circuit cooling.

Trillium Flow Technologies™ works with many other industries across the globe, including other power generation markets such as nuclear energy and hydrogen.

KNOWLEDGE AND SUPPORT 24/7

You’ll discover that our depth of knowledge, operational support, and aftermarket services for fossil power generation makes us an exceptional partner for your operation. We have a strong reputation for proven designs, long life cycles, and knowledgeable project specialists who are dedicated to your success.

We serve our worldwide installed base with a full range of responsive services including:

- Spare and replacement parts

- Replacement pumps and valves

- Field service crews

- Outage support

- Maintenance, repair, and modification

- Responsive technical support

- Pump and valve training onsite or at our factory

When it comes to confidence in your flow control, Trillium Flow Technologies™ offers products and service that support you throughout the life of your operation.

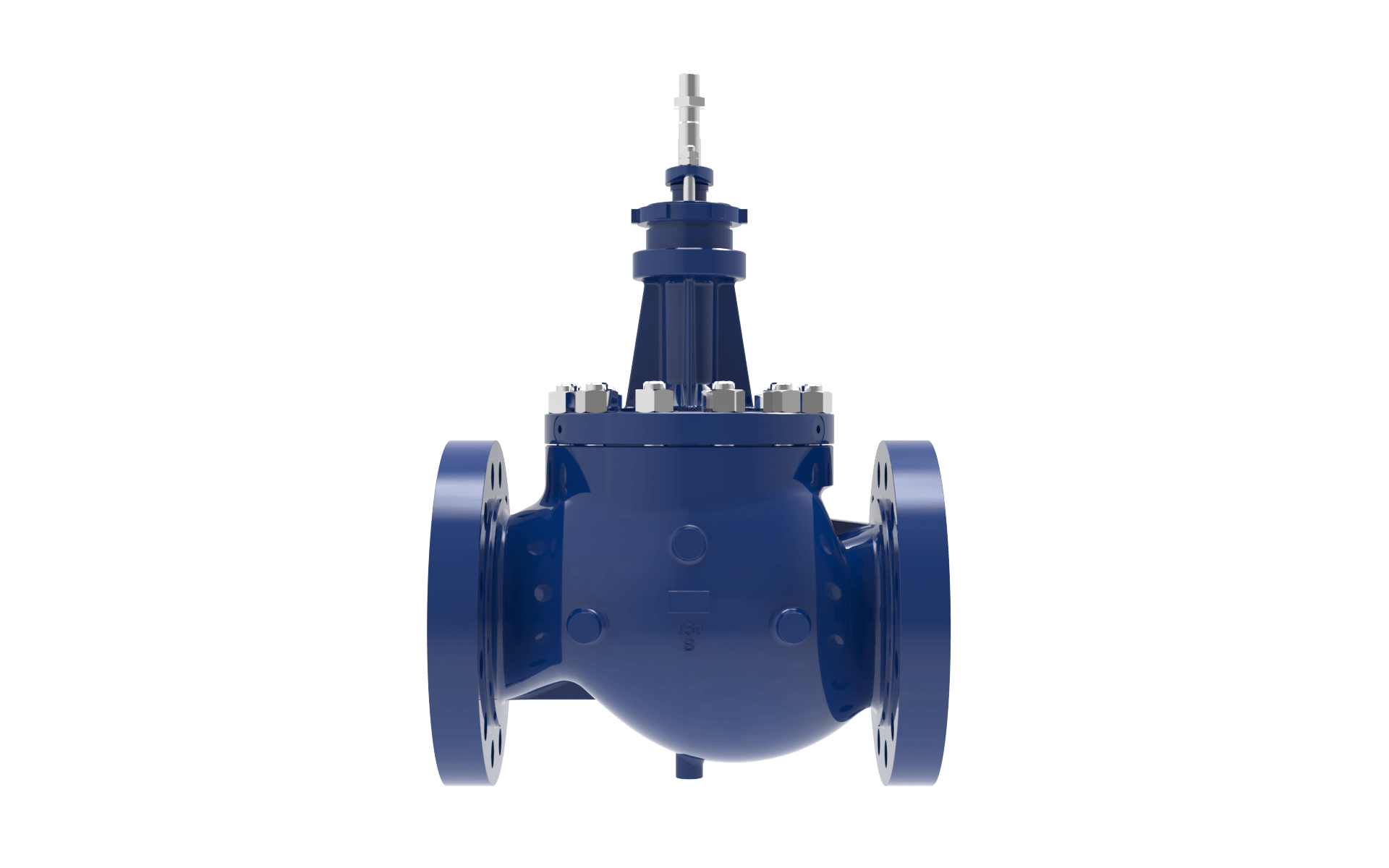

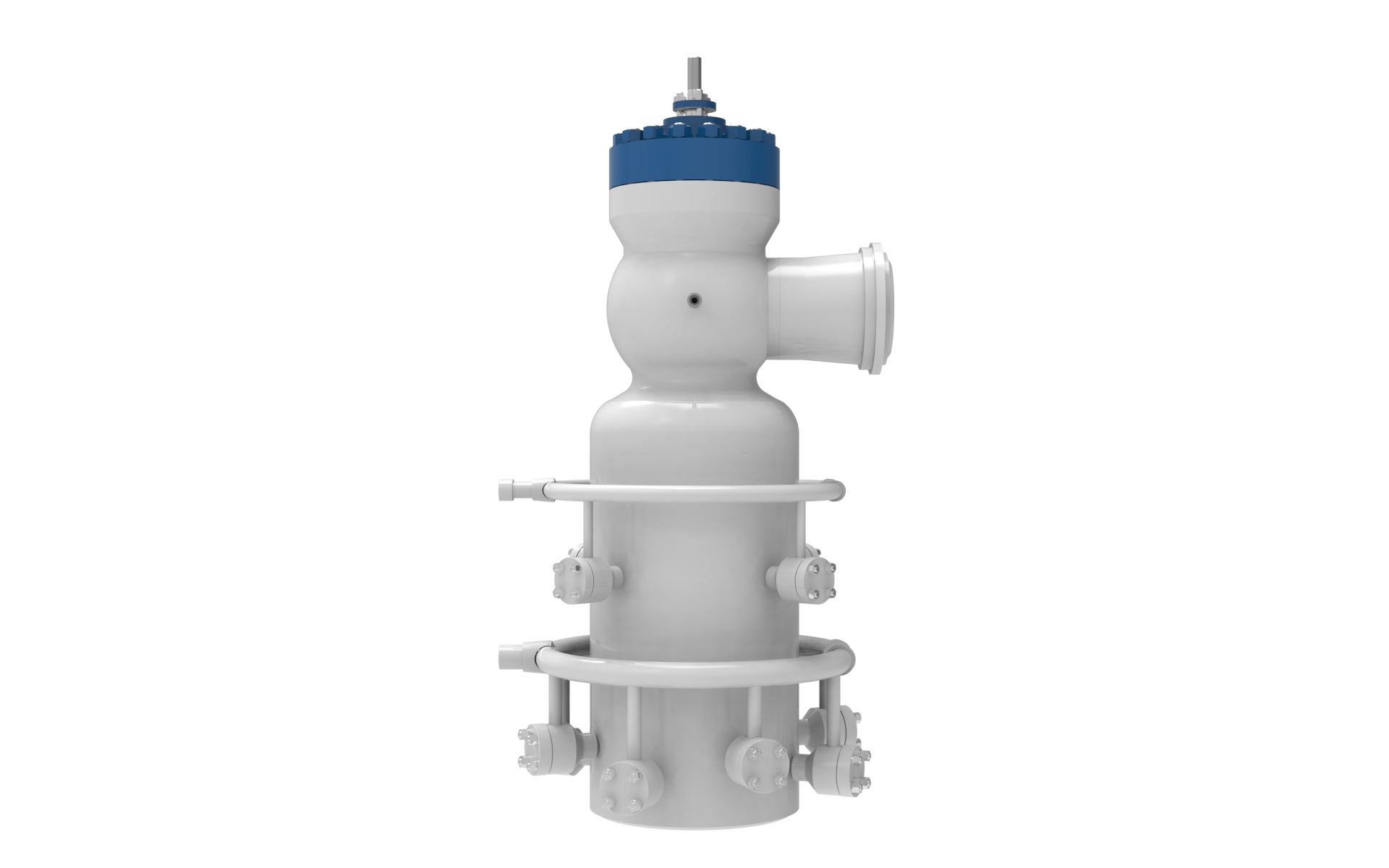

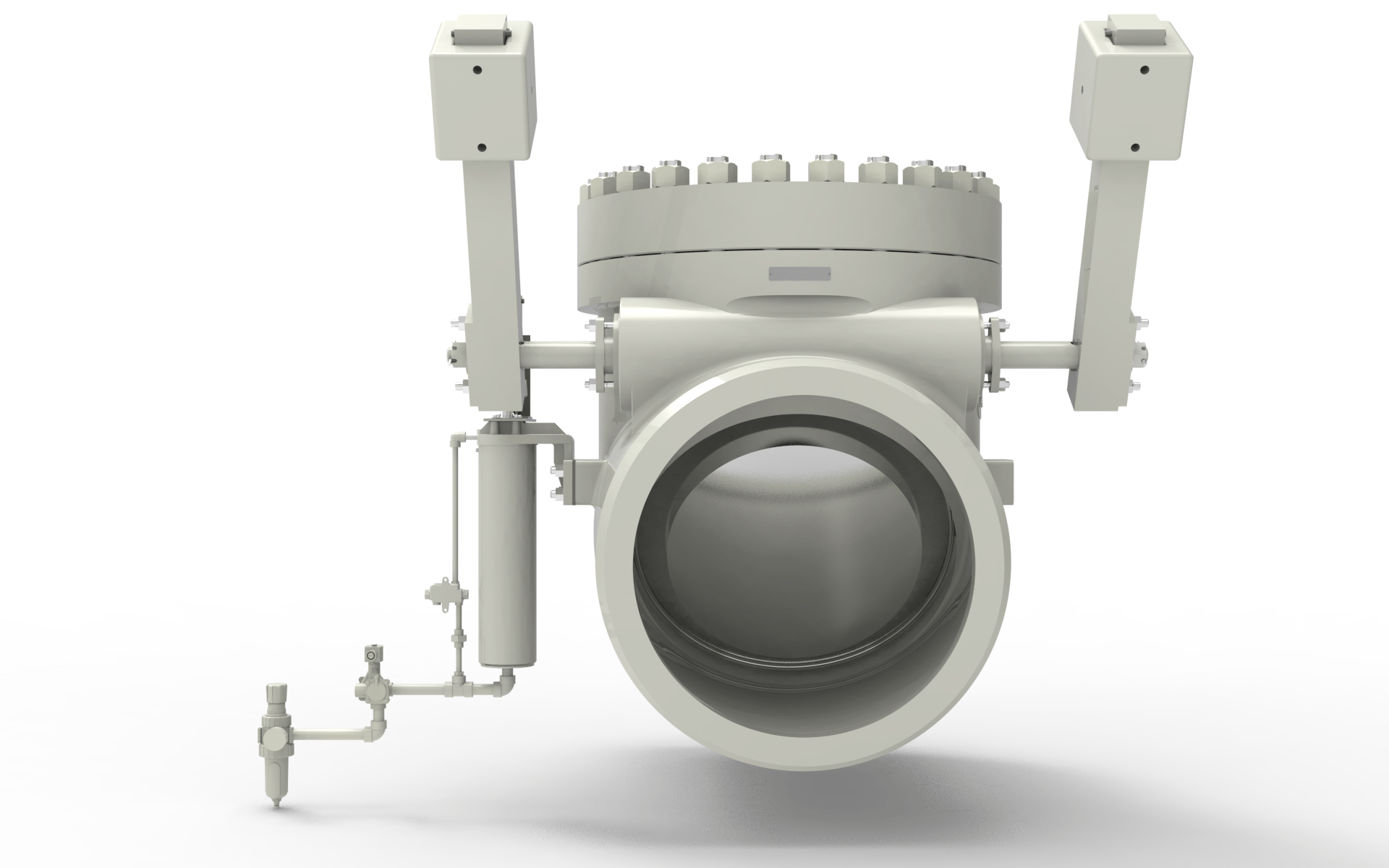

TRILLIUM VALVES FOR COMBINED CYCLE PLANTS

Take a virtual tour of a combined cycle power plant to see some of the Trillium valves that can be employed at your plant. Contact Trillium Flow Technologies™ for any of your power plant valve needs.

When it comes to coal, combined cycle, and simple cycle, you’ll be confident with Trillium Flow Technologies™. Across the globe, we design, install, and maintain engineered isolation pressure relief and control applications for coal, engineered isolation, control and turbine bypass, and pressure relief for combine cycle, and gas turbine for simple cycle applications.

TRADITIONAL POWER PRODUCTS

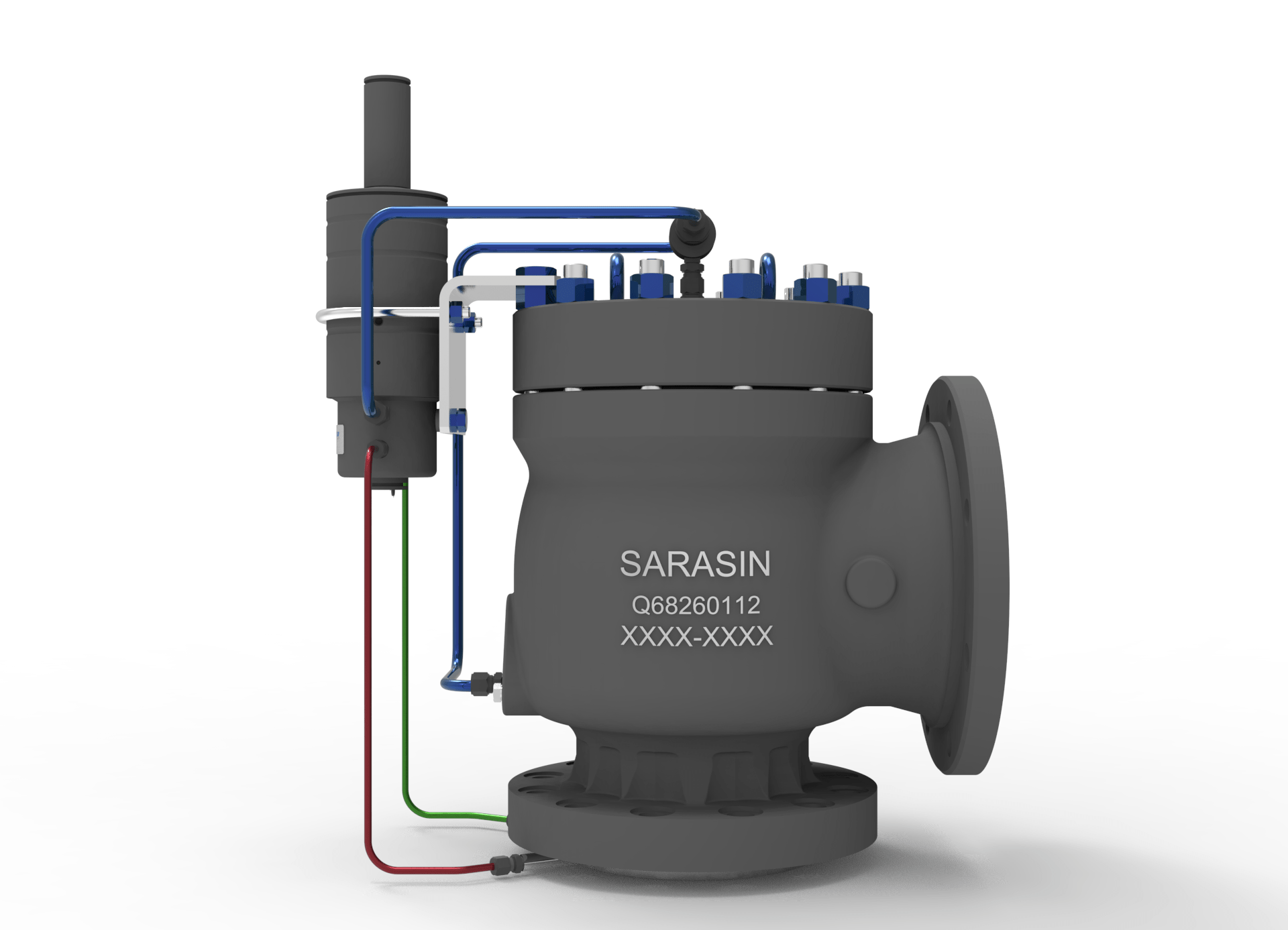

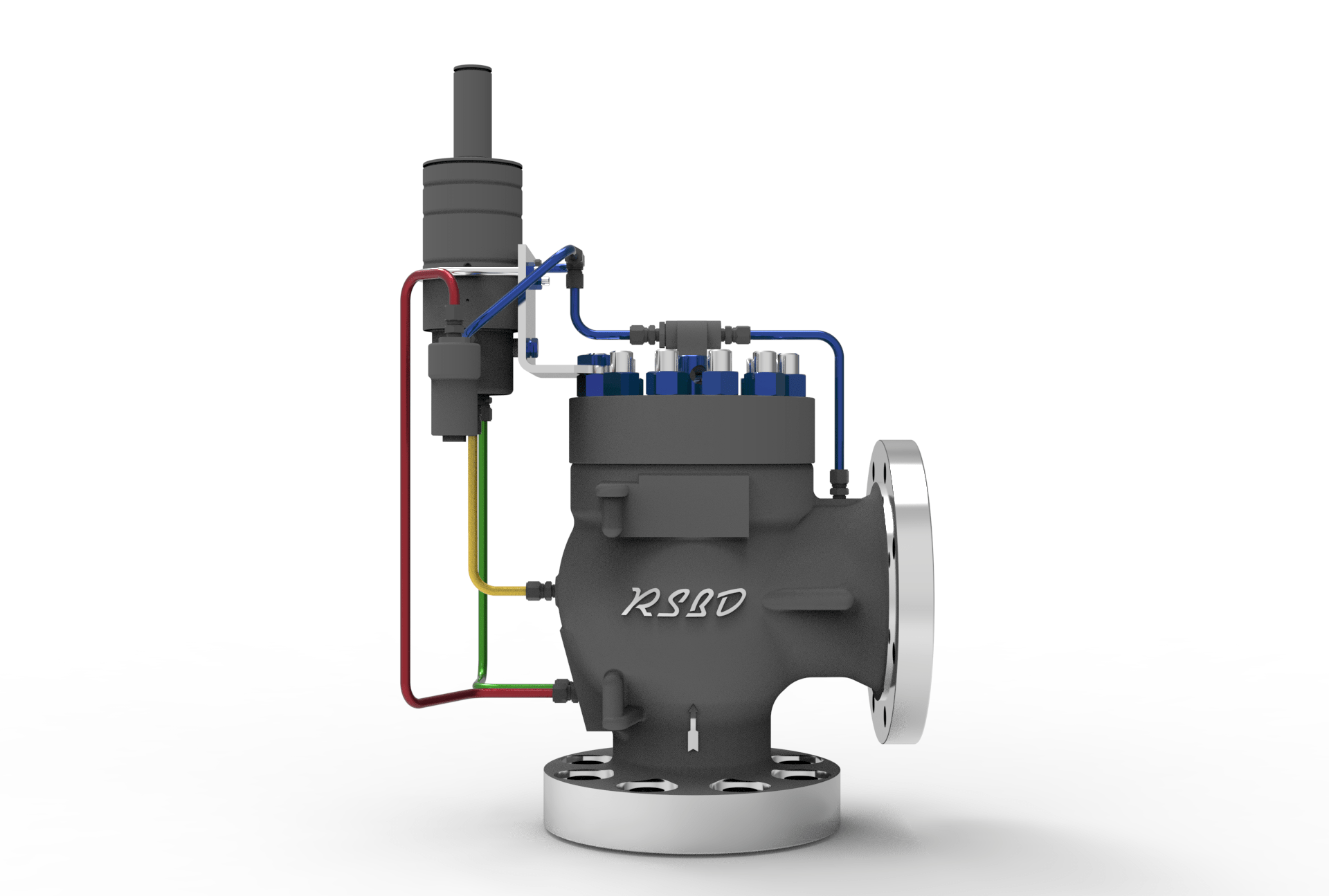

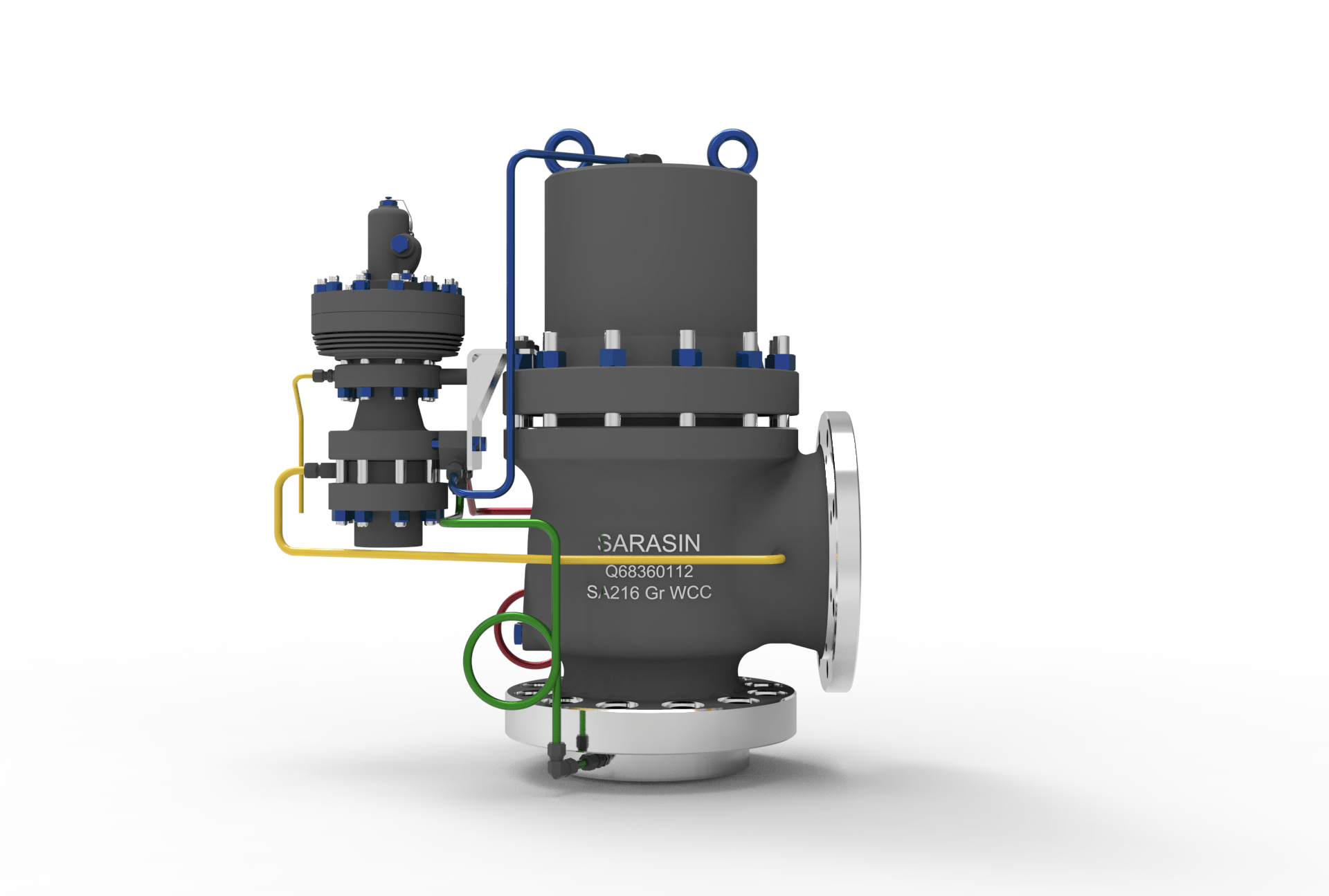

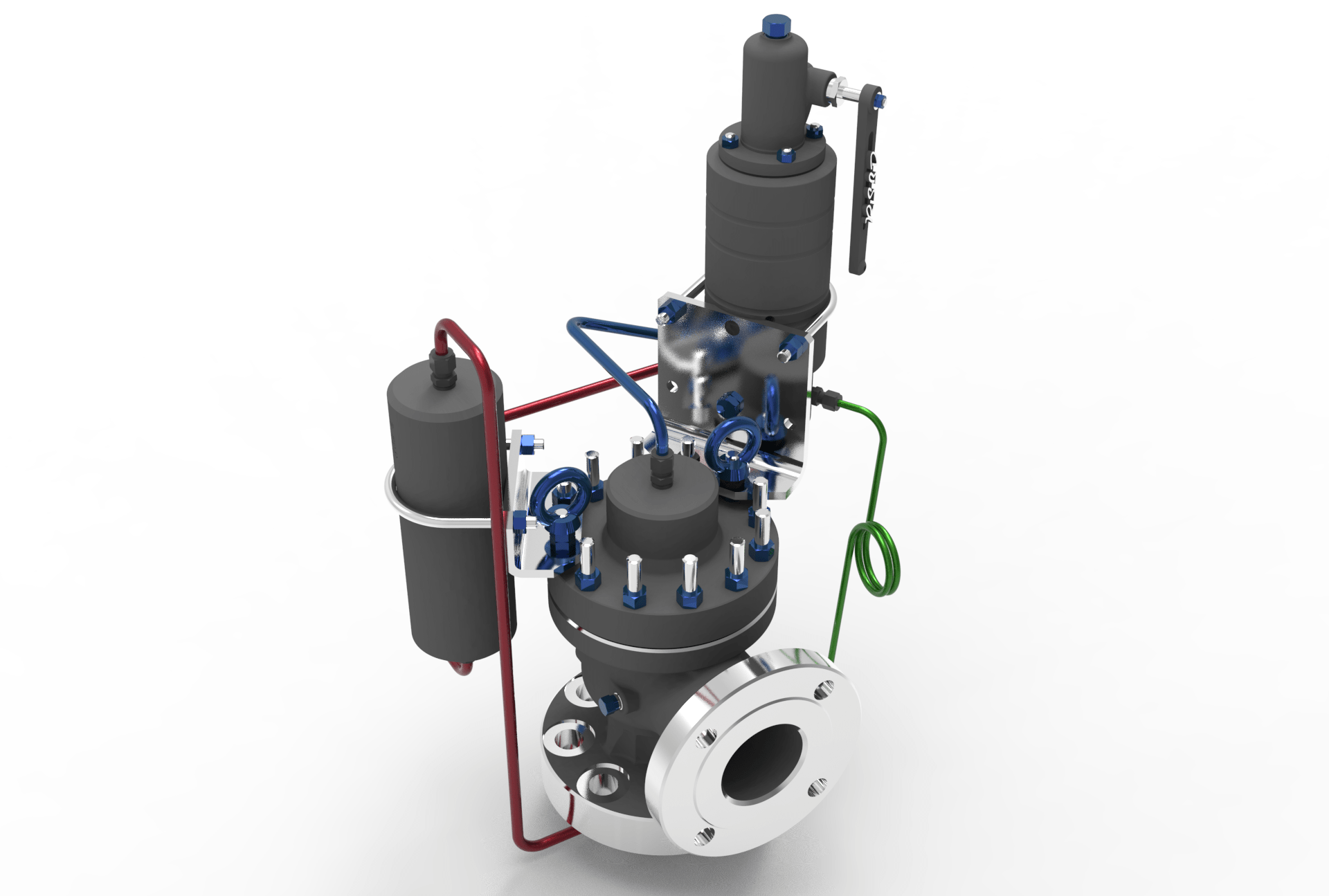

- Sarasin-RSBD®Red Point®Air,API,ASME,ATEX,Food & Beverage,FPSO,Gas,General Industry,Industries,ISO,Liquid,LNG,Media,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Renewable Power,Standard,Steam,Traditional Energy,Traditional Power,Water & WastewaterMain_Valves,Pilot Operated Pressure Relief Valves

Main_Valves,Pilot Operated Pressure Relief Valves

543

- Sarasin-RSBD®Red Point®Air,API,ASME,ATEX,Food & Beverage,FPSO,Gas,General Industry,Industries,ISO,LNG,Media,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Renewable Power,Standard,Steam,Traditional Energy,Traditional Power,Water & WastewaterMain_Valves,Pilot Operated Pressure Relief Valves

Main_Valves,Pilot Operated Pressure Relief Valves

2219

- Sarasin-RSBD®Red Point®ATEX,Industries,ISO,Media,Nonrenewable Power,Standard,Steam,Traditional Energy,Traditional PowerMain_Valves,Pilot Operated Pressure Relief Valves

Main_Valves,Pilot Operated Pressure Relief Valves

2233

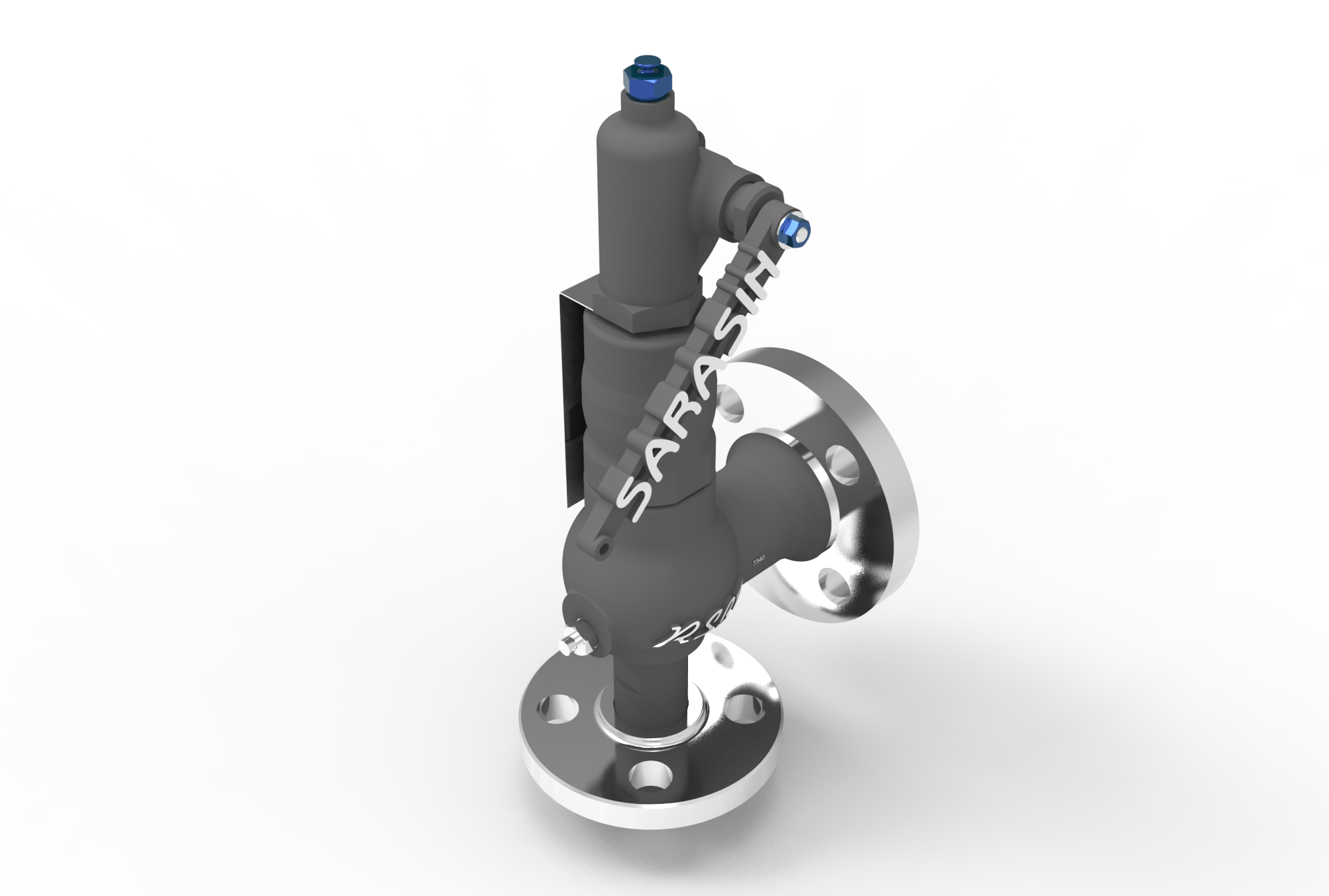

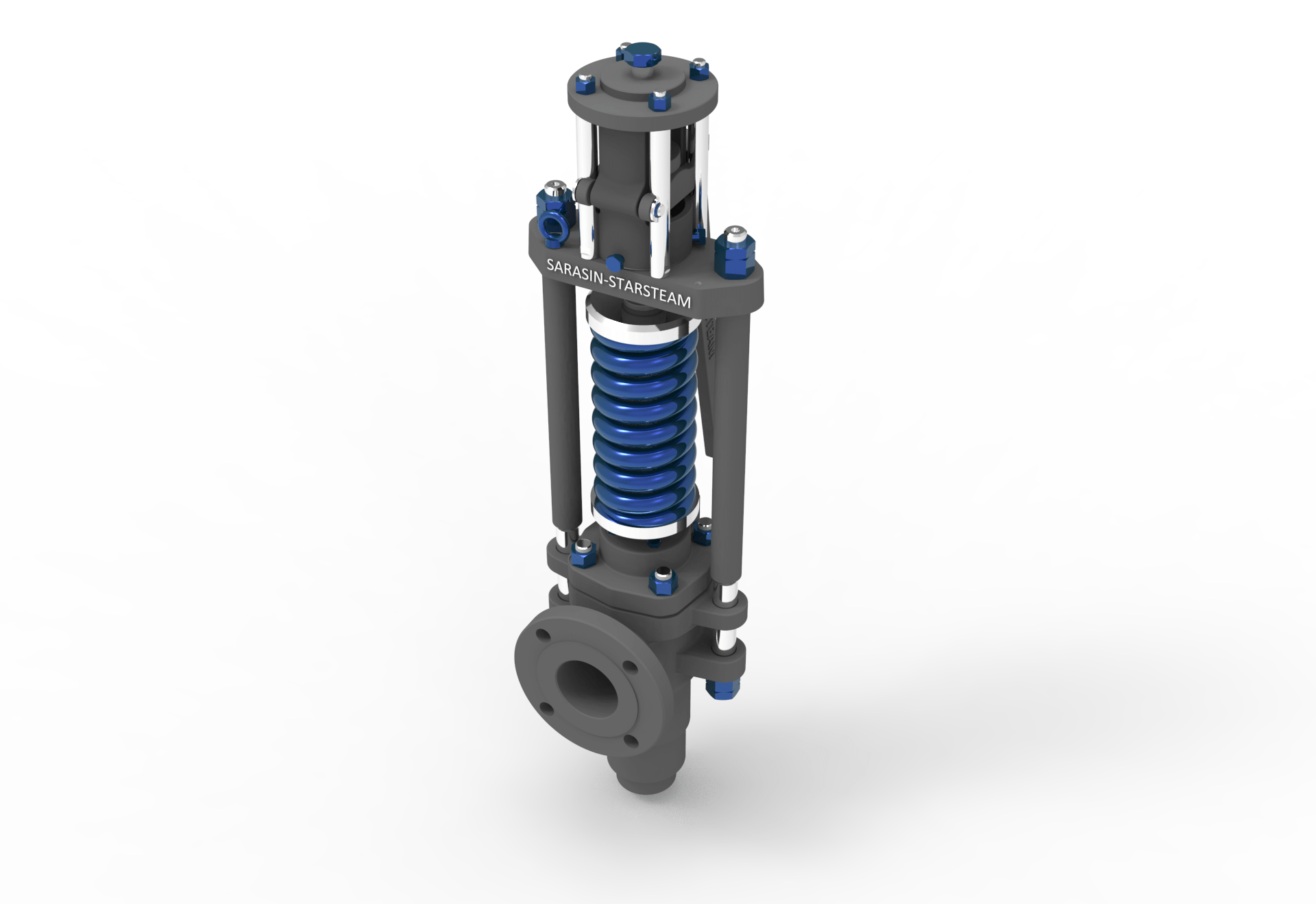

- Sarasin-RSBD®Red Point®Air,ANSI,API,ASME,Fertilizer,Food & Beverage,FPSO,Gas,General Industry,Hydrogen,Industries,ISO,LNG,Media,Molten Salt,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional Power,Water & WastewaterMain_Valves,Spring Loaded Pressure Relief Valve

Main_Valves,Spring Loaded Pressure Relief Valve

546

- Gabbioneta Pumps® Termomeccanica PompeRed Point®API,Desalination,Fertilizer,FPSO,General Industry,Industries,Liquid,LNG,Media,Mining & Minerals,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Renewable Power,Standard,Traditional Energy,Traditional Power,Water & WastewaterBetween Bearings,Main_Pumps

Between Bearings,Main_Pumps

435

- Red Point®Red Point®API,ASME,Fertilizer,FPSO,Gas,General Industry,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Standard,Traditional Energy,Traditional PowerGlobe Valves,Main_Valves

Globe Valves,Main_Valves

4650

- Termomeccanica PompeRed Point®API,ASME,Desalination,General Industry,Industries,ISO,Liquid,LNG,Media,Nonrenewable Power,Oil & Gas - Upstream,Renewable Power,Standard,Traditional Energy,Traditional Power,Water & WastewaterBetween Bearings,Main_Pumps

Between Bearings,Main_Pumps

6188

- Red Point®Red Point®API,ASME,Fertilizer,FPSO,Gas,General Industry,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Standard,Traditional Energy,Traditional PowerAutomated Valves,Main_Valves

Automated Valves,Main_Valves

5068

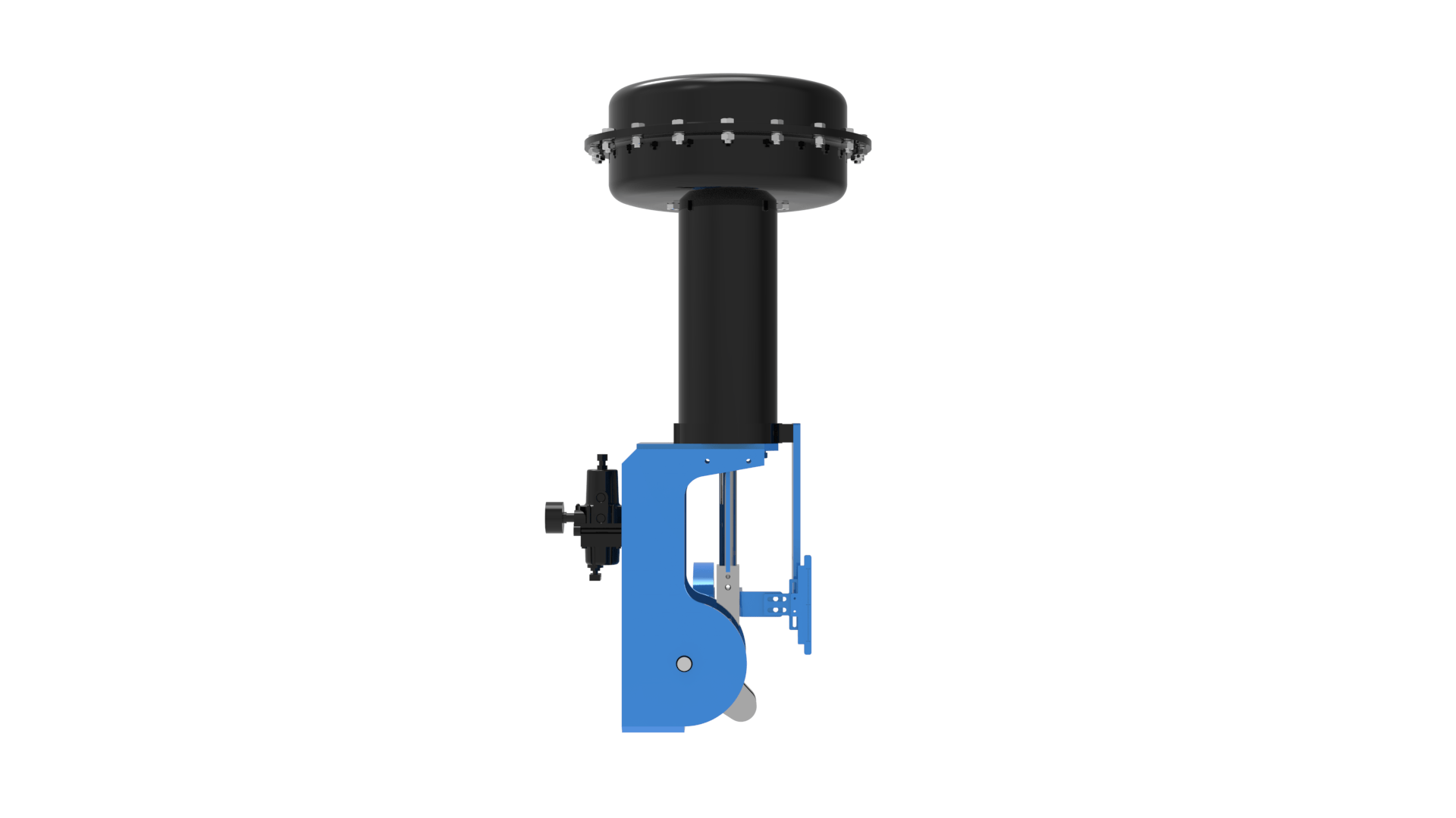

- AutoTork™Red Point®Coal Fired,Gas Fired,Industries,Media,Nonrenewable Power,Nuclear Power,Standard,Traditional Energy,Traditional PowerMain_Actuators

Main_Actuators

71

- Red Point®Red Point®API,ASME,Fertilizer,FPSO,Gas,General Industry,Hydrogen,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Renewable Power,Standard,Traditional Energy,Traditional PowerGate Valves,Main_Valves

Gate Valves,Main_Valves

4640

- Red Point®Red Point®API,ASME,Fertilizer,FPSO,Gas,General Industry,Hydrogen,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Renewable Power,Standard,Traditional Energy,Traditional PowerGlobe Valves,Main_Valves

Globe Valves,Main_Valves

4648

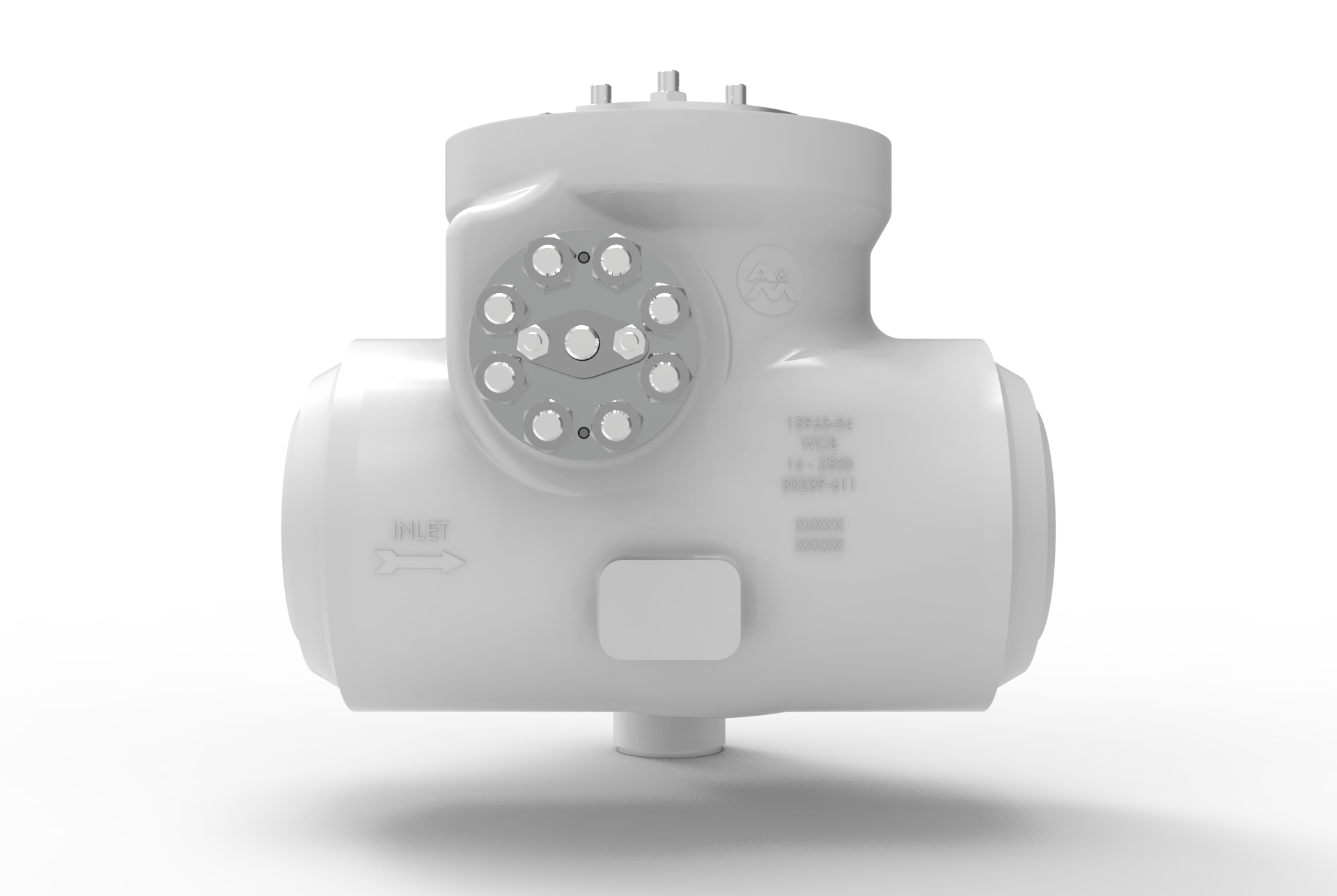

- Atwood & Morrill®Red Point®ASME,Coal Fired,Gas Fired,General Industry,Industries,Liquid,Media,Nonrenewable Power,Nuclear Power,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerCheck Valves,Isolation Valves,Main_Valves

Check Valves,Isolation Valves,Main_Valves

489

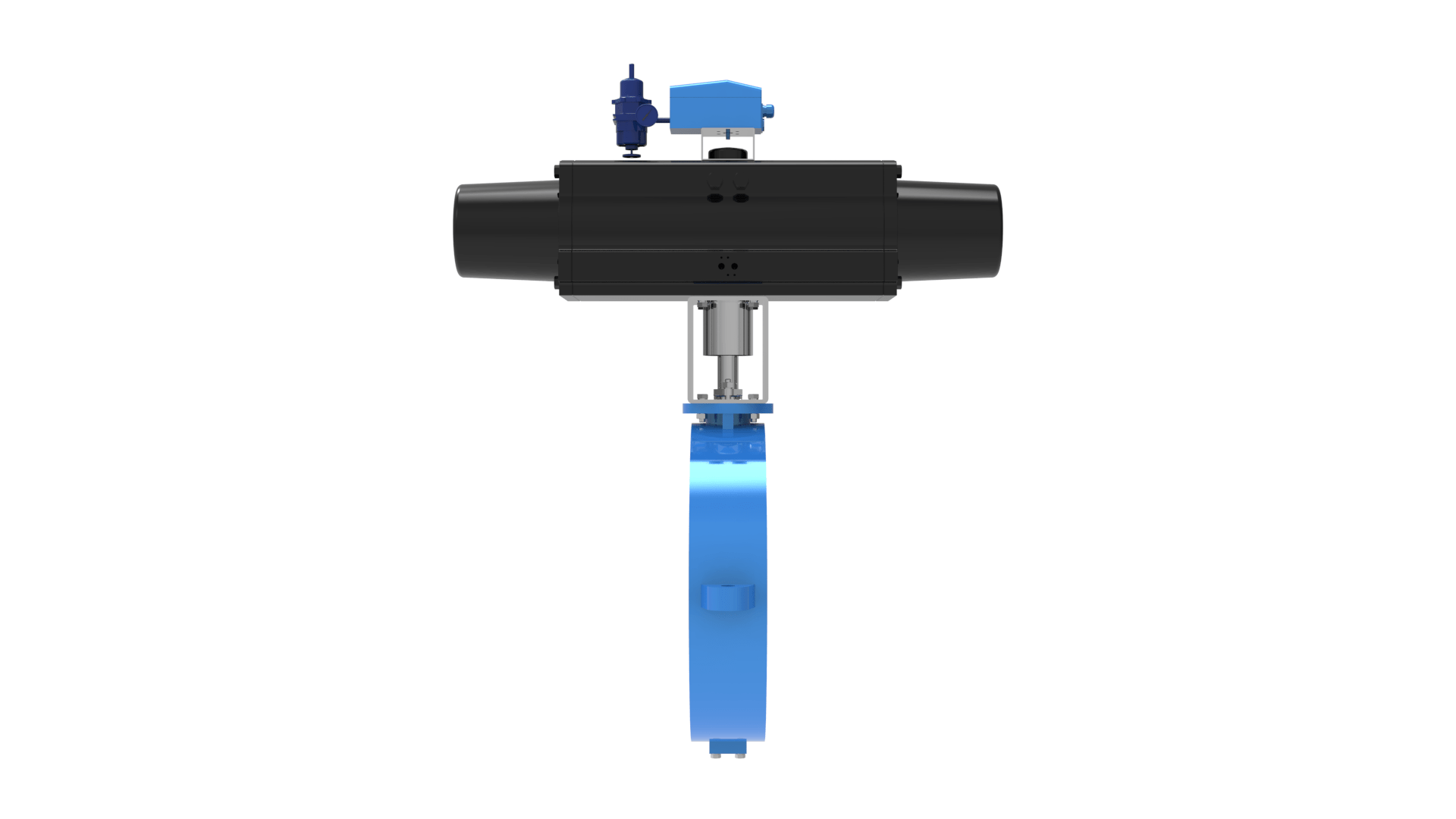

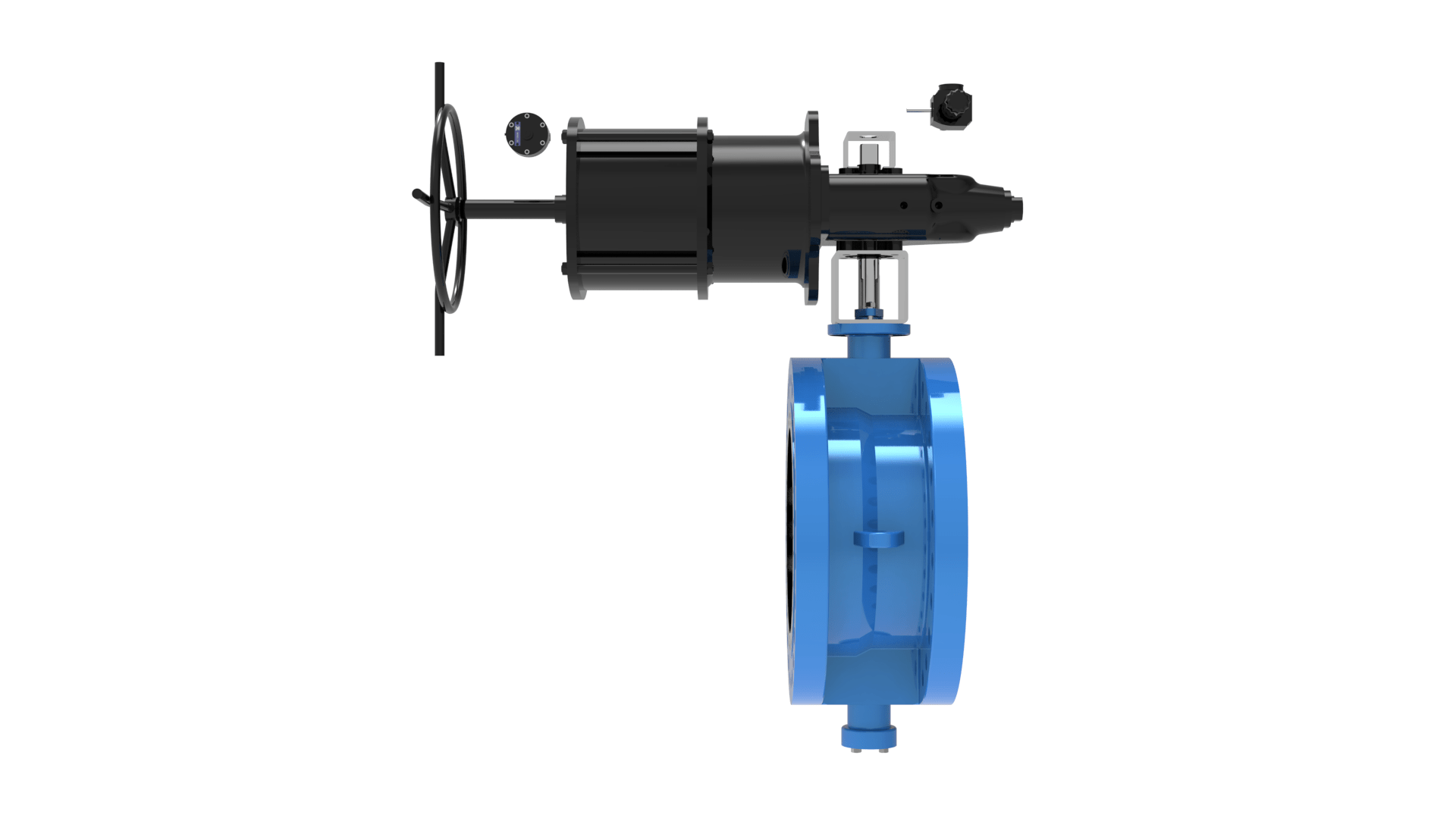

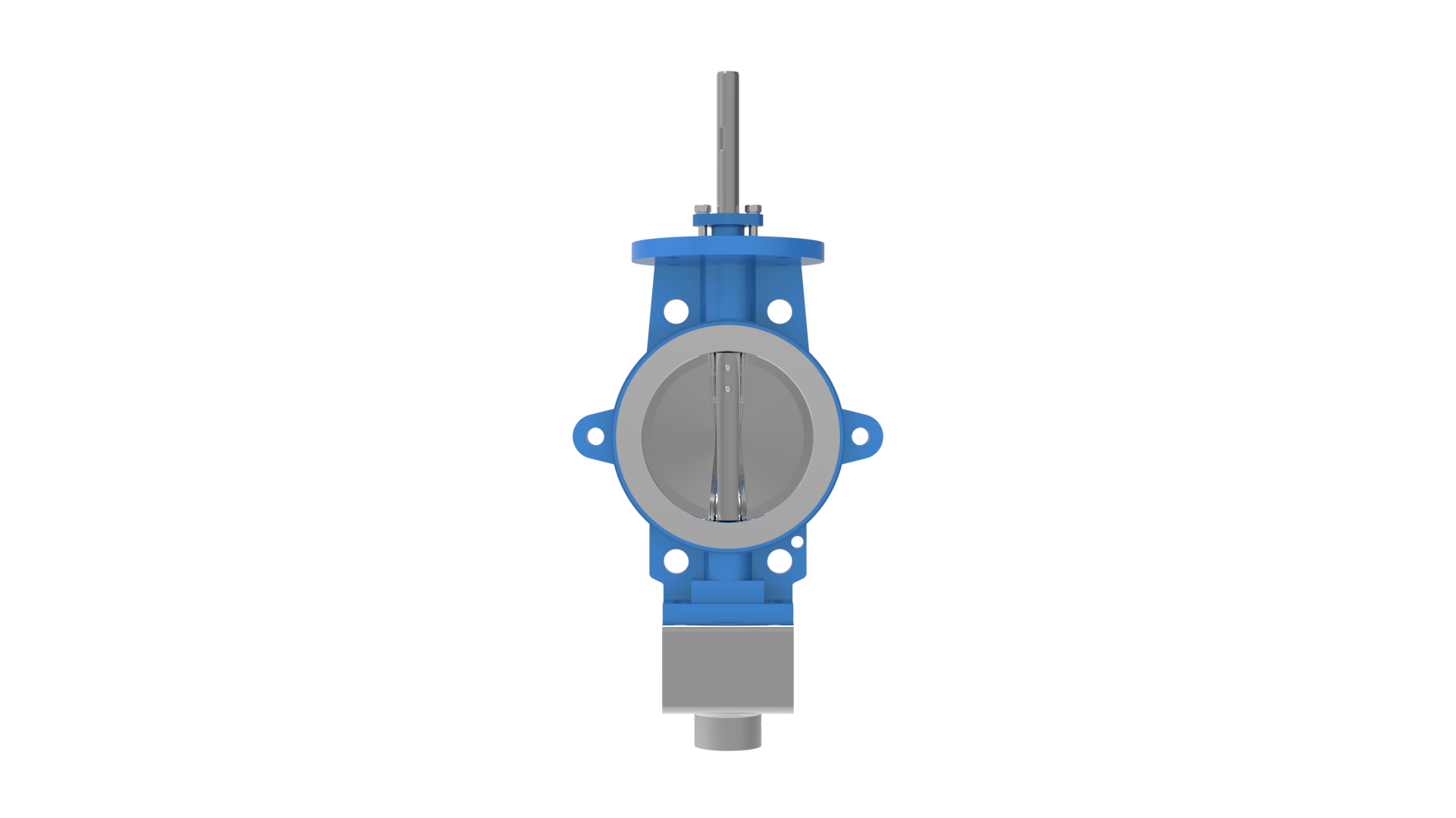

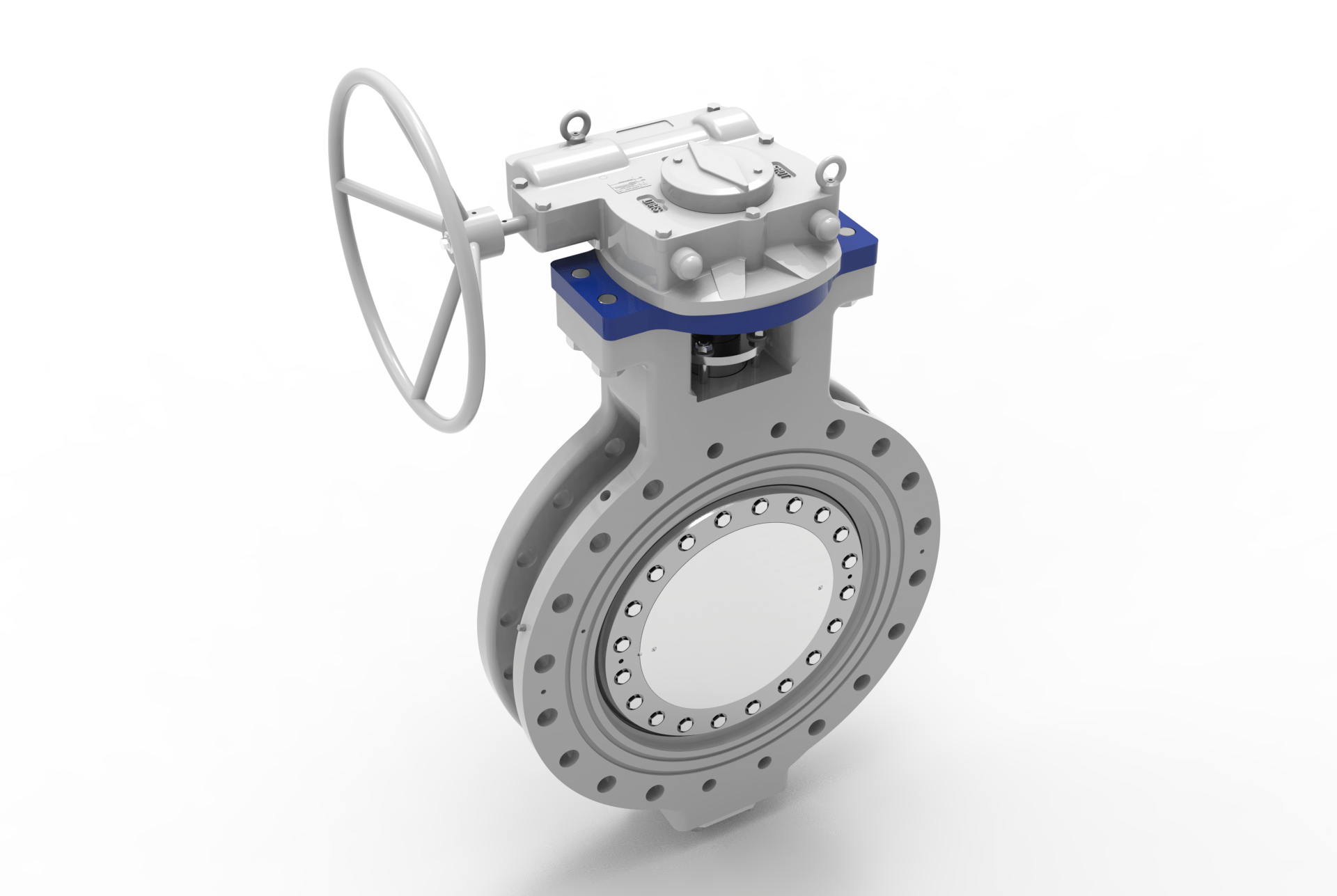

- Batley Valve®Red Point®Coal Fired,Fertilizer,Food & Beverage,Gas Fired,General Industry,Industries,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Traditional Energy,Traditional PowerButterfly Control Valves,Control Valves,Main_Valves

Butterfly Control Valves,Control Valves,Main_Valves

72

- Batley Valve®Red Point®ANSI,ASME,Coal Fired,Fertilizer,Food & Beverage,Gas Fired,General Industry,Industries,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Traditional Energy,Traditional Power,Water & WastewaterButterfly Control Valves,Control Valves,Main_Valves

Butterfly Control Valves,Control Valves,Main_Valves

511

- Batley Valve®Red Point®ANSI,ASME,Coal Fired,DIN,Fertilizer,Food & Beverage,Gas Fired,General Industry,Industries,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Traditional Energy,Traditional Power,Water & WastewaterButterfly Control Valves,Control Valves,Main_Valves

Butterfly Control Valves,Control Valves,Main_Valves

514

- Batley Valve®Red Point®ANSI,API,ASME,Coal Fired,DIN,Fertilizer,Food & Beverage,Gas,Gas Fired,General Industry,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Traditional Energy,Traditional PowerButterfly Control Valves,Control Valves,Main_Valves

Butterfly Control Valves,Control Valves,Main_Valves

516

- Batley Valve®Red Point®ANSI,API,ASME,Coal Fired,DIN,Fertilizer,Food & Beverage,Gas Fired,General Industry,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Solids Handling,Standard,Traditional Energy,Traditional PowerButterfly Control Valves,Control Valves,Main_Valves

Butterfly Control Valves,Control Valves,Main_Valves

518

- Batley Valve®Red Point®API,ASME,Coal Fired,DIN,Fertilizer,Food & Beverage,Gas Fired,General Industry,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Traditional Energy,Traditional Power,Water & WastewaterButterfly Control Valves,Control Valves,Main_Valves

Butterfly Control Valves,Control Valves,Main_Valves

524

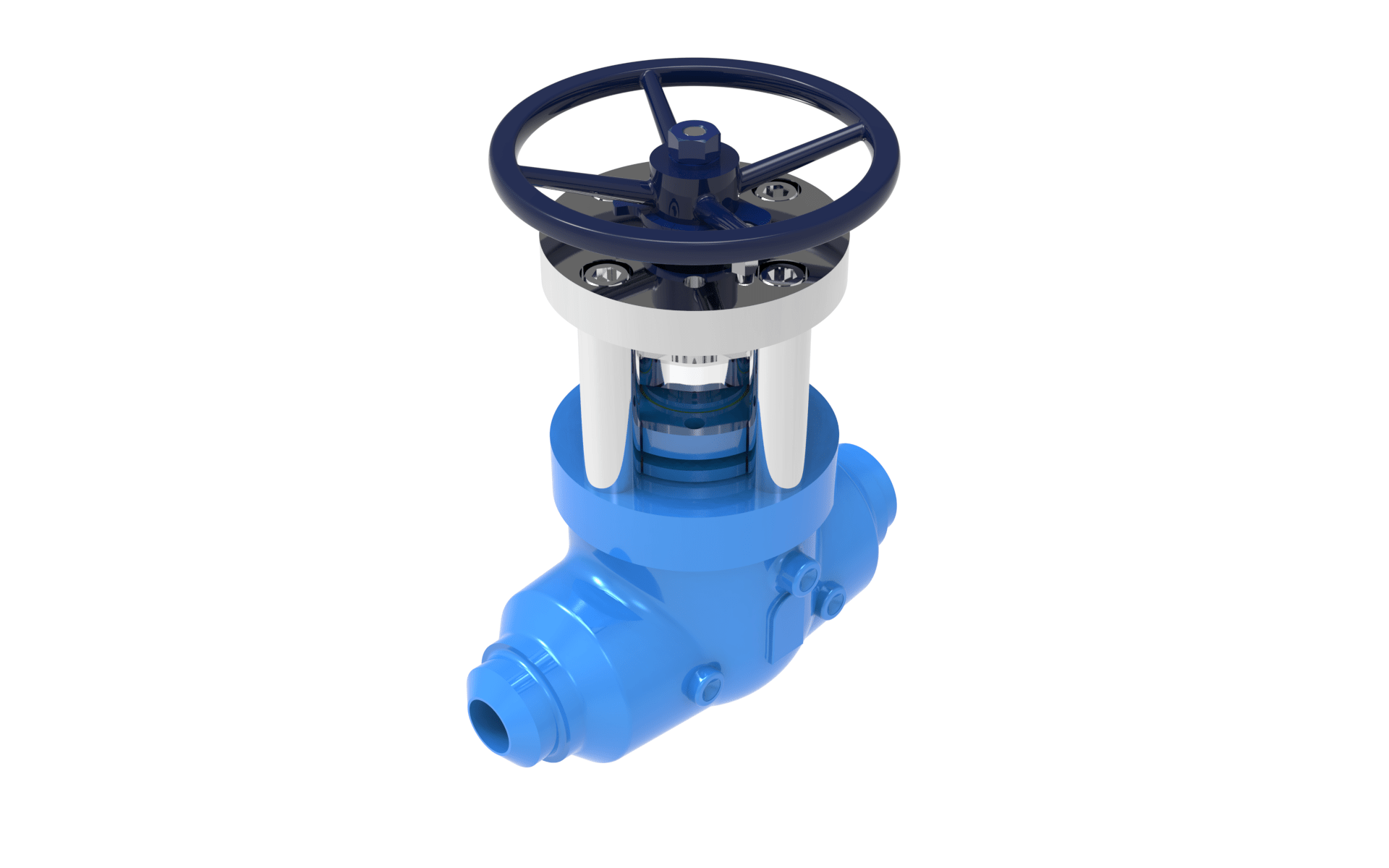

- Blakeborough®Red Point®API,ATEX,Fertilizer,Food & Beverage,FPSO,Gas,General Industry,Hydrogen,Industries,ISO,LNG,Media,Mining & Minerals,Molten Salt,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerControl Valves,Globe Control Valves,Main_Valves

Control Valves,Globe Control Valves,Main_Valves

525

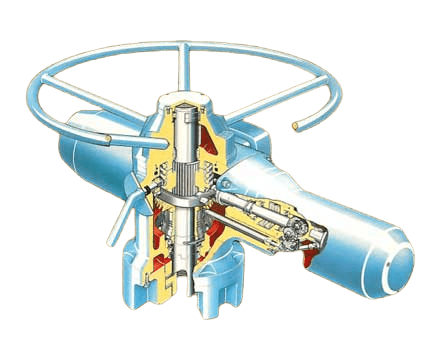

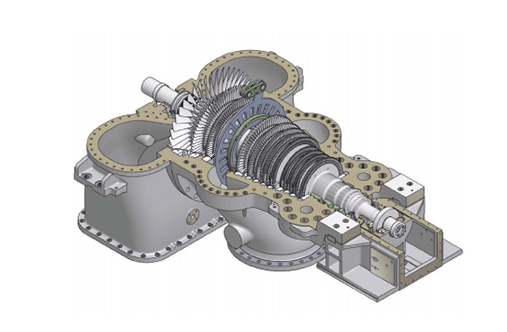

- Blakeborough®Red Point®ASME,Fertilizer,Food & Beverage,Gas,General Industry,Hydrogen,Industries,LNG,Media,Mining & Minerals,Molten Salt,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerControl Valves,Main_Steamturbines

Control Valves,Main_Steamturbines

432

- Blakeborough®Red Point®Air,ANSI,ASME,ATEX,Fertilizer,Food & Beverage,Gas,General Industry,Industries,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerControl Valves,Globe Control Valves,Main_Valves

Control Valves,Globe Control Valves,Main_Valves

529

- Blakeborough®Red Point®ANSI,Fertilizer,Food & Beverage,General Industry,Industries,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerDesuperheaters and Turbine Bypass,Main_Valves

Desuperheaters and Turbine Bypass,Main_Valves

530

- Blakeborough®Red Point®ANSI,Fertilizer,Food & Beverage,General Industry,Industries,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerDesuperheaters and Turbine Bypass,Main_Valves

Desuperheaters and Turbine Bypass,Main_Valves

531

- Blakeborough®Red Point®ANSI,API,ASME,ATEX,Fertilizer,Food & Beverage,FPSO,Gas,General Industry,Hydrogen,Industries,ISO,Liquid,LNG,Media,Mining & Minerals,Molten Salt,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerControl Valves,Globe Control Valves,Main_Valves

Control Valves,Globe Control Valves,Main_Valves

528

- Blakeborough®Red Point®ANSI,General Industry,Industries,Media,Nonrenewable Power,Nuclear Power,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerControl Valves,Globe Control Valves,Main_Valves

Control Valves,Globe Control Valves,Main_Valves

534

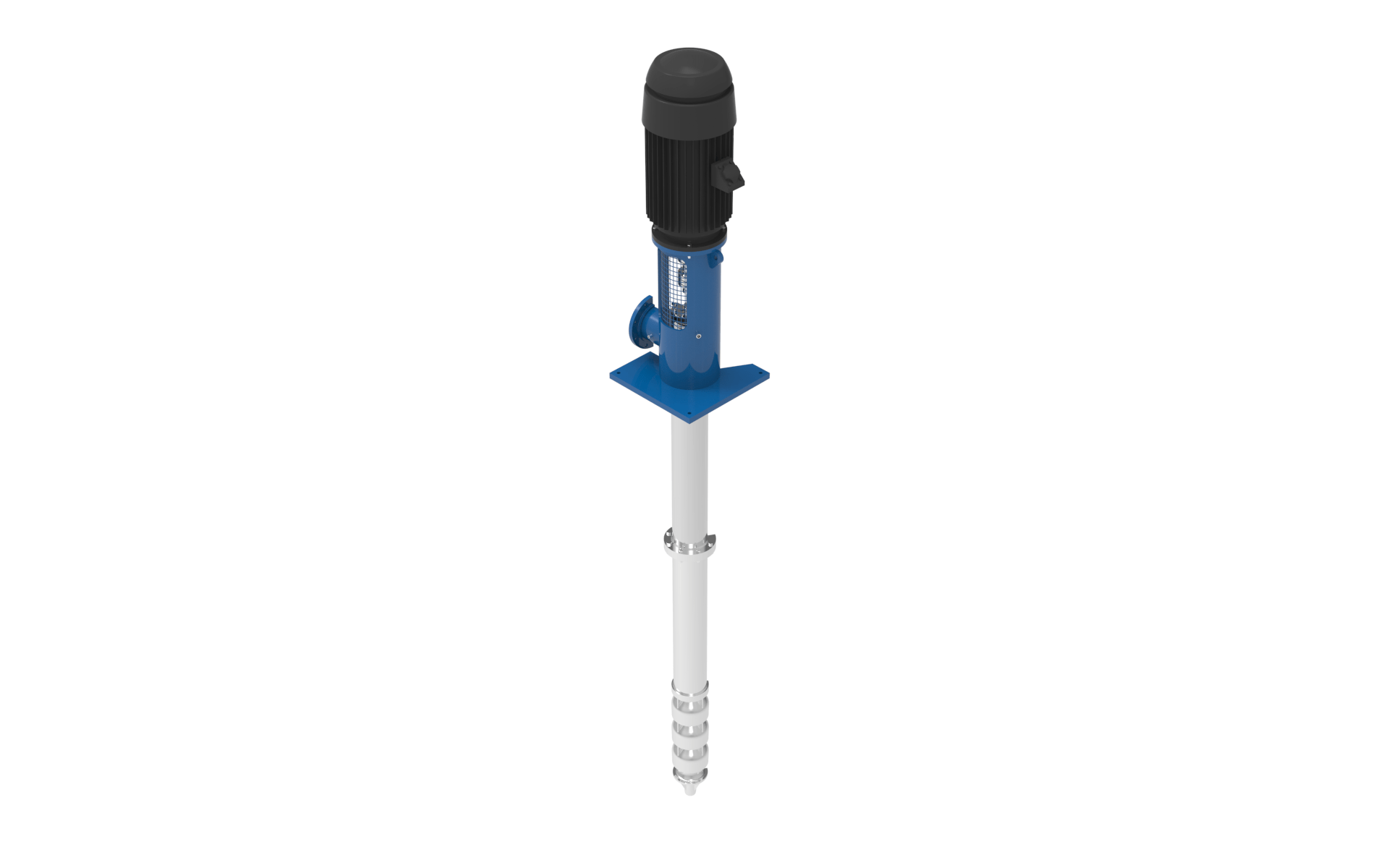

- Termomeccanica PompeRed Point®API,ASME,Desalination,General Industry,Industries,ISO,Liquid,LNG,Media,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Standard,Traditional Energy,Traditional Power,Water & WastewaterMain_Pumps,Vertical

Main_Pumps,Vertical

6193

- Atwood & Morrill®Red Point®ASME,Coal Fired,Gas Fired,Industries,Media,Nonrenewable Power,Renewable Power,Standard,Steam,Traditional Energy,Traditional PowerCheck Valves,Isolation Valves,Main_Valves

Check Valves,Isolation Valves,Main_Valves

502

- Termomeccanica PompeRed Point®API,ASME,Desalination,FPSO,General Industry,Industries,ISO,Liquid,Media,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Standard,Traditional Energy,Traditional Power,Water & WastewaterMain_Pumps,Vertical

Main_Pumps,Vertical

6190

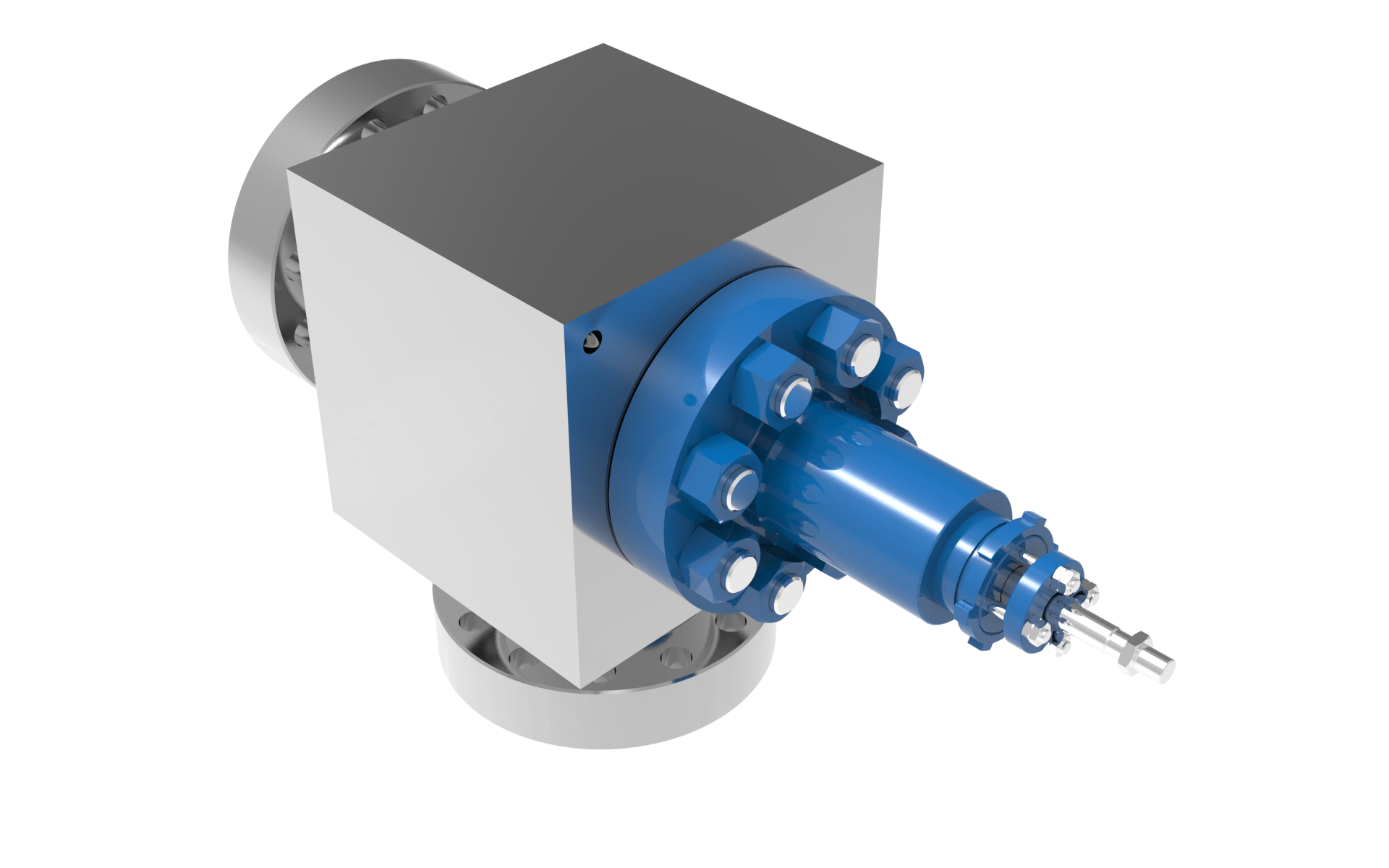

- Red Point®Red Point®API,ASME,Fertilizer,FPSO,Gas,General Industry,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Standard,Traditional Energy,Traditional PowerDouble Block & Bleed Valves,Main_Valves

Double Block & Bleed Valves,Main_Valves

5061

- Red Point®Red Point®API,ASME,Fertilizer,FPSO,Gas,General Industry,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Standard,Traditional Energy,Traditional PowerCheck Valves,Check Valves,Main_Valves

Check Valves,Check Valves,Main_Valves

4656

- Atwood & Morrill®Red Point®ASME,Coal Fired,Gas Fired,Industries,Media,Nonrenewable Power,Renewable Power,Standard,Steam,Traditional Energy,Traditional PowerCheck Valves,Gate Valves,Globe Valves,Isolation Valves,Main_Valves

Check Valves,Gate Valves,Globe Valves,Isolation Valves,Main_Valves

2707

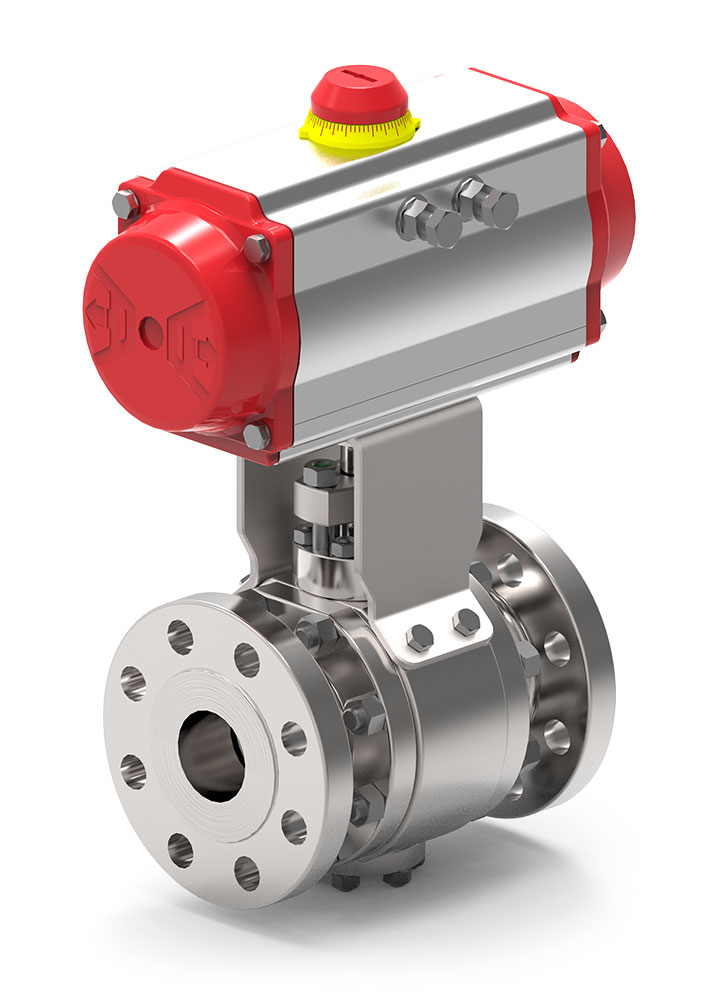

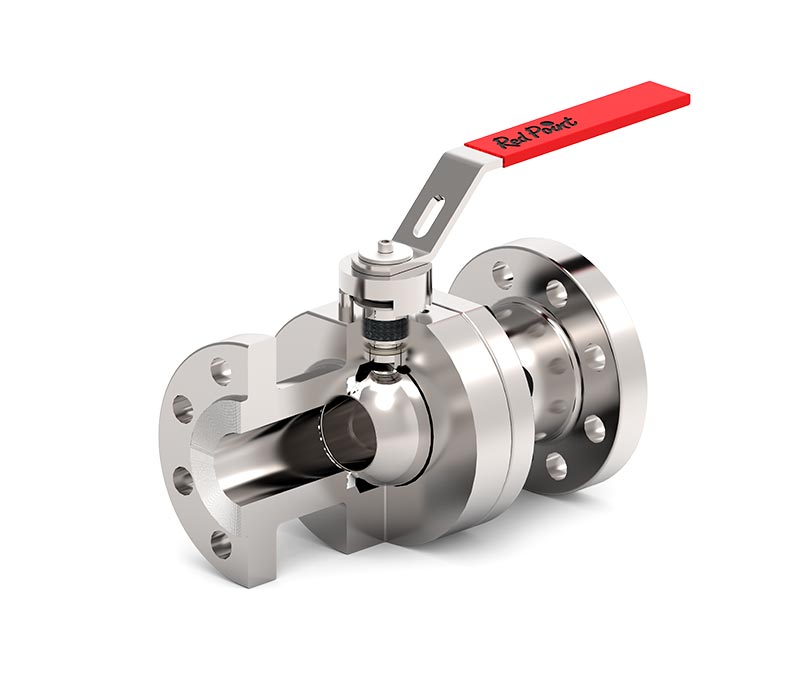

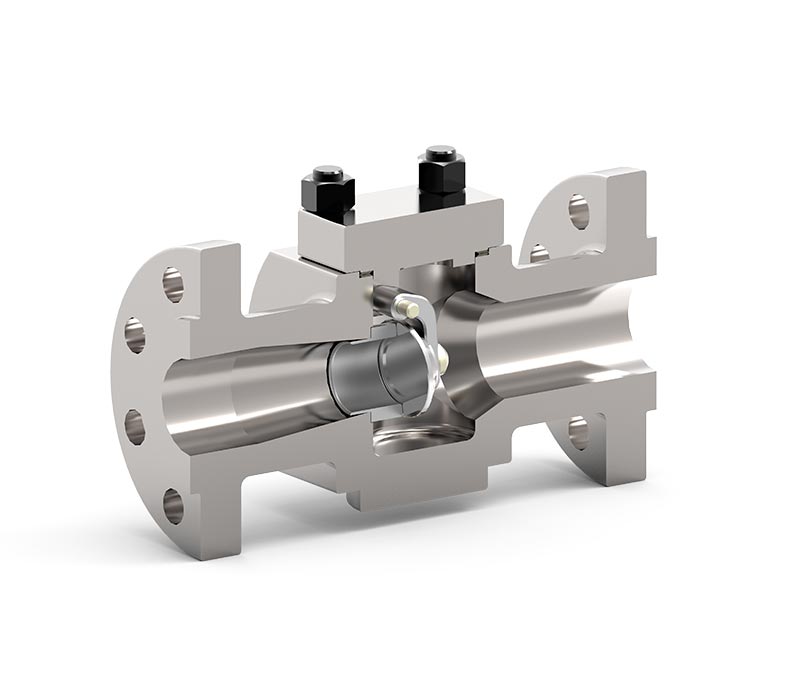

- Red Point®Red Point®API,ASME,Fertilizer,FPSO,Gas,General Industry,Hydrogen,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Traditional Energy,Traditional PowerBall Valves,Main_Valves

Ball Valves,Main_Valves

4630

- Termomeccanica PompeRed Point®API,ASME,Industries,ISO,Liquid,Media,Nonrenewable Power,Oil & Gas,Oil & Gas - Midstream,Oil & Gas - Upstream,Standard,Traditional PowerMain_Pumps,Vertical

Main_Pumps,Vertical

6191

- Red Point®Red Point®API,ASME,Fertilizer,FPSO,Gas,General Industry,Hydrogen,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Traditional Energy,Traditional PowerBall Valves,Main_Valves

Ball Valves,Main_Valves

4625

- Red Point®Red Point®API,ASME,Fertilizer,FPSO,Gas,General Industry,Hydrogen,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Renewable Power,Standard,Traditional Energy,Traditional PowerBall Valves,Main_Valves

Ball Valves,Main_Valves

4628

- Hopkinsons®Red Point®ASME,Fertilizer,Food & Beverage,General Industry,Industries,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas - Downstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerGate Valves,Isolation Valves,Main_Steamturbines

Gate Valves,Isolation Valves,Main_Steamturbines

428

- Atwood & Morrill®Red Point®ASME,Coal Fired,Gas Fired,Industries,Media,Nonrenewable Power,Oil & Gas - Downstream,Renewable Power,Standard,Steam,Traditional Energy,Traditional PowerCheck Valves,Gate Valves,Isolation Valves,Main_Valves

Check Valves,Gate Valves,Isolation Valves,Main_Valves

504

- Atwood & Morrill®Red Point®ASME,Coal Fired,Gas Fired,Industries,Media,Nonrenewable Power,Oil & Gas - Downstream,Renewable Power,Standard,Steam,Traditional Energy,Traditional PowerCheck Valves,Gate Valves,Globe Valves,Isolation Valves,Main_Valves

Check Valves,Gate Valves,Globe Valves,Isolation Valves,Main_Valves

2407

- Atwood & Morrill®Red Point®ASME,Coal Fired,Gas Fired,General Industry,Industries,Media,Nonrenewable Power,Nuclear Power,PWR,Renewable Power,SMR,Standard,Steam,Traditional PowerCheck Valves,Gate Valves,Isolation Valves,Main_Valves

Check Valves,Gate Valves,Isolation Valves,Main_Valves

70

- Hopkinsons®Red Point®ASME,Fertilizer,Food & Beverage,General Industry,Industries,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas - Downstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerIsolation Valves,Main_Valves,Parallel Slide Valves

Isolation Valves,Main_Valves,Parallel Slide Valves

535

- Hopkinsons®Red Point®ASME,Fertilizer,Food & Beverage,General Industry,Industries,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerGate Valves,Isolation Valves,Main_Valves

Gate Valves,Isolation Valves,Main_Valves

75

- Red Point®Red Point®API,ASME,Fertilizer,FPSO,Gas,General Industry,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Standard,Traditional Energy,Traditional PowerGate Valves,Main_Valves

Gate Valves,Main_Valves

4642

- Hopkinsons®Red Point®ASME,Fertilizer,Food & Beverage,General Industry,Industries,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas - Downstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerGlobe Valves,Isolation Valves,Main_Valves

Globe Valves,Isolation Valves,Main_Valves

538

- Hopkinsons®Red Point®ASME,Fertilizer,Food & Beverage,General Industry,Industries,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,PWR,Renewable Power,SMR,Standard,Traditional Energy,Traditional PowerGate Valves,Isolation Valves,Main_Valves

Gate Valves,Isolation Valves,Main_Valves

536

- Roto-Jet®Red Point®API,Fertilizer,Food & Beverage,FPSO,General Industry,Industries,Liquid,Media,Mining & Minerals,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Standard,Traditional Energy,Traditional PowerHigh Pressure,Main_Pumps

High Pressure,Main_Pumps

73

- Red Point®Red Point®API,ASME,Fertilizer,FPSO,Gas,General Industry,Hydrogen,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Traditional Energy,Traditional PowerBall Valves,Main_Valves

Ball Valves,Main_Valves

4576

- Red Point®Red Point®API,ASME,Fertilizer,FPSO,Gas,General Industry,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Standard,Traditional Energy,Traditional PowerCheck Valves,Check Valves,Main_Valves

Check Valves,Check Valves,Main_Valves

4658

- Red Point®Red Point®API,ASME,Fertilizer,FPSO,Gas,General Industry,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Standard,Traditional Energy,Traditional PowerGate Valves,Main_Valves

Gate Valves,Main_Valves

4636

- Red Point®Red Point®API,ASME,Fertilizer,FPSO,Gas,General Industry,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Standard,Traditional Energy,Traditional PowerGlobe Valves,Main_Valves

Globe Valves,Main_Valves

4646

- Red Point®Red Point®API,ASME,DIN,Fertilizer,FPSO,Gas,General Industry,Hydrogen,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Renewable Power,Standard,Traditional Energy,Traditional PowerBall Valves,Main_Valves

Ball Valves,Main_Valves

4622

- Red Point®Red Point®API,ASME,Fertilizer,FPSO,Gas,General Industry,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Standard,Traditional Energy,Traditional PowerGlobe Valves,Main_Valves

Globe Valves,Main_Valves

4660

- Red Point®Red Point®API,ASME,Fertilizer,FPSO,Gas,General Industry,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Standard,Traditional Energy,Traditional PowerGate Valves,Main_Valves

Gate Valves,Main_Valves

4634

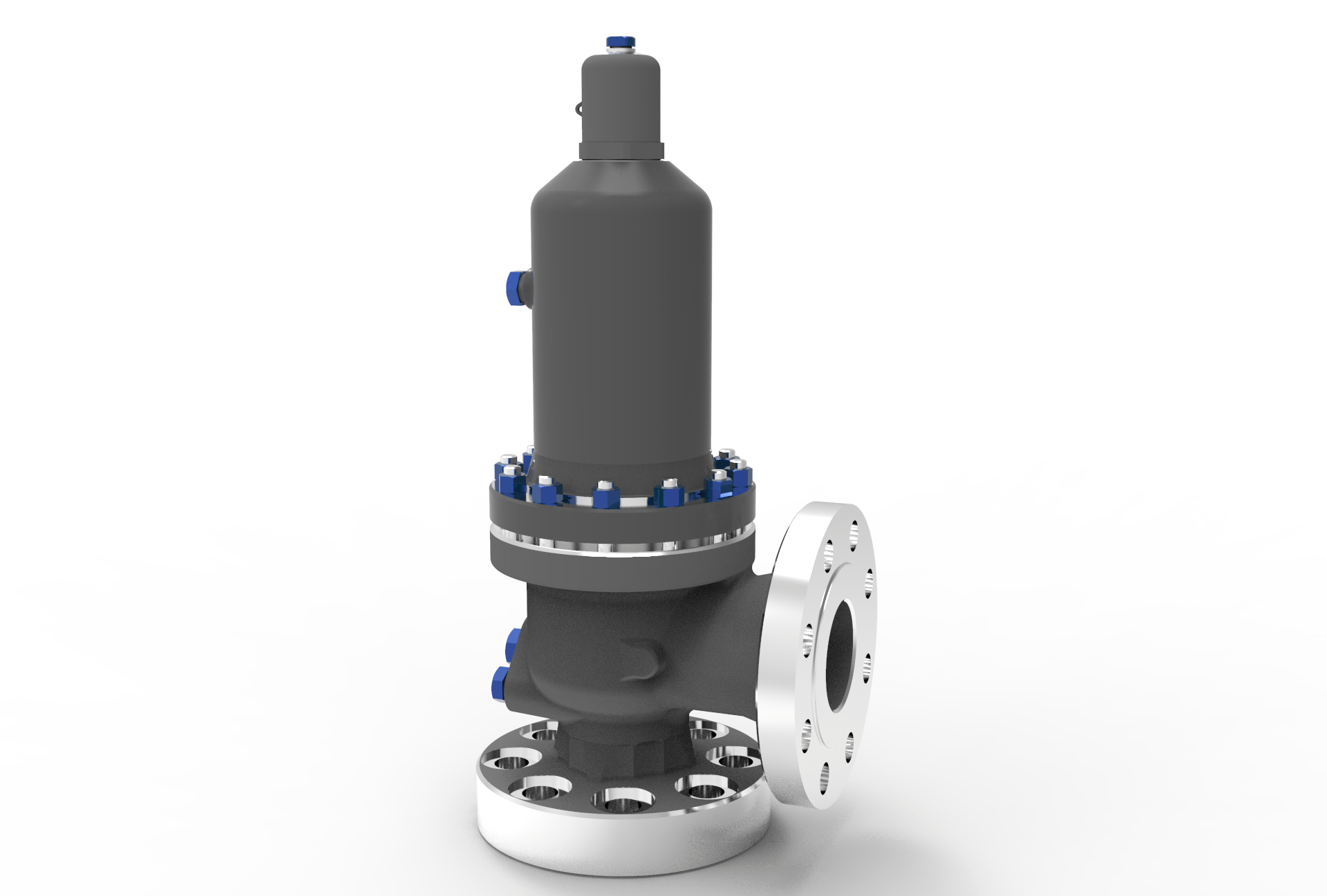

- Sarasin-RSBD®Red Point®ASME,General Industry,Industries,ISO,Liquid,Media,Nonrenewable Power,Renewable Power,Standard,Steam,Traditional Energy,Traditional PowerMain_Valves,Pilot Operated Pressure Relief Valves

Main_Valves,Pilot Operated Pressure Relief Valves

545

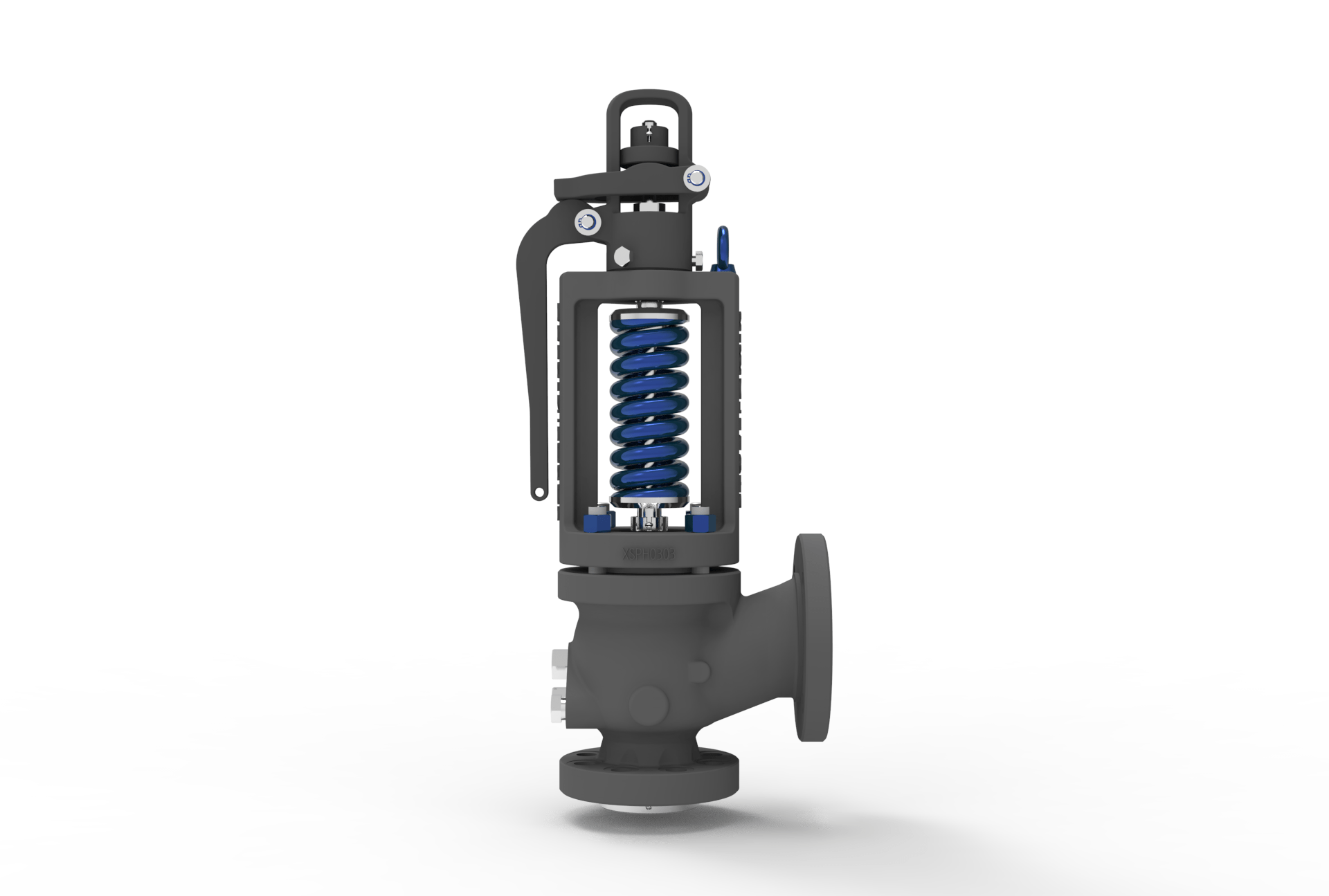

- Sarasin-RSBD®Red Point®Air,ANSI,API,ASME,Fertilizer,Food & Beverage,FPSO,Gas,General Industry,Hydrogen,Industries,ISO,Liquid,LNG,Media,Molten Salt,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional Power,Water & WastewaterMain_Valves,Spring Loaded Pressure Relief Valve

Main_Valves,Spring Loaded Pressure Relief Valve

74

- Sarasin-RSBD®Red Point®ASME,General Industry,Industries,ISO,Media,Nonrenewable Power,Oil & Gas,Renewable Power,Standard,Steam,Traditional Energy,Traditional PowerMain_Valves,Spring Loaded Pressure Relief Valve

Main_Valves,Spring Loaded Pressure Relief Valve

426

- Sarasin-RSBD®Red Point®ASME,General Industry,Industries,ISO,Media,Nonrenewable Power,Nuclear Power,Oil & Gas,Renewable Power,Standard,Steam,Traditional Energy,Traditional PowerMain_Valves,Spring Loaded Pressure Relief Valve

Main_Valves,Spring Loaded Pressure Relief Valve

544

- Allen Steam Turbines™Red Point®Coal Fired,Gas Fired,General Industry,Industries,Media,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Renewable Power,Standard,Steam,Traditional Energy,Traditional PowerMain_Steamturbines

Main_Steamturbines

2560

- Red Point®Red Point®API,ASME,Fertilizer,FPSO,Gas,General Industry,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Standard,Traditional Energy,Traditional PowerCheck Valves,Check Valves,Main_Valves

Check Valves,Check Valves,Main_Valves

4652

- Red Point®Red Point®API,ASME,Fertilizer,FPSO,Gas,General Industry,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,SMR,Standard,Traditional Energy,Traditional PowerMain_Valves,Tailor-made Valves

Main_Valves,Tailor-made Valves

5072

- Atwood & Morrill®Red Point®ASME,Coal Fired,Gas Fired,Industries,Liquid,Media,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Renewable Power,Standard,Steam,Traditional Energy,Traditional PowerCheck Valves,Gate Valves,Isolation Valves,Main_Valves

Check Valves,Gate Valves,Isolation Valves,Main_Valves

497

- Red Point®Red Point®API,ASME,Fertilizer,FPSO,Gas,General Industry,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Standard,Traditional Energy,Traditional PowerGate Valves,Main_Valves

Gate Valves,Main_Valves

4638

- Red Point®Red Point®API,ASME,Fertilizer,FPSO,Gas,General Industry,Hydrogen,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Renewable Power,Standard,Traditional Energy,Traditional PowerBall Valves,Main_Valves

Ball Valves,Main_Valves

4632

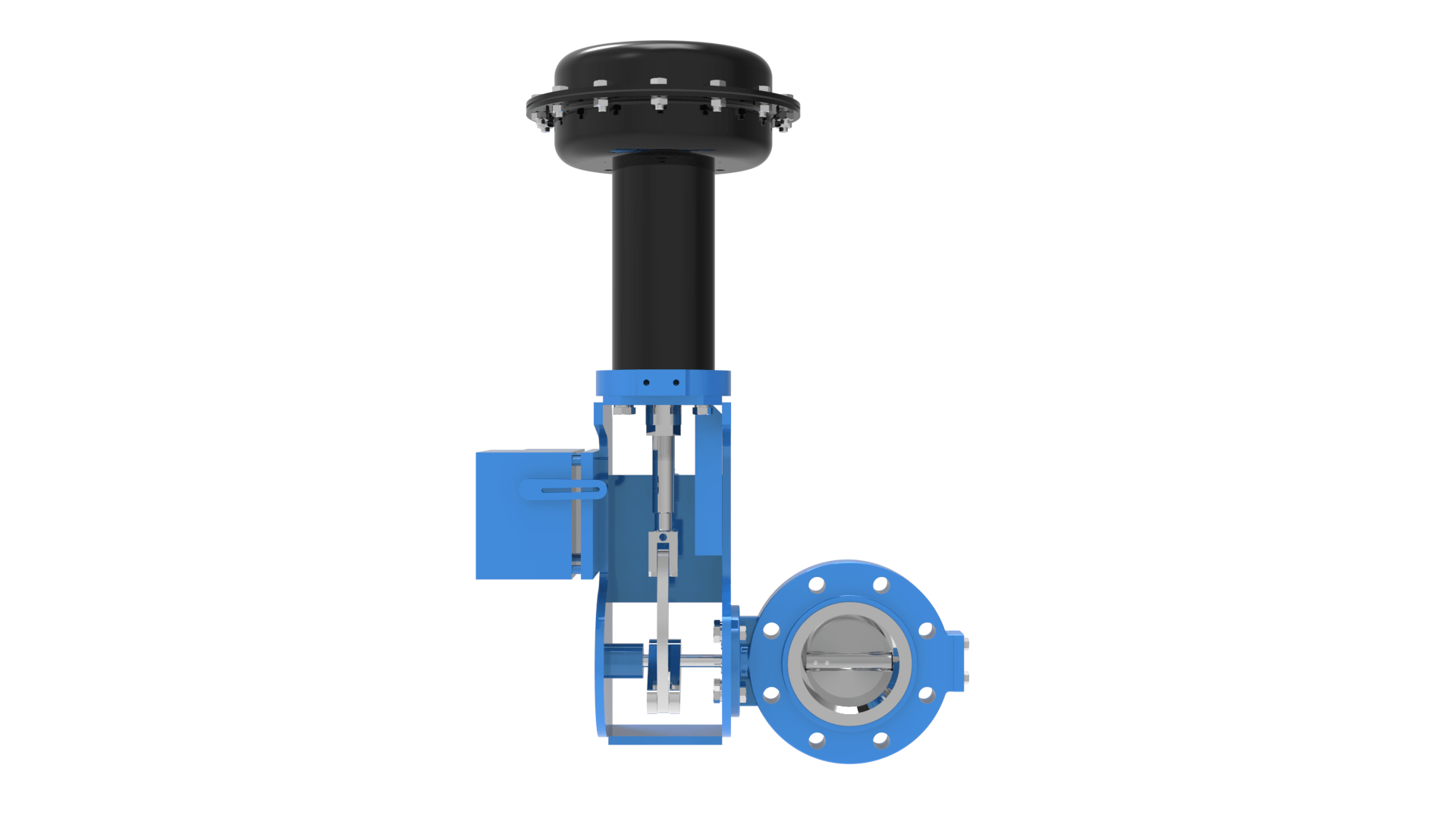

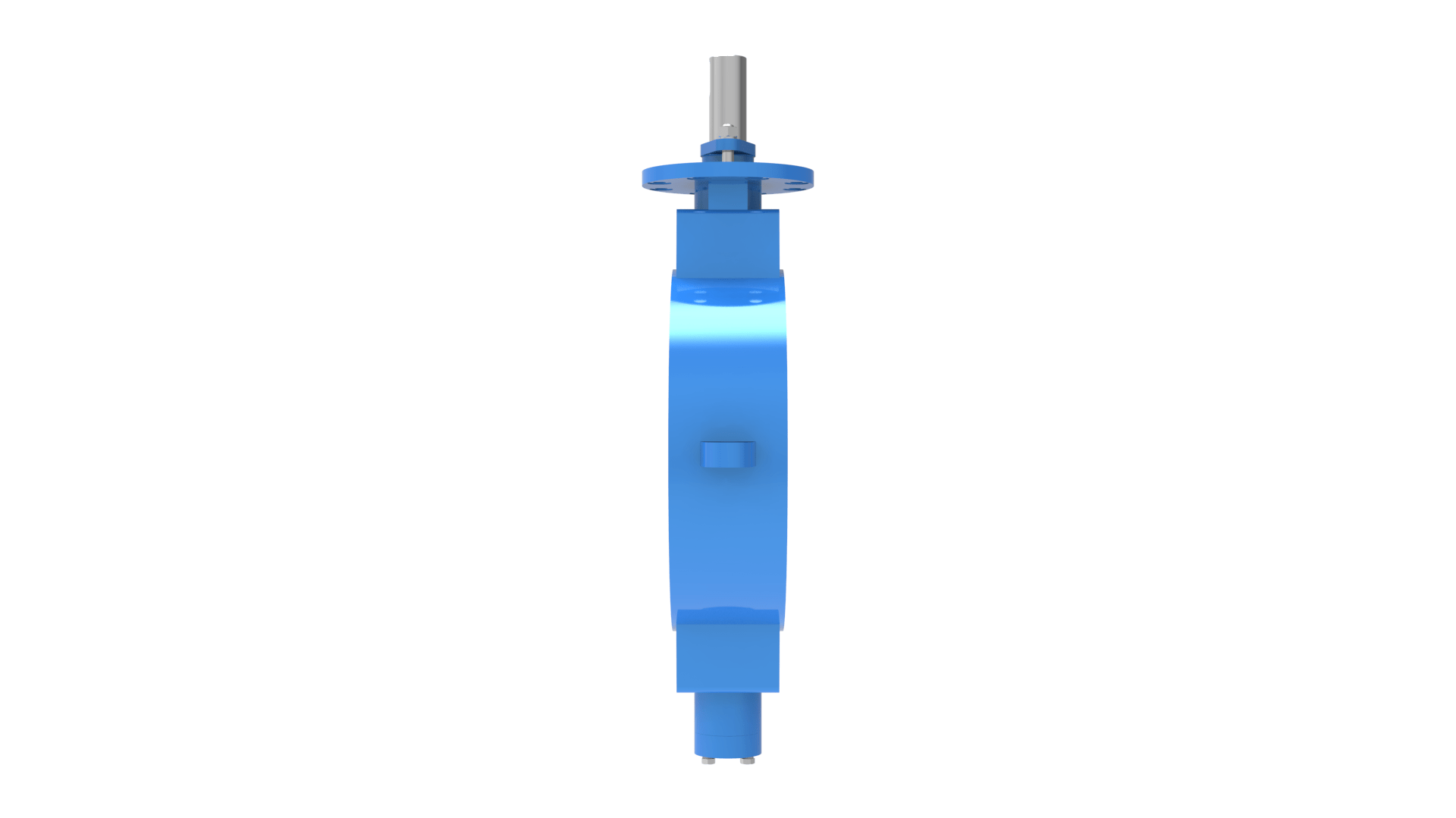

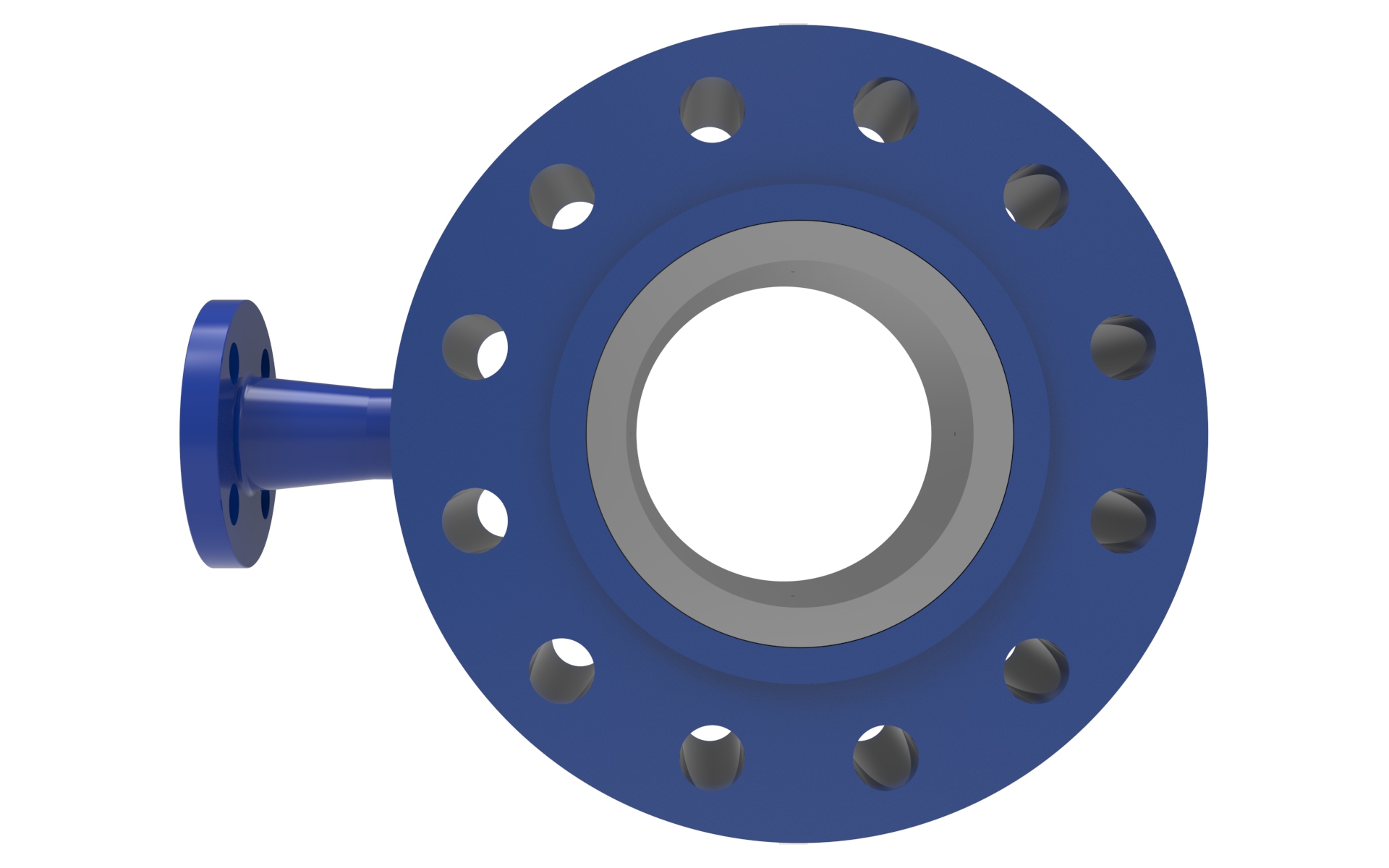

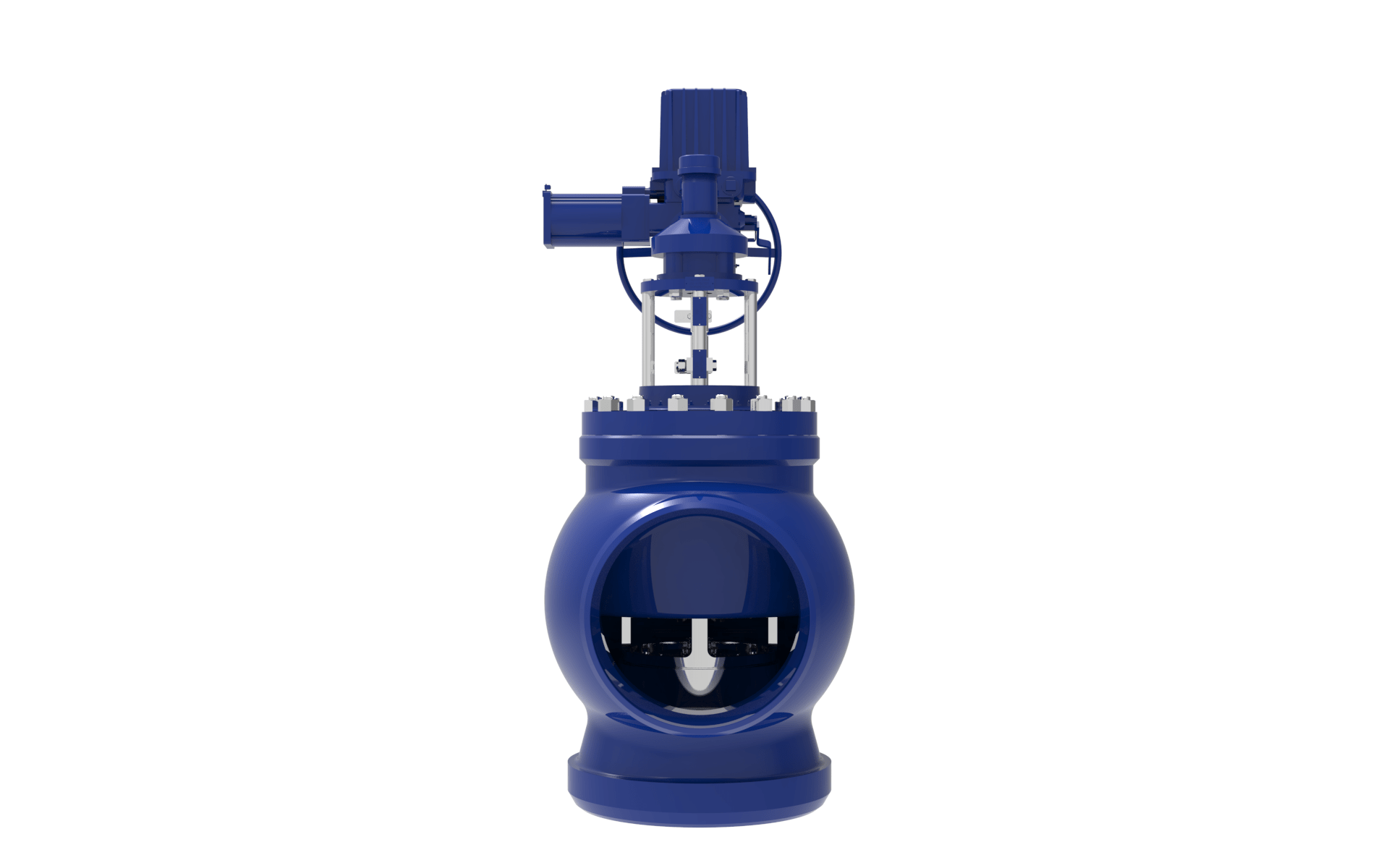

- Tricentric®Red Point®ASME,Fertilizer,Gas,General Industry,Industries,Liquid,Media,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional Power,Water & WastewaterButterfly Control Valves,Control Valves,Isolation Valves,Main_Valves

Butterfly Control Valves,Control Valves,Isolation Valves,Main_Valves

423

- Hopkinsons®Red Point®ASME,Fertilizer,Food & Beverage,General Industry,Industries,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,PWR,Renewable Power,SMR,Standard,Steam,Traditional Energy,Traditional PowerIsolation Valves,Main_Valves

Isolation Valves,Main_Valves

539

- Gabbioneta Pumps® Termomeccanica PompeRed Point®API,Industries,Liquid,LNG,Media,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,PWR,Standard,Traditional Energy,Traditional PowerMain_Pumps,Vertical

Main_Pumps,Vertical

417

- Floway®Red Point®ANSI,Fertilizer,FPSO,General Industry,HI,Industries,Liquid,LNG,Media,Mining & Minerals,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,Standard,Traditional Energy,Traditional Power,UL/FM,Water & WastewaterMain_Pumps,Vertical

Main_Pumps,Vertical

645

- Atwood & Morrill®Red Point®ASME,Coal Fired,Gas Fired,General Industry,Industries,Liquid,Media,Nonrenewable Power,Nuclear Power,Oil & Gas - Downstream,PWR,Renewable Power,Standard,Steam,Traditional Energy,Traditional PowerCheck Valves,Gate Valves,Isolation Valves,Main_Valves

Check Valves,Gate Valves,Isolation Valves,Main_Valves

495

- Blakeborough®Red Point®Fertilizer,Food & Beverage,Gas,General Industry,Industries,ISA,Liquid,Media,Mining & Minerals,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,PWR,Renewable Power,SMR,Standard,Traditional Energy,Traditional PowerControl Valves,Globe Control Valves,Main_Valves

Control Valves,Globe Control Valves,Main_Valves

526

- Red Point®Red Point®API,ASME,Fertilizer,FPSO,Gas,General Industry,Industries,ISO,Liquid,Media,Mining & Minerals,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Standard,Traditional Energy,Traditional PowerGlobe Valves,Main_Valves

Globe Valves,Main_Valves

4644